engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 757 of 920

SUSPENSION - FRONT

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:24PM

alignment. See WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES article in

the WHEEL ALIGNMENT section.

STRUT ASSEMBLY

Removal

1) Raise and support vehicle. Remove wheel assembly.

Disconnect and wire caliper aside. Remove bolts retaining strut to

steering knuckle. Note top bolt is used for front wheel camber

adjustment.

2) Support front suspension arm and components. Pry

suspension strut from steering knuckle. Remove upper strut retaining

nuts from inside engine compartment. Remove strut assembly.

Installation

To install, reverse removal procedure. Tighten bolts and nuts

to specification. See TORQUE SPECIFICATIONS table at end of article.

Check wheel alignment. See WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

article in the WHEEL ALIGNMENT section.

FRONT SUSPENSION ASSEMBLY

Removal

1) Raise and support vehicle at center with safety stands.

Disconnect brake line and plug openings. Leave flex line in place.

Remove stabilizer link rod nut, bushings and washers.

2) Remove tie rod nut. Separate tie rod from steering

knuckle. Disconnect inner portion of constant velocity joint from

transaxle drive flange.

3) Remove lower control arm front pivot bolt. Remove "U"

shaped bracket bolts at control arm rear pivot.

NOTE: On vehicles with automatic transmission, engine may have to

be lifted slightly to gain access to pivot bolts.

4) Support suspension assembly. Remove upper strut retaining

nuts. Remove suspension assembly from vehicle.

Installation

To install, reverse removal procedure. Ensure convex side of

thrust washer faces pivot bolt head. Tighten bolts and nuts to

specification. Check wheel alignment. Proceed to appropriate

WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES article in the WHEEL

ALIGNMENT section.

WHEEL BEARING

Removal

1) Remove axle shaft nut with front wheels on ground. Raise

and support vehicle. Allow suspension to hang free. Remove wheel

assembly. Remove brake caliper attaching bolts. Remove caliper and

wire aside. Remove brake disc retaining screw and remove disc.

Page 760 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

ARTICLE BEGINNING

EMISSION RECALL BULLETIN

VACUUM HOSE ROUTING LABEL REPLACEMENT - RECALL CODE SQ

Model(s): 1992-93 Volkswagen Corrado VR6

Recall No.: SQ

Date: July 6, 1993

Number of Affected Vehicles: 4,300

Beginning Date of Manufacture: August 1991

Ending Date of Manufacture: November 1992

DEFECT INFORMATION REPORT

1. Manufacturer: Volkswagen AG (VWAG)

Importer: Volkswagen of America, Inc. (VWoA)

2. Description of the Defect:

Volkswagen has found that affected Corrado VR6 vehicles were

inadvertently equipped during assembly with a label containing

emission specifications intended and applicable to Passat model

VR6 vehicles. The diagram of the vacuum hose routing is

incorrect as applied to the Corrado.

3. Class or Category of Vehicles Potentially Affected:

The affected vehicles are 1992 and early production model 1993

Volkswagen Corrado VR6 vehicles equipped with a VR6 engine,

identified by the following engine families:

1992 1993

ÄÄÄÄÄÄÄÄÄÄÄÄ ÄÄÄÄÄÄÄÄÄÄÄÄ California and 49-State NVW2.8V5FWE7 PVW2.8V5FWE9

PVW2.8V5FWH1

4.1. Number of Vehicles Estimated to Have the Defect:

According to Volkswagen's records, a total of approximately

3,625 49-states and 675 California equipped vehicles are

affected. These vehicles were manufactured from August 1991

through November 1992 and are within the following vehicle

identification number range:

WVW___50_NK000001 - WVW___50_PK005031

Other Description: Vehicles equipped with VR6 engines

4.2. Production Plants: Wilhelm Karmann GmbH

Osnabrueck Plant

Page 761 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Osnabrueck, Germany

5. Evaluation of Emissions and Driveability of the Defect:

Not Applicable.

6. Available Emissions Data:

Not Applicable.

7. Anticipated Follow-Up Action:

VWoA will recall all affected vehicles and instruct dealers to

affix a new label in addition to performing safety recall work.

The details of the safety recall have been reported to the

NHTSA.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄATTACHMENT I

RECALL CAMPAIGN BULLETIN - SQ

Date: July 1993

SECURE ENGINE COMPARTMENT ELECTRICAL WIRING AND AFFIX

VACUUM HOSE ROUTING LABEL

REPLACEMENT PARTS REQUIRED

ÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄRepair Step

³ Quantity ³ Description ³ Part Number

ÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄ A

³ 1 (290 mm) ³ Protective Sleeve ³ N905 930.01

³ 1 ³ Beading ³ 535 853 879 A

³ 1 ³ Tie Wrap ³ N020 906.3

³ 3 ³ Tie Wrap ³ ZVW 601 100

B

³ 2 ³ Lock Nut ³ N902 920.01

C

³ ³ No parts required ³ D

³ 1 ³ Beading ³ 701 947 149A

E

³ 1 ³ Clamp ³ 535 253 139

F

³ 1 ³ ECM ³ 095 927 731BD

G

³ 1 ³ Label ³ 021 010 058G

ÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄ General Repair Information

REPAIR STEPS TO BE PERFORMED

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ VIN Range

³ Repair Steps

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFrom 50_NK 000 001 through 50_PK 002 707

³ A, B, C, D, E and G

From 50_PK 000 708 through 50_PK 003 049

³ A, B, C, D, and E

Page 762 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

From 50_PK 003 050 through 50_PK 005 031 ³ A, B, C, and D

From 50_NK 004 148 through 50_NK 012 142

³ A, C, D, E, F and G

³ (automatic transmission

³ vehicles)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ REPAIR STEPS EXPLANATION:

Repair Step A - Secure Cooling Fan Wiring Harness

Repair Step B - Modify Shift Linkage Balance Weight Mounting

(Standard Transmission Only)

Repair Step C - Re-route Ignition Cables and Breather Hose

Repair Step D - Secure Engine Compartment Harness

Repair Step E - Secure Exhaust System

Repair Step F - Replace Transmission Control Module (Automatic

Transmission Only)

Repair Step G - Replace Vacuum Hose Routing Label

WORK PROCEDURE

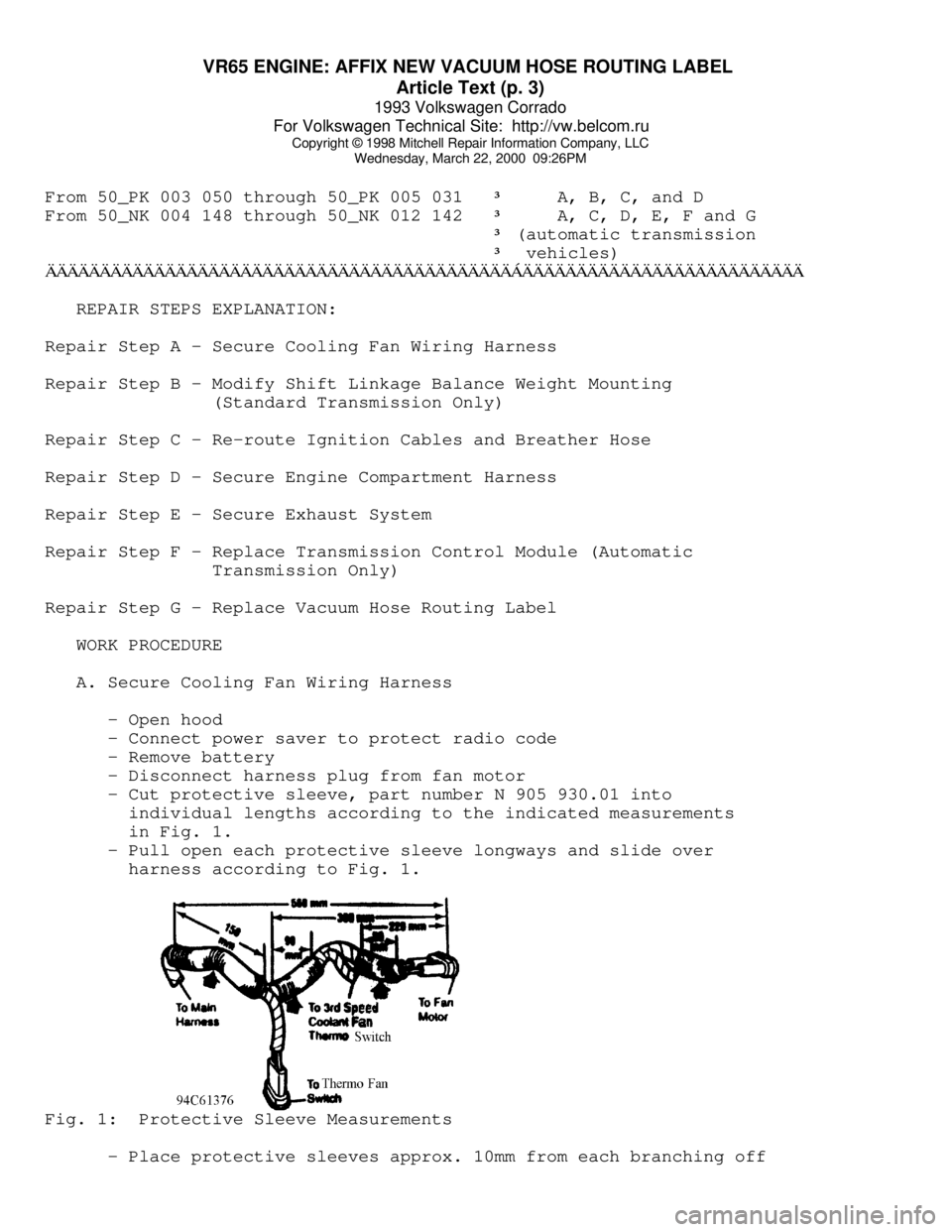

A. Secure Cooling Fan Wiring Harness

- Open hood

- Connect power saver to protect radio code

- Remove battery

- Disconnect harness plug from fan motor

- Cut protective sleeve, part number N 905 930.01 into

individual lengths according to the indicated measurements

in Fig. 1.

- Pull open each protective sleeve longways and slide over

harness according to Fig. 1.Fig. 1: Protective Sleeve Measurements

- Place protective sleeves approx. 10mm from each branching off

Page 763 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

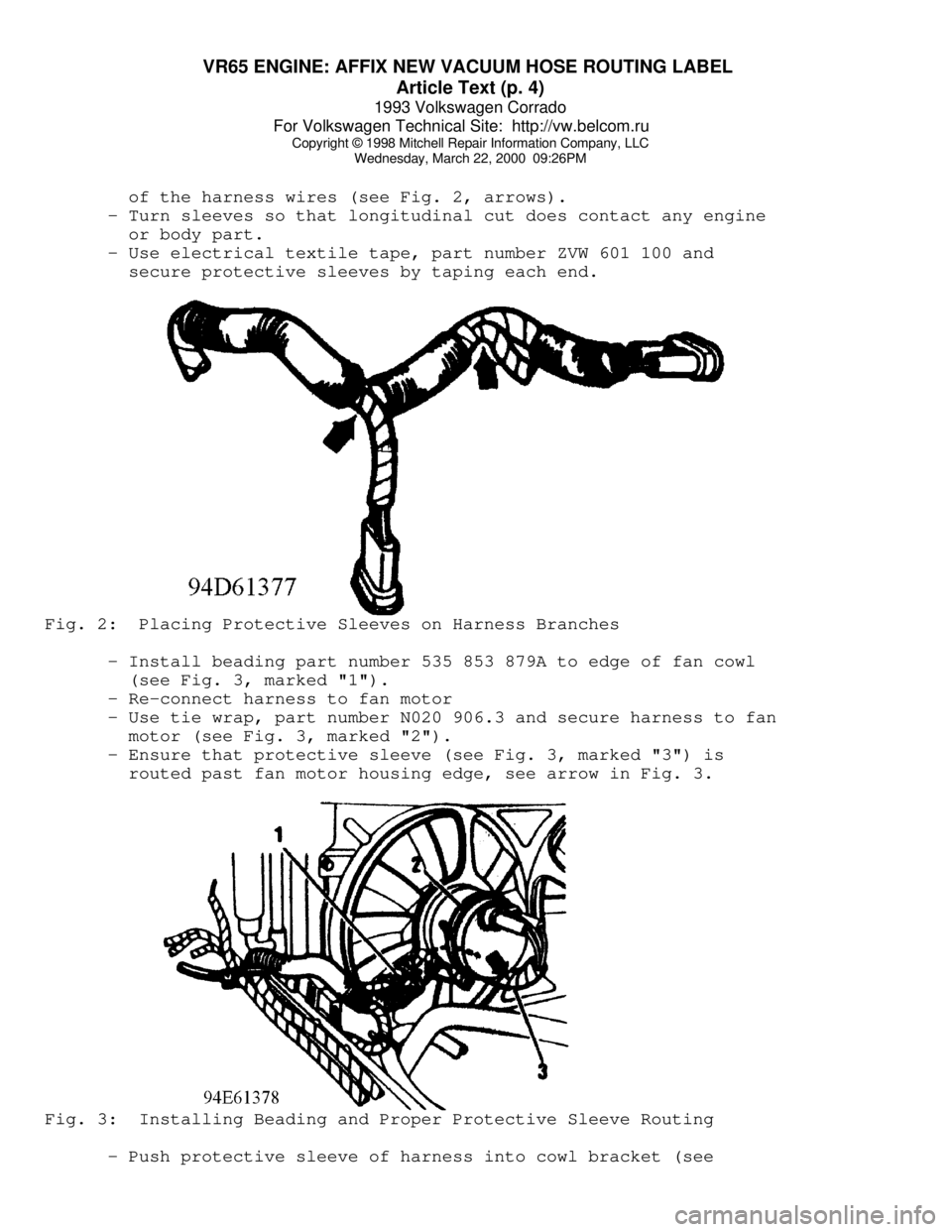

of the harness wires (see Fig. 2, arrows).

- Turn sleeves so that longitudinal cut does contact any engine

or body part.

- Use electrical textile tape, part number ZVW 601 100 and

secure protective sleeves by taping each end.Fig. 2: Placing Protective Sleeves on Harness Branches

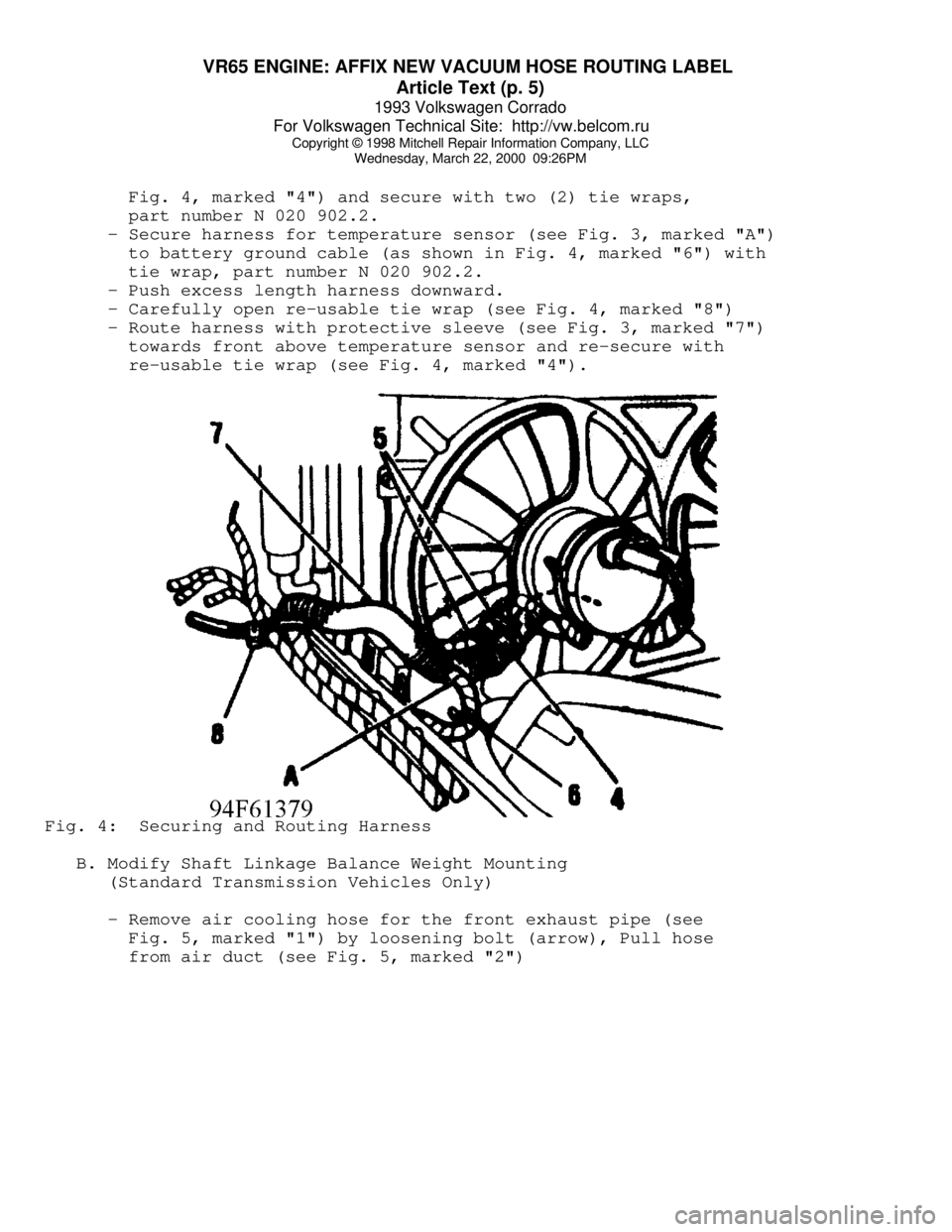

- Install beading part number 535 853 879A to edge of fan cowl

(see Fig. 3, marked "1").

- Re-connect harness to fan motor

- Use tie wrap, part number N020 906.3 and secure harness to fan

motor (see Fig. 3, marked "2").

- Ensure that protective sleeve (see Fig. 3, marked "3") is

routed past fan motor housing edge, see arrow in Fig. 3.Fig. 3: Installing Beading and Proper Protective Sleeve Routing

- Push protective sleeve of harness into cowl bracket (see

Page 764 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Fig. 4, marked "4") and secure with two (2) tie wraps,

part number N 020 902.2.

- Secure harness for temperature sensor (see Fig. 3, marked "A")

to battery ground cable (as shown in Fig. 4, marked "6") with

tie wrap, part number N 020 902.2.

- Push excess length harness downward.

- Carefully open re-usable tie wrap (see Fig. 4, marked "8")

- Route harness with protective sleeve (see Fig. 3, marked "7")

towards front above temperature sensor and re-secure with

re-usable tie wrap (see Fig. 4, marked "4").Fig. 4: Securing and Routing Harness

B. Modify Shaft Linkage Balance Weight Mounting

(Standard Transmission Vehicles Only)

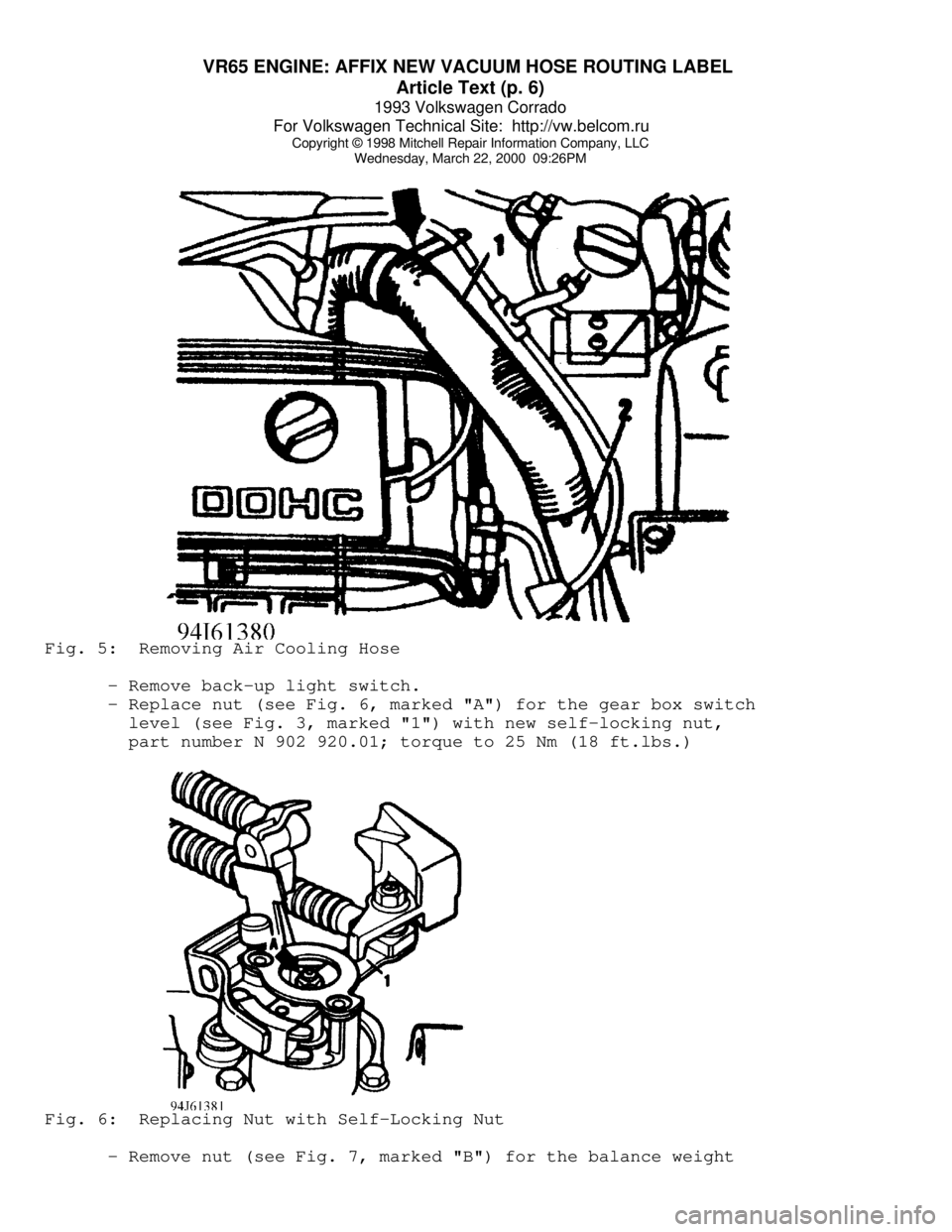

- Remove air cooling hose for the front exhaust pipe (see

Fig. 5, marked "1") by loosening bolt (arrow), Pull hose

from air duct (see Fig. 5, marked "2")

Page 765 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PMFig. 5: Removing Air Cooling Hose

- Remove back-up light switch.

- Replace nut (see Fig. 6, marked "A") for the gear box switch

level (see Fig. 3, marked "1") with new self-locking nut,

part number N 902 920.01; torque to 25 Nm (18 ft.lbs.)Fig. 6: Replacing Nut with Self-Locking Nut

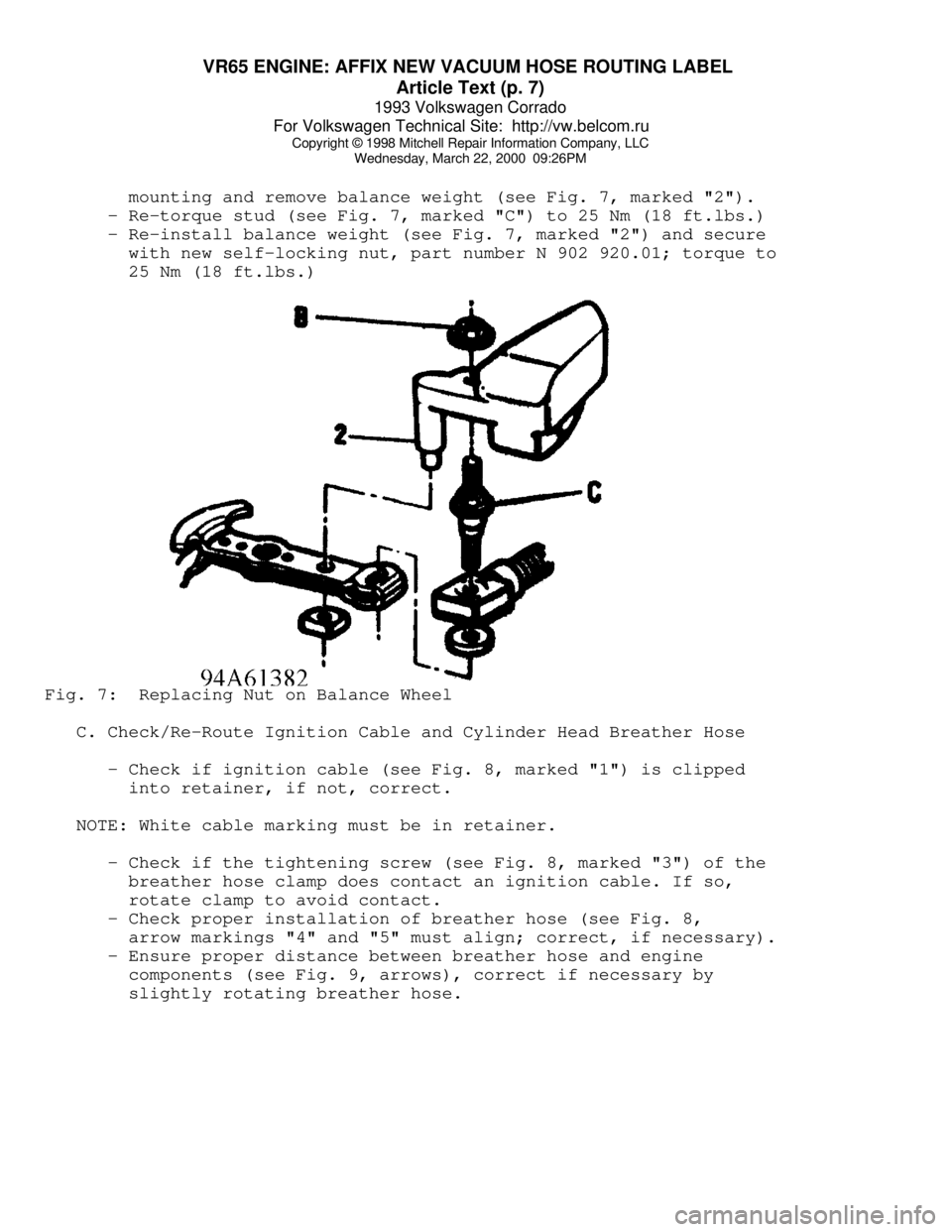

- Remove nut (see Fig. 7, marked "B") for the balance weight

Page 766 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

mounting and remove balance weight (see Fig. 7, marked "2").

- Re-torque stud (see Fig. 7, marked "C") to 25 Nm (18 ft.lbs.)

- Re-install balance weight (see Fig. 7, marked "2") and secure

with new self-locking nut, part number N 902 920.01; torque to

25 Nm (18 ft.lbs.)Fig. 7: Replacing Nut on Balance Wheel

C. Check/Re-Route Ignition Cable and Cylinder Head Breather Hose

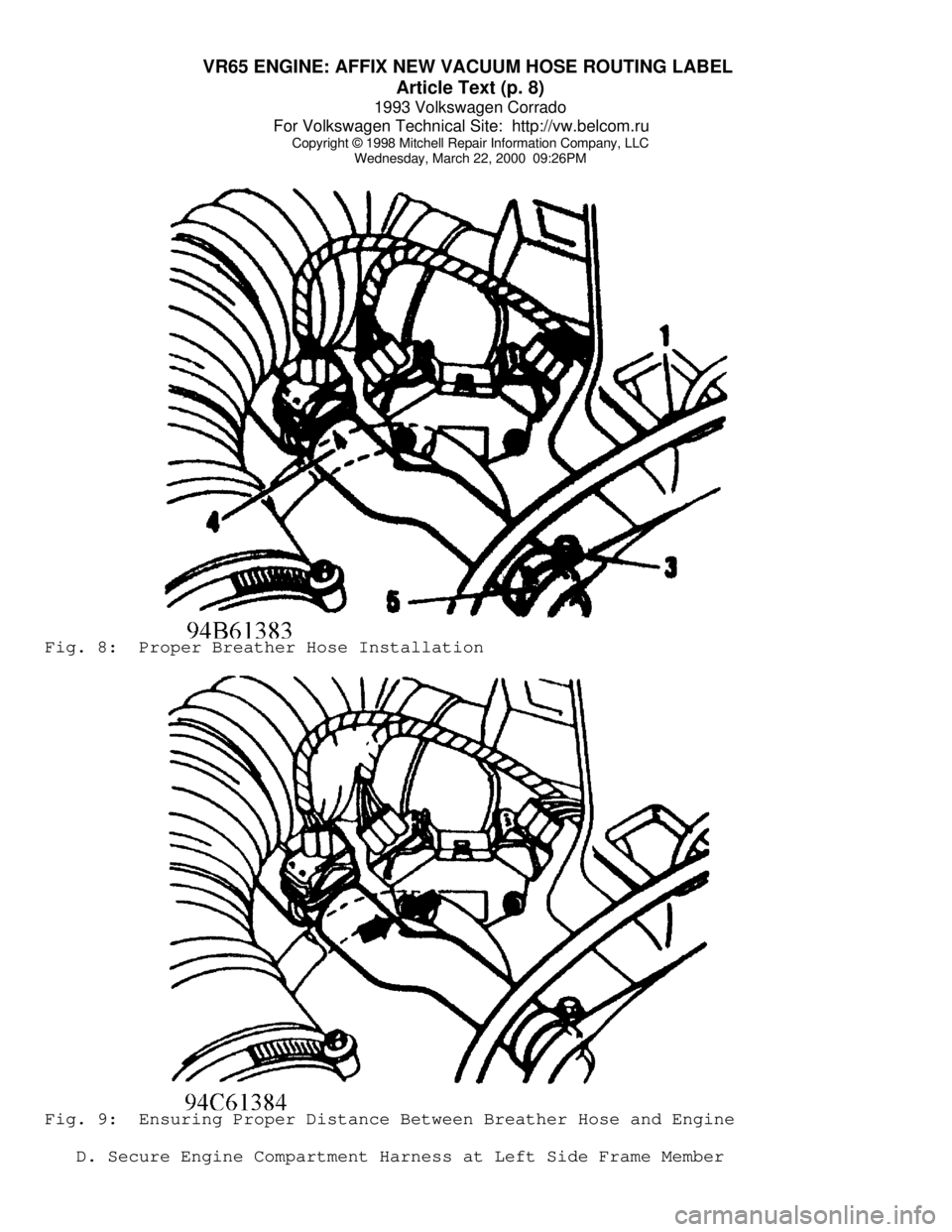

- Check if ignition cable (see Fig. 8, marked "1") is clipped

into retainer, if not, correct.

NOTE: White cable marking must be in retainer.

- Check if the tightening screw (see Fig. 8, marked "3") of the

breather hose clamp does contact an ignition cable. If so,

rotate clamp to avoid contact.

- Check proper installation of breather hose (see Fig. 8,

arrow markings "4" and "5" must align; correct, if necessary).

- Ensure proper distance between breather hose and engine

components (see Fig. 9, arrows), correct if necessary by

slightly rotating breather hose.

Page 767 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PMFig. 8: Proper Breather Hose InstallationFig. 9: Ensuring Proper Distance Between Breather Hose and Engine

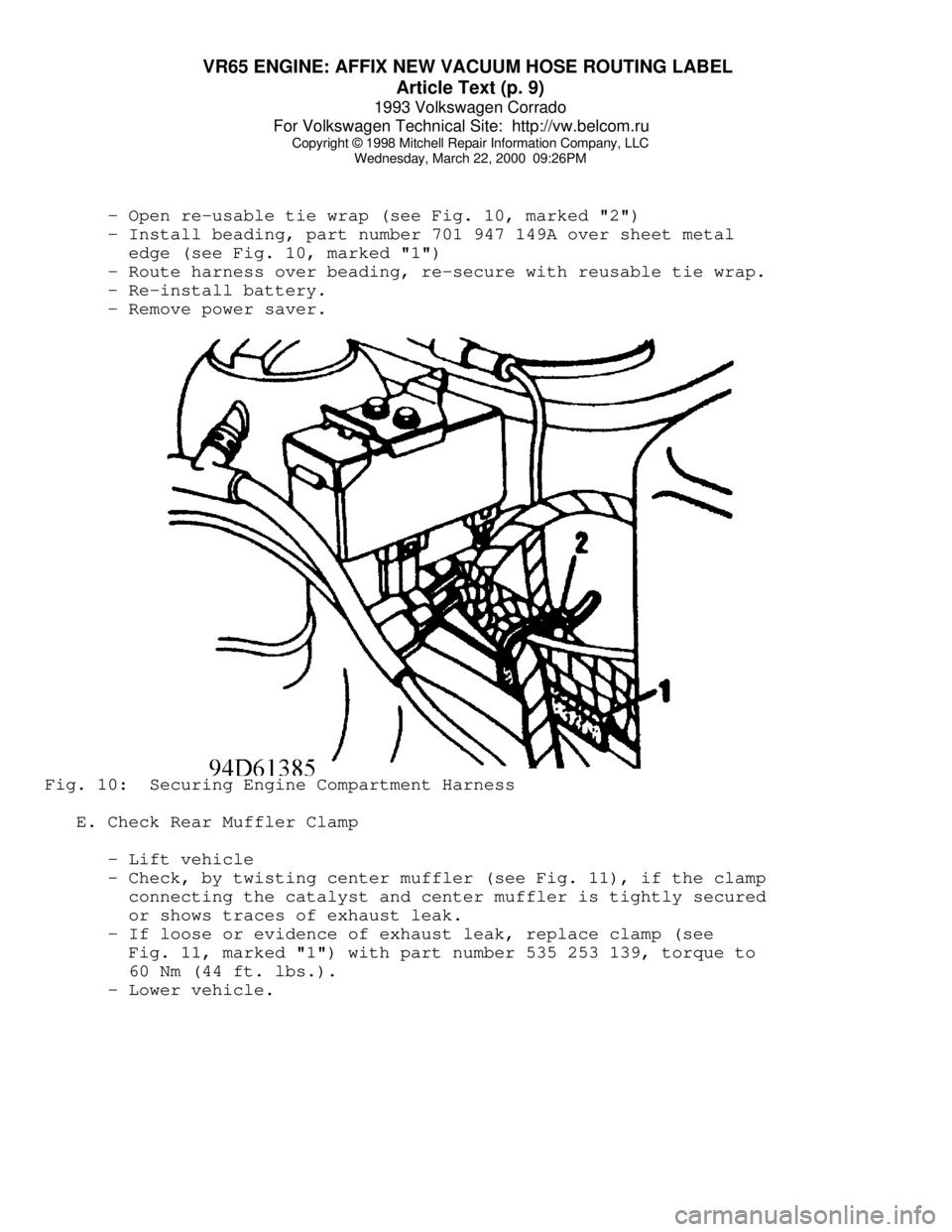

D. Secure Engine Compartment Harness at Left Side Frame Member

Page 768 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

- Open re-usable tie wrap (see Fig. 10, marked "2")

- Install beading, part number 701 947 149A over sheet metal

edge (see Fig. 10, marked "1")

- Route harness over beading, re-secure with reusable tie wrap.

- Re-install battery.

- Remove power saver.Fig. 10: Securing Engine Compartment Harness

E. Check Rear Muffler Clamp

- Lift vehicle

- Check, by twisting center muffler (see Fig. 11), if the clamp

connecting the catalyst and center muffler is tightly secured

or shows traces of exhaust leak.

- If loose or evidence of exhaust leak, replace clamp (see

Fig. 11, marked "1") with part number 535 253 139, torque to

60 Nm (44 ft. lbs.).

- Lower vehicle.