engine YAMAHA GRIZZLY 125 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: GRIZZLY 125, Model: YAMAHA GRIZZLY 125 2005Pages: 362, PDF Size: 5.52 MB

Page 260 of 362

8-31

EBU14840

Engine air filter element and V-belt case air

filter element cleaning

Both air filter elements should be cleaned at the

specified intervals in the periodic maintenance

chart.

Engine air filter element

NOTE:

There is a check hose at the bottom of the air fil-

ter case. If dust or water collects in this hose,

empty the hose and clean the air filter element

and air filter case.

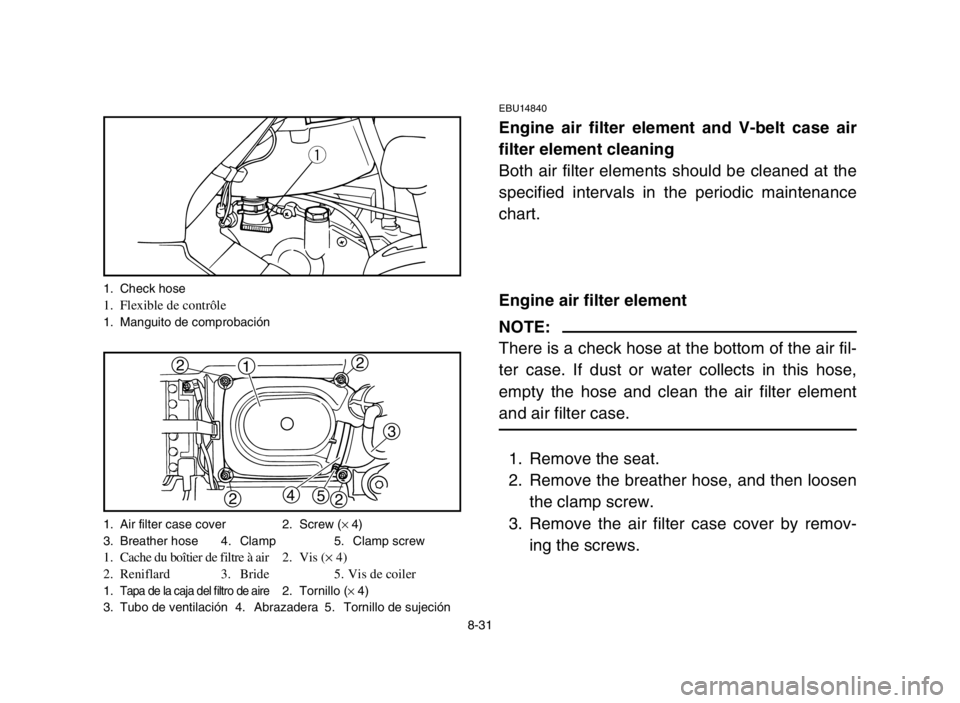

1. Remove the seat.

2. Remove the breather hose, and then loosen

the clamp screw.

3. Remove the air filter case cover by remov-

ing the screws.

q

1

3

4

5

2

2

2

2

1. Check hose1. Flexible de contrôle1. Manguito de comprobación

1. Air filter case cover 2. Screw (

× 4)

3. Breather hose 4. Clamp 5. Clamp screw

1. Cache du boîtier de filtre à air 2.Vis (× 4)

2. Reniflard 3. Bride 5. Vis de coiler

1.Tapa de la caja del filtro de aire2. Tornillo (× 4)

3. Tubo de ventilación 4. Abrazadera 5. Tornillo de sujeción

1C5-9-61-08 9/4/04 9:30 AM Page 8-32

Page 262 of 362

8-33

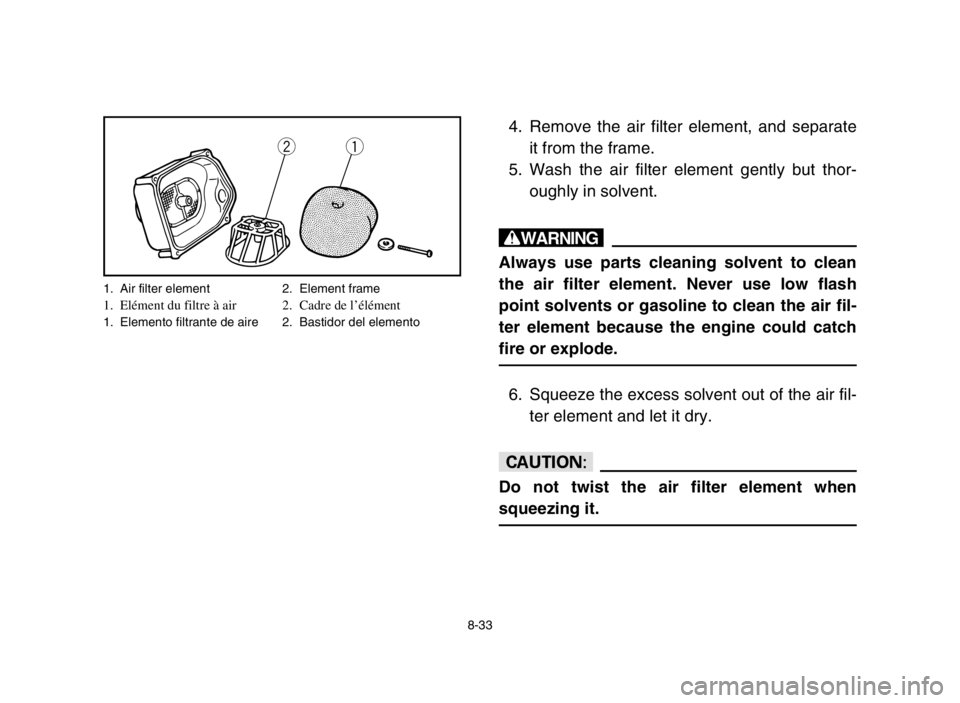

4. Remove the air filter element, and separate

it from the frame.

5. Wash the air filter element gently but thor-

oughly in solvent.

w

Always use parts cleaning solvent to clean

the air filter element. Never use low flash

point solvents or gasoline to clean the air fil-

ter element because the engine could catch

fire or explode.

6. Squeeze the excess solvent out of the air fil-

ter element and let it dry.

cC

Do not twist the air filter element when

squeezing it.

qw

1. Air filter element 2. Element frame1. Elément du filtre à air 2. Cadre de l’élément1. Elemento filtrante de aire 2. Bastidor del elemento

1C5-9-61-08 9/4/04 9:30 AM Page 8-34

Page 266 of 362

8-37

NOTE:

The air filter element should be cleaned every

20-40 hours. It should be cleaned and lubricated

more often if the machine is operated in

extremely dusty areas. Each time air filter ele-

ment maintenance is performed, check the air

inlet to the air filter case for obstructions. Check

the air filter case rubber joint to the carburetor

and manifold fittings for an airtight seal. Tighten

all fittings securely to avoid the possibility of

unfiltered air entering the engine.

cC

Never operate the engine with the air filter

element removed. This will allow unfiltered

air to enter, causing rapid engine wear and

possible engine damage. Additionally, opera-

tion without the air filter element will affect

carburetor jetting with subsequent poor per-

formance and possible engine overheating.

1C5-9-61-08 9/4/04 9:30 AM Page 8-38

Page 272 of 362

8-43

EBU13020

Idle speed adjustment

NOTE:

A diagnostic tachometer must be used for this

procedure.

1. Start the engine and warm it up for a few

minutes at approximately 1,000 to 2,000

r/min. Occasionally rev the engine to 4,000

to 5,000 r/min. The engine is warm when it

quickly responds to the throttle.

2. Connect the tachometer to the spark plug

lead, and then set the idle to the specified

idling speed by adjusting the throttle stop

screw. Turn the screw in direction ato

increase the engine speed, and in direction

bto decrease the engine speed.

ab

q

1. Throttle stop screw1. Vis de butée de papillon1. Tornillo tope del acelerador

Specified idle speed:

1,650–1,750 r/min

1C5-9-61-08 9/4/04 9:30 AM Page 8-44

Page 274 of 362

8-45

EBU00303

Valve clearance adjustment

The correct valve clearance changes with use,

resulting in improper fuel/air supply or engine

noise. To prevent this, the valve clearance must

be adjusted regularly. This adjustment however,

should be left to a professional Yamaha service

technician.

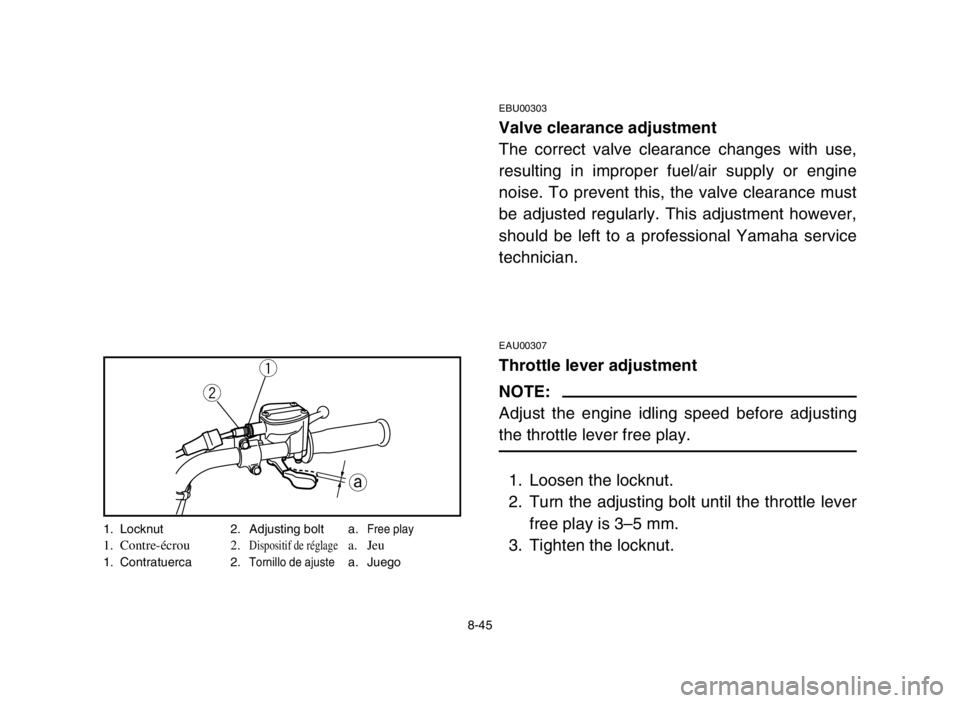

EAU00307

Throttle lever adjustment

NOTE:

Adjust the engine idling speed before adjusting

the throttle lever free play.

1. Loosen the locknut.

2. Turn the adjusting bolt until the throttle lever

free play is 3–5 mm.

3. Tighten the locknut.a q

w

1. Locknut 2. Adjusting bolt a.Free play1. Contre-écrou 2.Dispositif de réglagea. Jeu 1. Contratuerca 2.Tornillo de ajustea. Juego

1C5-9-61-08 9/4/04 9:30 AM Page 8-46

Page 292 of 362

8-63

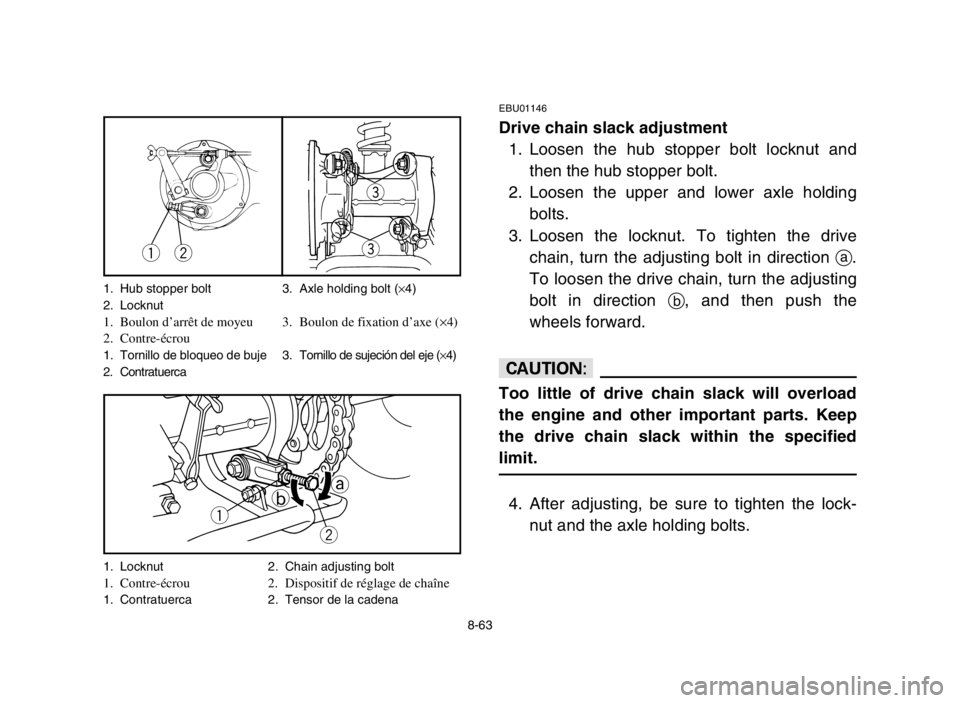

EBU01146

Drive chain slack adjustment

1. Loosen the hub stopper bolt locknut and

then the hub stopper bolt.

2. Loosen the upper and lower axle holding

bolts.

3. Loosen the locknut. To tighten the drive

chain, turn the adjusting bolt in direction a.

To loosen the drive chain, turn the adjusting

bolt in direction b, and then push the

wheels forward.

cC

Too little of drive chain slack will overload

the engine and other important parts. Keep

the drive chain slack within the specified

limit.

4. After adjusting, be sure to tighten the lock-

nut and the axle holding bolts.

wq

e

e

q

wa

b

1. Hub stopper bolt 3. Axle holding bolt (×4)

2. Locknut

1. Boulon d’arrêt de moyeu 3. Boulon de fixation d’axe (×4)

2. Contre-écrou

1. Tornillo de bloqueo de buje 3.Tornillo de sujeción del eje (×4)

2. Contratuerca

1. Locknut 2. Chain adjusting bolt

1. Contre-écrou 2. Dispositif de réglage de chaîne

1. Contratuerca 2. Tensor de la cadena

1C5-9-61-08 9/4/04 9:30 AM Page 8-64

Page 298 of 362

8-69

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a

special O-ring chain lubricant.

cC

Do not use engine oil or any other lubricants

for the drive chain, as they may contain sub-

stances that could damage the O-rings.

EBU00355

Draining the V-belt compartment

If water leaks into the V-belt compartment such

as when the machine is driven in water, remove

the drain screw on the bottom of compartment

and drain the water. Be sure to drive slowly until

the V-belt becomes dry. If slipping is noticed,

ask a Yamaha dealer to inspect.

q

q

1. O-ring1. Joint toriques1. Junta tóricas

1. Drain screw

1. Vis de vidange1. Tornillo de drenaje

1C5-9-61-08 9/4/04 9:30 AM Page 8-70

Page 300 of 362

8-71

EBU00570

Cable inspection and lubrication

w

Inspect cables frequently and replace if dam-

aged. Corrosion can result when the outer

covering of control cables becomes dam-

aged. Cables can also become frayed or

kinked. Operation of controls could be

restricted, which could cause an accident or

injury.

Lubricate the inner cables and the cable ends. If

the cables do not operate smoothly, ask a

Yamaha dealer to replace them.

Recommended lubricant:

Engine oil

1C5-9-61-08 9/4/04 9:30 AM Page 8-72

Page 328 of 362

8-99

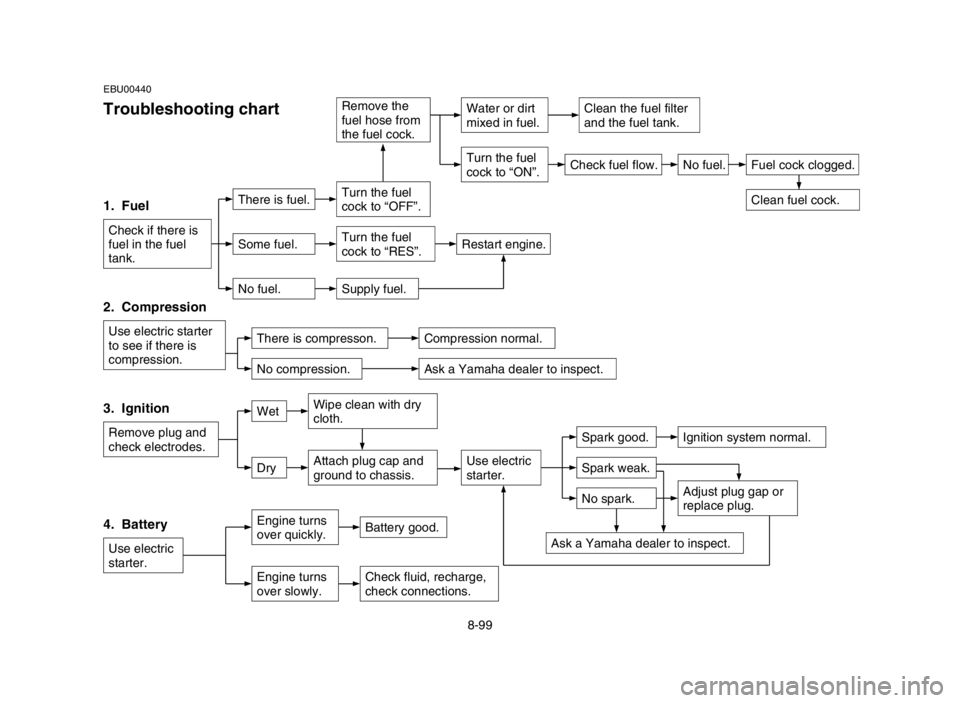

EBU00440

Troubleshooting chart

1. Fuel

Check if there is

fuel in the fuel

tank.

2. Compression

Use electric starter

to see if there is

compression.

3. Ignition

Remove plug and

check electrodes.

WetWipe clean with dry

cloth.

DryAttach plug cap and

ground to chassis.Use electric

starter.Spark weak.

Spark good.Ignition system normal.

No spark.

Ask a Yamaha dealer to inspect.

Adjust plug gap or

replace plug.

There is compresson.Compression normal.

Ask a Yamaha dealer to inspect.No compression.

There is fuel.Turn the fuel

cock to “OFF”.

Remove the

fuel hose from

the fuel cock.

Some fuel.Turn the fuel

cock to “RES”.Restart engine.

No fuel.Supply fuel.

4. Battery

Use electric

starter.

Engine turns

over quickly.Battery good.

Engine turns

over slowly.Check fluid, recharge,

check connections.

Check fuel flow.

Water or dirt

mixed in fuel.

Turn the fuel

cock to “ON”.No fuel.Fuel cock clogged.

Clean the fuel filter

and the fuel tank.

Clean fuel cock.

1C5-9-61-08 9/4/04 9:30 AM Page 8-100

Page 332 of 362

9-1

EBU00418

CLEANING AND STORAGE

A. CLEANING

Frequent, thorough cleaning of your machine

will not only enhance its appearance but will

improve its general performance and extend the

useful life of many components.

1. Before cleaning the machine:

a. Block off the end of the exhaust pipe to

prevent water entry. A plastic bag and

strong rubber band may be used.

b. Make sure the spark plug and all filler

caps are properly installed.

2. If the engine case is excessively greasy,

apply degreaser with a paint brush. Do not

apply degreaser to the chain, sprockets or

wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose. Use only enough pressure to do

the job.

1C5-9-61-09~11 9/4/04 9:29 AM Page 2