check engine VOLKSWAGEN CORRADO 1993 Owner's Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 325 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 11)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

Component Ounces

Condenser ........................................ 1.0-1.7

Evaporator ....................................... 1.5-2.5

Receiver-Drier ................................... 0.5-0.8

Refrigerant Lines (1) ............................ 1.0-1.7

(1) - Add only if a refrigerant oil leak is indicated.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCOMPONENT REFRIGERANT OIL CAPACITIES (CALSONIC V6)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Condenser ............................................ 2.5

Evaporator ........................................... 2.5

Receiver-Drier ....................................... 0.2

Refrigerant Lines (1) ................................ 1.0

(1) - Add only if a refrigerant oil leak is indicated.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Subaru

1) Before checking and adjusting oil level, operate engine at

1000-1500 RPM. Set controls at maximum cooling and high blower motor

speed for 20 minutes to return oil to compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Drain compressor oil from

compressor drain plug and measure oil amount.

3) Fill compressor with total amount drained, using new oil.

If any major components of the system were also replaced, determine

the amount of additional oil needed. See appropriate SUBARU COMPONENT

REFRIGERANT OIL CAPACITIES table for specified amount.

SUBARU COMPONENT REFRIGERANT OIL CAPACITIES (LEGACY)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Compressor ........................................... 2.4

Condenser ............................................ 1.7

Evaporator ........................................... 2.4

Refrigerant Lines (1) ................................ 1.7

(1) - Add only if a refrigerant oil leak is indicated.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄSUBARU COMPONENT REFRIGERANT OIL CAPACITIES (SVX)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Compressor ........................................... 2.4

Condenser ............................................ 1.7

Page 326 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 12)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

Evaporator ........................................... 2.4

Refrigerant Lines (1) ................................ 1.7

(1) - Add only if a refrigerant oil leak is indicated.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ DIESEL KIKI

ROTARY VANE

1) Before checking and adjusting oil level, operate engine at

800-1000 RPM. Set controls at maximum cooling and high blower motor

speed for 20 minutes to return oil to compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Remove oil drain plug and

measure amount of oil drained.

3) If amount drained is less than 3 ounces (1.7 ounces on Geo

Storm), conduct leak tests at system connections. Repair or replace

faulty parts as necessary.

4) If amount drained is more 3 ounces (1.7 ounces on Geo

Storm), oil level is okay. Fill compressor with same amount drained,

using new oil. If amount drained is less than 3 ounces (1.7 ounces on

Geo Storm), pour in 3 (1.7) ounces of new refrigerant oil.

5) When replacing other A/C system components, add the

following amount(s) of refrigerant oil. See COMPONENT REFRIGERANT OIL

CAPACITIES (DIESEL KIKI ROTARY VANE) table.

COMPONENT REFRIGERANT OIL CAPACITIES (DIESEL KIKI ROTARY VANE)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Condenser ............................................... 1.7

Evaporator .............................................. 1.0

Receiver-Drier .......................................... 1.0

Refrigerant Lines ....................................... 0.3

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ 5 & 6-CYLINDER

1) Before checking and adjusting oil level, operate engine at

800-1000 RPM. Set controls at maximum cooling and high blower motor

speed for 20 minutes to return oil to compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Remove oil drain plug and

measure amount of oil drained.

3) If amount drained is less than 3 ounces, conduct leak

tests at system connections. Repair or replace faulty parts as

necessary.

4) If amount drained is more 3 ounces, oil level is okay.

Fill compressor with same amount drained, using new oil.

5) When replacing other A/C system components, add the

following amount(s) of refrigerant oil. See COMPONENT REFRIGERANT OIL

Page 328 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 14)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

2) Add one ounce of refrigerant oil when replacing

evaporator. Add1/2 ounce when replacing condenser. When replacing

receiver-drier or hoses, add 1/3 ounce per component replaced.

HARRISON

R4 4-CYLINDER

1) Before checking and adjusting oil level, operate engine at

800-1000 RPM. Set controls at maximum cooling and high blower motor

speed for 20 minutes to return oil to compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Remove oil drain plug and

measure amount of oil drained.

3) If amount drained is less than one ounce, conduct leak

tests at system connections. Repair or replace faulty parts as

necessary. Fill compressor with 2 ounces, using new refrigerant oil.

4) If amount drained is more one ounce, oil level is okay.

Fill compressor with same amount drained, using new oil.

5) When replacing other A/C system components, add the

following amount(s) of refrigerant oil. See COMPONENT REFRIGERANT OIL

CAPACITIES (HARRISON R4 4-CYLINDER) table.

COMPONENT REFRIGERANT OIL CAPACITIES (HARRISON R4 4-CYLINDER)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Condenser ............................................... 1.0

Evaporator .............................................. 1.7

Receiver-Drier .......................................... 1.0

Refrigerant Lines ....................................... 0.3

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ V5 5-CYLINDER

1) If system is operable, run A/C system for several minutes

to stabilize system. Turn off engine. Discharge system and remove

compressor. See SERVICING PRECAUTIONS. Remove drain plug and measure

oil.

2) If one ounce or more is drained, add same amount. If less

than one ounce is drained, add 2 ounces of new refrigerant oil to

compressor.

3) If condenser is replaced, add one ounce. Add 3.5 ounces if

accumulator is replaced. If evaporator is replaced or if a large

refrigerant leak occurred, add 3 ounces of new refrigerant oil.

HITACHI

6-CYLINDER

1) Before checking and adjusting oil level, operate

compressor at 1000-1500 engine RPM, and set controls at maximum

Page 329 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 15)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

cooling and high blower motor speed for about 10 minutes to return oil

to compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Drain oil from compressor

through suction port. Measure amount of oil drained.

3) If amount drained is 2.4 ounces or more, fill with same

amount using new oil. If amount drained is less than 2.4 ounces, fill

with 2.4 ounces. Install compressor and recharge.

4) If A/C components are replaced, add refrigerant oil to

system. Add 1.7 ounces if condenser is replaced. Add 2.4 ounces if

evaporator is replaced. Oil does not need to be added if receiver-

drier is replaced. Add 1.7 ounces of refrigerant oil only if a

refrigerant oil leak is indicated.

MATSUSHITA

ROTARY VANE

Geo (Prizm)

1) If system is operable, run A/C system for several minutes

to stabilize system. Turn off engine. Discharge system and remove

compressor. See SERVICING PRECAUTIONS. Remove drain plug and measure

oil.

2) If one ounce or more is drained, add same amount. If less

than one ounce is drained, add 2 ounces of new refrigerant oil to

compressor.

3) If condenser is replaced, add one ounce. Add 3.5 ounces if

receiver-drier is replaced. If evaporator is replaced or if a large

refrigerant leak occurred, add 3 ounces of new refrigerant oil.

Toyota

Discharge system. See SERVICING PRECAUTIONS. Remove

compressor from vehicle. Drain oil from compressor through inlet and

outlet ports. Fill compressor with 3.4-4.1 ounces of oil through

suction port. Add 0.7 ounces if receiver-drier was replaced. When

replacing condenser or evaporator, add 1.4-1.7 ounces of refrigerant

oil.

NIPPONDENSO

ROTARY VANE

1) Before checking and adjusting oil level, operate

compressor at engine idle speed, and set controls at maximum cooling

and high blower motor speed for 20-30 minutes to return oil to

compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Drain compressor oil through

compressor intake and discharge ports. Measure amount drained.

3) Fill compressor with same amount as drained, plus one

ounce. When replacing condenser, add one ounce. When replacing

evaporator, add 1 1/2 ounces. When replacing receiver-drier, add 1/3

Page 332 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 18)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

component replaced.

Honda

1) Discharge system. See SERVICING PRECAUTIONS. Remove

compressor from vehicle. Drain all oil from NEW compressor and fill

compressor with 4 ounces of clean refrigerant oil.

2) On Civic and Civic Del Sol, add 1 1/2 ounce of refrigerant

oil when replacing evaporator. Add 2/3 ounce when replacing condenser.

When replacing receiver-drier or hoses, add 1/3 ounce per component

replaced.

3) On Prelude, add one ounce of refrigerant oil when

replacing evaporator. When replacing other A/C components, add 1/3

ounce per component replaced (including hoses).

Hyundai

Add 1 1/2 ounces of refrigerant oil when replacing

evaporator. Add one ounce when replacing condenser. When replacing

receiver-drier, add 1/3 ounce of refrigerant oil.

5-CYLINDER

Mazda

Add one ounce of refrigerant oil when replacing condenser.

Add 1 2/3 ounce when replacing evaporator. When replacing receiver-

drier, add 1/2 ounce of refrigerant oil.

NOTE: Saab and Volvo (Sanden 5 or 7-cylinder) compressor oil

checking procedures are not available from manufacturer.

7-CYLINDER

Hyundai & Mitsubishi (Excel & Precis)

1) Before checking and adjusting oil level, operate

compressor at engine idle speed, and set controls at maximum cooling

and high blower motor speed for 20-30 minutes to return oil to

compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS. Remove oil drain plug and

drain oil. Measure amount of oil drained. Install drain plug with new

"O" ring.

3) If amount drained is 2.3 ounces or more, fill compressor

with same amount using new oil. If amount drained is less than 2.3

ounces, fill with 2.3 ounces. Install filler plug. Install compressor

and recharge system.

COMPONENT REFRIGERANT OIL CAPACITIES (SANDEN 7-CYLINDER)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Condenser ............................................ 1.0

Evaporator ............................................. 3

Receiver-Drier ......................................... 1

Page 333 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 19)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PMÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Jaguar (XJS)

1) Operate engine at idle speed for 10 minutes, to return

refrigerant oil to compressor. Stop engine. Discharge refrigerant. See

SERVICING PRECAUTIONS. Clean area around compressor filler plug and

remove plug slowly.

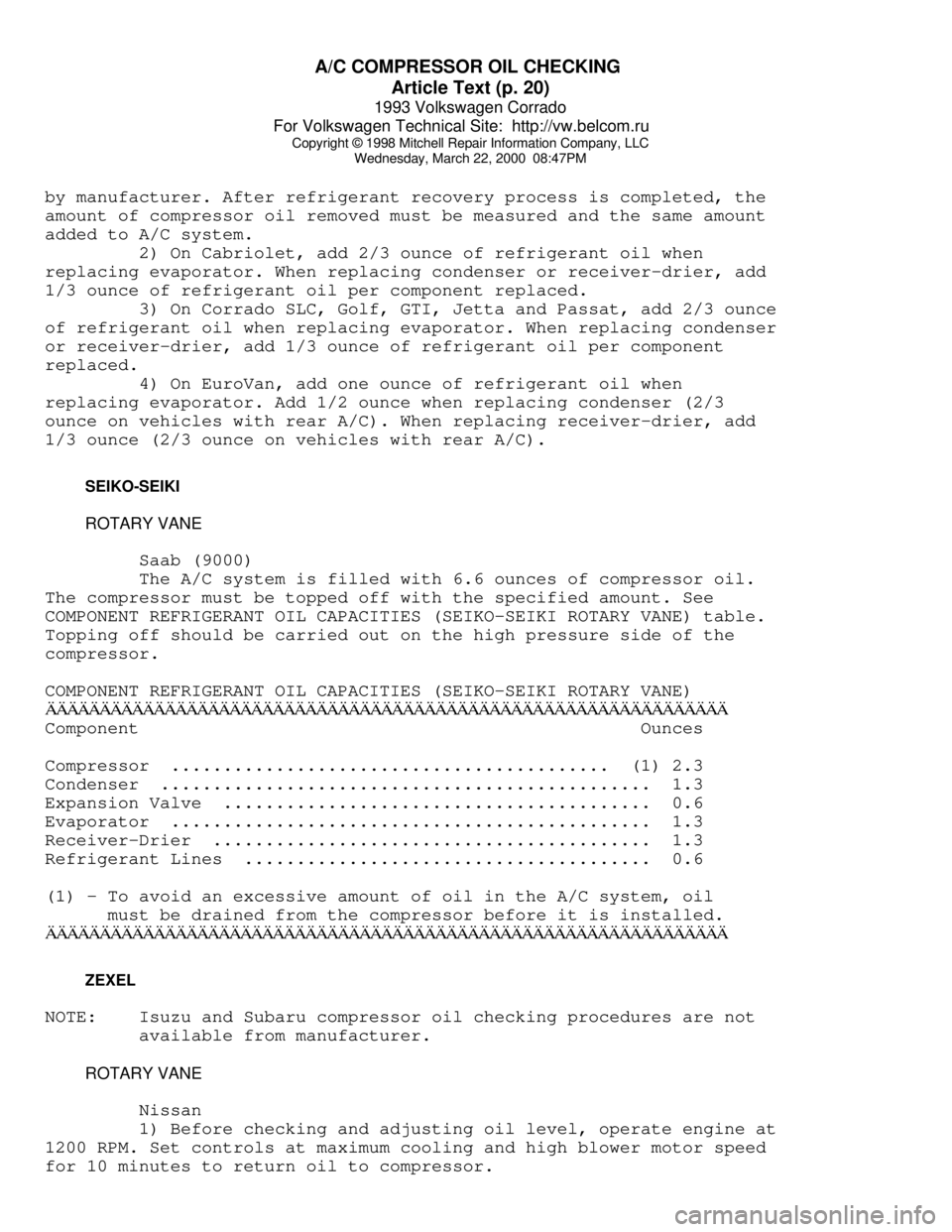

2) Determine angle at which compressor is mounted. Insert

compressor dipstick diagonally until stop on dipstick contacts filler

plug surface. See Fig. 1. Remove dipstick and note oil fill level.

Each increment on dipstick represents one ounce of oil.

3) Determine amount of oil needed according to mounting

angle. See COMPRESSOR OIL CAPACITIES (JAGUAR XJS) table for specified

amount.

4) If necessary, correct compressor oil level. Install

compressor oil plug, and tighten it to 72-108 INCH lbs. (8-12 N.m).

Evacuate and recharge A/C system. Perform leak test.Fig. 1: Checking Jaguar XJS Compressor Oil Level (Sanden 7-Cylinder)

Courtesy of Jaguar Cars, Inc.

COMPRESSOR OIL CAPACITIES (JAGUAR XJS)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMounting Angle (In Degrees) Oil Level In Increments

0 .................................................... 3-5

10 ................................................... 4-6

20 ................................................... 5-7

30 ................................................... 6-8

40 ................................................... 7-9

50 .................................................. 8-10

60 .................................................. 9-11

90 ................................................. 10-12

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Volkswagen

1) The use of refrigerant recovery/recycling is recommended

Page 334 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 20)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

by manufacturer. After refrigerant recovery process is completed, the

amount of compressor oil removed must be measured and the same amount

added to A/C system.

2) On Cabriolet, add 2/3 ounce of refrigerant oil when

replacing evaporator. When replacing condenser or receiver-drier, add

1/3 ounce of refrigerant oil per component replaced.

3) On Corrado SLC, Golf, GTI, Jetta and Passat, add 2/3 ounce

of refrigerant oil when replacing evaporator. When replacing condenser

or receiver-drier, add 1/3 ounce of refrigerant oil per component

replaced.

4) On EuroVan, add one ounce of refrigerant oil when

replacing evaporator. Add 1/2 ounce when replacing condenser (2/3

ounce on vehicles with rear A/C). When replacing receiver-drier, add

1/3 ounce (2/3 ounce on vehicles with rear A/C).

SEIKO-SEIKI

ROTARY VANE

Saab (9000)

The A/C system is filled with 6.6 ounces of compressor oil.

The compressor must be topped off with the specified amount. See

COMPONENT REFRIGERANT OIL CAPACITIES (SEIKO-SEIKI ROTARY VANE) table.

Topping off should be carried out on the high pressure side of the

compressor.

COMPONENT REFRIGERANT OIL CAPACITIES (SEIKO-SEIKI ROTARY VANE)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Compressor .......................................... (1) 2.3

Condenser ............................................... 1.3

Expansion Valve ......................................... 0.6

Evaporator .............................................. 1.3

Receiver-Drier .......................................... 1.3

Refrigerant Lines ....................................... 0.6

(1) - To avoid an excessive amount of oil in the A/C system, oil

must be drained from the compressor before it is installed.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ZEXEL

NOTE: Isuzu and Subaru compressor oil checking procedures are not

available from manufacturer.

ROTARY VANE

Nissan

1) Before checking and adjusting oil level, operate engine at

1200 RPM. Set controls at maximum cooling and high blower motor speed

for 10 minutes to return oil to compressor.

Page 335 of 920

A/C COMPRESSOR OIL CHECKING

Article Text (p. 21)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:47PM

2) Stop engine. Discharge refrigerant. See SERVICING

PRECAUTIONS. Measure the amount of oil drained/discharged into

refrigerant recovery/recycling equipment.

3) Remove compressor from vehicle. Drain compressor oil from

compressor drain plug and measure oil amount. Add this amount to

amount drained in step 2), to obtain total amount drained.

4) Fill compressor with total amount drained, using new oil.

If any major components of the system were also replaced, determine

the amount of additional oil needed. See COMPONENT REFRIGERANT OIL

CAPACITIES (ZEXEL ROTARY VANE & 6-CYLINDER) table for specified

amount.

COMPONENT REFRIGERANT OIL CAPACITIES (ZEXEL ROTARY VANE & 6-CYLINDER)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Ounces

Condenser

Altima & Maxima ............................................... 2.5

NX, Pickup, Sentra & 300ZX ................................ 1.0-1.7

Evaporator

Altima & Maxima ............................................... 2.5

NX, Pickup, Sentra & 300ZX ................................ 1.5-2.5

Receiver-Drier

Altima & Maxima ............................................... 0.2

NX, Pickup, Sentra & 300ZX ................................ 0.5-0.8

Refrigerant Lines (1) .......................................... 1.0

(1) - Add only if a refrigerant oil leak is indicated.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ 6-CYLINDER

Audi

1) The use of refrigerant recovery/recycling is recommended

by manufacturer. After refrigerant recovery process is completed, the

amount of compressor oil removed must be measured and the same amount

added to A/C system.

2) Add one ounce of refrigerant oil when replacing

accumulator. When replacing condenser, add amount drained from

condenser plus 1/3 ounce of refrigerant oil. When replacing

evaporator, add amount drained from evaporator plus 2/3 ounce of

refrigerant oil.

Nissan

1) Before checking and adjusting oil level, operate engine at

1200 RPM. Set controls at maximum cooling and high blower motor speed

for 10 minutes to return oil to compressor.

2) Stop engine. Discharge refrigerant. See SERVICING

PRECAUTIONS. Measure the amount of oil drained/discharged into

refrigerant recovery/recycling equipment.

3) Remove compressor from vehicle. Drain compressor oil from

compressor drain plug and measure oil amount. Add this amount to

Page 363 of 920

A/C SYSTEM GENERAL DIAGNOSTIC PROCEDURES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

ARTICLE BEGINNING

1993 AIR CONDITIONING & HEAT

A/C General Diagnostic Procedures

Diagnosis is an important first step in A/C system servicing.

To save time and effort, systems should be carefully checked to

identify the causes of poor performance. By using the following

diagnostic charts, defective components or system problems can be

quickly located. To identify problems that are specific to one system,

refer to the repair section of this manual. The charts in this section

apply to all systems.

PREPARATION FOR TESTING

1) Attach Low and High pressure gauges.

2) Start engine and allow to warm up.

3) Set system to COOL and blower to HIGH.

4) Open car doors and hood.

5) Run engine at fast idle for 2-3 minutes.

AIR CONDITIONING SYSTEM PERFORMANCE CHECK

AIR CONDITIONING SYSTEM PERFORMANCE CHECK TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄPERFORM TESTS: SHOULD BE: IF:

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature Check Temperature Check Is:

* Switch to LOW blower.

* Close doors.

* Check outlet temperature. 35-45

ø F Too warm - Check

control lever

operation, heater

water valve, cooling

system and gauge readings.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄPERFORM TESTS: SHOULD BE: IF:

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄVisual Check Visual Check Shows:

* Compressor Quiet with no leaks Noisy - Check belts,

oil level, seals,

gaskets, reed valves.

* Condenser Free of obstructions Blocked - Clean off.

Plugged - Flush or

replace.

* Receiver-Drier Dry and warm to touch Frosty - Check for

restriction, replace

desiccant.

Page 379 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

too low. This protects compressor if not enough refrigerant is in

system. Low-pressure cut-out switch shuts compressor off at about 29

psi (2.0 kg/cmý).

THERMOSWITCH

Thermoswitch shuts compressor off if coolant temperature is

greater than 248

øF (120øC).

ADJUSTMENTS

AIR DISTRIBUTION CONTROL

1) Move air distribution control knob to defrost position.

Connect 3-foot long control cable to footwell/defrost flap lever. Push

flap lever toward cable and secure cable sheath with retainer clip.

2) Move air distribution control knob to panel (vent)

position. Connect 2-foot long control cable to center flap lever. Push

flap lever away from cable and secure cable sheath with retainer clip.

TEMPERATURE CONTROL

Move temperature knob to full cool position. Connect

temperature control cable (Blue sheath) to temperature flap lever.

Push flap lever away from cable and secure cable sheath with retainer

clip.

TROUBLE SHOOTING

NO COOLING

1) Ensure blower fan motor operates in all 4 speeds. Ensure

air duct closes off outside air and heater water valve is closed.

Clean condenser.

2) Inspect receiver-drier pressure seal. If seal is good, go

to step 3). If seal is broken, replace seal. Evacuate and recharge

system. If system cools properly, testing is complete. If system does

not cool, connect pressure gauges.

3) Adjust engine speed to 2500 RPM. Set controls for maximum

cooling and high fan. Insert thermometer in left air duct and close

all other ducts. With vehicle in shade, close windows and doors and

connect pressure gauges. Operate system for 10 minutes.

4) If fan does not operate, replace pressure switch. Ensure

system is okay. If fan does come on, turn engine off, and check for

condenser obstructions and blocked airflow.

5) Turn air conditioner on and off with temperature control.

Ensure compressor clutch engages. Push lever to extreme right position

and back again. A click should be heard from compressor clutch. If a

click is not heard, check for voltage at clutch coil wire with switch

on. If voltage is present, replace clutch coil. If voltage is not

present, check wiring or replace thermostatic switch.

6) If compressor clutch operates, check gauge readings. If