gearbox VOLKSWAGEN UP! 2021 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: UP!, Model: VOLKSWAGEN UP! 2021Pages: 211, PDF Size: 5.98 MB

Page 110 of 211

Indicator lamps

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Lit upPossible causeSolution

The start/stop system is not available.

Automatic engine stop active.

The start/stop system is available, but an

automatic engine stop is not possible.

Check whether all technical requirements

have been fulfilled. If not, remedy any

shortfalls ⇒ Start/stop system.

Start/stop system cannot start the engine.

Start the engine again manually using the

vehicle key ⇒ Starting and stopping the

engine.

Fault in the alternator.⇒ Vehicle battery

FlashesPossible causeSolution

Start/stop system not available.Proceed to a qualified workshop.

Several warning and indicator lamps will light up briefly as a functional check when the ignition is

switched on. They will switch off after a few seconds.

Start/stop system

Fig. 103 In the upper part of the centre console: button for the start/stop system

First read and observe the introductoryinformation and safety warnings⇒

Introduction

When the start/stop system is active, the engine is switched off whenever the vehicle is stationary.

The engine then restarts automatically as soon as it is required.

The function is automatically activated every time the ignition is switched on. The instrument cluster

display shows information about the current status ⇒ Indicator lamps.

Always switch off the start/stop system manually when driving through water.

Vehicles with a manual gearbox

•When the vehicle is stationary, disengage the gear and release the clutch pedal. The engine is

stopped.

The intelligent technology of the pull-away assist systems cannot overcome the laws of

physics. Never let the extra convenience afforded by pull-away assist systems tempt you into

taking any risks when driving – this can cause accidents.

•Unintentional vehicle movements can cause serious injury.

•The pull-away assist systems cannot replace the full concentration of the driver.

•Always adapt your speed and driving style to suit visibility, weather, road and traffic

conditions.

•A pull-away assist system cannot hold the vehicle in all hill start situations or brake it

sufficiently on all slopes going downhill (e.g. if the ground is slippery or icy).

WARNING

Failure to observe the warning lamps could lead to your vehicle breaking down in traffic, and

to accidents and serious injuries.

•Never ignore any warning lamps that are lit up.

•Stop the vehicle as soon as it is possible and safe to do so.

WARNING

Failure to observe the illuminated indicator lamps could lead to the vehicle being damaged.

NOTICE

Page 111 of 211

•Depress the clutch pedal to restart the engine.

Important preconditions for automatic engine switch-off

•The driver is wearing their seat belt.

•The driver door is closed.

•The bonnet is closed.

•A minimum engine temperature has been reached.

•The vehicle has been moved since the engine was last switched off.

•The defrost function of the air conditioning system is not switched on.

•The charging state of the vehicle battery is sufficient.

•The temperature of the vehicle battery is not too low or too high.

•The vehicle is not on a steep incline.

•Reverse gear is not engaged.

Conditions for an automatic restart

The engine can start automatically under the following conditions:

•If the vehicle rolls on.

•If the voltage of the vehicle battery falls.

Conditions that make a key start necessary

The engine has to be started manually with the vehicle key in the following conditions:

•If the driver unfastens their seat belt.

•If the driver door is opened.

•If the bonnet is opened.

Switching the start/stop system on and off

•Press the button in the centre console ⇒ Fig. 103.

•If start/stop system has been deactivated, the indicator lamp in the button lights up.

If the start/stop system has switched the engine off, the engine will start again as soon as the

system has been switched off manually with the button.

In some cases, it will be necessary to restart the engine manually with the vehicle key. Take

note of the corresponding indicator lamp in the instrument cluster.

Hill Hold Assist

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The Hill Hold Assist function actively holds the vehicle when pulling away on an incline.

The Hill Hold Assist function is automatically activated if the following

conditions are met

Points 1 to 3 must be fulfilled at the same time:

Manual gearboxAutomated manual gearbox

1.On an incline, the stationary vehicle must be held in position with the footbrake until the

vehicle starts moving.

2.The engine is running smoothly.

3.

Fully depress the clutch pedal and move the

gear stick to the 1st gear position if you want

to drive forwards up a hill or to the R position

if you want to reverse up a hill.

Position D is selected when driving forwards

up an incline or position R is selected for

driving in reverse up an incline.

The brake servo and the electromechanical steering will not function if the engine is switched

off.

•Never allow the vehicle to roll if the engine is switched off.

•The start/stop system must be switched off if work is to be carried out in the engine

compartment.

WARNING

If the start/stop system is used in very high outside temperatures over a long period, the

vehicle battery can be damaged.

NOTICE

Page 112 of 211

Points 1 to 3 must be fulfilled at the same time:

Manual gearboxAutomated manual gearbox

In order to start moving, remove your foot

from the brake pedal, then release the clutch

pedal (clutch engages) and press the

accelerator simultaneously. The brake will

gradually be released as the clutch is

engaged.

To start moving, remove your foot from the

brake pedal and press the accelerator

immediately. The brake will gradually be

released as the vehicle pulls away.

The Hill Hold Assist function will be deactivated immediately:

•As soon as one of the conditions indicated on ⇒ The Hill Hold Assist function is automatically

activated if the following conditions are met is not fulfilled.

•If the engine is not running smoothly or there is an engine fault.

•If the engine is switched off or has stalled.

•Vehicles with automated manual gearbox: if the selector lever in is the neutral position N.

ParkPilot

Introduction

This chapter contains information on the followingsubjects:

⇒ Operating ParkPilot

⇒ Acoustic and optical ParkPilot signals at the rear of the vehicle

The ParkPilot assists the driver when manoeuvring and parking.

The ultrasound sensors in the rear bumper transmit and receive ultrasonic waves. The system uses

the time difference between the ultrasonic waves (i.e. between the transmission and reflection from

obstacles and the point of reception) to continuously calculate the distance between the bumper

and the obstacle.

Additional information and warnings:

•Exterior views ⇒ Exterior views

•Braking, stopping and parking ⇒ Braking, stopping and parking

•Cleaning and caring for the vehicle exterior ⇒ Caring for and cleaning the vehicle exterior

•Accessories, modifications, repairs and renewal of parts ⇒ Accessories, modifications, repairs

and renewal of parts

•Portable navigation device (delivered by Volkswagen) ⇒ Accessories, modifications, repairs and

renewal of parts

•Radio ⇒BookletRadio,

Page 116 of 211

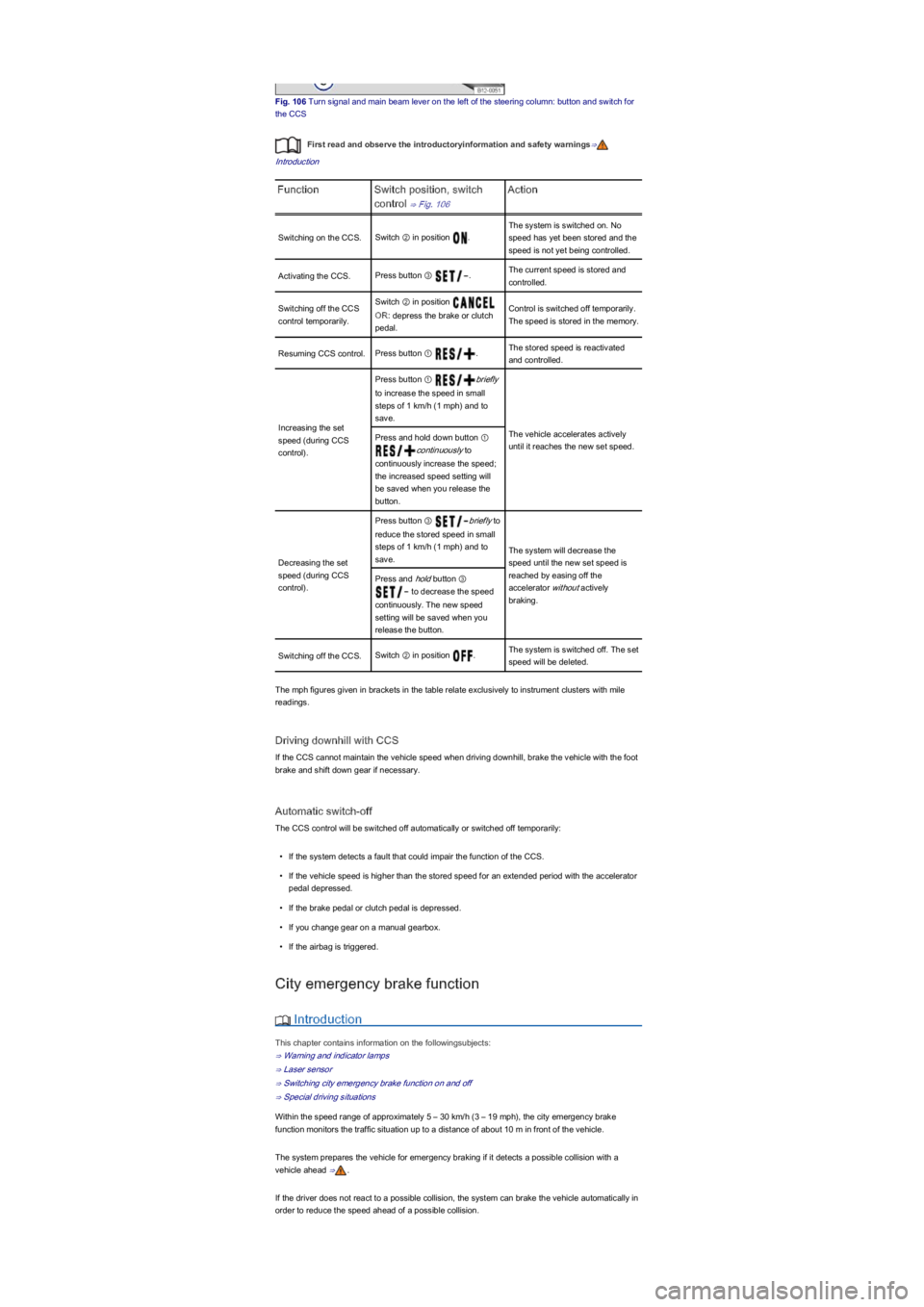

Fig. 106 Turn signal and main beam lever on the left of the steering column: button and switch for

the CCS

First read and observe the introductoryinformation and safety warnings⇒

Introduction

FunctionSwitch position, switch

control ⇒ Fig. 106

Action

Switching on the CCS.Switch ② in position .

The system is switched on. No

speed has yet been stored and the

speed is not yet being controlled.

Activating the CCS.Press button ③ .The current speed is stored and

controlled.

Switching off the CCS

control temporarily.

Switch ② in position

OR: depress the brake or clutch

pedal.

Control is switched off temporarily.

The speed is stored in the memory.

Resuming CCS control.Press button ① .The stored speed is reactivated

and controlled.

Increasing the set

speed (during CCS

control).

Press button ① briefly

to increase the speed in small

steps of 1 km/h (1 mph) and to

save.

The vehicle accelerates actively

until it reaches the new set speed.

Press and hold down button ①

continuously to

continuously increase the speed;

the increased speed setting will

be saved when you release the

button.

Decreasing the set

speed (during CCS

control).

Press button ③ briefly to

reduce the stored speed in small

steps of 1 km/h (1 mph) and to

save.

The system will decrease the

speed until the new set speed is

reached by easing off the

accelerator without actively

braking.

Press and hold button ③

to decrease the speed

continuously. The new speed

setting will be saved when you

release the button.

Switching off the CCS.Switch ② in position .The system is switched off. The set

speed will be deleted.

The mph figures given in brackets in the table relate exclusively to instrument clusters with mile

readings.

Driving downhill with CCS

If the CCS cannot maintain the vehicle speed when driving downhill, brake the vehicle with the foot

brake and shift down gear if necessary.

Automatic switch-off

The CCS control will be switched off automatically or switched off temporarily:

•If the system detects a fault that could impair the function of the CCS.

•If the vehicle speed is higher than the stored speed for an extended period with the accelerator

pedal depressed.

•If the brake pedal or clutch pedal is depressed.

•If you change gear on a manual gearbox.

•If the airbag is triggered.

City emergency brake function

Introduction

This chapter contains information on the followingsubjects:

⇒ Warning and indicator lamps

⇒ Laser sensor

⇒ Switching city emergency brake function on and off

⇒ Special driving situations

Within the speed range of approximately 5 – 30 km/h (3 – 19 mph), the city emergency brake

function monitors the traffic situation up to a distance of about 10 m in front of the vehicle.

The system prepares the vehicle for emergency braking if it detects a possible collision with a

vehicle ahead ⇒.

If the driver does not react to a possible collision, the system can brake the vehicle automatically in

order to reduce the speed ahead of a possible collision.

Page 172 of 211

You will need an external aerial to use a two-way radio in the vehicle.

Any retrofit installation of electrical or electronic equipment in the vehicle will affect its vehicle type

approval. Under certain circumstances, this can negate the type approval for the vehicle.

Volkswagen has approved the vehicle for use with two-way radios subject to the following

conditions:

•Correct installation of external aerial.

•A maximum transmitting power of 10 watts.

An external aerial is needed to give the equipment its optimal range.

Check first with a qualified workshop if you wish to use a two-way radio with a transmitting power of

over 10 watts. A qualified workshop is familiar with the technical options for retrofitting. Volkswagen

recommends using a Volkswagen dealership for this purpose.

Please observe legislation and the instructions and information given in the operating manuals for

radio equipment.

Information stored in the control units

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Your vehicle is factory fitted with electronic control units which are responsible for engine and

gearbox management. The control units also monitor the function of the exhaust system and the

airbags.

These electronic control units continuously evaluate data relevant to the vehicle while the vehicle is

being driven. Only these data will be stored if there are any faults recorded or any deviations from

the specified values. This is generally displayed by the indicator lamps on the instrument cluster.

Special units are required to read and evaluate data stored in the control units.

These data are stored so that specialist workshops can diagnose and solve problems. The

following data may have been stored:

•Engine and gearbox-relevant data.

•Speed.

•Direction of travel.

•Braking power.

•Seat belt monitor.

The control units never record conversations that take place in the vehicle. It is neither possible nor

permitted to use the stored data to create movement profiles.

When the vehicle is being used, situations may arise in which the stored data (alone or in

conjunction with other information such as accident reports, vehicle damage, witness statements

etc.) can become assignable to a particular person, in which case it may be necessary to consult an

expert and use the expert's information.

In vehicles with an emergency call function via a mobile telephone or other units, the current

location can be transmitted. In the event of an accident in which the control units register that an

airbag has been triggered, the system can automatically send out a signal. This depends on your

service provider. Transmission is possible only in areas with a sufficiently strong mobile telephone

signal.

Additional functions that are contractually agreed with the customer, e.g. vehicle positioning in an

emergency, allow certain vehicle data to be transmitted from the vehicle.

If radio equipment is not secured or not properly secured in the vehicle, it could be flung

though the interior during a sudden driving or braking manoeuvre, or in the event of an

accident. This can cause injuries.

•While the vehicle is in motion, always secure two-way radios properly outside the airbag

deployment zones or stow them away safely.

WARNING

If two-way radios that are not connected to an external aerial are used, electromagnetic

radiation in the vehicle could exceed limit values and thus be a health hazard for drivers and

other vehicle occupants. This also applies to external aerials that have not been correctly

installed.

•Two-way radios should only be used in the vehicle if an external aerial is properly

connected.

CAUTION

Page 177 of 211

There are many precautions that have to be followed when lifting a vehicle on a workshop hoist or

floor jack. Do not try to lift a vehicle on a lifting platform or vehicle jack unless you have the training,

knowledge and experience to be able to do so safely.

Using the jack to lift the vehicle ⇒ Changing a wheel.

Consumer information

Introduction

This chapter contains information on the followingsubjects:

⇒ Information stickers and plates

⇒ Using the vehicle in other countries and continents

⇒ Radio reception and aerials

⇒ Volkswagen repair information

⇒ Declaration of conformity

⇒ Declaration of conformity for wheels and tyres

⇒ Recycling and scrapping end-of-life vehicles

Additional information and warnings:

•Exterior views ⇒ Exterior views

•Pull-away assist systems ⇒ Pull-away assist systems

•Accessories, modifications, repairs and renewal of parts ⇒ Accessories, modifications, repairs

and renewal of parts

•⇒BookletService schedule,

Lifting your vehicle incorrectly with a lifting platform or vehicle jack can cause accidents and

serious personal injury:

•Always read and heed the operating instructions from the lifting platform or vehicle jack

manufacturer and any legal regulations before lifting the vehicle.

•All occupants should leave the vehicle before it is lifted.

•The vehicle should only be lifted at the points indicated in the illustrations ⇒ Fig. 137 and

⇒ Fig. 138. If the vehicle is not lifted at the points shown, it could fall off the lifting platform

when work is carried out, e.g. when the engine or gearbox is removed.

•The vehicle jacking points must be placed on the centre of the vehicle lift support surfaces,

with as much surface contact between the vehicle and the support surfaces as possible.

•Never start the engine when the vehicle is raised. The vibration of the engine could cause

the vehicle to fall off the lifting point.

•If work has to be carried out underneath the lifted vehicle, secure the vehicle with suitable

jack stands with a sufficient load-bearing capacity.

•Never climb up the lifting platform.

•Always ensure that the vehicle is not heavier than the lifting capacity of the lifting platform.

WARNING

•Never lift the vehicle by the engine oil sump, the gearbox or the front or rear axle.

•To prevent damage to the underside of the vehicle when lifting, rubber pads must be used.

Ensure that the lifting platform arms are able to move freely.

•The lifting platform arms must not be allowed to come into contact with the sills or any

other part of the vehicle.

NOTICE

Handling the vehicle incorrectly will increase the risk of accident and injuries.

•Comply with legal regulations.

•Observe the owner's manual.

WARNING

Handling the vehicle incorrectly could lead to the vehicle becoming damaged.

•Comply with legal regulations.

•Carry out service jobs in accordance with the service schedule.

•Observe the owner's manual.

NOTICE

Page 189 of 211

In the event of a flat tyre, park your vehicle on a firm and level surface at a safe distance

from the flow of traffic.

Apply the handbrake firmly Braking, stopping and parking.

With an automated manual gearbox, move the selector lever to D or R with the ignition on

Changing gear.

Stop the engine and remove the vehicle key from the ignition Starting and stopping the

engine.

Manual gearbox: select a gear Changing gear.

Ensure that all vehicle occupants exit the vehicle and proceed to a safe position, e.g.

behind the safety barrier.

Chock the wheel opposite the wheel being worked on with a stone or a similar object.

Remove any items of luggage in the luggage compartment.

Remove the spare wheel or temporary spare wheel and vehicle toolkit from the luggage

compartment.

Remove the hubcaps Hubcaps.

⇒ Lifting the vehicle with the jack

⇒ Changing a wheel

⇒ After changing a wheel

Some models are delivered without a factory-fitted jack or box spanner. If this is the case, the wheel

should be changed by a qualified workshop.

The vehicle jack supplied with the vehicle is only designed for changing a wheel when one vehicle

tyre is damaged and has to be replaced. Seek expert assistance if both tyres on one side of the

vehicle, both tyres on one axle, or all tyres are damaged.

Only change the wheel yourself when the car is parked in a safe place, you are familiar with the

necessary steps and safety procedures and you have access to all the correct tools. Seek expert

assistance if this is not the case.

Additional information and warnings:

•Exterior views ⇒ Exterior views

•Vehicle key set ⇒ Vehicle key set

•Wheels and tyres ⇒ Wheels and tyres

•In an emergency ⇒ In an emergency

•Vehicle toolkit ⇒ Vehicle toolkit

•Hubcaps ⇒ Hubcaps

Preparation for changing a wheel

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Checklist

The following actions must always be carried out in the given order in preparation for changing

the wheel ⇒:

Changing a wheel can be dangerous, especially when carried out at the side of a road. Please

note the following steps in order to reduce the risk of serious injuries:

•Stop the vehicle as soon as possible and when safe to do so. Park the vehicle at a safe

distance from moving traffic in order to carry out the wheel change.

•All passengers and children in particular must be at a safe distance and away from your

area of work during the wheel change.

•Switch on the hazard warning lights to warn other road users.

•The ground should be firm and level. If necessary use a large, strong board or similar

support for the vehicle jack.

•Only change the wheel yourself if you feel confident carrying out the procedure. If not,

seek expert assistance.

•Always use suitable and undamaged tools to change the wheel.

•Always switch off the engine, firmly apply the handbrake and move the selector lever to D

or R with the ignition switched on, or select a gear on a manual gearbox in order to reduce

the risk of unintended vehicle movement.

•The wheel bolt tightening torque should be checked with a torque wrench immediately

after changing a wheel.

WARNING

Page 191 of 211

Find a firm and level surface suitable for lifting the vehicle.

Stop the engine, select a gear on a manual gearbox or with an automated manual

gearbox, move the selector lever to D or R with the ignition switched onChanging gear

then apply the handbrake firmly Braking, stopping and parking.

Chock the wheel diagonally opposite using the collapsible chocks or other suitable objects.

Loosen the wheel bolts on the wheel that is being changed Wheel bolts.

Find the jacking point under the vehicle which is closest to the wheel that is being

changed.

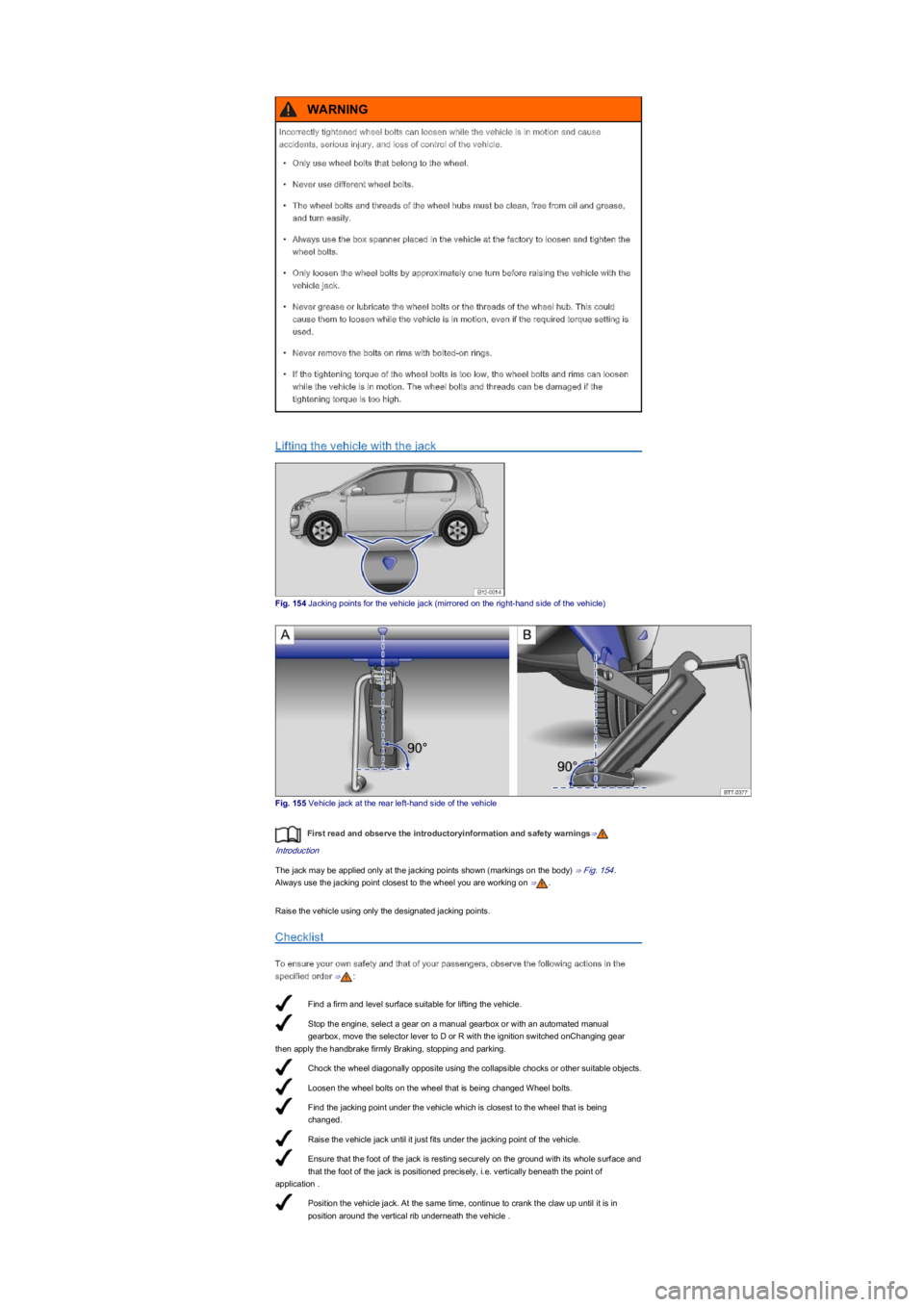

Raise the vehicle jack until it just fits under the jacking point of the vehicle.

Ensure that the foot of the jack is resting securely on the ground with its whole surface and

that the foot of the jack is positioned precisely, i.e. vertically beneath the point of

application .

Position the vehicle jack. At the same time, continue to crank the claw up until it is in

position around the vertical rib underneath the vehicle .

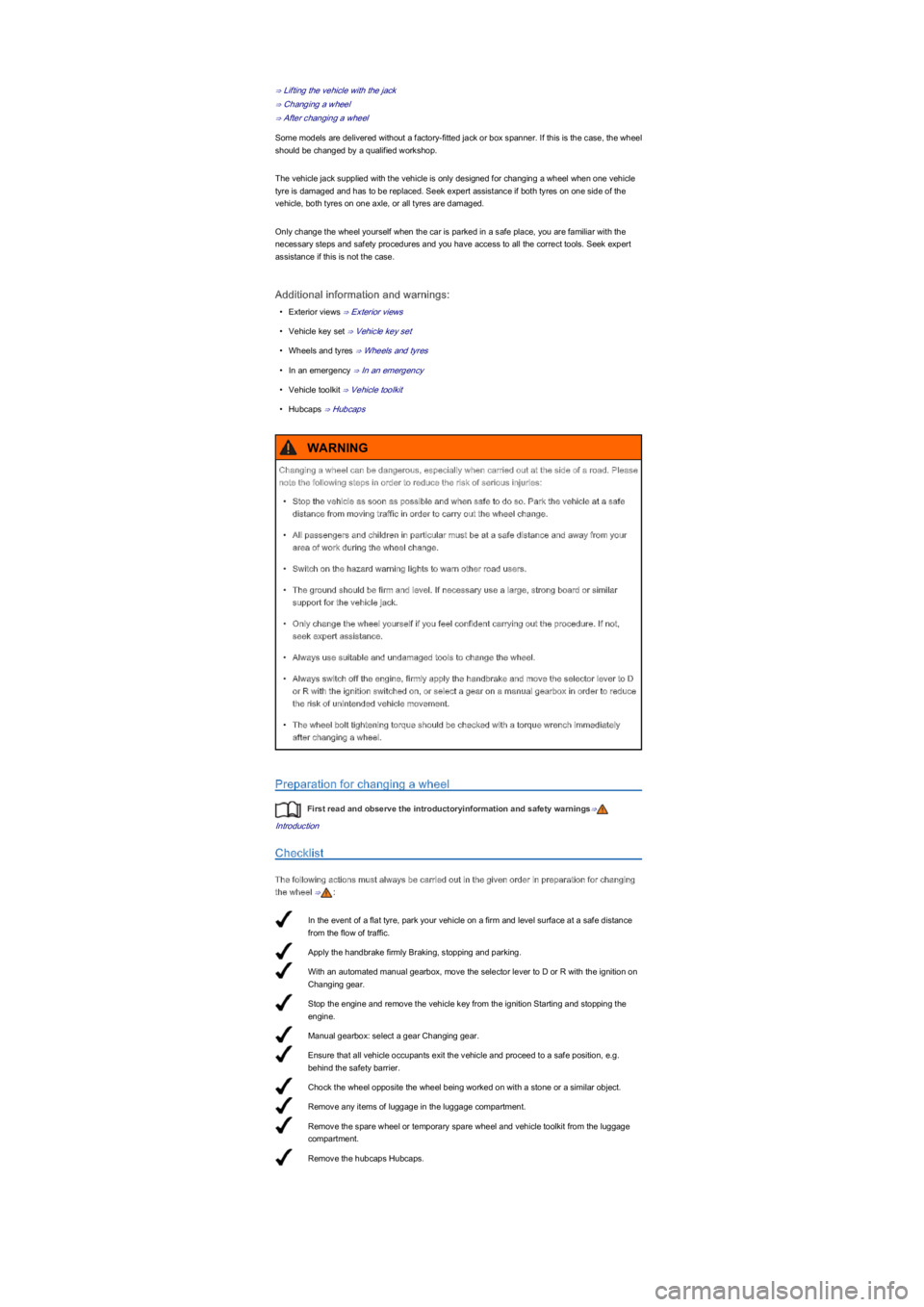

Lifting the vehicle with the jack

Fig. 154 Jacking points for the vehicle jack (mirrored on the right-hand side of the vehicle)

Fig. 155 Vehicle jack at the rear left-hand side of the vehicle

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The jack may be applied only at the jacking points shown (markings on the body) ⇒ Fig. 154.

Always use the jacking point closest to the wheel you are working on ⇒.

Raise the vehicle using only the designated jacking points.

Checklist

To ensure your own safety and that of your passengers, observe the following actions in the

specified order ⇒:

Incorrectly tightened wheel bolts can loosen while the vehicle is in motion and cause

accidents, serious injury, and loss of control of the vehicle.

•Only use wheel bolts that belong to the wheel.

•Never use different wheel bolts.

•The wheel bolts and threads of the wheel hubs must be clean, free from oil and grease,

and turn easily.

•Always use the box spanner placed in the vehicle at the factory to loosen and tighten the

wheel bolts.

•Only loosen the wheel bolts by approximately one turn before raising the vehicle with the

vehicle jack.

•Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could

cause them to loosen while the vehicle is in motion, even if the required torque setting is

used.

•Never remove the bolts on rims with bolted-on rings.

•If the tightening torque of the wheel bolts is too low, the wheel bolts and rims can loosen

while the vehicle is in motion. The wheel bolts and threads can be damaged if the

tightening torque is too high.

WARNING

Page 194 of 211

Dispose of used or out-of-date sealant in accordance with legal requirements.

You can get a new tyre filler bottle from a Volkswagen dealership.

Observe the separate instructions from the manufacturer of the breakdown set.

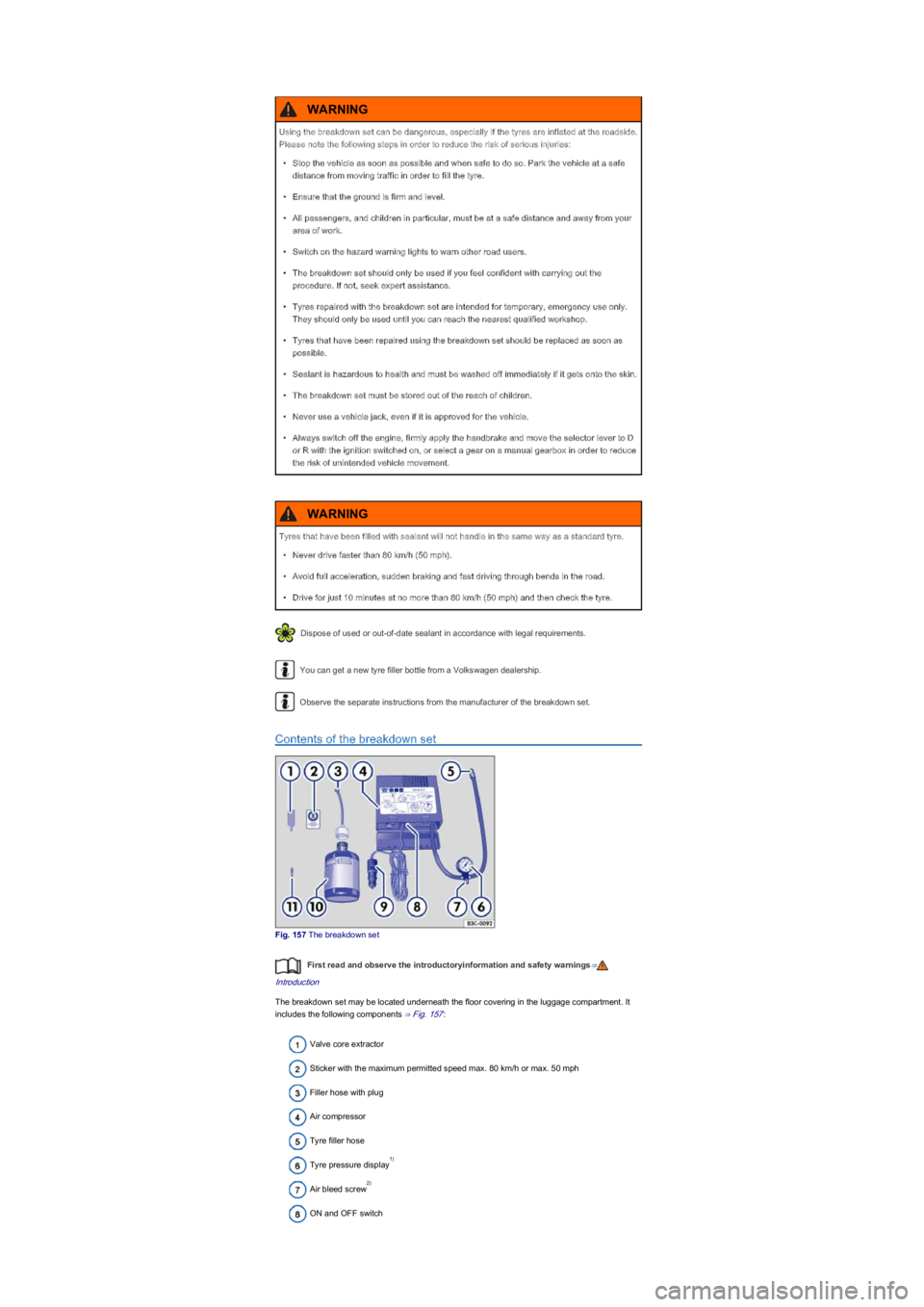

Contents of the breakdown set

Fig. 157 The breakdown set

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The breakdown set may be located underneath the floor covering in the luggage compartment. It

includes the following components ⇒ Fig. 157:

Valve core extractor

Sticker with the maximum permitted speed max. 80 km/h or max. 50 mph

Filler hose with plug

Air compressor

Tyre filler hose

Tyre pressure display

Air bleed screw

ON and OFF switch

Using the breakdown set can be dangerous, especially if the tyres are inflated at the roadside.

Please note the following steps in order to reduce the risk of serious injuries:

•Stop the vehicle as soon as possible and when safe to do so. Park the vehicle at a safe

distance from moving traffic in order to fill the tyre.

•Ensure that the ground is firm and level.

•All passengers, and children in particular, must be at a safe distance and away from your

area of work.

•Switch on the hazard warning lights to warn other road users.

•The breakdown set should only be used if you feel confident with carrying out the

procedure. If not, seek expert assistance.

•Tyres repaired with the breakdown set are intended for temporary, emergency use only.

They should only be used until you can reach the nearest qualified workshop.

•Tyres that have been repaired using the breakdown set should be replaced as soon as

possible.

•Sealant is hazardous to health and must be washed off immediately if it gets onto the skin.

•The breakdown set must be stored out of the reach of children.

•Never use a vehicle jack, even if it is approved for the vehicle.

•Always switch off the engine, firmly apply the handbrake and move the selector lever to D

or R with the ignition switched on, or select a gear on a manual gearbox in order to reduce

the risk of unintended vehicle movement.

WARNING

Tyres that have been filled with sealant will not handle in the same way as a standard tyre.

•Never drive faster than 80 km/h (50 mph).

•Avoid full acceleration, sudden braking and fast driving through bends in the road.

•Drive for just 10 minutes at no more than 80 km/h (50 mph) and then check the tyre.

WARNING

1)

2)

Page 195 of 211

If you get a flat tyre, park your vehicle on a firm and level surface at a safe distance from

the flow of traffic.

Apply the handbrake firmly Braking, stopping and parking.

With an automated manual gearbox, move the selector lever to D or R with the ignition on

Changing gear.

Stop the engine and remove the vehicle key from the ignition Starting and stopping the

engine.

Manual gearbox: select a gear Changing gear.

Ensure that all vehicle occupants exit the vehicle and proceed to a safe position, e.g.

behind the safety barrier.

Switch on the hazard warning lights and position the warning triangle In an emergency.

Observe any legal requirements.

Check whether the puncture can be repaired with the breakdown set The tyre sealant must

not be used:.

Remove any items of luggage in the luggage compartment.

Take the breakdown set out of the luggage compartment.

Take the sticker ② from the breakdown set and stick it on the dash panel within the

driver's field of vision.

Do not remove foreign objects (e.g. screws or nails) from the tyre.

12-volt plug

Tyre filler bottle with sealant

Spare valve core

There is a slot on the lower end of the valve core extractor ① for the valve core. This is required

for extracting and fitting the tyre valve. This also applies to the spare valve core ⑪.

Could also be integrated in the compressor.

This function may be carried out by a button in the compressor instead.

Preparation

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Checklist

The following actions must always be carried out in the given order in preparation for filling a

tyre ⇒:

Sealing and inflating tyres

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Sealing a tyre

•Unscrew the cap from the tyre valve.

•Use the valve core extractor ⇒ Fig. 157① to screw the valve core out of the tyre valve. Place

the core on a clean surface.

•Shake the tyre filler bottle ⇒ Fig. 157⑩ vigorously up and down several times.

•Screw the filler hose ⇒ Fig. 157③ tightly onto the tyre filler bottle in a clockwise direction. The

plastic foil on the plug is pierced automatically.

•Remove the plug from the filler hose ⇒ Fig. 157③ and place the open end fully on the tyre

valve.

•Hold the bottle upside down and inject the entire contents of the tyre filler bottle into the tyre.

•Remove the empty tyre filler bottle from the valve.

•Use the valve core extractor ⇒ Fig. 157① to screw the valve core back onto the tyre valve.

Inflating the tyre

•Screw the tyre filler hose ⇒ Fig. 157⑤ of the air compressor tightly onto the tyre valve.

•Check that the bleed screw ⇒ Fig. 157⑦ is closed.

•Start the engine and let it run.

1)

1)

2)

Ignoring any of the items on this important safety checklist can lead to accidents and severe

injuries.

•Always follow the instructions in the checklist and observe the general safety procedures.

WARNING