display VOLKSWAGEN PASSAT 1995 B3, B4 / 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1995, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1995 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 138 of 369

Downloaded from www.Manualslib.com manuals search engine 42-42

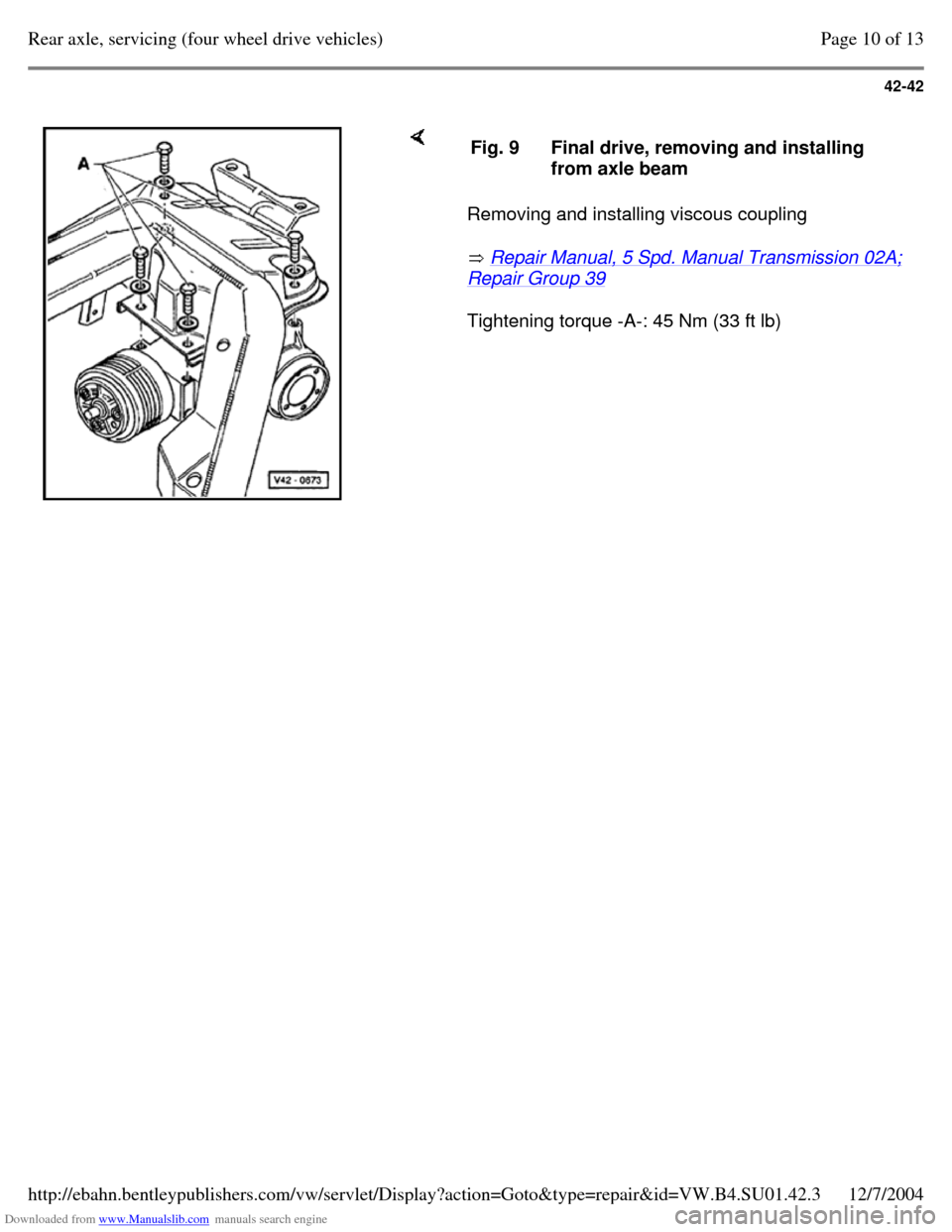

Removing and installing viscous coupling

Repair Manual, 5 Spd. Manual Transmission 02A; Repair Group 39

Tightening torque -A-: 45 Nm (33 ft lb) Fig. 9 Final drive, removing and installing

from axle beam Page 10 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 139 of 369

Downloaded from www.Manualslib.com manuals search engine 42-43

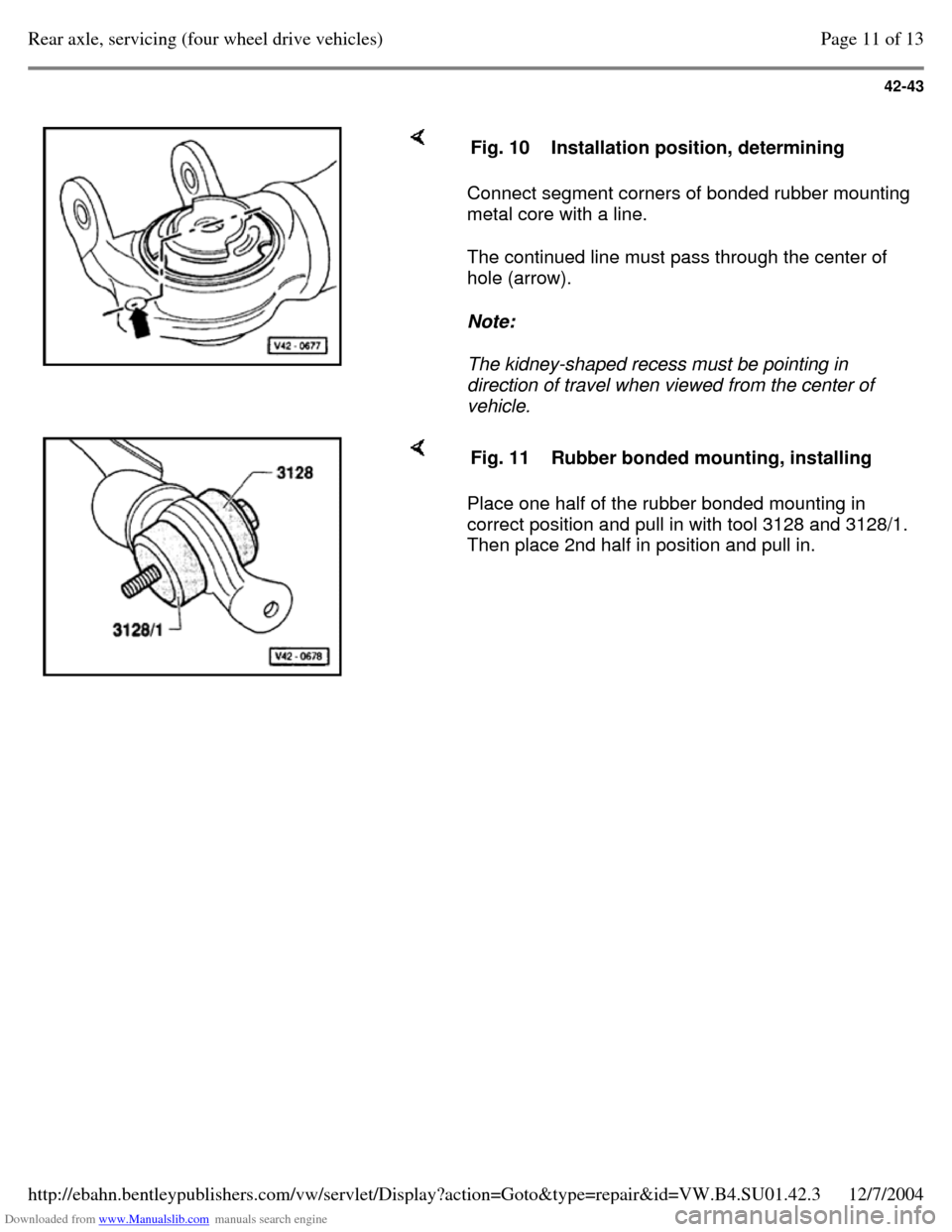

Connect segment corners of bonded rubber mounting

metal core with a line.

The continued line must pass through the center of

hole (arrow).

Note:

The kidney-shaped recess must be pointing in

direction of travel when viewed from the center of

vehicle. Fig. 10 Installation position, determining Place one half of the rubber bonded mounting in

correct position and pull in with tool 3128 and 3128/1.

Then place 2nd half in position and pull in. Fig. 11 Rubber bonded mounting, installing Page 11 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 140 of 369

Downloaded from www.Manualslib.com manuals search engine 42-44

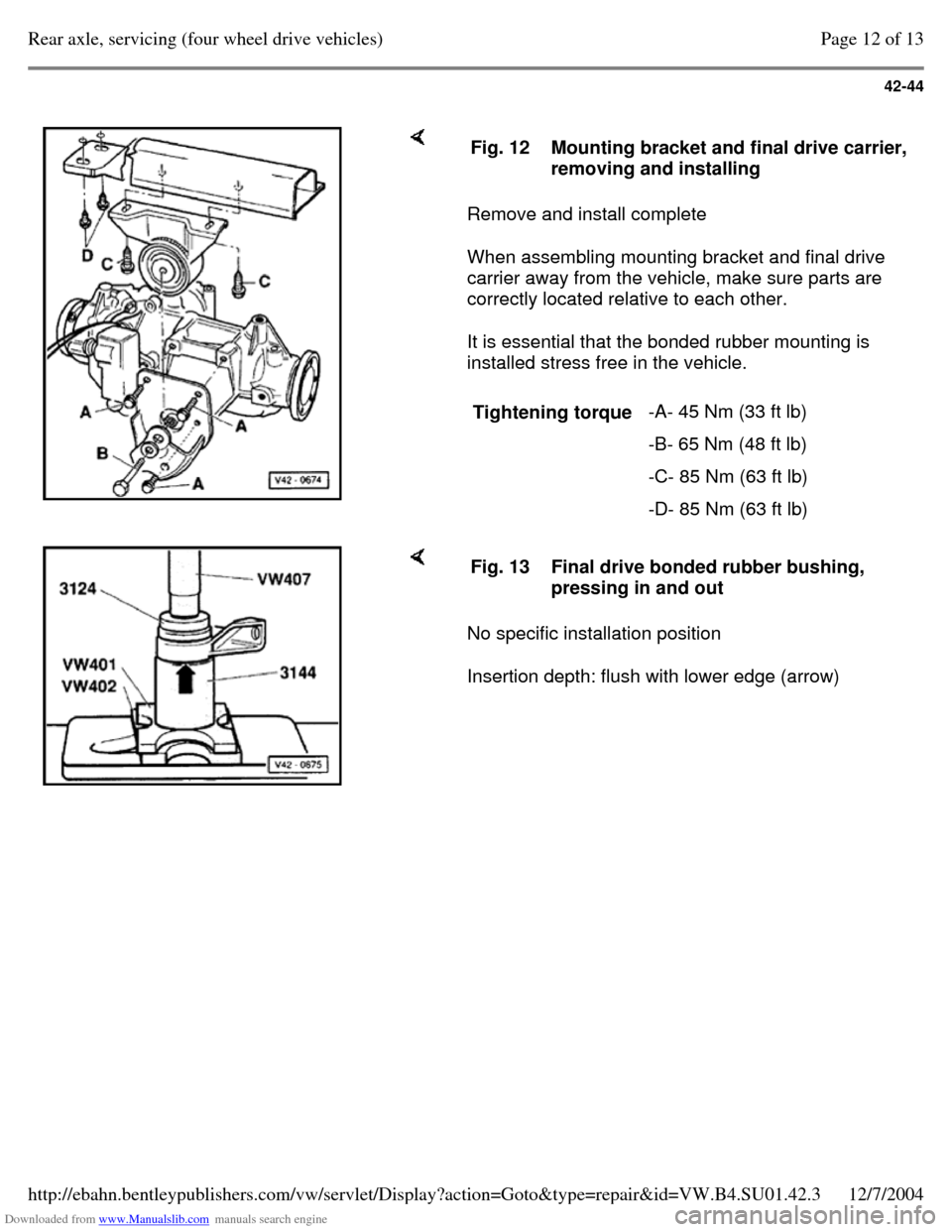

Remove and install complete

When assembling mounting bracket and final drive

carrier away from the vehicle, make sure parts are

correctly located relative to each other.

It is essential that the bonded rubber mounting is

installed stress free in the vehicle. Fig. 12 Mounting bracket and final drive carrier, removing and installing

Tightening torque -A- 45 Nm (33 ft lb)

-B- 65 Nm (48 ft lb)

-C- 85 Nm (63 ft lb)

-D- 85 Nm (63 ft lb) No specific installation position

Insertion depth: flush with lower edge (arrow) Fig. 13 Final drive bonded rubber bushing,

pressing in and out Page 12 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 141 of 369

Downloaded from www.Manualslib.com manuals search engine 42-45

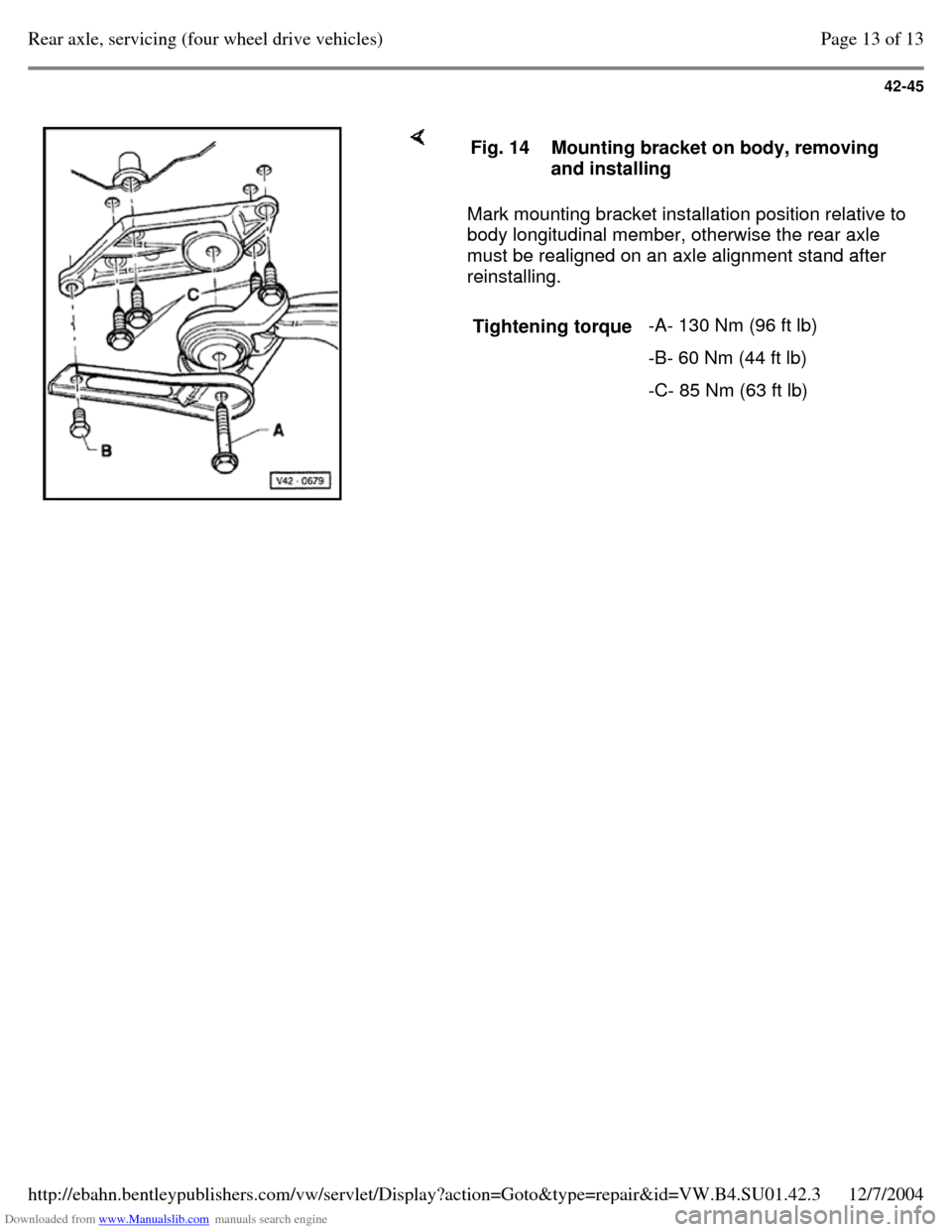

Mark mounting bracket installation position relative to

body longitudinal member, otherwise the rear axle

must be realigned on an axle alignment stand after

reinstalling. Fig. 14 Mounting bracket on body, removing

and installing

Tightening torque -A- 130 Nm (96 ft lb)

-B- 60 Nm (44 ft lb)

-C- 85 Nm (63 ft lb) Page 13 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 142 of 369

Downloaded from www.Manualslib.com manuals search engine 42-46

Rear drive shafts, servicing

Removing and installing drive shafts Page 42-37

Note:

Grease quantity:

- - outer constant velocity joint 80 g G-6.3

- - inner constant velocity joint 80 9 G-6.3 Greasing outer joint: press half of the grease

into the joint, and the other half evenly into the

boot.

Greasing inner joint: press half of the grease

into the inner joint from both sides, the other

half evenly into the boot.

When replacing the boot, regrease joint if

required. Page 1 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 143 of 369

Downloaded from www.Manualslib.com manuals search engine 42-47

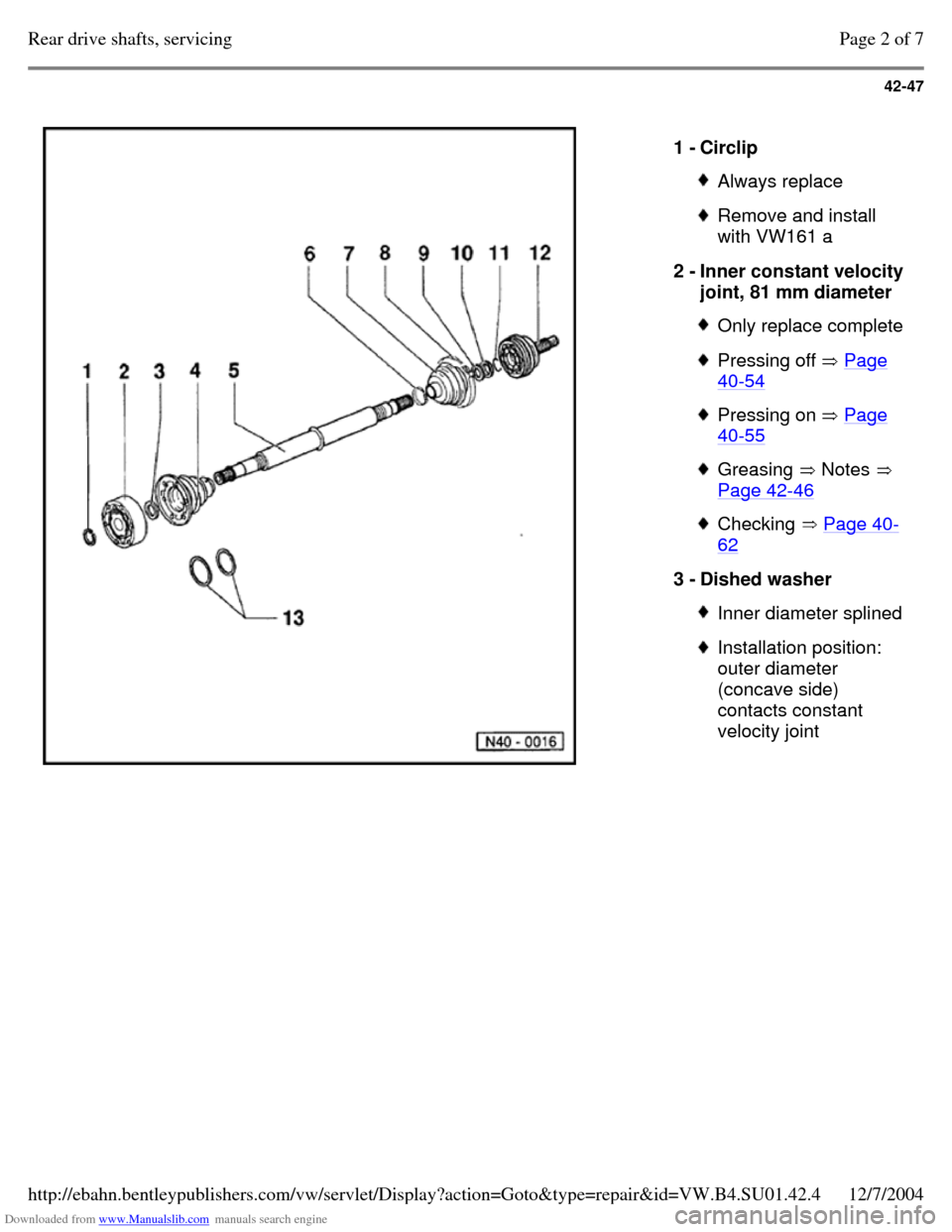

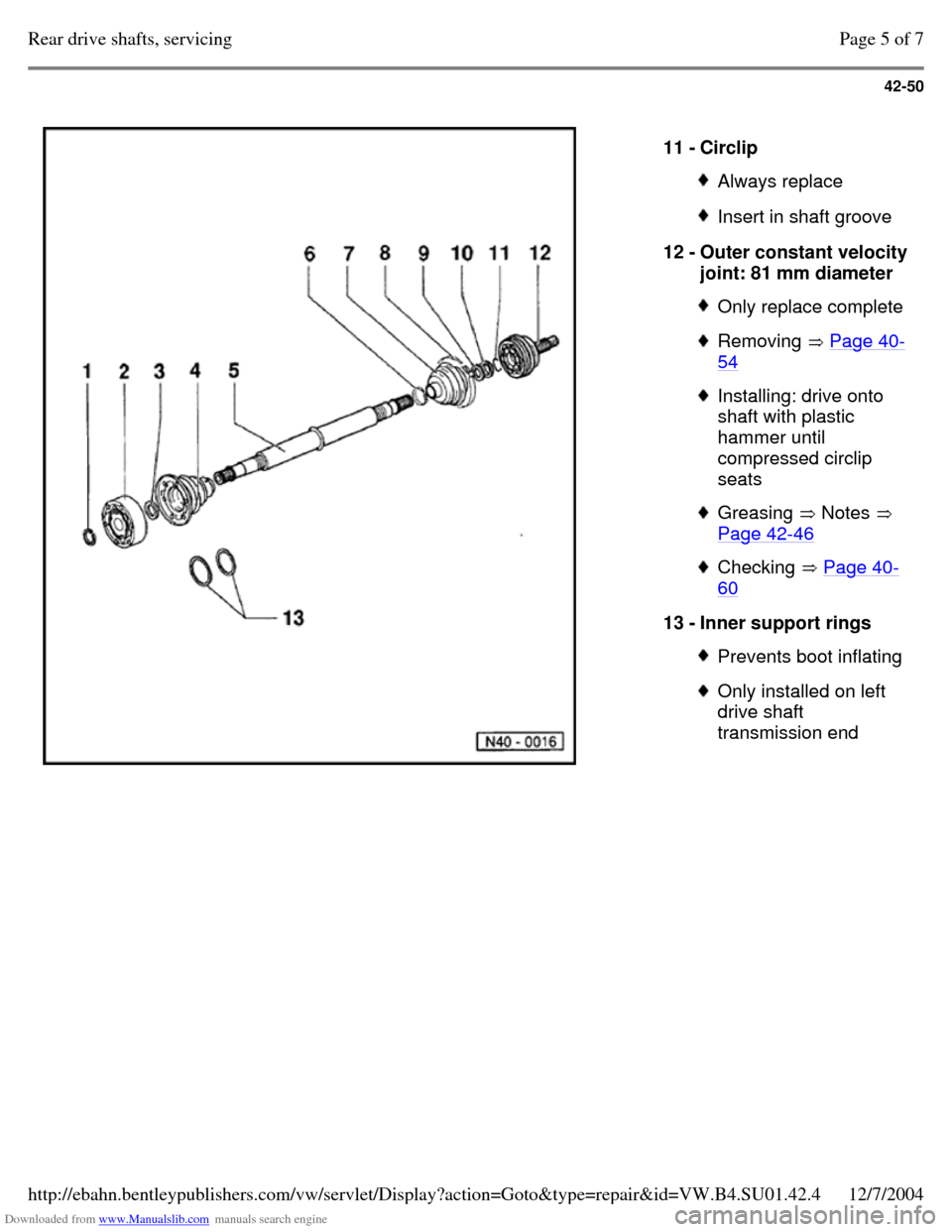

1 - Circlip Always replace Remove and install

with VW161 a

2 - Inner constant velocity

joint, 81 mm diameter Only replace complete Pressing off Page 40-54 Pressing on Page 40-55 Greasing Notes

Page 42-46 Checking Page 40-62 3 - Dished washer Inner diameter splined Installation position:

outer diameter

(concave side)

contacts constant

velocity joint Page 2 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 144 of 369

Downloaded from www.Manualslib.com manuals search engine 42-48

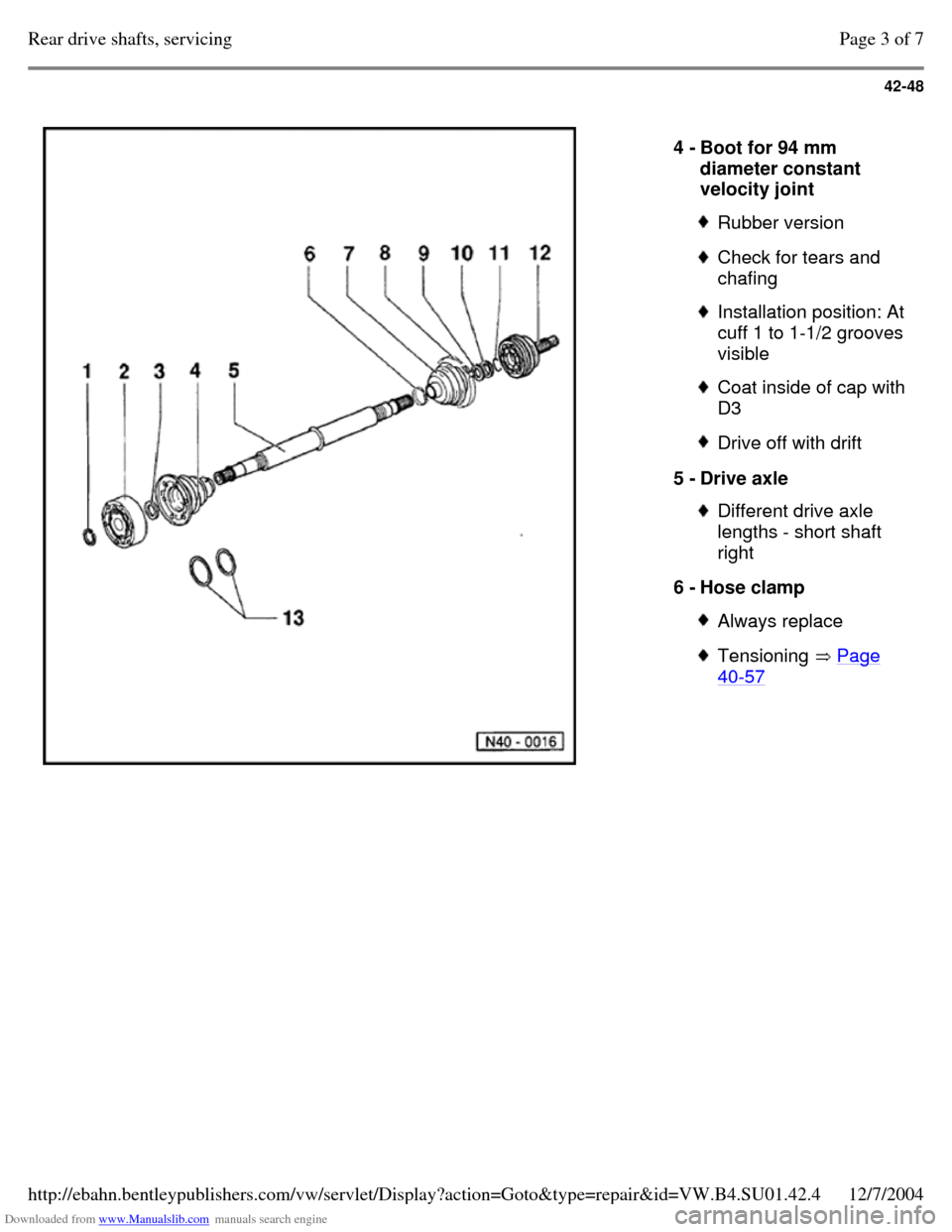

4 - Boot for 94 mm

diameter constant

velocity joint Rubber version Check for tears and

chafing Installation position: At

cuff 1 to 1-1/2 grooves

visible Coat inside of cap with D3 Drive off with drift 5 - Drive axle Different drive axle

lengths - short shaft

right

6 - Hose clamp Always replace Tensioning Page 40-57 Page 3 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 145 of 369

Downloaded from www.Manualslib.com manuals search engine 42-49

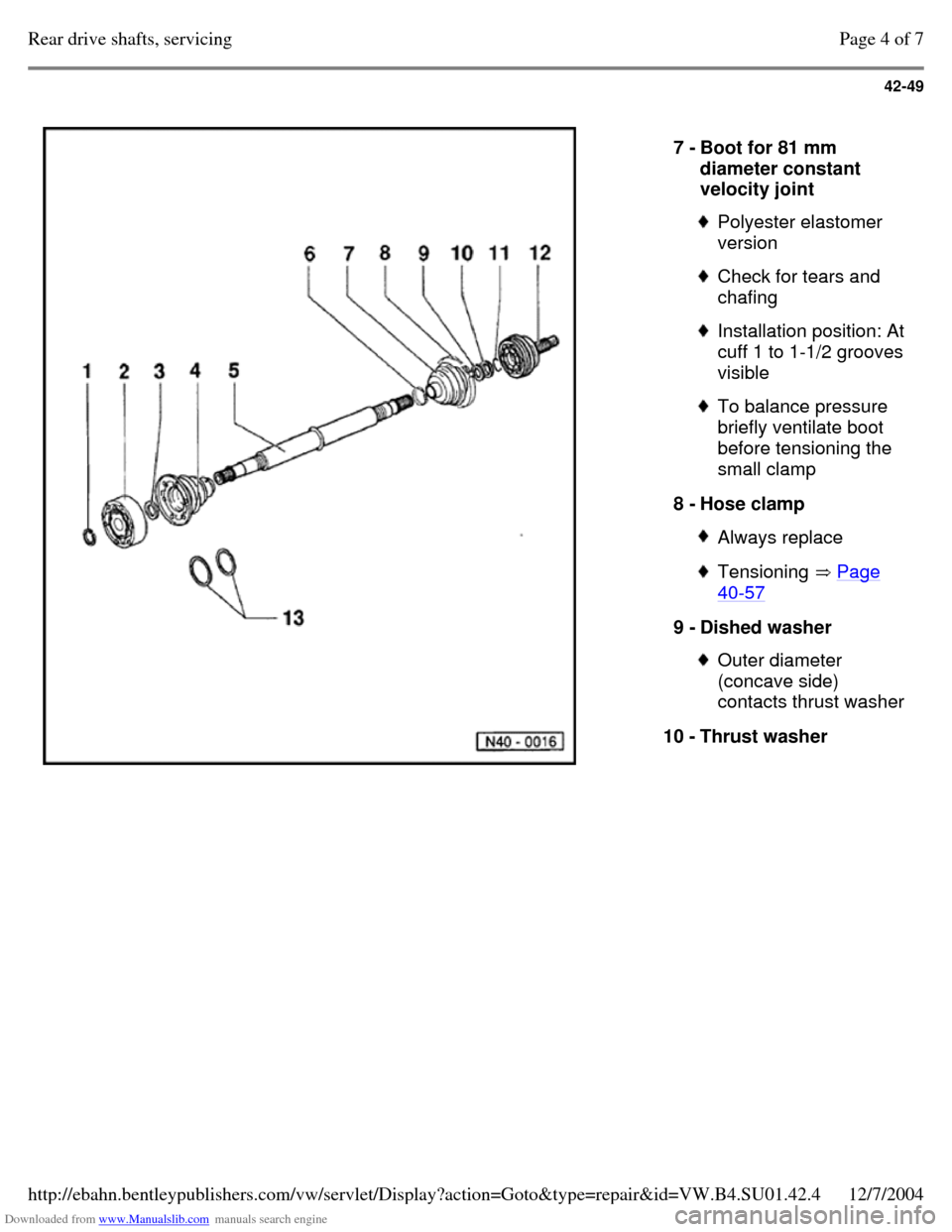

7 - Boot for 81 mm

diameter constant

velocity joint Polyester elastomer

version Check for tears and

chafing Installation position: At

cuff 1 to 1-1/2 grooves

visible To balance pressure

briefly ventilate boot

before tensioning the

small clamp

8 - Hose clamp Always replace Tensioning Page 40-57 9 - Dished washer Outer diameter

(concave side)

contacts thrust washer

10 - Thrust washer Page 4 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 146 of 369

Downloaded from www.Manualslib.com manuals search engine 42-50

11 - Circlip Always replace Insert in shaft groove 12 - Outer constant velocity joint: 81 mm diameter Only replace complete Removing Page 40-54 Installing: drive onto

shaft with plastic

hammer until

compressed circlip

seats Greasing Notes

Page 42-46 Checking Page 40-60 13 - Inner support rings Prevents boot inflating Only installed on left

drive shaft

transmission end Page 5 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 147 of 369

Downloaded from www.Manualslib.com manuals search engine 42-51

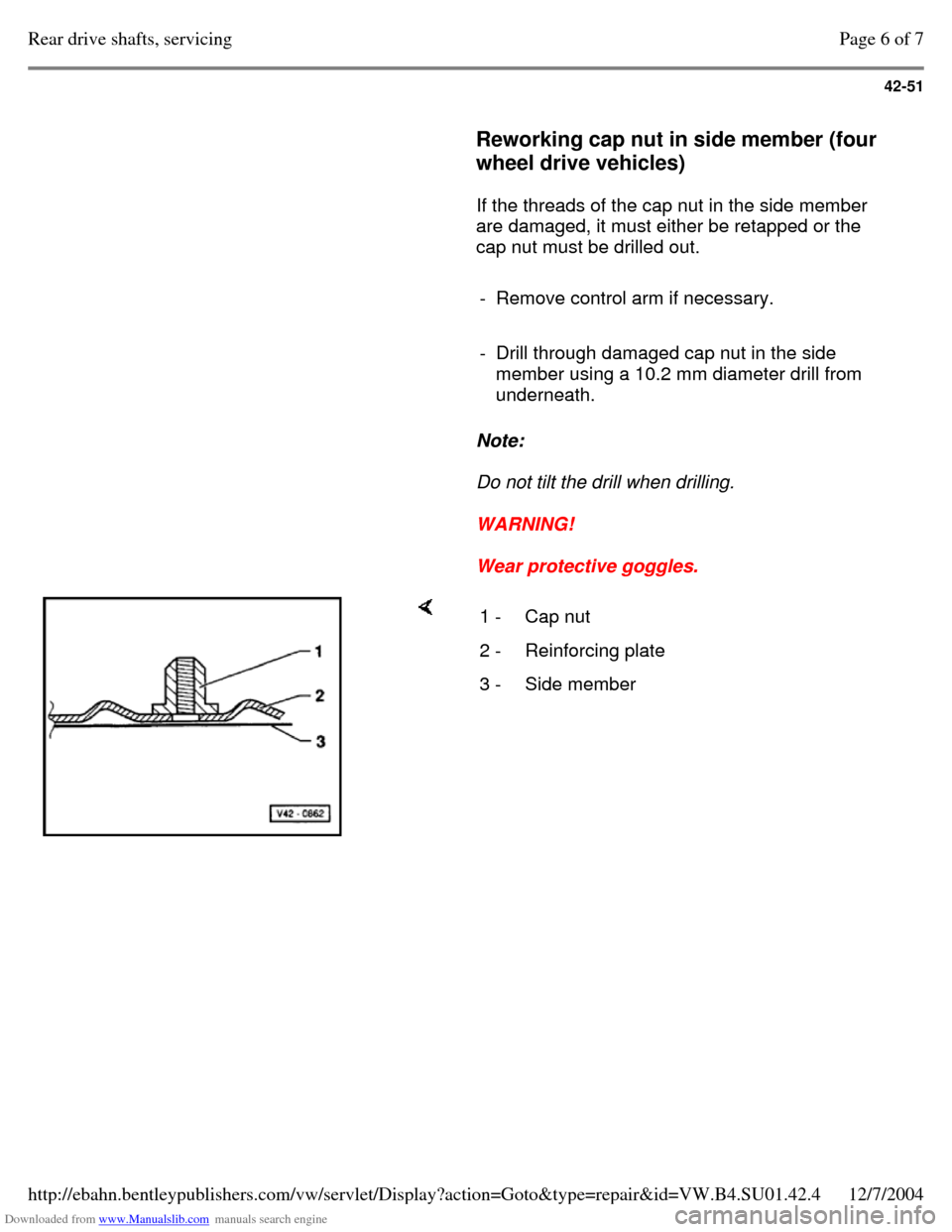

Reworking cap nut in side member (four

wheel drive vehicles)

If the threads of the cap nut in the side member

are damaged, it must either be retapped or the

cap nut must be drilled out.

- Remove control arm if necessary.

- Drill through damaged cap nut in the side

member using a 10.2 mm diameter drill from

underneath.

Note:

Do not tilt the drill when drilling.

WARNING!

Wear protective goggles. 1 - Cap nut 2 - Reinforcing plate 3 - Side member Page 6 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4