YAMAHA CYGNUS 125 2005 Service Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: CYGNUS 125, Model: YAMAHA CYGNUS 125 2005Pages: 76, PDF Size: 1.28 MB

Page 41 of 76

6-7

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAUT1170

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked in

accordance with the periodic mainte-

nance and lubrication char t. In addition,

the condition of the spark plug can re-

veal the condition of the engine.

To remove the spark plug

1. Remove panel C. (See page 6-6.)

2. Remove the spark plug cap.

3. Remove the spark plug as shown,

with the spark plug wrench included

in the owner’s tool kit.ZAUM00**1

1. Spark plug wrench

To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light tan

(the ideal color when the vehicle is

ridden normally).NOTE:

If the spark plug shows a distinctly dif-

ferent color, the engine could be defec-

tive. Do not attempt to diagnose such

problems yourself. Instead, have a

Yamaha dealer check the vehicle.2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if nec-

essary.

Specified spark plug:

CR7E (NGK)

To install the spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

ZAUM00**

12(×4)

1. Panel B

2. ScrewTo install the panel

Place the panel in the original position,

and then install the screws.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 7

Page 42 of 76

6-8

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIRZAUM00**

1

1. Spark plug gap

Spark plug gap:

0.6~0.7 mm (0.024~0.028 in)

2. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the

spark plug threads.

3. Install the spark plug with the spark

plug wrench, and then tighten it to

the specified torque.

Tightening torque:

Spark plug:

13 Nm (1.3m kgf, 9.4ft lbf)

NOTE:

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4~1/2 turn past

finger tight. However, the spark plug

should be tightened to the specified

torque as soon as possible.4. Install the spark plug cap.

5. Install the panel.

EAUT1350

Engine oil and oil strainerThe engine oil level should be checked

before each ride. In addition, the oil must

be changed and the oil strainer cleaned

at the intervals specified in the periodic

maintenance and lubrication chart. The

engine oil must also be changed at the

initial 1000 km (600 mi) and when the

oil change indicator changes from green

to red. The oil change indicator must be

reset after the initial 1000 km (600 mi).

(See page 3-2 for reset procedures.)

To check the engine oil level

1.Place the vehicle on the centerstand.NOTE:

Make sure that the vehicle is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.2. Start the engine, warm it up for sev-

eral minutes, and then turn it off.

3. Wait a few minutes until the oil

settles, remove the oil filler cap,

wipe the dipstick clean, inser t it

back into the oil filler hole (without

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 8

Page 43 of 76

6-9

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

screwing it in), and then remove it

again to check the oil level.

NOTE:

The engine oil should be between the

minimum and maximum level marks.ZAUM00**

1

2

1. Maximum level mark

1. Minimum level mark4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.To change the engine oil and clean

the oil strainer

1. Start the engine, warm it up for sev-

eral minutes, and then turn it off.

2. Place an oil pan under the engine

to collect the used oil.

3. Remove the engine oil filler cap and

drain bolts to drain the oil from the

crankcase.

ECA10410

cCWhen removing the engine oil drain

bolt, the O-ring, spring, and oil

strainer will fall out. Take care not to

lose these parts.ZAUM00**

1

1. Oil filler cap

ZAUM00**

1

1. Engine oil drain bolt AZAUM00**

1

1. Engine oil drain bolt B4. Clean the oil strainer with solvent,

and then check it for damage and

replace it if necessary.

5. Check the O-ring for damage and

replace it if necessary.

6. Install the oil strainer, spring, O-ring

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 9

Page 44 of 76

6-10

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

and engine oil drain bolts, and then

tighten the drain bolts to the speci-

fied torque.

Tightening torque:

Engine oil drain bolt A:

20 Nm (2.0 m kgf, 14.5ft lbf)

Engine oil drain bolt B:

20 Nm (2.0 m kgf, 14.5 ft lbf)

NOTE:

Make sure that the O-ring is properly

seated.7. Add the specified amount of the

recommended engine oil, and then

install and tighten the engine oil filler

cap.

Recommended engine oil:

See page 8-1.

Oil change quantity:

0.9 L (0.98 US qt) (0.83 Imp.qt)

ECA11670

cC8 88 8

8Do not use oils with a diesel

specification of “CD” or oils of a

higher quality than specified. Inaddition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

8 88 8

8Be sure no foreign material en-

ters the crankcase.

8. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off and

check for the cause.

9. Turn the engine off, and then check

the oil level and correct it if neces-

sary.

10. Reset the oil change indicator. (See

page 3-2 for reset procedures.)NOTE:

If the engine oil is changed before the

oil change indicator changes to red (i.e.

before the periodic oil change interval

has been reached), the indicator must

be reset after the oil change for the next

periodic oil change to be indicated at the

correct time.

EAU20060

Final transmission oilThe final transmission case must be

checked for oil leakage before each ride.

If any leakage is found, have a Yamaha

dealer check and repair the scooter. In

addition, the final transmission oil must

be changed as follows at the intervals

specified in the periodic maintenance

and lubrication chart.

1. Start the engine, warm it up by

riding the scooter for several min-

utes, and then stop the engine.

2. Place the scooter on the

centerstand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

4. Remove the oil filler cap and drain

bolt to drain the oil from the final

transmission case.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 10

Page 45 of 76

6-11

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

ZAUM00**

1

1. Final transmission oil filler cap5. Install the final transmission oil

drain bolt, and then tighten it to the

specified torque.ZAUM00**

1

1. Final transmission oil drain bolt

Tightening torque:

Final transmission oil drain bolt:

23 Nm (2.3 m kgf, 16.6 ft lbf)

6. Add the specified amount of the

recommended final transmission

oil, and then install and tighten the

oil filler cap.

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.13 L (0.14 US qt) (0.1 Imp.qt)

EWA11310

w8 88 8

8Make sure that no foreign mate-

rial enters the final transmission

case.

8 88 8

8Make sure that no oil gets on the

tire or wheel.7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAUT1341

Air filter and V-belt case air fil-

ter elementsThe air filter and V-belt case air filter el-

ements should be cleaned at the inter-

vals specified in the periodic mainte-

nance and lubrication chart. Clean both

filter elements more frequently if you are

riding in unusually wet or dusty areas.

Cleaning the air filter element

1. Place the scooter on the

centerstand.

2. Remove the air filter case cover by

removing the screws.ZAUM00**

2(×6)

1

1. Air filter case cover

2. Screw3. Pull the air filter element out, and

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 11

Page 46 of 76

6-12

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

then blow the dirt out with com-

pressed air as shown.

ZAUM00**

1

1. Air filter element4. Check the air filter element for dam-

age and replace it if necessary.

5. Insert the air filter element into the

air filter case.

ECA10480

cC8 88 8

8Make sure that the air filter ele-

ment is properly seated in the air

filter case.

8 88 8

8The engine should never be op-

erated without the air filter ele-

ment installed, otherwise the

piston(s) and/or cylinder(s) may

become excessively worn.

6. Install the air filter case cover by

installing the screws.

Cleaning the V-belt case air filter ele-

ment

1. Remove the V-belt air filter case

cover by removing the screws.ZAUM00**

21

1. Air filter case cover

2. Screw2. Remove the filter element holder by

removing the screw.

ZAUM00**

1

1. Air filter element holder3. Pull the air filter element out, and

then clean it with solvent. After

cleaning, remove the remaining

solvent by squeezing the element.

EWA10430

wUse only a dedicated parts cleaning

solvent. To avoid the risk of fire or

explosion, do not use gasoline or

solvents with a low flash point.

ECA10520

cCTo avoid damaging the air filter ele-

ment, handle it gently and carefully,

and do not twist it.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 12

Page 47 of 76

6-13

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

ZAUM00**

1

1. V-belt case air filter element4. Apply oil of the recommended type

to the entire surface of the sponge

material, and then squeeze the ex-

cess oil out.NOTE:

The air filter element should be wet but

not dripping.

Recommended oil:

Engine oil

5. Insert the element into the air filter

case.

6. Install the filter element holder by

installing the screw.

EAU21300

Adjusting the carburetorThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, all carbu-

retor adjustments should be left to a

Yamaha dealer, who has the necessary

professional knowledge and experience. 7. Install the V-belt air filter case cover

by installing the screws.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 13

Page 48 of 76

6-14

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU21370

Adjusting the throttle cable

free playThe throttle cable free play should mea-

sure 3~5 mm (0.12~0.20 in) at the

throttle grip. Periodically check the

throttle cable free play and, if necessary,

adjust it as follows.NOTE:

The engine idling speed must be cor-

rectly adjusted before checking and ad-

justing the throttle cable free play.1. Loosen the locknut.

2. To increase the throttle cable free

play, turn the adjusting nut in direc-

tion (a). To decrease the throttle

cable free play, turn the adjusting

nut in direction (b).

ZAUM00**

1

2

(a)

(b)

1. Locknut

1. Adjusting nut3. Tighten the locknut.

EAU21401

Valve clearanceThe valve clearance changes with use,

resulting in improper air-fuel mixture and/

or engine noise. To prevent this from

occurring, the valve clearance must be

adjusted by a Yamaha dealer at the in-

tervals specified in the periodic mainte-

nance and lubrication chart.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 14

Page 49 of 76

6-15

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU33600

TiresTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified tires.

Tire air pressure

The tire air pressure should be checked

and, if necessary, adjusted before each

ride.

EWA10500

w8 88 8

8The tire air pressure must be

checked and adjusted on cold

tires (i.e., when the temperature

of the tires equals the ambient

temperature).

8 88 8

8The tire air pressure must be

adjusted in accordance with the

riding speed and with the total

weight of rider, passenger, cargo,

and accessories approved for this

model.

Tire air pressure (measured on cold

tires):

0~90 kg (0~198 lb):

Front:

175 kPa (26 psi) (1.75 kgf/cm

2)

Rear:

200 kPa (29 psi) (2.0 kgf/cm2)

90~170 kg (198~419 lb) to maxi-

mum load:

Front:

200 kPa (29 psi) (2.0 kgf/cm2)

Rear:

225 kPa (33 psi) (2.25 kgf/cm2)

Maximum load*:

170 kg (374 lb)

* Total weight of rider, passenger,

cargo and accessories

EWA11200

wBecause loading has an enormous

impact on the handling, braking, per-

formance and safety characteristics

of your vehicle, you should keep the

following precautions in mind.

8 88 8

8NEVER OVERLOAD THE VE-

HICLE! Operation of an over-

loaded motorcycle may result in

tire damage, loss of control, orsevere injury. Make sure that the

total weight of rider, passenger,

cargo, and accessories does not

exceed the specified maximum

load for the vehicle.

8 88 8

8Do not carry along loosely

packed items, which can shift

during a ride.

Securely pack the heaviest items

close to the center of the vehicle

and distribute the weight evenly

on both sides.

8 88 8

8Adjust the tire air pressure with

regard to the load.

Check the tire condition and air

pressure before each ride.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 15

Page 50 of 76

6-16

1

2

3

4

5

6

7

8

9

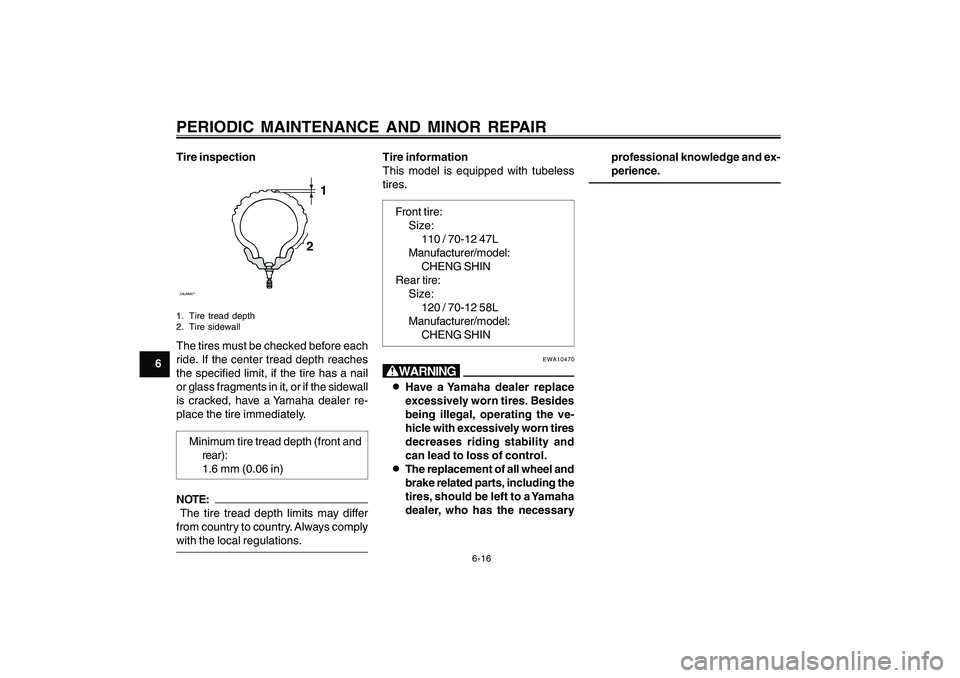

PERIODIC MAINTENANCE AND MINOR REPAIRTire inspectionZAUM00**

1

2

1. Tire tread depth

2. Tire sidewallThe tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the sidewall

is cracked, have a Yamaha dealer re-

place the tire immediately.

Minimum tire tread depth (front and

rear):

1.6 mm (0.06 in)NOTE:

The tire tread depth limits may differ

from country to country. Always comply

with the local regulations.

Tire information

This model is equipped with tubeless

tires.

Front tire:

Size:

110 / 70-12 47L

Manufacturer/model:

CHENG SHIN

Rear tire:

Size:

120 / 70-12 58L

Manufacturer/model:

CHENG SHIN

EWA10470

w8 88 8

8Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the ve-

hicle with excessively worn tires

decreases riding stability and

can lead to loss of control.

8 88 8

8The replacement of all wheel and

brake related parts, including the

tires, should be left to a Yamaha

dealer, who has the necessaryprofessional knowledge and ex-

perience.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 16