display VOLKSWAGEN PASSAT 1995 B3, B4 / 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1995, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1995 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 127 of 369

Downloaded from www.Manualslib.com manuals search engine 42-31

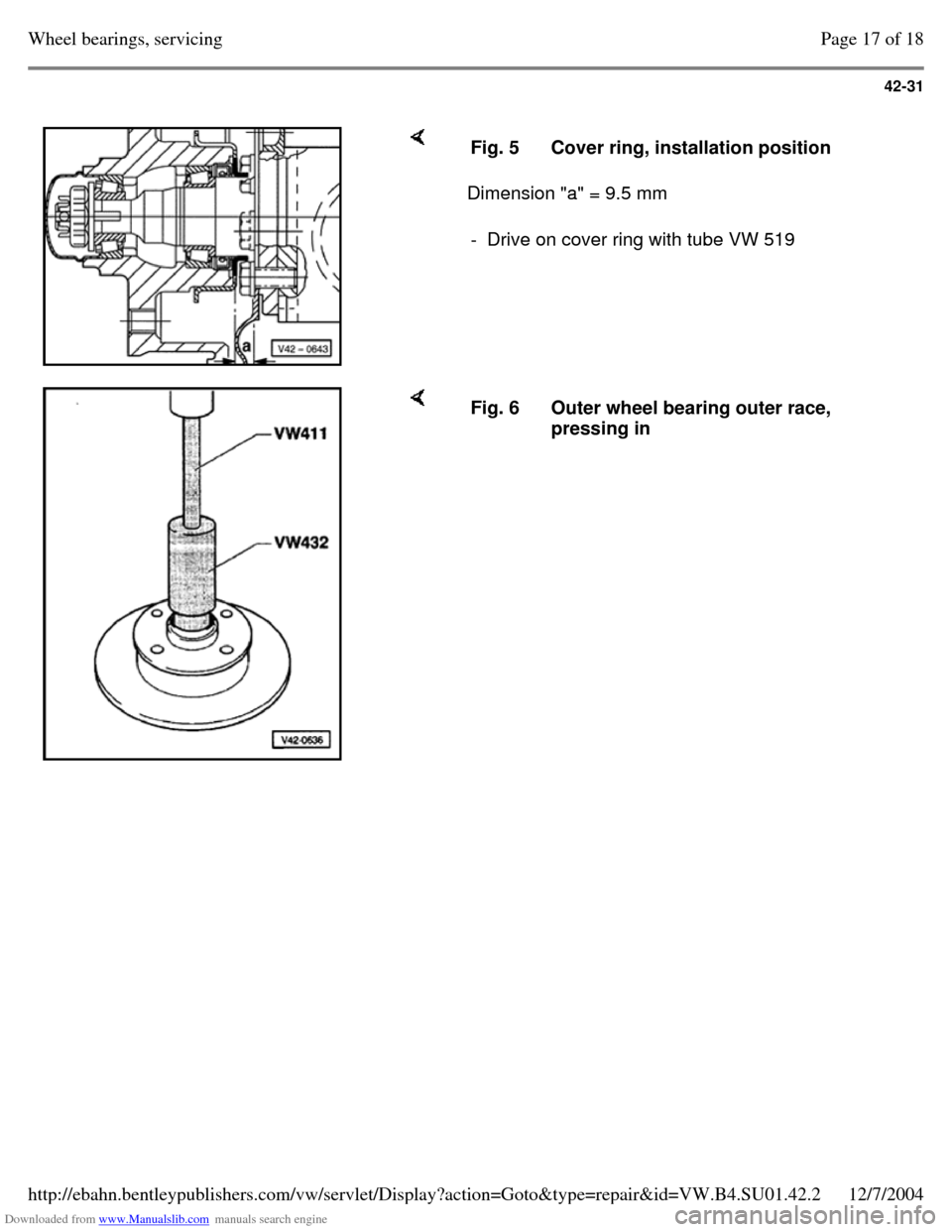

Dimension "a" = 9.5 mm Fig. 5 Cover ring, installation position - Drive on cover ring with tube VW 519 Fig. 6 Outer wheel bearing outer race,

pressing in Page 17 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 128 of 369

Downloaded from www.Manualslib.com manuals search engine 42-32

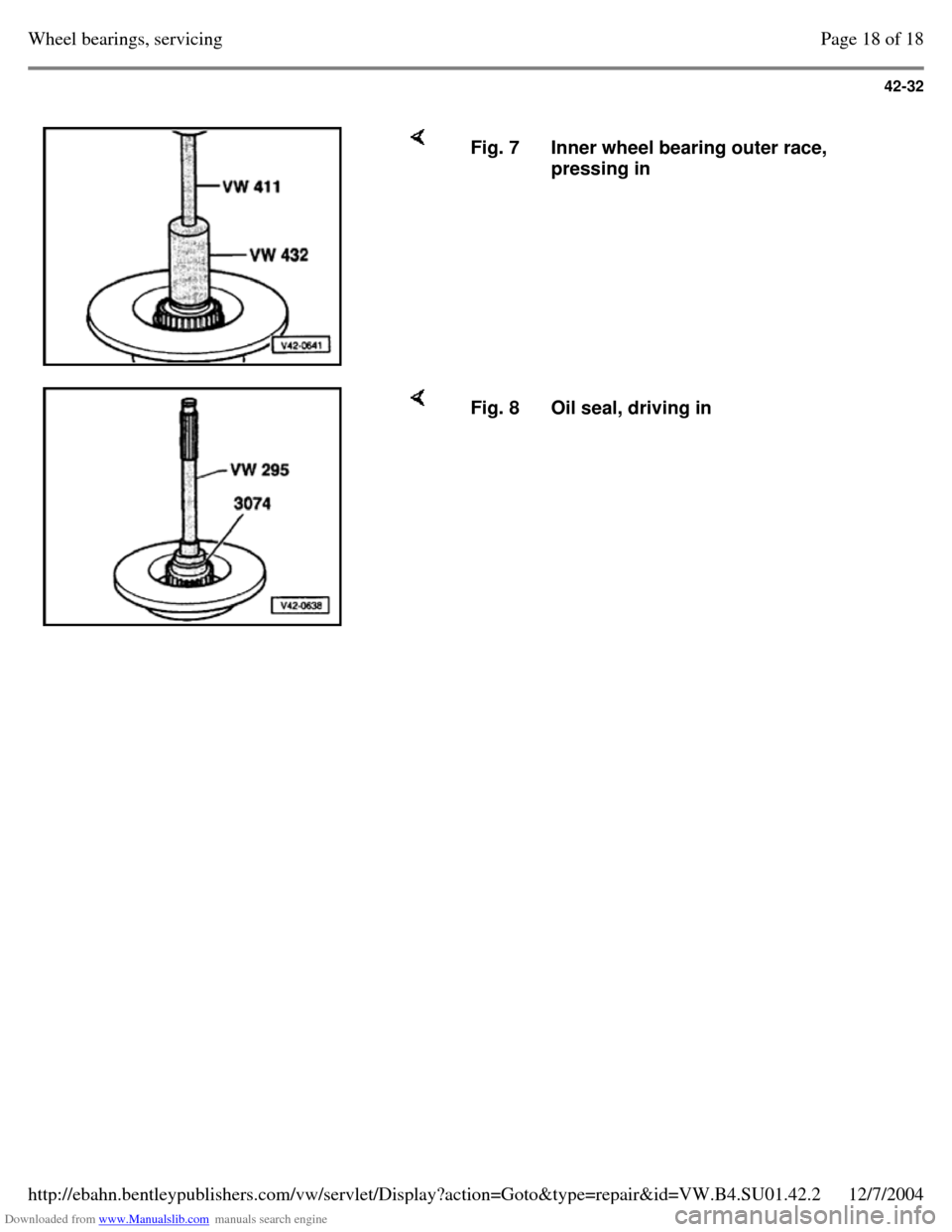

Fig. 7 Inner wheel bearing outer race,

pressing in Fig. 8 Oil seal, driving in Page 18 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 129 of 369

Downloaded from www.Manualslib.com manuals search engine 42-33

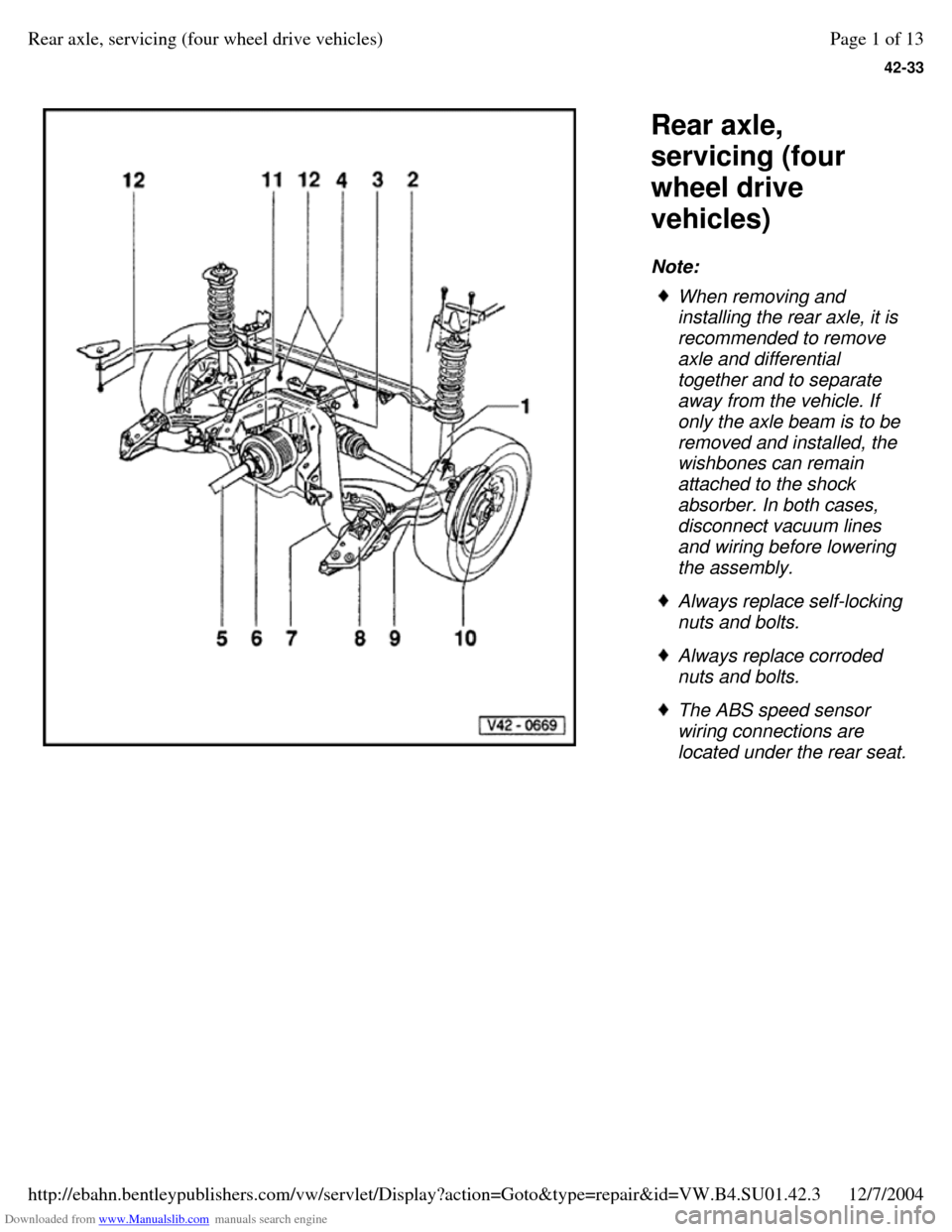

Rear axle,

servicing (four

wheel drive

vehicles)

Note: When removing and

installing the rear axle, it is

recommended to remove

axle and differential

together and to separate

away from the vehicle. If

only the axle beam is to be

removed and installed, the

wishbones can remain

attached to the shock

absorber. In both cases,

disconnect vacuum lines

and wiring before lowering

the assembly. Always replace self-locking

nuts and bolts. Always replace corroded

nuts and bolts. The ABS speed sensor

wiring connections are

located under the rear seat. Page 1 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 130 of 369

Downloaded from www.Manualslib.com manuals search engine 42-34

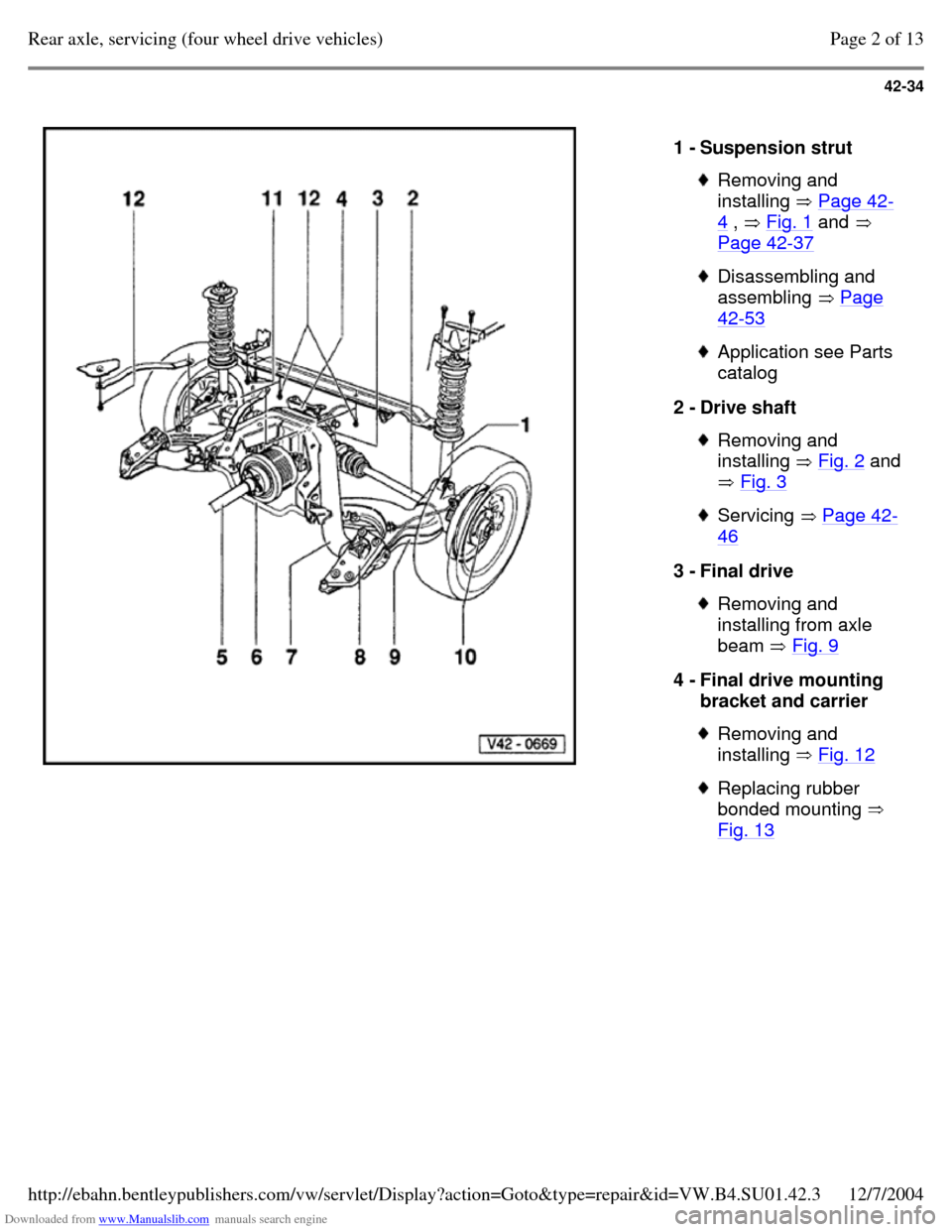

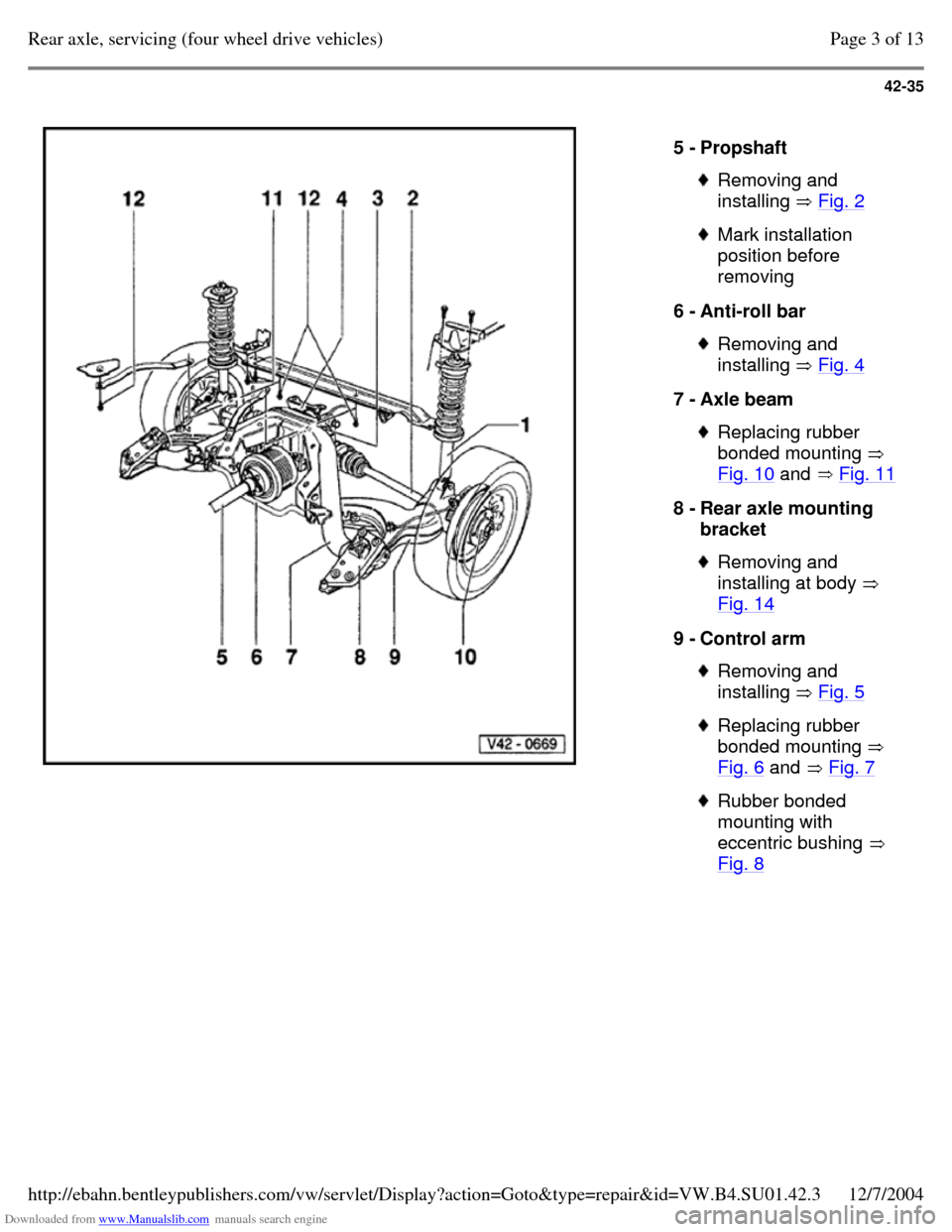

1 - Suspension strut Removing and

installing Page 42-4 , Fig. 1 and

Page 42-37 Disassembling and

assembling Page 42-53 Application see Parts

catalog

2 - Drive shaft Removing and

installing Fig. 2 and

Fig. 3 Servicing Page 42-46 3 - Final drive Removing and

installing from axle

beam Fig. 9 4 - Final drive mounting

bracket and carrier Removing and

installing Fig. 12 Replacing rubber

bonded mounting

Fig. 13 Page 2 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 131 of 369

Downloaded from www.Manualslib.com manuals search engine 42-35

5 - Propshaft Removing and

installing Fig. 2 Mark installation

position before

removing

6 - Anti-roll bar Removing and

installing Fig. 4 7 - Axle beam Replacing rubber

bonded mounting

Fig. 10 and Fig. 11 8 - Rear axle mounting

bracket Removing and

installing at body

Fig. 14 9 - Control arm Removing and

installing Fig. 5 Replacing rubber

bonded mounting

Fig. 6 and Fig. 7 Rubber bonded

mounting with

eccentric bushing

Fig. 8 Page 3 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 132 of 369

Downloaded from www.Manualslib.com manuals search engine 42-36

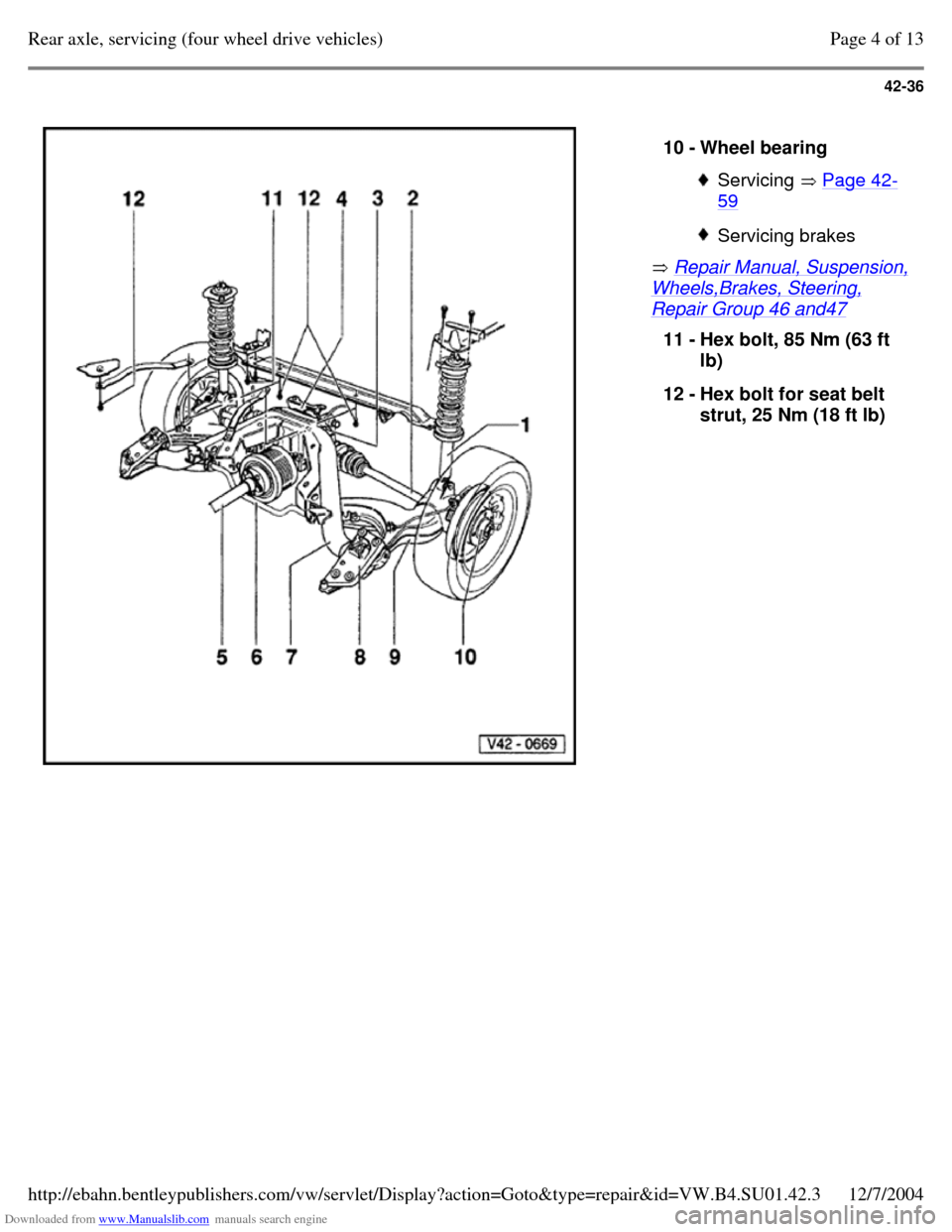

Repair Manual, Suspension, Wheels,Brakes, Steering, Repair Group 46 and47 10 - Wheel bearing Servicing Page 42-59 Servicing brakes 11 - Hex bolt, 85 Nm (63 ft

lb)

12 - Hex bolt for seat belt

strut, 25 Nm (18 ft lb) Page 4 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 133 of 369

Downloaded from www.Manualslib.com manuals search engine 42-37

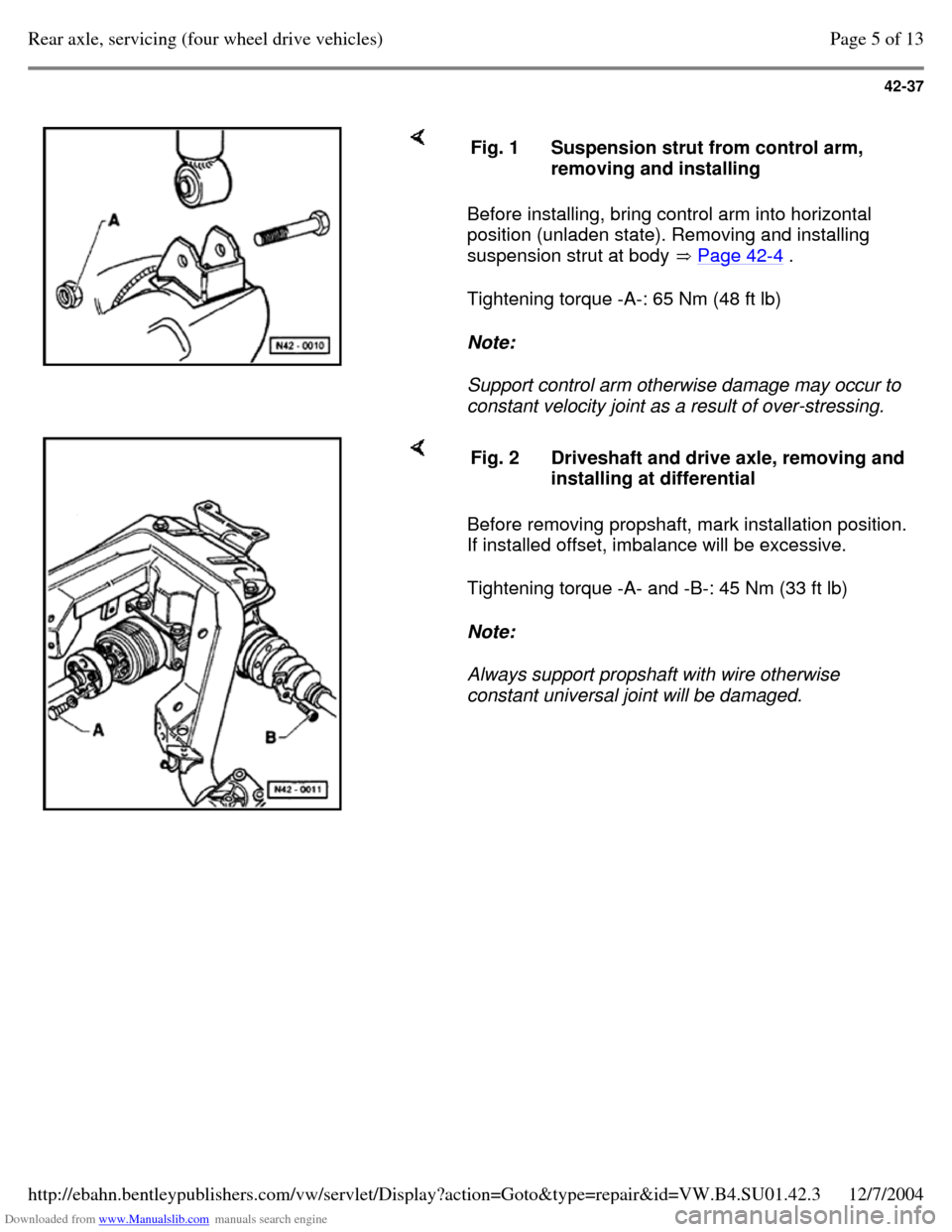

Before installing, bring control arm into horizontal

position (unladen state). Removing and installing

suspension strut at body Page 42-4 .

Tightening torque -A-: 65 Nm (48 ft lb)

Note:

Support control arm otherwise damage may occur to

constant velocity joint as a result of over-stressing. Fig. 1 Suspension strut from control arm,

removing and installing Before removing propshaft, mark installation position.

If installed offset, imbalance will be excessive.

Tightening torque -A- and -B-: 45 Nm (33 ft lb)

Note:

Always support propshaft with wire otherwise

constant universal joint will be damaged. Fig. 2 Driveshaft and drive axle, removing and

installing at differential Page 5 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 134 of 369

Downloaded from www.Manualslib.com manuals search engine 42-38

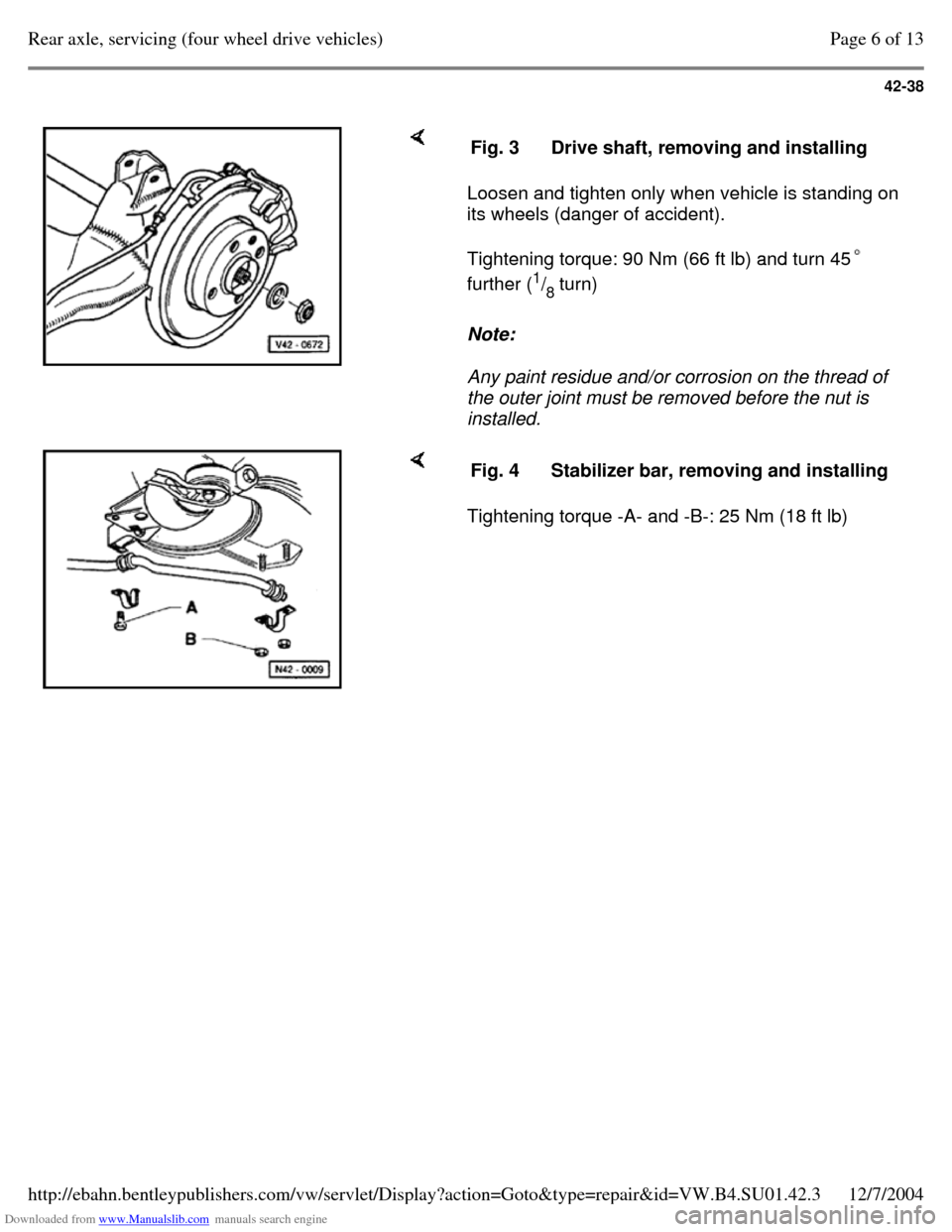

Loosen and tighten only when vehicle is standing on

its wheels (danger of accident).

Tightening torque: 90 Nm (66 ft lb) and turn 45

further (1

/

8 turn)

Note:

Any paint residue and/or corrosion on the thread of

the outer joint must be removed before the nut is

installed. Fig. 3 Drive shaft, removing and installing Tightening torque -A- and -B-: 25 Nm (18 ft lb) Fig. 4 Stabilizer bar, removing and installing Page 6 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 136 of 369

Downloaded from www.Manualslib.com manuals search engine 42-40

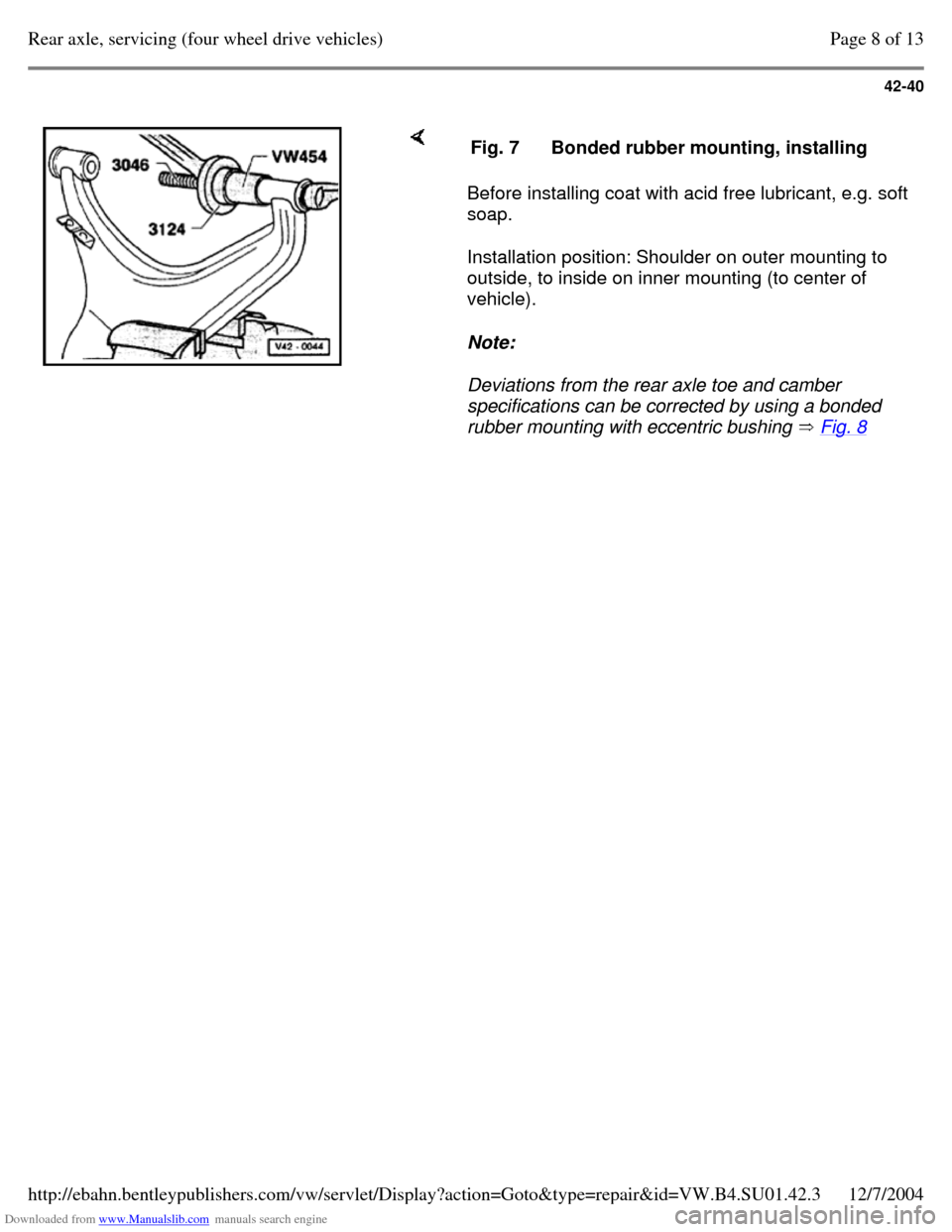

Before installing coat with acid free lubricant, e.g. soft

soap.

Installation position: Shoulder on outer mounting to

outside, to inside on inner mounting (to center of

vehicle).

Note:

Deviations from the rear axle toe and camber

specifications can be corrected by using a bonded

rubber mounting with eccentric bushing Fig. 8 Fig. 7 Bonded rubber mounting, installing Page 8 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 137 of 369

Downloaded from www.Manualslib.com manuals search engine 42-41

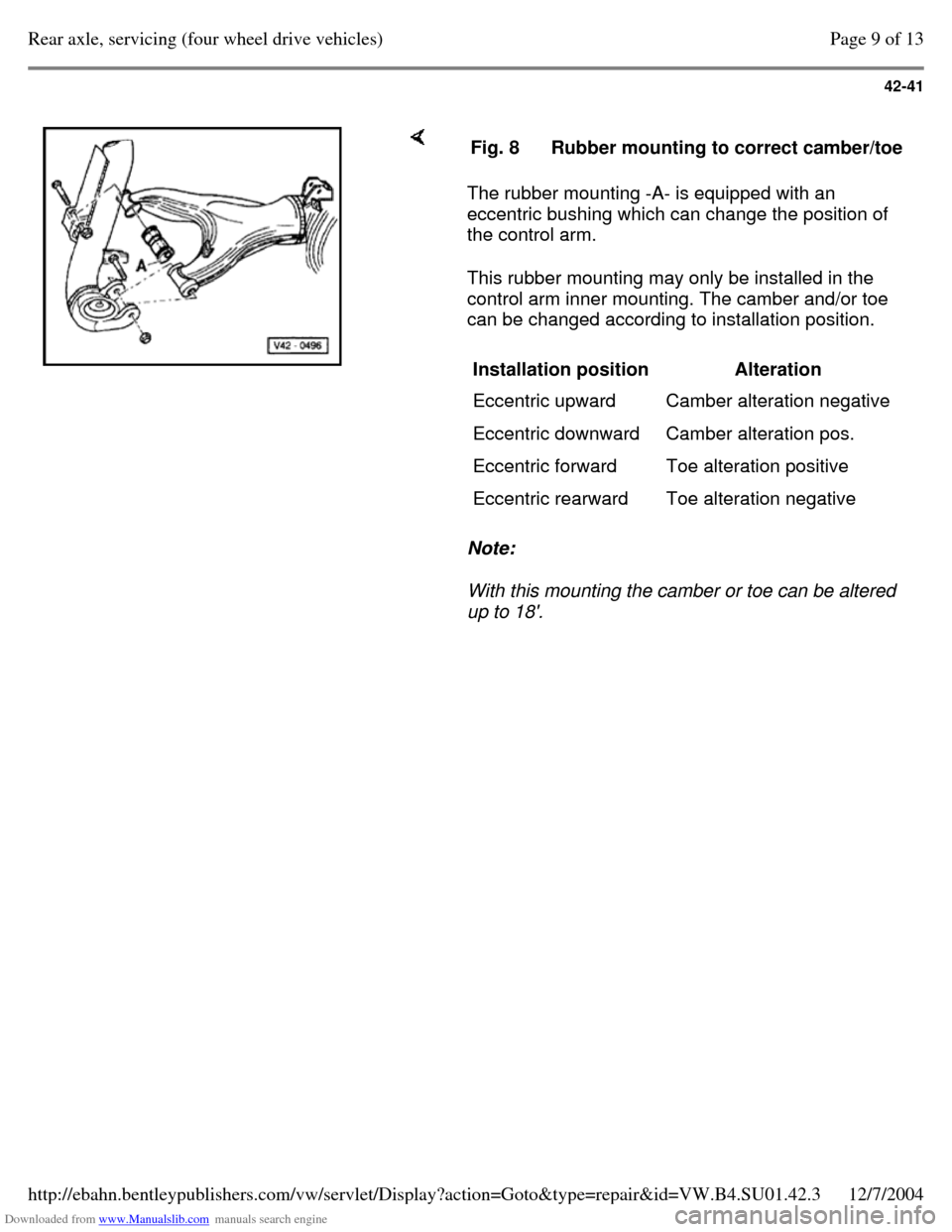

The rubber mounting -A- is equipped with an

eccentric bushing which can change the position of

the control arm.

This rubber mounting may only be installed in the

control arm inner mounting. The camber and/or toe

can be changed according to installation position.

Note:

With this mounting the camber or toe can be altered

up to 18'. Fig. 8 Rubber mounting to correct camber/toe Installation position

Alteration

Eccentric upward Camber alteration negative

Eccentric downward Camber alteration pos.

Eccentric forward Toe alteration positive

Eccentric rearward Toe alteration negative Page 9 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3