Abs engine VOLKSWAGEN PASSAT 1997 B3, B4 / 3.G Service User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1997, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1997 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 112 of 369

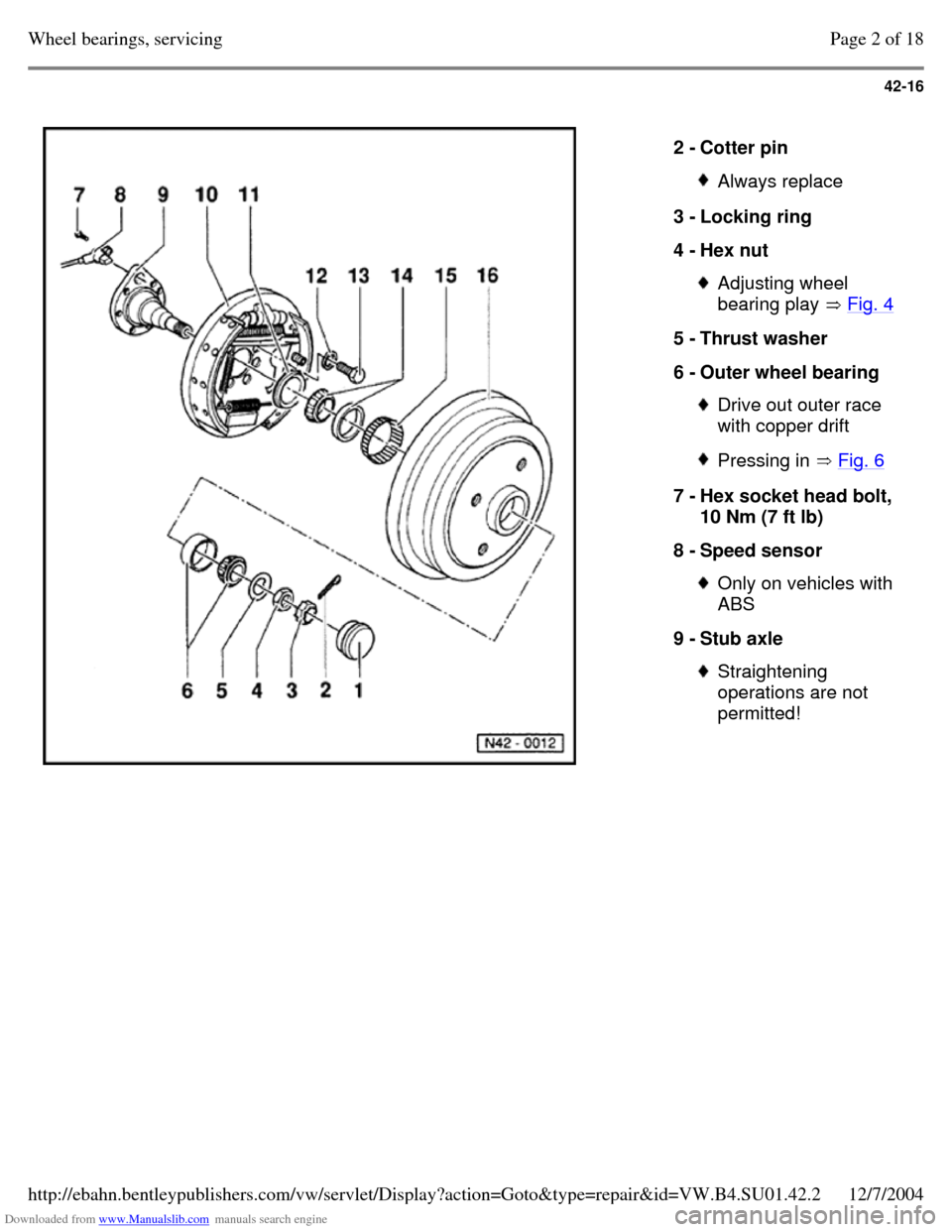

Downloaded from www.Manualslib.com manuals search engine 42-16

2 - Cotter pin Always replace 3 - Locking ring

4 - Hex nut Adjusting wheel

bearing play Fig. 4 5 - Thrust washer

6 - Outer wheel bearing Drive out outer race

with copper drift Pressing in Fig. 6 7 - Hex socket head bolt,

10 Nm (7 ft lb)

8 - Speed sensor Only on vehicles with

ABS

9 - Stub axle Straightening

operations are not

permitted! Page 2 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 120 of 369

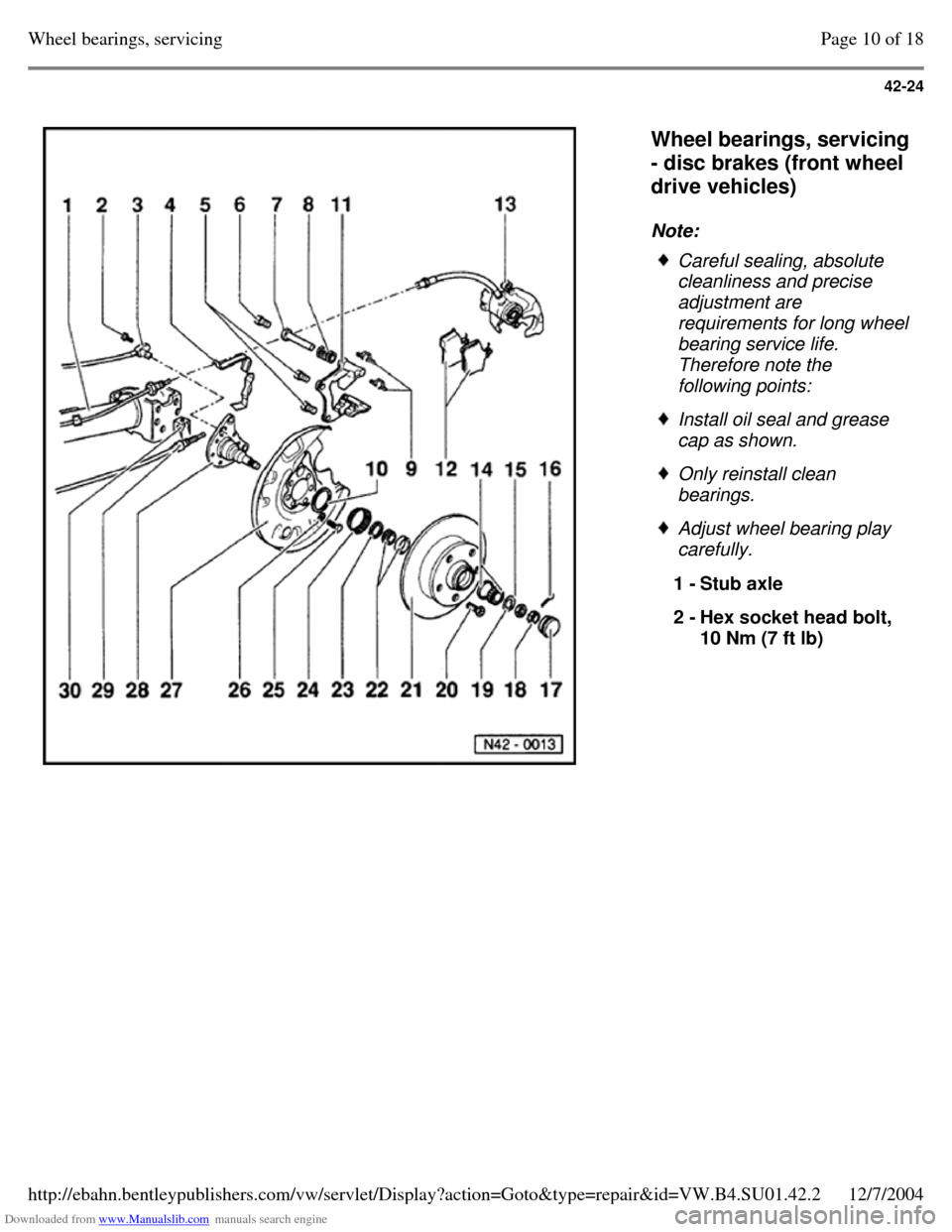

Downloaded from www.Manualslib.com manuals search engine 42-24

Wheel bearings, servicing

- disc brakes (front wheel

drive vehicles)

Note: Careful sealing, absolute

cleanliness and precise

adjustment are requirements for long wheel bearing service life.

Therefore note the

following points: Install oil seal and grease

cap as shown. Only reinstall clean

bearings. Adjust wheel bearing play

carefully.

1 - Stub axle

2 - Hex socket head bolt,

10 Nm (7 ft lb) Page 10 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 121 of 369

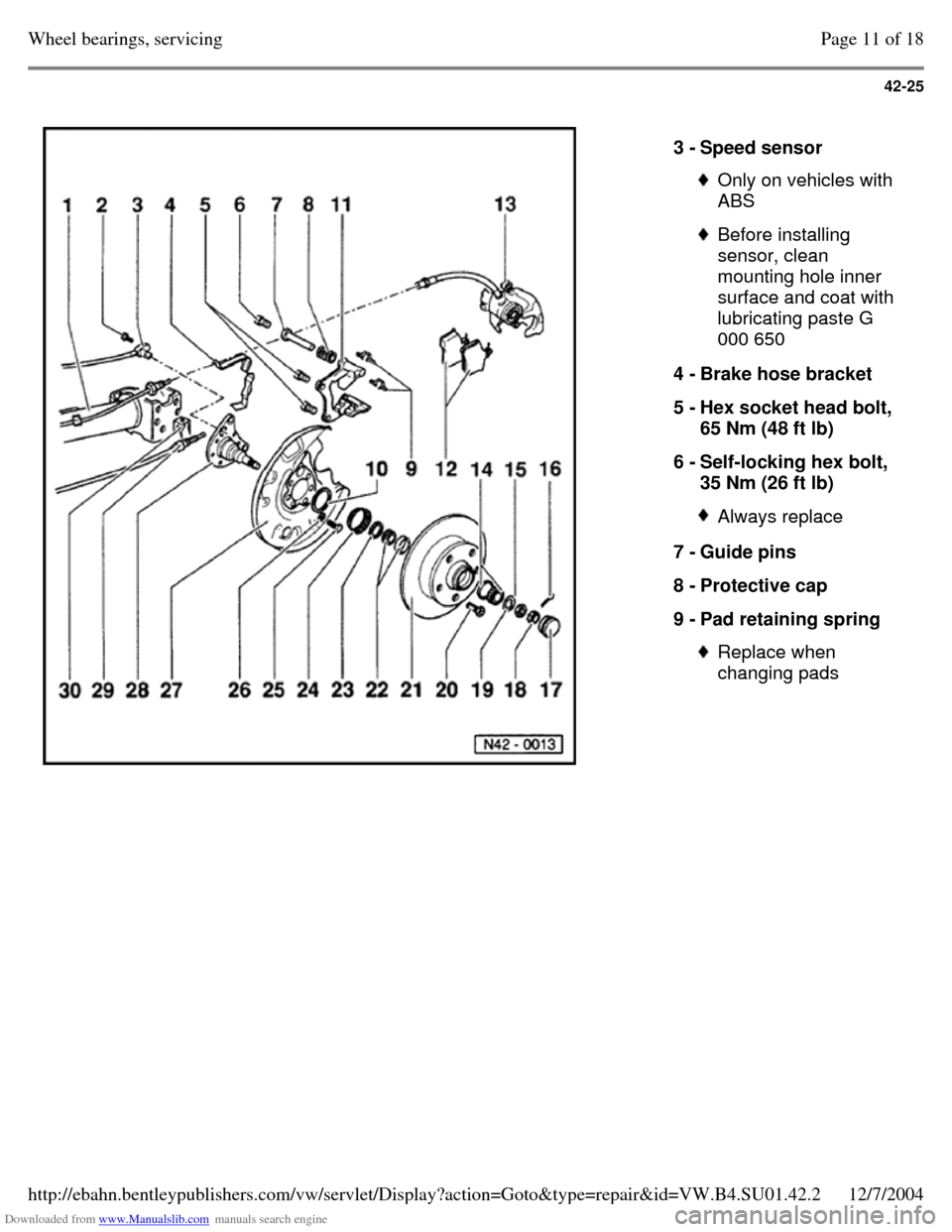

Downloaded from www.Manualslib.com manuals search engine 42-25

3 - Speed sensor Only on vehicles with

ABS Before installing

sensor, clean

mounting hole inner

surface and coat with

lubricating paste G

000 650

4 - Brake hose bracket

5 - Hex socket head bolt,

65 Nm (48 ft lb)

6 - Self-locking hex bolt,

35 Nm (26 ft lb) Always replace 7 - Guide pins

8 - Protective cap

9 - Pad retaining spring Replace when

changing pads Page 11 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 123 of 369

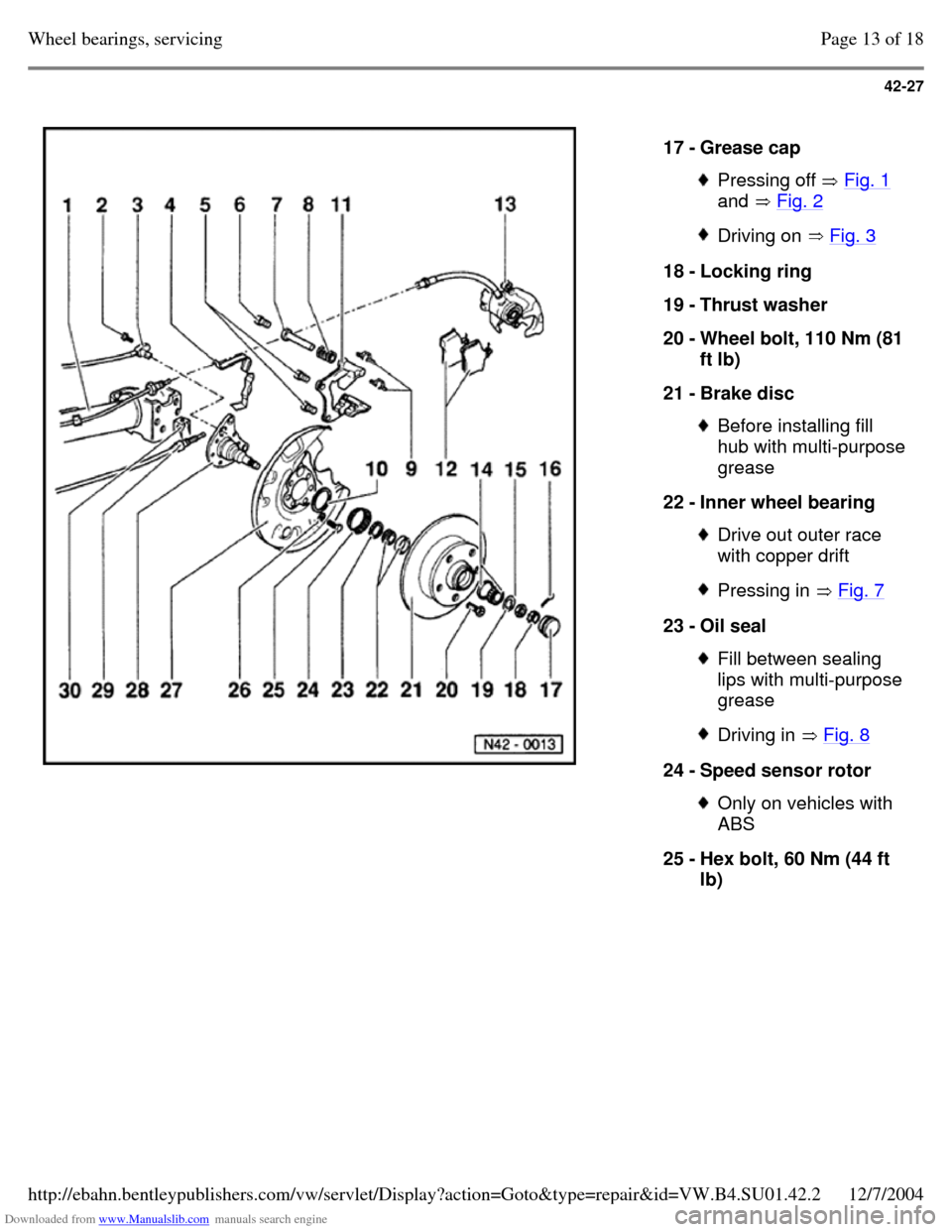

Downloaded from www.Manualslib.com manuals search engine 42-27

17 - Grease cap Pressing off Fig. 1

and Fig. 2 Driving on Fig. 3 18 - Locking ring

19 - Thrust washer

20 - Wheel bolt, 110 Nm (81

ft lb)

21 - Brake disc Before installing fill

hub with multi-purpose grease

22 - Inner wheel bearing Drive out outer race

with copper drift Pressing in Fig. 7 23 - Oil seal Fill between sealing

lips with multi-purpose

grease Driving in Fig. 8 24 - Speed sensor rotor Only on vehicles with

ABS

25 - Hex bolt, 60 Nm (44 ft

lb) Page 13 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 129 of 369

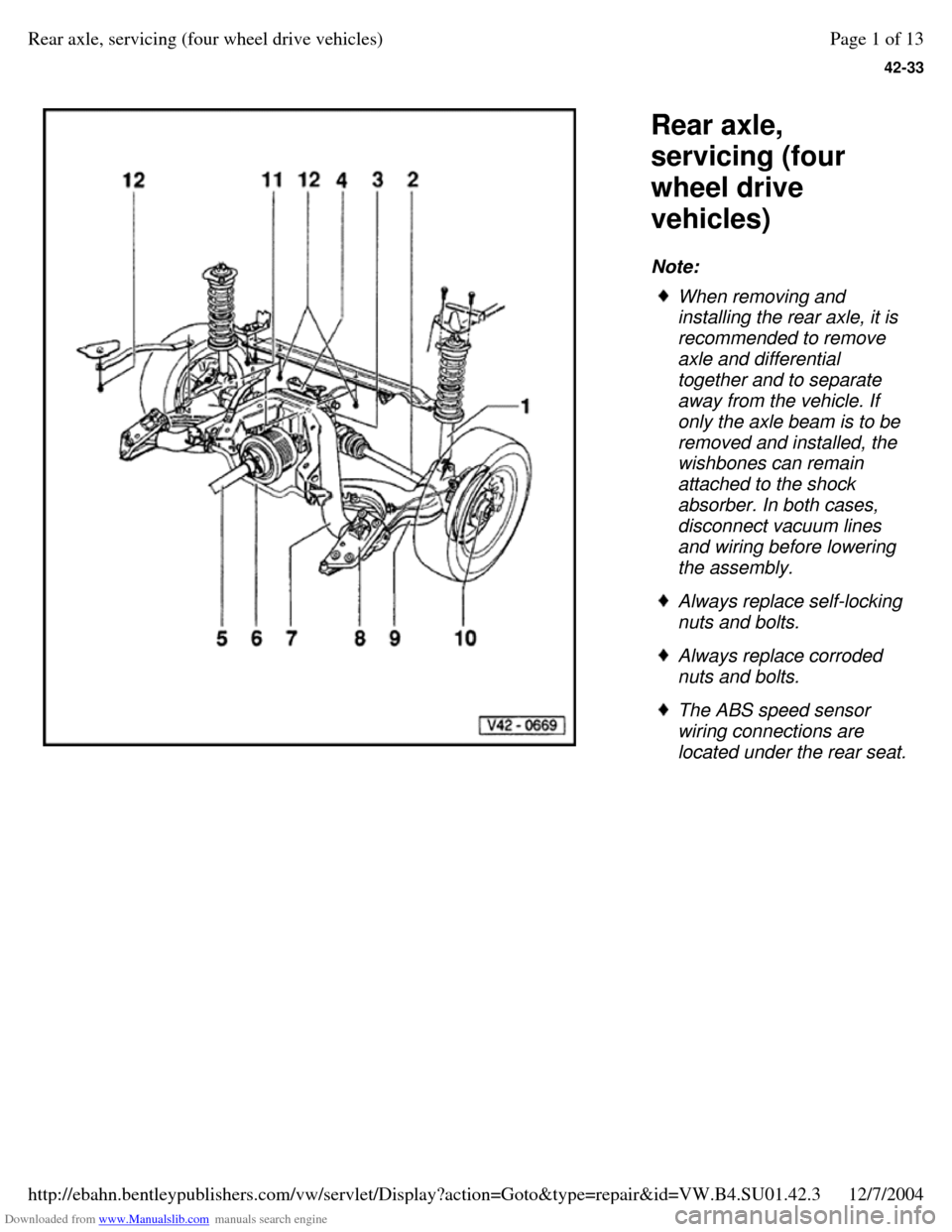

Downloaded from www.Manualslib.com manuals search engine 42-33

Rear axle,

servicing (four

wheel drive

vehicles)

Note: When removing and

installing the rear axle, it is

recommended to remove

axle and differential

together and to separate

away from the vehicle. If

only the axle beam is to be

removed and installed, the

wishbones can remain

attached to the shock

absorber. In both cases,

disconnect vacuum lines

and wiring before lowering

the assembly. Always replace self-locking

nuts and bolts. Always replace corroded

nuts and bolts. The ABS speed sensor

wiring connections are

located under the rear seat. Page 1 of 13Rear axle, servicing (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.3

Page 151 of 369

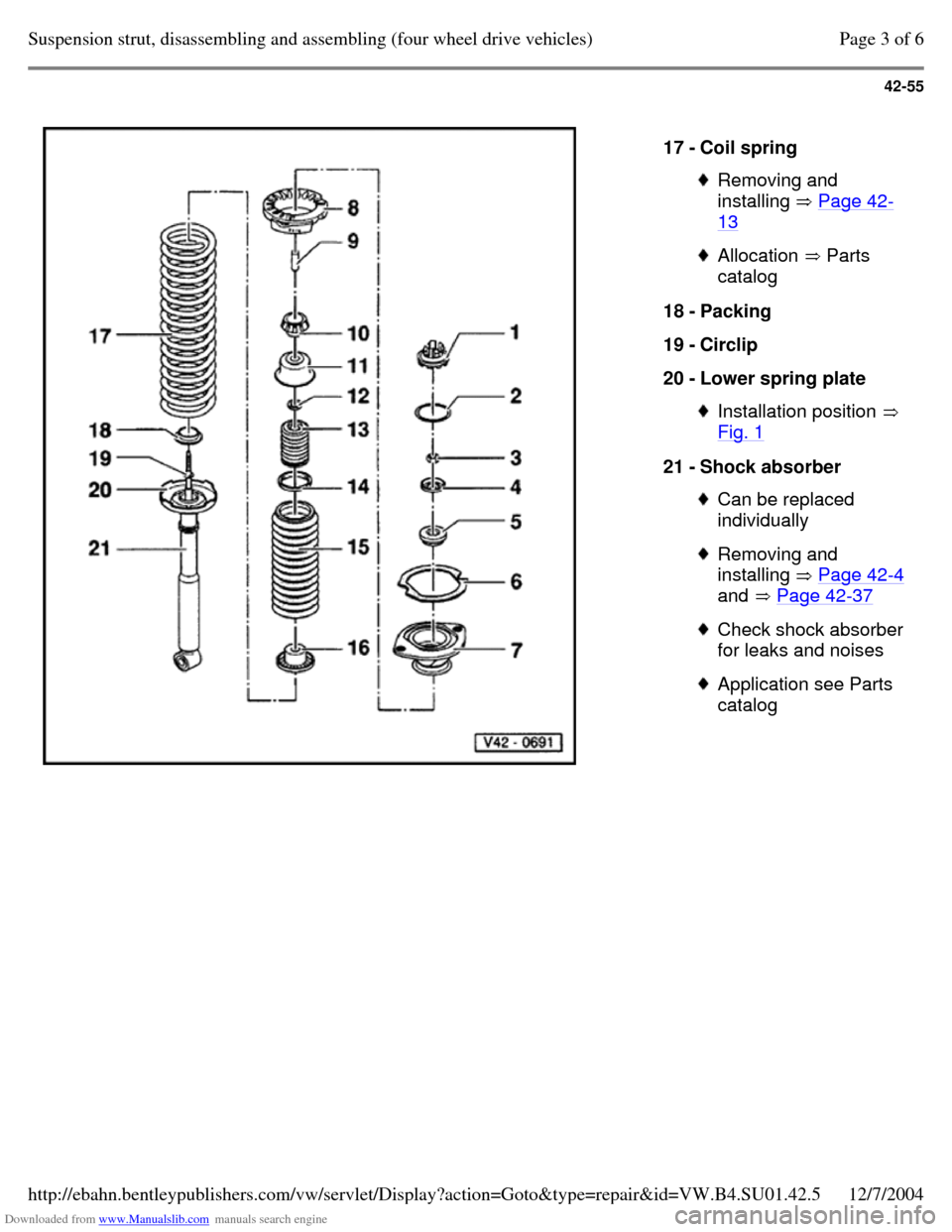

Downloaded from www.Manualslib.com manuals search engine 42-55

17 - Coil spring Removing and

installing Page 42-13 Allocation Parts

catalog 18 - Packing

19 - Circlip

20 - Lower spring plate Installation position

Fig. 1 21 - Shock absorber Can be replaced

individually Removing and

installing Page 42-4

and Page 42-37 Check shock absorber

for leaks and noises Application see Parts

catalog Page 3 of 6Suspension strut, disassembling and assembling (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.5

Page 152 of 369

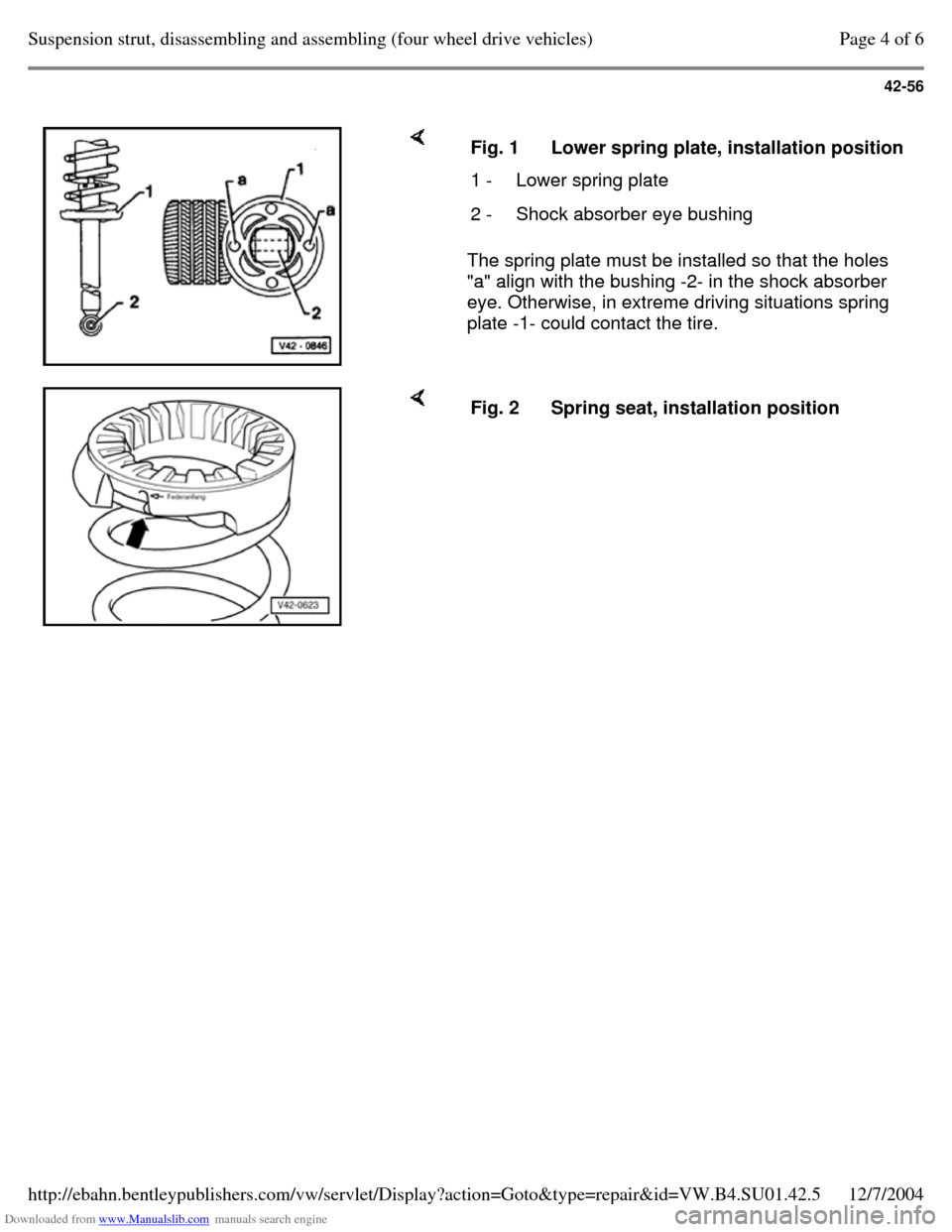

Downloaded from www.Manualslib.com manuals search engine 42-56

The spring plate must be installed so that the holes

"a" align with the bushing -2- in the shock absorber

eye. Otherwise, in extreme driving situations spring

plate -1- could contact the tire. Fig. 1 Lower spring plate, installation position 1 - Lower spring plate 2 - Shock absorber eye bushing Fig. 2 Spring seat, installation position Page 4 of 6Suspension strut, disassembling and assembling (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.5

Page 153 of 369

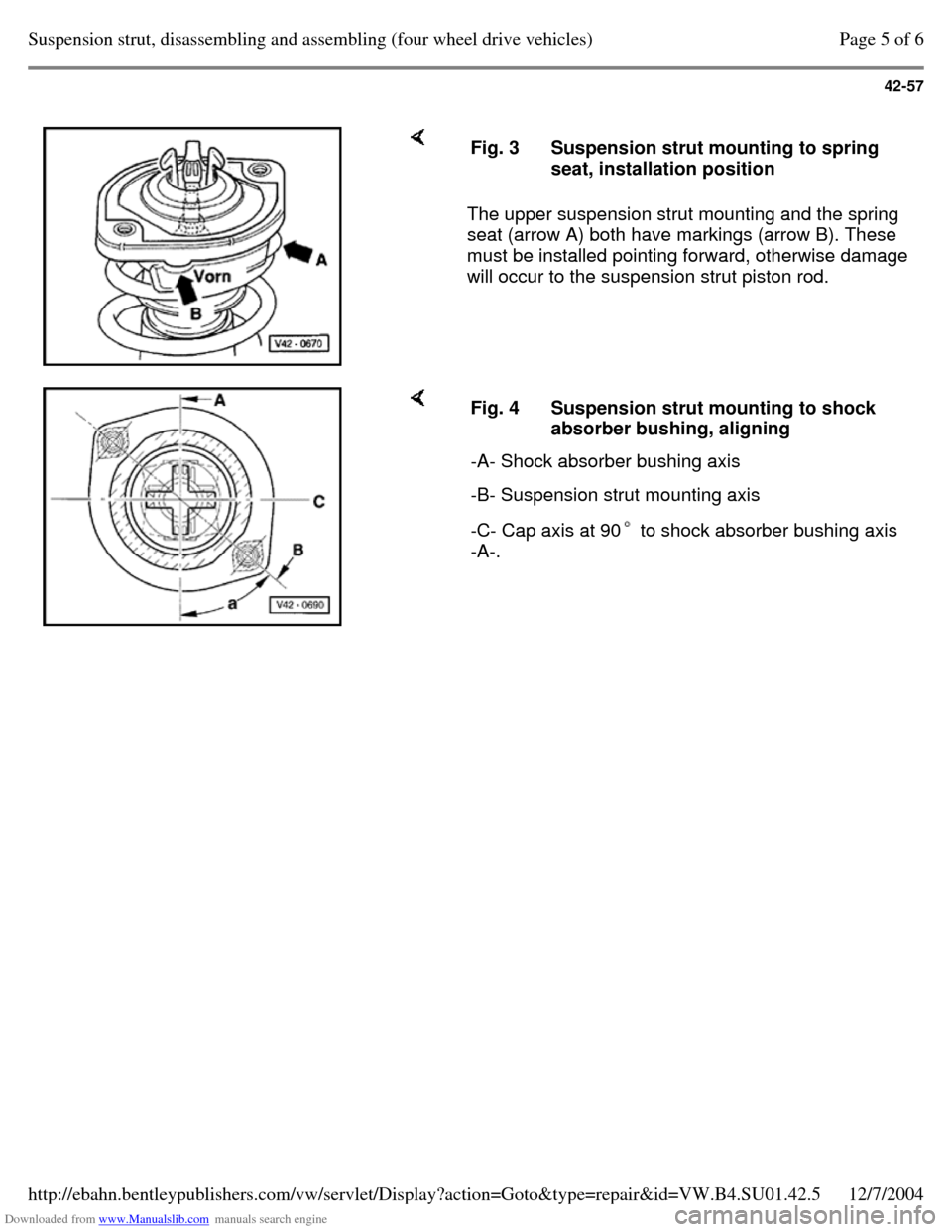

Downloaded from www.Manualslib.com manuals search engine 42-57

The upper suspension strut mounting and the spring

seat (arrow A) both have markings (arrow B). These

must be installed pointing forward, otherwise damage

will occur to the suspension strut piston rod. Fig. 3 Suspension strut mounting to spring

seat, installation position Fig. 4 Suspension strut mounting to shock

absorber bushing, aligning

-A- Shock absorber bushing axis -B- Suspension strut mounting axis -C- Cap axis at 90 to shock absorber bushing axis

-A-. Page 5 of 6Suspension strut, disassembling and assembling (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.5

Page 170 of 369

Downloaded from www.Manualslib.com manuals search engine 45-1

Anti-locking Brake System

(ABS) and Anti-locking Brake

System with Electronic

Differential Lock (ABS/EDL)

Teves 04

The ABS, ABS/EDL brake system is divided

diagonally. The servo-assist is effected

pneumatically, by the vacuum brake servo unit.

Located between the brake master cylinder and

the vacuum servo unit is a mounting bracket for

the hydraulic unit with pump.

The hydraulic unit together with pump, supplies

only the anti-locking brake system (ABS) or anti-

locking brake system and traction control system

(ABS/EDL).

Malfunctions on the ABS, ABS/EDL systems do

not influence the brake system and servo. The

vehicle can be driven without the ABS, ABS/EDL

functions operating. Page 1 of 5Anti-locking Brake System (ABS) and Anti-locking Brake System with Electronic Differential Lock (A...12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.45.1

Page 171 of 369

Downloaded from www.Manualslib.com manuals search engine 45-2

Notes for repair work on ABS, ABS/EDL

Before doing any repair work on the anti-locking system, determine the cause of the malfunction

using On Board Diagnostic (OBD).

Repair Manual, Brake System On Board Diagnostic (OBD), Repair Group 01 Before working on the ABS, ABS/EDL system,

disconnect the battery Ground strap. On

vehicles with coded radio, obtain cooling.

When working with brake fluid, observe the

relevant safety precautions and notes Page 47-27 . After work for which the brake system had to be opened, bleed the brake system with brake filler and bleeder unit VAS 5234 Page 47-27 . During the final road test, make sure that a

controlled brake test is performed at least once

(pulsations must be felt at the brake pedal).

Absolute cleanliness is required when working

on the anti-locking brake system; it is not

permitted to use any products which contain

mineral oils, such as oils, greases etc. Page 2 of 5Anti-locking Brake System (ABS) and Anti-locking Brake System with Electronic Differential Lock (A...12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.45.1