boot VOLKSWAGEN PASSAT 1996 B3, B4 / 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1996, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1996 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 17 of 369

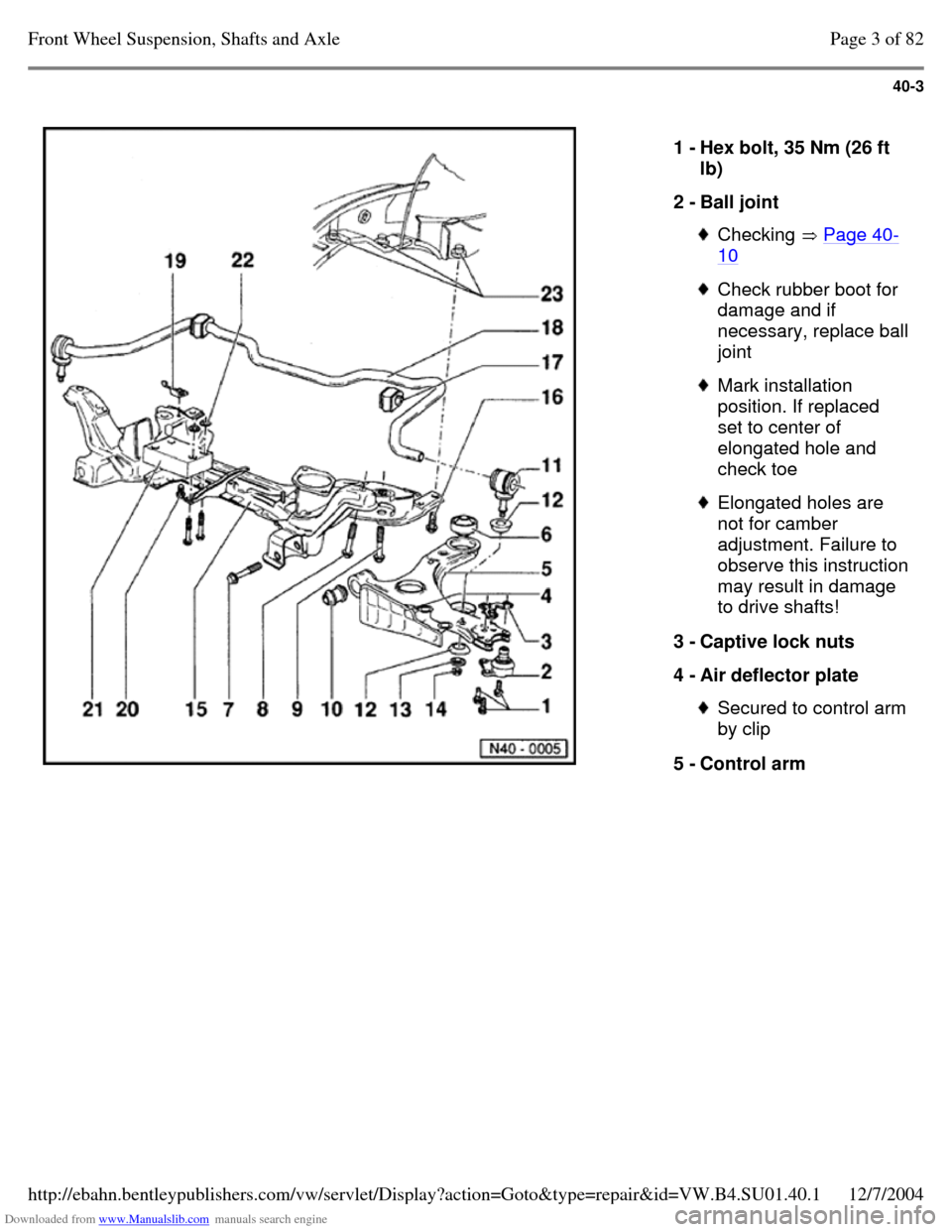

Downloaded from www.Manualslib.com manuals search engine 40-3

1 - Hex bolt, 35 Nm (26 ft

lb)

2 - Ball joint Checking Page 40-10 Check rubber boot for

damage and if necessary, replace ball joint Mark installation

position. If replaced

set to center of

elongated hole and

check toe Elongated holes are

not for camber

adjustment. Failure to observe this instruction may result in damage

to drive shafts!

3 - Captive lock nuts

4 - Air deflector plate Secured to control arm by clip

5 - Control arm Page 3 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 41 of 369

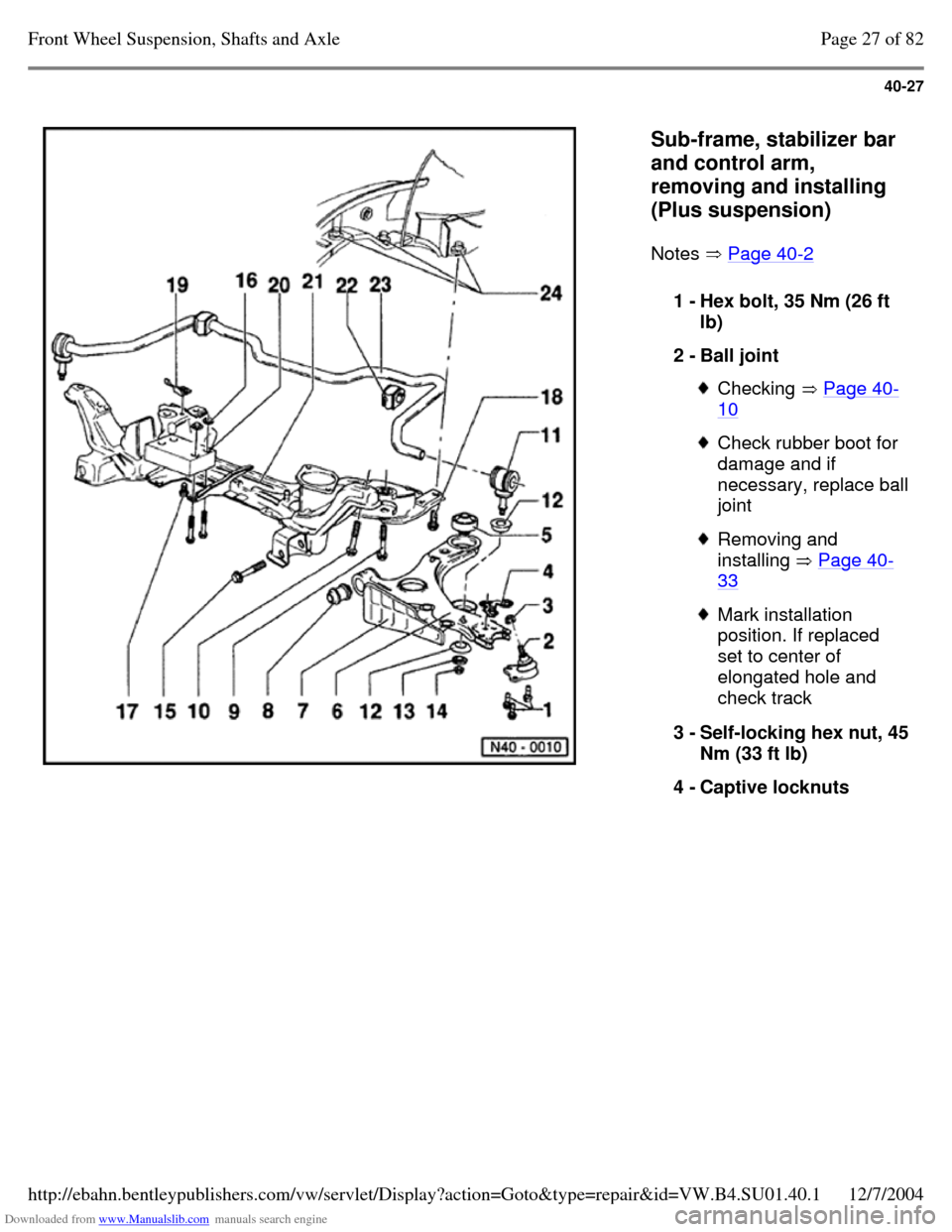

Downloaded from www.Manualslib.com manuals search engine 40-27

Sub-frame, stabilizer bar

and control arm,

removing and installing

(Plus suspension)

Notes Page 40-2 1 - Hex bolt, 35 Nm (26 ft

lb)

2 - Ball joint Checking Page 40-10 Check rubber boot for

damage and if necessary, replace ball joint Removing and

installing Page 40-33 Mark installation

position. If replaced

set to center of

elongated hole and

check track

3 - Self-locking hex nut, 45 Nm (33 ft lb)

4 - Captive locknuts Page 27 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 49 of 369

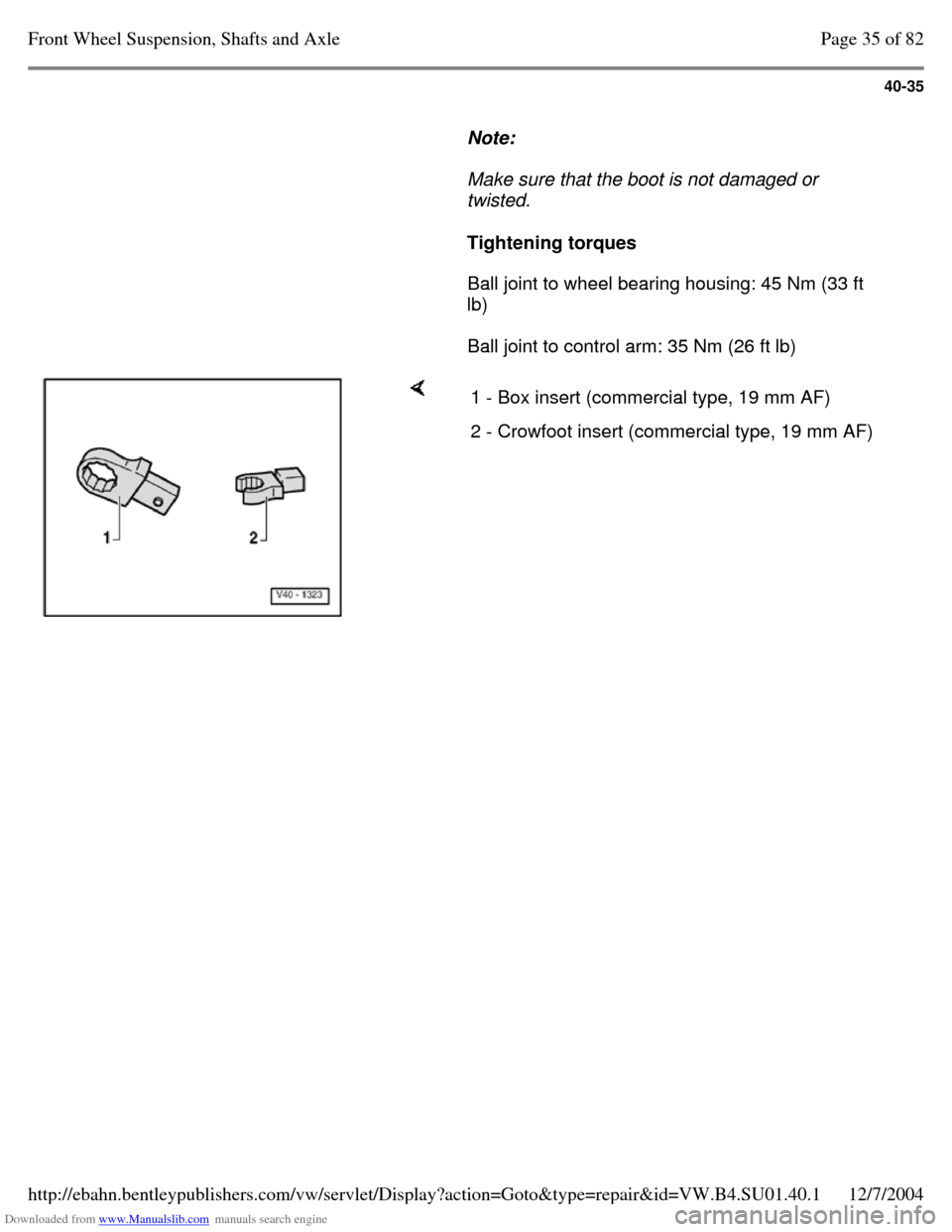

Downloaded from www.Manualslib.com manuals search engine 40-35

Note:

Make sure that the boot is not damaged or

twisted.

Tightening torques

Ball joint to wheel bearing housing: 45 Nm (33 ft

lb)

Ball joint to control arm: 35 Nm (26 ft lb) 1 - Box insert (commercial type, 19 mm AF) 2 - Crowfoot insert (commercial type, 19 mm AF) Page 35 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 60 of 369

Downloaded from www.Manualslib.com manuals search engine 40-46

Drive shaft, repairing

Drive shafts on vehicles with Plus suspension

have shorter and finer splines on the outer joint.

The wheel bearing is secured by a 12-point nut.

The splines of the outer joint and the hub on Plus

suspensions are secured with locking fluid D 185

400 A2.

Drive shaft, removing and installing

Vehicles with Base suspension Page 40-14 Vehicles with Plus suspension Page 40-43

Note:

Grease quantity:

- - Outer constant velocity joint 100 g of G-6.3

grease

- - Inner constant velocity joint 110 g of G-6.3

grease

Greasing outer joint: press half of the grease

into the joint, and the other half evenly into the

boot.

Greasing inner joint: press half of the grease

into the inner joint from both sides, the other

half evenly into the boot.

When replacing the boot grease joint as

required. Page 46 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 62 of 369

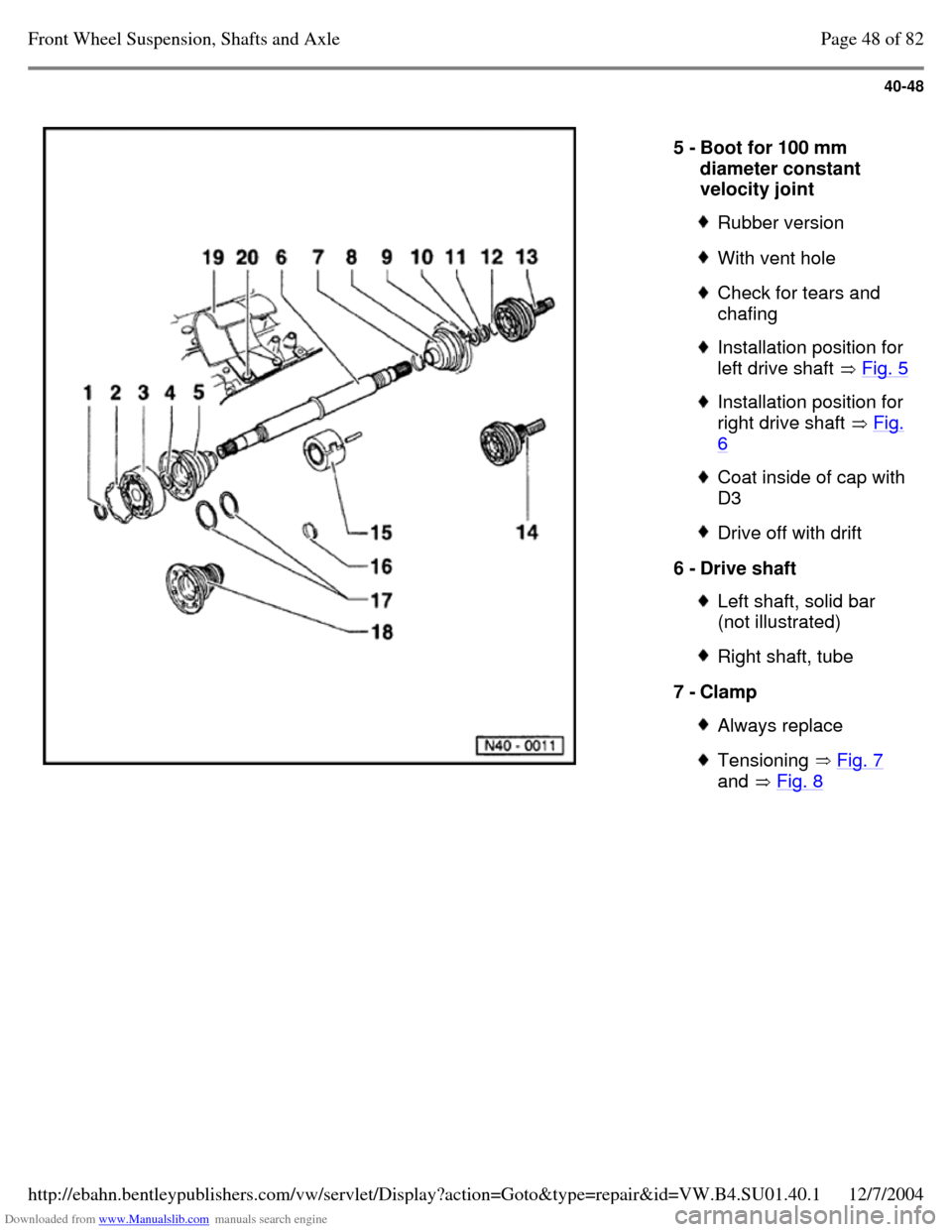

Downloaded from www.Manualslib.com manuals search engine 40-48

5 - Boot for 100 mm

diameter constant

velocity joint Rubber version With vent hole Check for tears and

chafing Installation position for

left drive shaft Fig. 5 Installation position for

right drive shaft Fig. 6 Coat inside of cap with D3 Drive off with drift 6 - Drive shaft Left shaft, solid bar

(not illustrated) Right shaft, tube 7 - Clamp Always replace Tensioning Fig. 7

and Fig. 8 Page 48 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 63 of 369

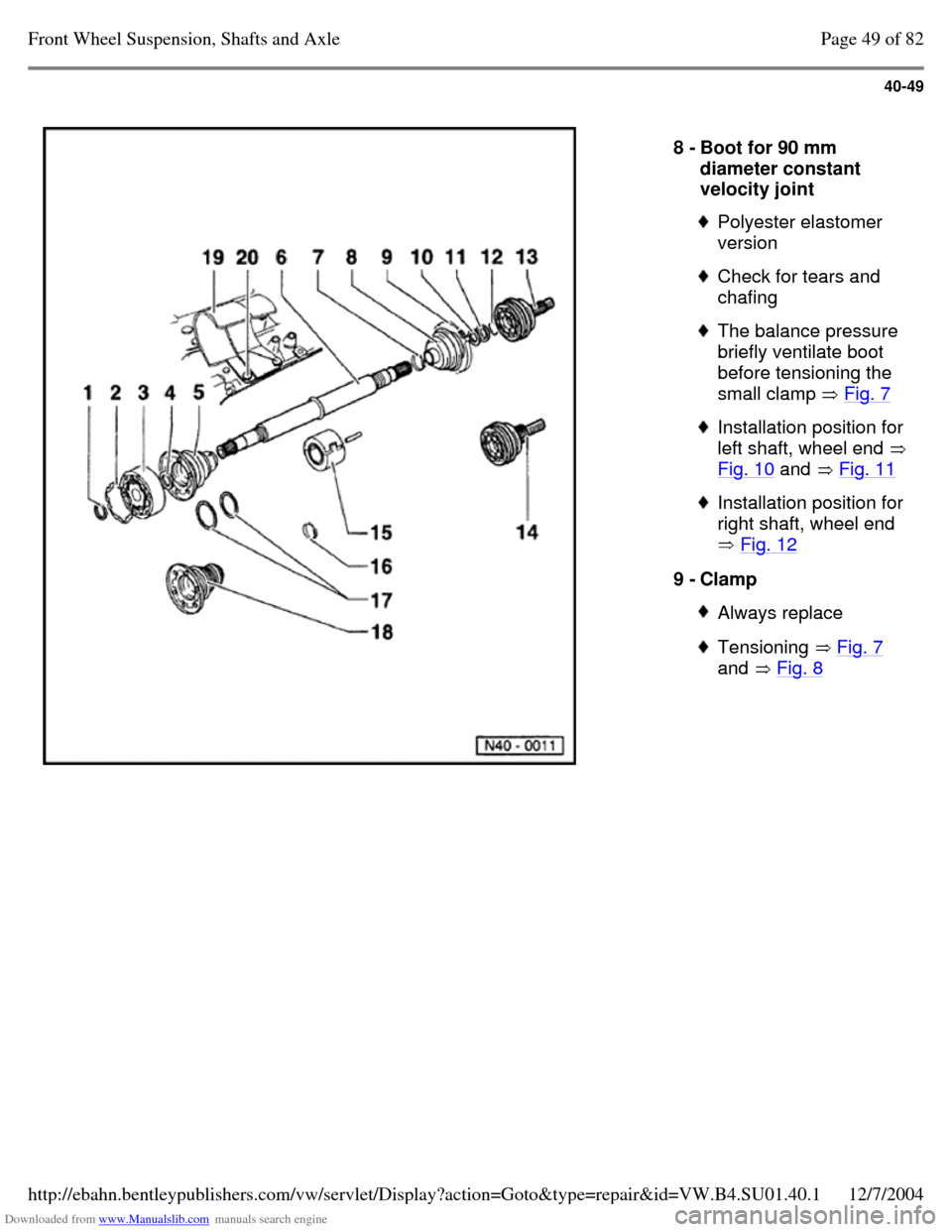

Downloaded from www.Manualslib.com manuals search engine 40-49

8 - Boot for 90 mm

diameter constant

velocity joint Polyester elastomer

version Check for tears and

chafing The balance pressure

briefly ventilate boot

before tensioning the

small clamp Fig. 7 Installation position for

left shaft, wheel end Fig. 10 and Fig. 11 Installation position for

right shaft, wheel end

Fig. 12 9 - Clamp Always replace Tensioning Fig. 7

and Fig. 8 Page 49 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

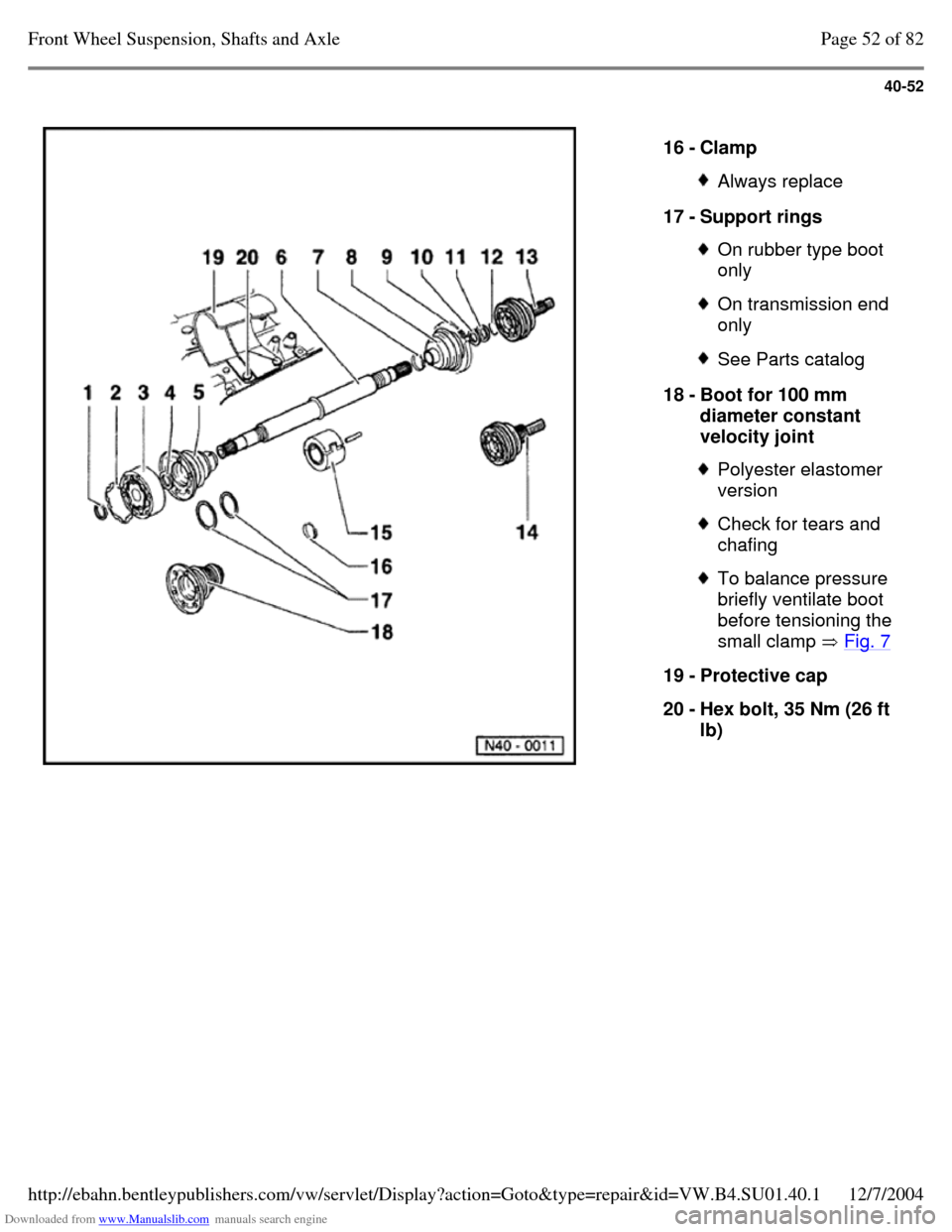

Page 66 of 369

Downloaded from www.Manualslib.com manuals search engine 40-52

16 - Clamp Always replace 17 - Support rings On rubber type boot

only On transmission end

only See Parts catalog 18 - Boot for 100 mm

diameter constant

velocity joint Polyester elastomer

version Check for tears and

chafing To balance pressure

briefly ventilate boot

before tensioning the

small clamp Fig. 7 19 - Protective cap

20 - Hex bolt, 35 Nm (26 ft

lb) Page 52 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 68 of 369

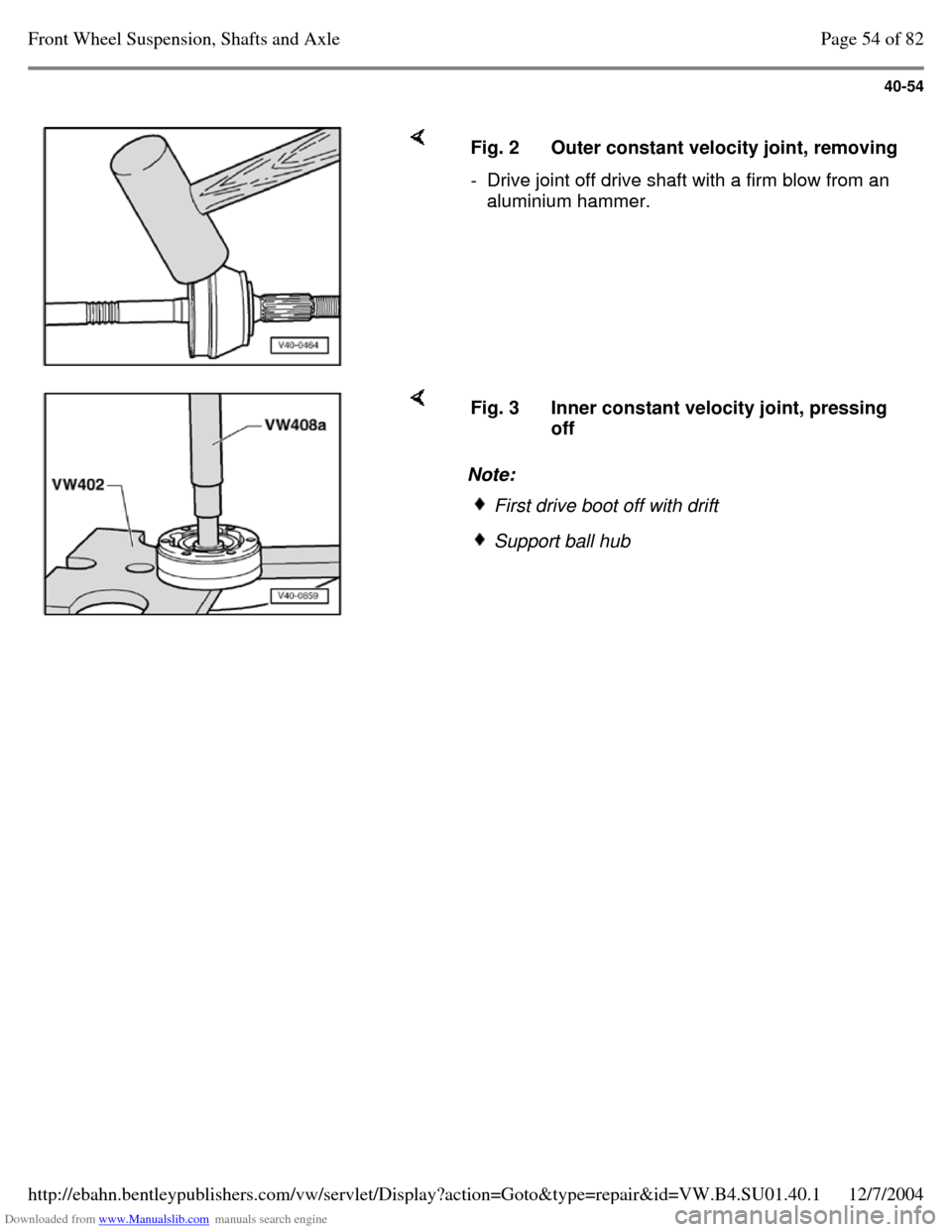

Downloaded from www.Manualslib.com manuals search engine 40-54

Fig. 2 Outer constant velocity joint, removing - Drive joint off drive shaft with a firm blow from an

aluminium hammer. Note: Fig. 3 Inner constant velocity joint, pressing

off First drive boot off with drift Support ball hub Page 54 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 69 of 369

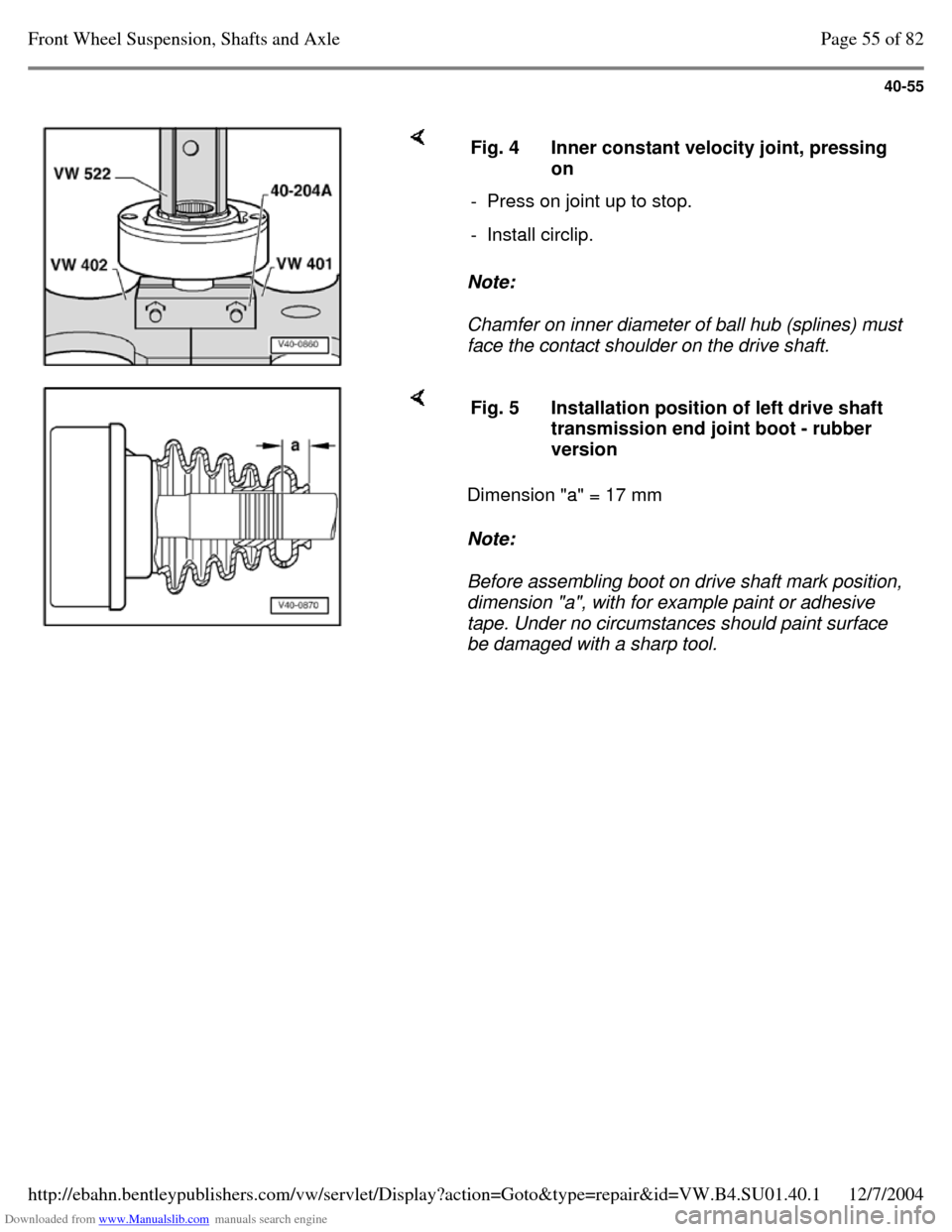

Downloaded from www.Manualslib.com manuals search engine 40-55

Note:

Chamfer on inner diameter of ball hub (splines) must

face the contact shoulder on the drive shaft. Fig. 4 Inner constant velocity joint, pressing

on

- Press on joint up to stop. - Install circlip. Dimension "a" = 17 mm

Note:

Before assembling boot on drive shaft mark position,

dimension "a", with for example paint or adhesive

tape. Under no circumstances should paint surface

be damaged with a sharp tool. Fig. 5 Installation position of left drive shaft

transmission end joint boot - rubber

version Page 55 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 70 of 369

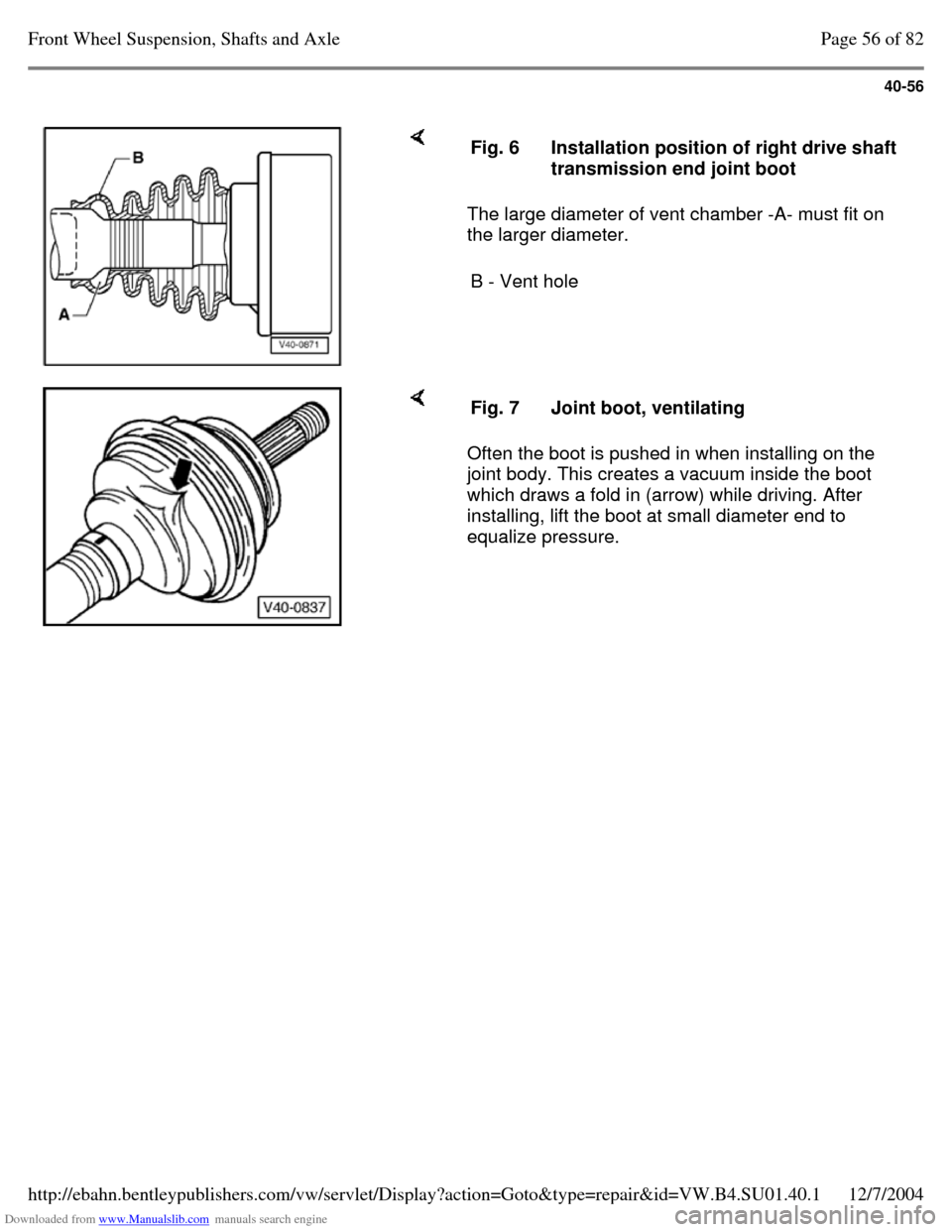

Downloaded from www.Manualslib.com manuals search engine 40-56

The large diameter of vent chamber -A- must fit on

the larger diameter. Fig. 6 Installation position of right drive shaft

transmission end joint boot

B - Vent hole Often the boot is pushed in when installing on the

joint body. This creates a vacuum inside the boot

which draws a fold in (arrow) while driving. After

installing, lift the boot at small diameter end to

equalize pressure. Fig. 7 Joint boot, ventilating Page 56 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1