check engine VOLKSWAGEN CORRADO 1993 Service Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 380 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

both gauges read too low, locate leak and recharge system. If both

gauges read too high, replace expansion valve. If low side is too high

and high side is too low, replace compressor.

INSUFFICIENT COOLING

1) Ensure blower fan motor operates at all 4 speeds. Ensure

air duct closes off outside air intake and heater water valve is

closed. Clean condenser.

2) Adjust engine speed to 2500 RPM. Set controls for maximum

cooling and high fan. Insert thermometer in left air duct and close

all other ducts. With vehicle in shade, close windows and doors and

connect pressure gauges. Operate system for 10 minutes.

3) If both gauges read too high, replace expansion valve. If

both gauges read low, locate leak and recharge system. If both gauge

readings are normal, go to next step. If high side is too high and

suction side is normal, go to step 5). If high side is too low and

suction side is too high, go to step 6). If high side is normal and

suction side is too low, go to step 7).

4) Turn compressor off and observe gauges. If readings

equalize in 30 seconds, replace compressor. If readings take longer to

equalize, ensure capillary tube installed length is 13" (330 mm).

5) If capillary tube installation is correct, run system at

maximum cooling for 15 minutes. If thermometer indicates temperature

is less than 36øF (2øC) when compressor is turned off, or temperature

is greater than 48

øF (9øC) with compressor on, replace thermostatic

switch.

6) Check condenser fins and clean or straighten. If operation

is still not correct, discharge system until bubbles appear in sight

glass. Recharge system until bubbles disappear, and recheck pressures.

If operation is still incorrect, locate leaks and tighten fittings.

Discharge A/C system using approved refrigerant recovery/recycling

equipment. Evacuate system to remove all air and recharge system.

7) Check for bubbles at sight glass. If bubbles are present,

repair leaks and recharge system. If no bubbles are present, check

condenser-to-expansion valve line for kinks and repair if necessary.

Check line (from condenser to expansion valve) for restrictions by

feeling line for cold spots. If there are no cold spots, replace

expansion valve.

8) If cold spot is felt, remove and flush out lines and

condenser. Check for bubbles at sight glass. If there are no bubbles

present, replace compressor. If bubbles are present, check for leaks.

Repair and recharge system.

INTERMITTENT COOLING

1) Ensure blower fan motor operates in all 4 speeds. Ensure

air duct closes off outside air and heater water valve is closed.

Clean condenser.

2) Adjust engine speed to 2500 RPM. Set controls for maximum

cooling and high fan. Insert thermometer in left air duct and close

all other ducts. With vehicle in shade, close windows and doors and

Page 381 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

connect pressure gauges. Operate system for 10 minutes.

3) Check for cool air from left duct. Low pressure gauge

should read more than 16 psi (1.1 kg/cmý). If low pressure gauge

reading is incorrect, place hands around expansion valve to warm

valve. If pressure rises, moisture is present in system. Discharge A/C

system using approved refrigerant recovery/recycling equipment.

Evacuate and recharge system. If pressure does not rise, go to next

step.

4) Check temperature on thermometer when thermostatic switch

turns compressor off. If temperature is 39

øF (4øC), system is okay. If

temperature is lower than 39

øF (4øC), ensure capillary tube installed

length is 13" (330 mm). If capillary tube installation is correct,

replace thermostatic switch.

TESTING

A/C SYSTEM PERFORMANCE

1) Park vehicle out of direct sunlight. Start engine and

operate engine at 2500 RPM. Set A/C controls to outside air, panel

(vent) mode, full cold, and A/C button on.

2) Set blower/fan on high speed and open windows. Operate

system for 6-7 minutes to allow system to stabilize. Insert

thermometer in center vent, and measure temperature. Temperature at

center vent must be 19-40

øF (-7 to 4øC) at center vent, with high side

and low side pressures within specification. See SPECIFICATIONS table

at beginning of article.

AMBIENT TEMPERATURE SWITCH

1) Remove air intake grille from right side cowl. Remove

switch from panel on right side of tray area. Place switch in freezer.

2) Using a DVOM, check switch resistance. Switch resistance

must be infinite (no continuity) below 30

øF (-1øC). Allow switch to

warm above 45

øF (7øC). Switch resistance must be zero ohms

(continuity). Replace switch if necessary.

COMPRESSOR CLUTCH COIL

Disconnect compressor clutch harness connector. Check

resistance between clutch connector terminals. Resistance reading

should be 3.6 ohms. If resistance reading is not as specified, replace

clutch coil.

DUAL-PRESSURE SWITCH

High-Pressure Cut-Out Switch

Locate dual-pressure switch on refrigerant line (right strut

tower). Switch is identified by its 4 wires. Ensure switch opens at

464 psi (32 kg/cm

ý). Ensure switch closes at 348 psi (24 kg/cmý).

NOTE: Dual-pressure switch may be removed without discharging

Page 389 of 920

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

* Replacement intervals.

* Belt adjustment.

* Engine Compression.

* Valve clearance.

* Valve Arrangement.

* Ignition coil specifications.

* High tension wire resistance.

* Spark plug type and gap.

* Firing order.

* Ignition timing.

* Fuel pump performance and injector resistance specifications

* Slow and fast idle speed and mixture specifications.

* Carbon monoxide (CO) level specifications.

* Throttle position sensor/switch specifications.

C - SPECIFICATIONS

This is a collection of quick-reference type specifications.

This article is helpful when you are familiar with proper adjustment

procedures and only need specifications. Included in this section are:

* Battery specifications.

* Fluid capacities.

* Replacement intervals.

* Belt adjustment.

* Engine Compression.

* Valve clearance.

* Valve Arrangement.

* Ignition coil specifications.

* High tension wire resistance.

* Spark plug type and gap.

* Firing order.

* Ignition timing.

* Fuel pump performance and injector resistance specifications

* Slow and fast idle speed and mixture specifications.

* Carbon monoxide (CO) level specifications.

* Throttle position sensor/switch specifications.

D - ADJUSTMENTS

This article contains the information that use to be included

in the TUNE-UP section. Checking and adjusting valves, spark plugs,

spark plug wires, base ignition timing and idle speed are found in

this section. Use this article for routine maintenance. Also, if you

have a driveability problem, ensure all on-vehicle adjustments are

correct before proceeding with any diagnosis.

E - THEORY/OPERATION

Page 390 of 920

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

This article covers basic theory and operation of engine

performance-related systems and components. Before diagnosing vehicles

or systems with which you are not completely familiar, read this

article.

F - BASIC TESTING

When diagnosing driveability problems, there are certain

"BASIC DIAGNOSTIC PROCEDURES" which must FIRST be performed. It is

necessary to perform a careful, complete check of basic engine

mechanical and electrical conditions, and verify spark availability

and adequate fuel supply.

The procedures apply to both computerized and non-

computerized systems. If all systems are okay, go to G - TESTS W/

CODES for vehicles with self-diagnostic systems or H - TESTS W/O CODES

for diagnosis by symptom.

G - TESTS W/ CODES

Use this article to retrieve and interpret trouble codes from

the engine computer self-diagnostic system. Once information is

retrieved, diagnostic procedures are given to help pinpoint and repair

computer system/component faults. Necessary steps for clearing trouble

codes are also given. If faults indicated by trouble codes are not

present at time of testing, proceed to TESTS W/O CODES for

intermittent testing procedures.

H - TESTS W/O CODES

This article helps trouble shoot driveability problems based

upon available "SYMPTOMS" and "INTERMITTENT TESTING" procedures.

Procedures in this section should lead you to specific component or

system tests which may or may not be computer monitored/controlled.

I - SYS/COMP TESTS

In this article, you will find tests for systems and

components related to air induction systems (turbochargers), fuel

control, ignition control, and emissions control systems.

J - PIN VOLTAGE CHARTS

PIN VOLTAGE CHARTS are supplied (where available) to speed up

the diagnostic process. By checking pin voltages at the electronic

control unit, it is possible to determine if the control unit is

receiving and transmitting proper voltage signals.

K - SENSOR RANGE CHARTS

Use the SENSOR OPERATING RANGE CHARTS to determine if a

Page 391 of 920

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

sensor is out of calibration. A sensor that is out of calibration may

not set a trouble code, but it will cause driveability problems.

L - WIRING DIAGRAMS

Use these WIRING DIAGRAMS to identify and trace component

circuits, locate shorts and opens in circuits, and understand how

individual circuits function as part of a system. The diagrams in this

article are only for fuel, ignition and emission systems

M - VACUUM DIAGRAMS

The VACUUM DIAGRAMS will assist you in finding incorrectly

routed vacuum hoses which may cause driveability problems or computer

indicated malfunctions.

N - REMOVE/INSTALL/OHAUL

N - REMOVE/INSTALL/OHAUL contains information found in the

sub-headings of REMOVAL, OVERHAUL & INSTALLATION. These are procedures

and specifications required to remove, overhaul (if possible) and

install components related to engine performance.

WHERE TO START

PERFORM BASIC INSPECTION

1) Verify customer complaint.

2) Perform visual inspection. See F - BASIC TESTING.

3) Test engine sub-system to determine that the following

systems are functioning properly. See F- BASIC TESTING.

* Mechanical conditions (compression)

* Ignition output

* Fuel Delivery

4) Check air induction system for leaks.

5) Check & adjust basic engine settings listed below to

ensure they are to specification. See D - ADJUSTMENTS.

* Ignition timing

* Idle speed

CHECK FOR TROUBLE CODES

1) If equipped with self-diagnostics, check for trouble

codes. Refer to G - TESTS W/ CODES.

2) Repair causes of trouble code(s).

3) Clear control unit memory.

SYMPTOM DIAGNOSIS

Page 395 of 920

ABBREVIATIONS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM³CBD ³Closed Bowl Distributor ³

³CBVV

³Carburetor Bowl Vent Valve ³

³cc

³Cubic Centimeter ³

³CCC

³Computer Command Control ³

³CCD

³Computer Controlled Dwell ³

³CCM

³Central Control Module ³

³CCO

³Converter Clutch Override ³

³CCOT

³Cycling Clutch Orifice Tube ³

³CCW

³Counterclockwise ³

³CDI

³Capacitor Discharge Ignition ³

³CEC

³Computerized Engine Control ³

³CFI

³Central Fuel Injection ³

³CID

³Cubic Inch Displacement ³

³CID

³Cylinder Identification sensor ³

³CIS

³Continuous Injection System ³

³CIS-E

³Continuous Injection System-Electronic ³

³CKT

³Circuit ³

³CLR

³Clear ³

³CNG

³Compressed Natural Gas ³

³CO

³Carbon Monoxide ³

³CO2

³Carbon Dioxide ³

³CONV

³Convertible ³

³CP

³Canister Purge ³

³CPA

³Connector Position Assurance ³

³CPS

³Crank Position Sensor ³

³CTS

³Coolant Temperature Sensor ³

³CV

³Check Valve or Constant Velocity ³

³CVC

³Constant Vacuum Control ³

³CW

³Clockwise ³

³CYL or Cyl.

³Cylinder ³

³Calif.

³California ³

³Carb.

³Carburetor ³

³Chrg.

³Charging ³

³Circ.

³Circuit ³

³Cntrl.

³Control ³

³Comp.

³Compressor or Compartment ³

³Conn.

³Connector ³

³Cont.

³Continued ³

³Conv.

³Convertible or Converter ³

³Cu. In.

³Cubic Inch ³

³Cyl.

³Cylinder ³

ÀÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ "D" ABBREVIATION TABLE

"D" ABBREVIATION TABLE

ÚÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ¿

³ABBREVIATION

³DEFINITION ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³"D"

³Drive ³

³DBC

³Dual Bed Catalyst ³

³DC

³Direct Current or Discharge ³

Page 406 of 920

ALTERNATOR & REGULATOR

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:56PM

(1) - Turn tensioning nut on toothed rack with Torque Wrench

(VAG1410) and Ring Insert (SW VAG 1410-2).

(2) - Start engine and let it idle for 5 minutes. Loosen bolts and

retighten belt to specification.

(3) - Serpentine belt tension automatically adjusted by tensioner.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ON-VEHICLE TESTING

WIRING CONTINUITY TEST

1) With ignition off, connect a voltmeter between alternator

B+ terminal and ground. Voltmeter should indicate battery voltage. If

battery voltage is not present, check wiring between alternator and

battery.

2) Turn ignition on and ensure alternator indicator light

comes on. If light does not come on, check wiring between alternator

and warning light, including indicator bulb.

OUTPUT TEST

CAUTION: DO NOT load electrical system for more than 15-20 seconds

during output test or possible system damage may occur.

1) Ensure connections at battery, alternator, and starter

(most vehicles) are clean and tight. Ensure alternator, engine and

body are properly grounded. Ensure alternator drive belt is tight and

in good condition.

2) Turn off all accessories. Start engine and allow to idle.

Connect ammeter following manufacturer's instructions. Run engine at

2000 RPM. Adjust carbon pile on tester to obtain maximum alternator

output. DO NOT allow battery voltage to drop to less than 12.6 volts.

3) Alternator output should equal alternator rated output,

minus 16-20 amps. If reading is more than 20 amps less than alternator

rating, replace regulator and retest. If output is still low, repair

or replace alternator.

REGULATOR CONTROL VOLTAGE TEST

1) Connect ammeter following manufacturer's instructions.

Connect voltmeter leads to battery terminals. Start engine and run at

3000 RPM.

2) Run engine until voltage stops rising. Voltage should be

13.5-14.5 volts. If reading is incorrect, remove regulator and ensure

brushes are longer than 3/16" (5 mm). Replace if necessary.

3) If brushes are okay and regulator fails to keep voltage

within specified limits, replace regulator and retest. If voltage is

still incorrect, repair or replace alternator.

BENCH TESTING

Page 414 of 920

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

HYDRAULIC MODULATOR/PUMP

Depressurize brake system. See DEPRESSURIZING BRAKE SYSTEM.

Turn ignition on. Hydraulic modulator/pump should operate for 60

seconds maximum and then stop. Depress brake pedal a few times; pump

should operate again for a few seconds. If pump motor does not

operate, check electrical system. If pump motor operates for more than

60 seconds, internal or external hydraulic leak may be indicated.

Check for external leaks. If external leak is not found, further

testing may be needed to check for internal leaks.

ANTILOCK WARNING LIGHT

Start engine. ANTILOCK warning light should come on, then

turn off after a few seconds. If light does not come on when engine is

started, check electrical system. If light comes on and stays on,

fault has been detected by the ECU and testing will be needed. See

SYSTEM TESTING under DIAGNOSIS & TESTING.

DIAGNOSIS & TESTING

SYSTEM TESTING

NOTE: Check battery condition, brake fluid level, electrical

connections and wiring for damage. If fluid level is

incorrect or battery and/or electrical connections are

faulty, correct problem before preceding. Perform each step,

in sequence, to test entire system, except for ECU. If

faulty ECU is suspected, replace with a known good one, and

retest system. Unplug ECU connector for all test steps.

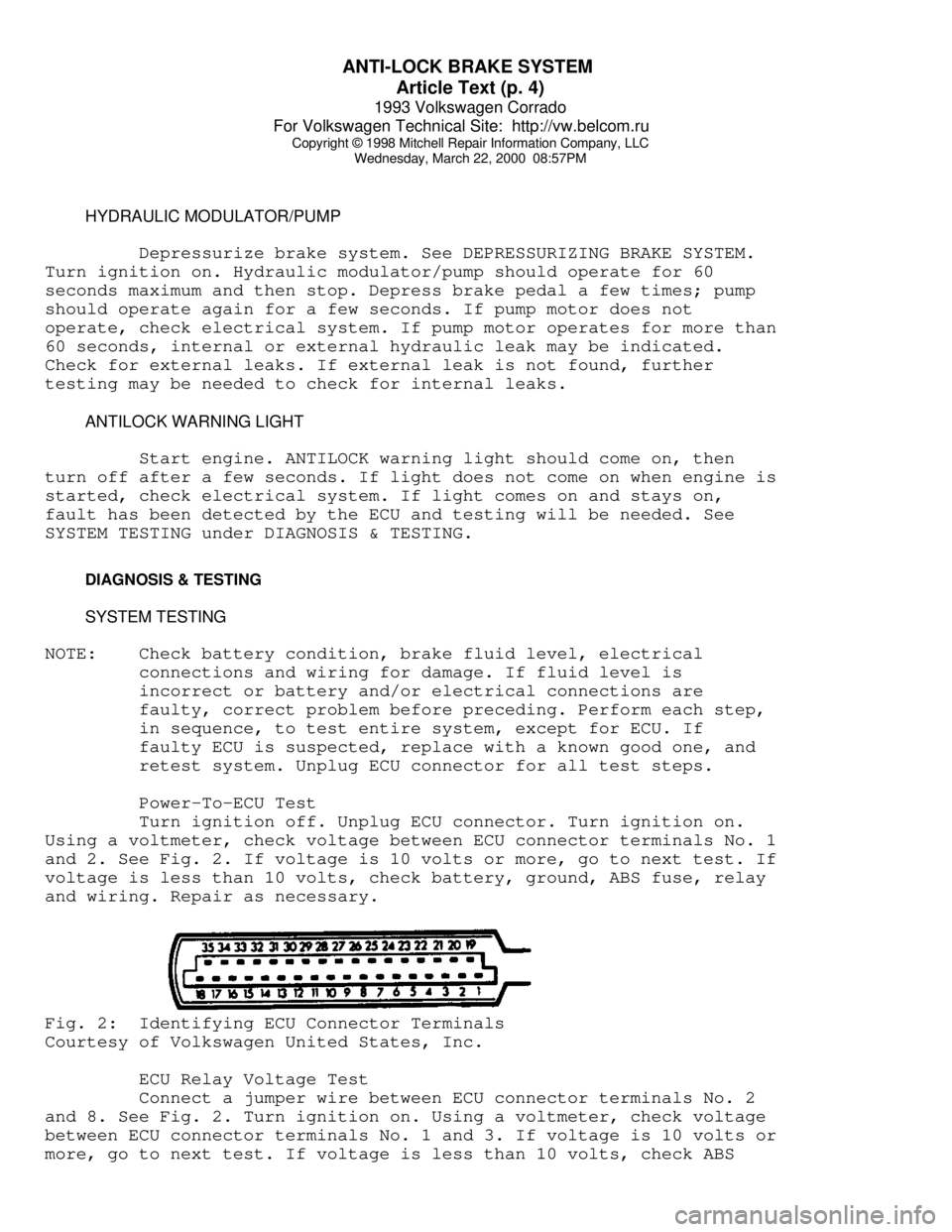

Power-To-ECU Test

Turn ignition off. Unplug ECU connector. Turn ignition on.

Using a voltmeter, check voltage between ECU connector terminals No. 1

and 2. See Fig. 2. If voltage is 10 volts or more, go to next test. If

voltage is less than 10 volts, check battery, ground, ABS fuse, relay

and wiring. Repair as necessary.Fig. 2: Identifying ECU Connector Terminals

Courtesy of Volkswagen United States, Inc.

ECU Relay Voltage Test

Connect a jumper wire between ECU connector terminals No. 2

and 8. See Fig. 2. Turn ignition on. Using a voltmeter, check voltage

between ECU connector terminals No. 1 and 3. If voltage is 10 volts or

more, go to next test. If voltage is less than 10 volts, check ABS

Page 425 of 920

ANTI-THEFT SYSTEM

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

positive lead to anti-theft control module 10-pin wiring harness

connector terminal No. "7" (Red/Yellow wire for Corrado SLC;

Yellow/Red wire for Passat). Insert key in driver's door lock. Turn

key against stop and hold momentarily. Voltmeter should register 12

volts. Repeat procedure for passengers door. If voltage is correct for

each door, go to next step. If voltage is correct, repair door switch

or open circuit.

3) Door Lock Switch Check

Connect voltmeter negative lead to ground. Connect positive

lead to anti-theft control module 10-pin wiring harness connector

terminal No. "6" (Red/Black wire). Insert key in driver's door lock.

Turn key against stop and hold momentarily. Voltmeter should register

12 volts. Repeat procedure for passengers door. If voltage is correct

for each door, replace control module. If voltage is not correct,

repair door switch or open circuit.

ALARM HORN INOPERATIVE

1) Alarm Horn Check

Ensure battery is fully charged. Obtain radio security code.

Disconnect battery cable terminals. Disconnect anti-theft control

module 6-pin and 10-pin wiring harness connector. See ANTI-THEFT

CONTROL MODULE LOCATION table.

2) Connect ohmmeter negative lead to ground. Connect positive

lead to anti-theft control module 6-pin wiring harness connector

terminal No. "4" (Black/Yellow wire). If continuity is present,

replace anti-theft control module. If continuity is not present, check

for open circuit and repair as necessary. If circuit is okay, replace

alarm horn.

LIGHTS DO NOT FLASH

1) Alarm Horn Check

Ensure battery is fully charged and emergency flasher system

is functional. Obtain radio security code. Disconnect battery cable

terminals. Disconnect anti-theft control module 6-pin and 10-pin

wiring harness connector. See ANTI-THEFT CONTROL MODULE LOCATION

table.

2) Connect voltmeter negative lead to ground. Connect

positive lead to anti-theft control module 6-pin wiring harness

connector terminal No. "1" (Black/White wire for Corrado SLC; Black

Yellow wire for Passat). Turn emergency flashers on. When lights flash

on, battery voltage should be present.

3) Remove voltmeter positive from terminal No. "1" and

connect to terminal No. "2" (Black/Green wire for Corrado SLC;

Green/Black wire for Passat). Turn emergency flashers on. When lights

flash on, battery voltage should be present. If voltage is correct,

replace anti-theft control module. If voltage is not correct, repair

open circuit in wiring harness between anti-theft control module and

lights.

ENGINE DOES NOT CRANK WITH ALARM SYSTEM OFF

Page 431 of 920

B - EMISSION APPLICATION

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:57PM

2.0L 4-Cyl. CIS-E Motronic

Major Control Systems & Devices ............. PCV, EVAP, TWC, FR,

(2) EGR, SPK, AP,

(1) O2, CEC, (2) MIL

Components & Other Related Devices ........ (4) EVAP-PV, EVAP-CV,

EGR-VA, EGR-TVV, SPK-CC

2.8L VR6 Motronic MFI

Major Control Systems & Devices ........ PCV, EVAP, TWC, FR, EGR,

SPK, AP, (1) O2, CEC, (2) MIL

Components & Other Related Devices ...... AP-EAP, AP-ERLY, AP-SV,

AP-SOV, EVAP-PV, EVAP-VC,

EGR-CV, EGR-TS, SPK-CC

(1) - Heated O2 sensor.

(2) - California only.

(3) - Digifant II only.

(4) - Two required.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ABBREVIATION DEFINITIONS

ABBREVIATION DEFINITION TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄAbbreviation Definition

AP ............................. Air Pump Injection System

AP-EAP .............................. AP Electric Air Pump

AP-ERLY ....................... AP Electric Air Pump Relay

AP-SV .......................... AP Solenoid (Inlet) Valve

AP-SOV ................................. AP Shut Off Valve

CEC ......................... Computerized Engine Controls

EGR ............................ Exhaust Gas Recirculation

EGR-CV ..................... EGR Control (Frequency) Valve

EGR-TS ............................ EGR Temperature Sensor

EGR-TVV ......................... EGR Thermal Vacuum Valve

EGR-VA .............................. EGR Vacuum Amplifier

EVAP ............................. Fuel Evaporative System

EVAP-CS ............................ EVAP Control Solenoid

EVAP-PV ................................. EVAP Purge Valve

EVAP-VC .............................. EVAP Vapor Canister

FR .................................. Fill Pipe Restrictor

HAI ....................................... Hot Air Intake

MIL ........... Malfunction Indicator (CHECK ENGINE) Light

MFI ............................. Multiport Fuel Injection

O2 ......................................... Oxygen Sensor

PCV ....................... Positive Crankcase Ventilation

SPK ................................. Spark Control System

SPK-CC ........................... SPK Computer Controlled

TWC ................................... Three-Way Catalyst

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE