torque YAMAHA GRIZZLY 125 2005 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: GRIZZLY 125, Model: YAMAHA GRIZZLY 125 2005Pages: 362, PDF Size: 5.52 MB

Page 102 of 362

5-15

EBU00498

Chain

Check the general condition of the chain and

check the chain slack before every ride.

Lubricate and adjust the chain as necessary.

(See pages 8-61–8-69 for details.)

EBU01083

Throttle lever

Check to see that the throttle lever operates cor-

rectly. It must open smoothly and spring back to

the idle position when released. Have a Yamaha

dealer repair as necessary for proper operation.

EBU01162

Fittings and fasteners

Always check the tightness of chassis fittings

and fasteners before a ride. Take the machine

to a Yamaha dealer or refer to the Service

Manual for correct tightening torque.

1C5-9-61-05 22/3/04 5:39 PM Page 16

Page 232 of 362

8-3

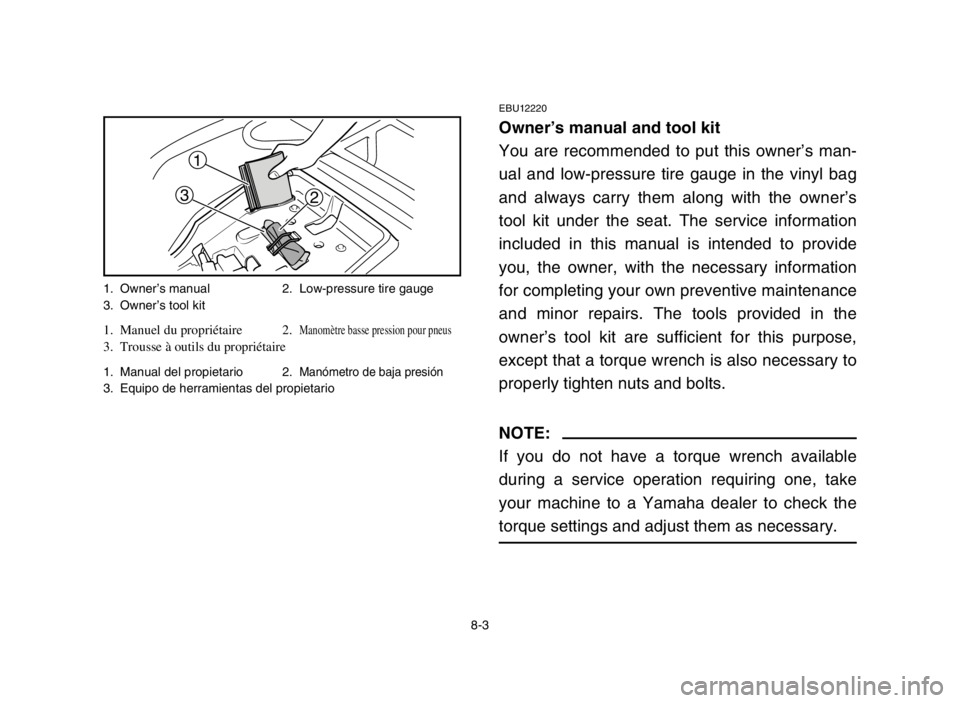

EBU12220

Owner’s manual and tool kit

You are recommended to put this owner’s man-

ual and low-pressure tire gauge in the vinyl bag

and always carry them along with the owner’s

tool kit under the seat. The service information

included in this manual is intended to provide

you, the owner, with the necessary information

for completing your own preventive maintenance

and minor repairs. The tools provided in the

owner’s tool kit are sufficient for this purpose,

except that a torque wrench is also necessary to

properly tighten nuts and bolts.

NOTE:

If you do not have a torque wrench available

during a service operation requiring one, take

your machine to a Yamaha dealer to check the

torque settings and adjust them as necessary.

1

3

2

1. Owner’s manual 2. Low-pressure tire gauge

3. Owner’s tool kit

1. Manuel du propriétaire 2.Manomètre basse pression pour pneus3. Trousse à outils du propriétaire

1. Manual del propietario 2.Manómetro de baja presión3. Equipo de herramientas del propietario

1C5-9-61-08 9/4/04 9:30 AM Page 8-4

Page 246 of 362

8-17

5. Clean the oil strainer with solvent.

6. Inspect the O-ring and replace it if dam-

aged.

7. Install the O-ring, oil strainer, compression

spring and drain bolt. Tighten the drain bolt

to specification.

cC

Before installing the drain bolt, be sure to

install the O-ring, compression spring and

oil strainer.

8. Fill the engine with oil and install the dip-

stick. Tightening torque:

Drain bolt:

32 Nm (3.2 m0kgf)

1C5-9-61-08 9/4/04 9:30 AM Page 8-18

Page 250 of 362

8-21

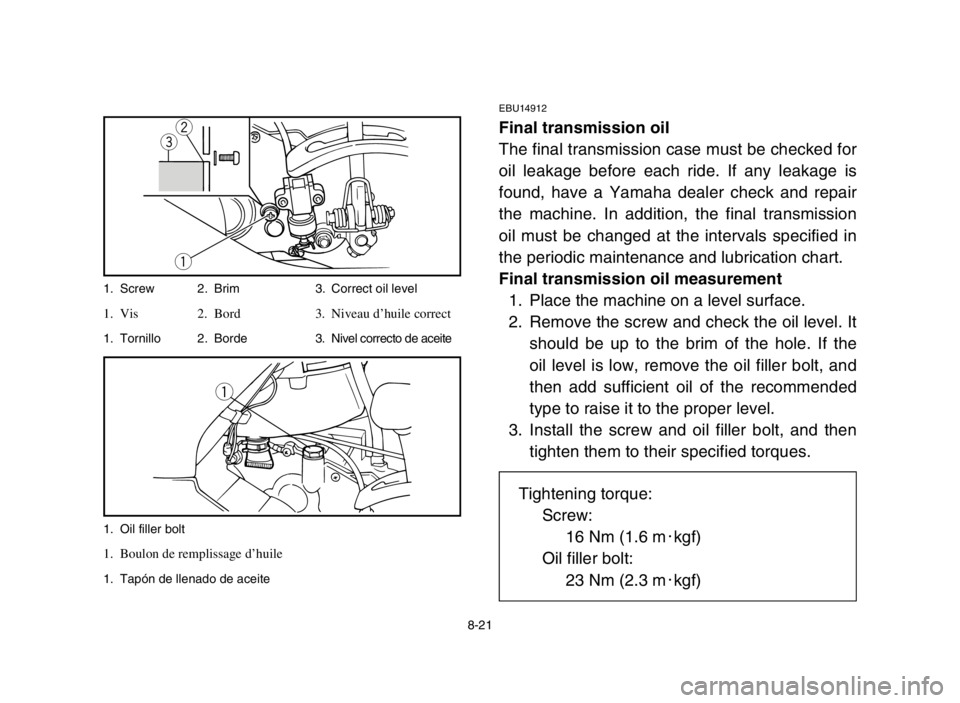

EBU14912

Final transmission oil

The final transmission case must be checked for

oil leakage before each ride. If any leakage is

found, have a Yamaha dealer check and repair

the machine. In addition, the final transmission

oil must be changed at the intervals specified in

the periodic maintenance and lubrication chart.

Final transmission oil measurement

1. Place the machine on a level surface.

2. Remove the screw and check the oil level. It

should be up to the brim of the hole. If the

oil level is low, remove the oil filler bolt, and

then add sufficient oil of the recommended

type to raise it to the proper level.

3. Install the screw and oil filler bolt, and then

tighten them to their specified torques.we

q

q

1. Screw 2. Brim 3. Correct oil level

1. Vis 2. Bord 3. Niveau d’huile correct

1. Tornillo 2. Borde 3. Nivel correcto de aceite

1. Oil filler bolt

1. Boulon de remplissage d’huile

1. Tapón de llenado de aceite

Tightening torque:

Screw:

16 Nm (1.6 m0kgf)

Oil filler bolt:

23 Nm (2.3 m0kgf)

1C5-9-61-08 9/4/04 9:30 AM Page 8-22

Page 252 of 362

8-23

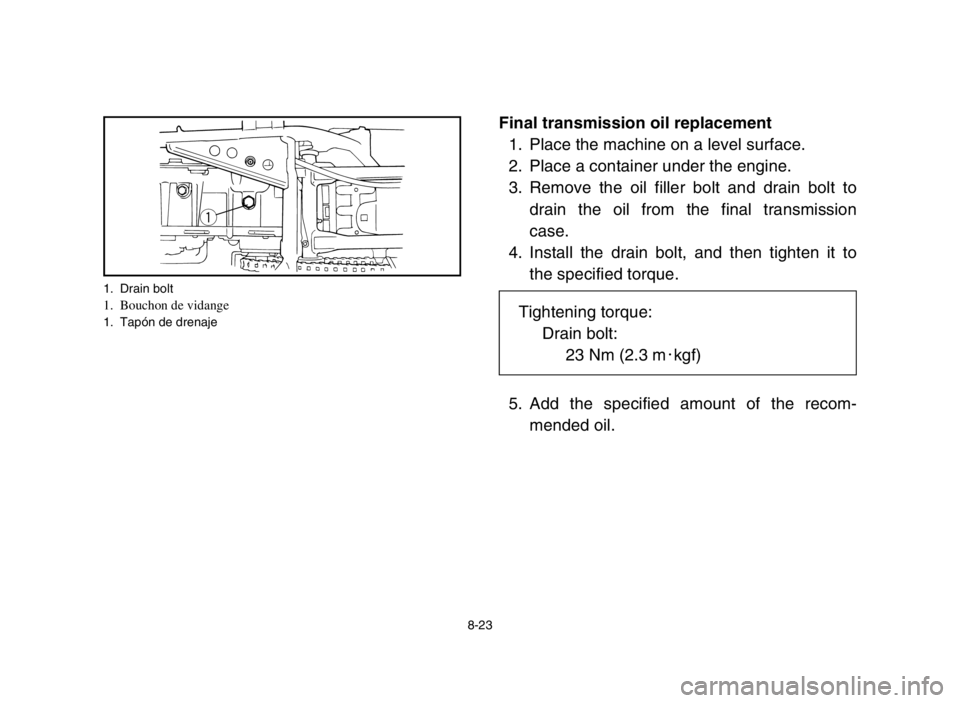

Final transmission oil replacement

1. Place the machine on a level surface.

2. Place a container under the engine.

3. Remove the oil filler bolt and drain bolt to

drain the oil from the final transmission

case.

4. Install the drain bolt, and then tighten it to

the specified torque.

5. Add the specified amount of the recom-

mended oil.

q

1. Drain bolt1. Bouchon de vidange1. Tapón de drenajeTightening torque:

Drain bolt:

23 Nm (2.3 m0kgf)

1C5-9-61-08 9/4/04 9:30 AM Page 8-24

Page 254 of 362

8-25

6. Install the oil filler bolt, and then tighten it to

the specified torque.

cC

8Make sure that no foreign material enters

the final transmission case.

8Make sure that no oil gets on the tires or

wheels.

Recommended oil:

See page 10-2.

Oil quantity:

0.6 L

1C5-9-61-08 9/4/04 9:30 AM Page 8-26

Page 258 of 362

8-29

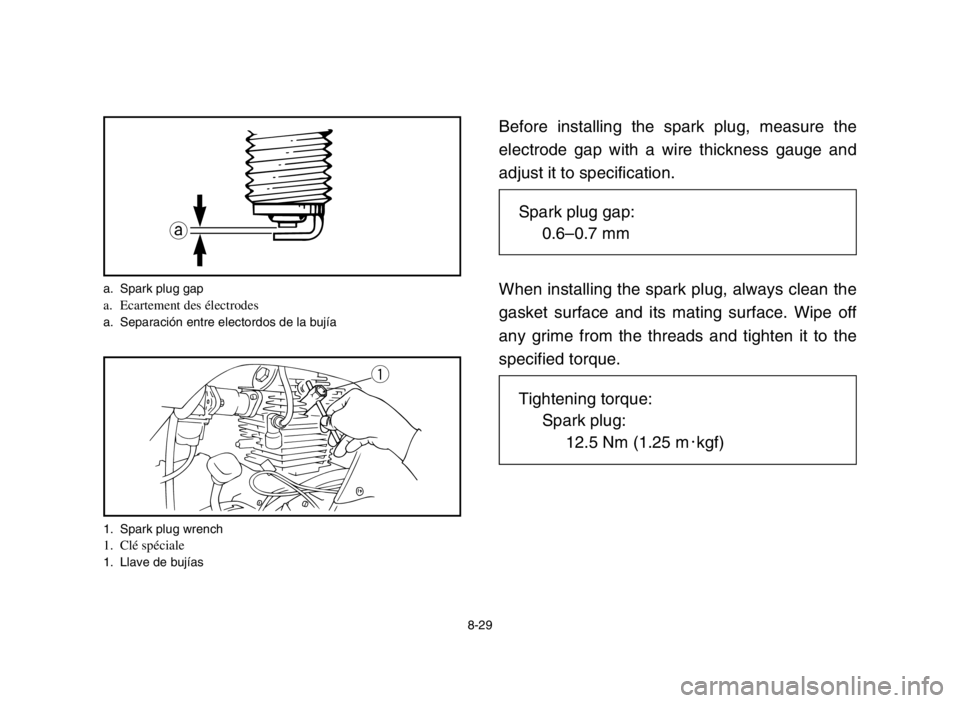

Before installing the spark plug, measure the

electrode gap with a wire thickness gauge and

adjust it to specification.

When installing the spark plug, always clean the

gasket surface and its mating surface. Wipe off

any grime from the threads and tighten it to the

specified torque.

a

q

a. Spark plug gapa. Ecartement des électrodesa. Separación entre electordos de la bujía

1. Spark plug wrench

1. Clé spéciale1. Llave de bujías

Spark plug gap:

0.6–0.7 mm

Tightening torque:

Spark plug:

12.5 Nm (1.25 m0kgf)

1C5-9-61-08 9/4/04 9:30 AM Page 8-30

Page 294 of 362

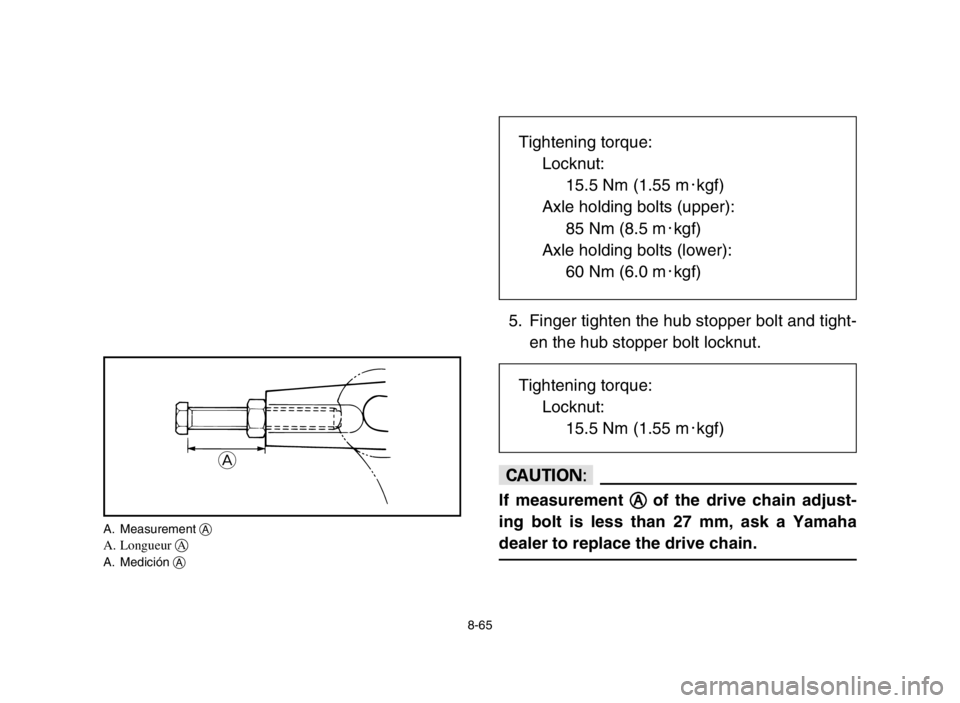

8-65

5. Finger tighten the hub stopper bolt and tight-

en the hub stopper bolt locknut.

cC

If measurement A A

of the drive chain adjust-

ing bolt is less than 27 mm, ask a Yamaha

dealer to replace the drive chain.

A

A. Measurement AA. Longueur AA. Medición A

Tightening torque:

Locknut:

15.5 Nm (1.55 m0kgf)

Tightening torque:

Locknut:

15.5 Nm (1.55 m0kgf)

Axle holding bolts (upper):

85 Nm (8.5 m0kgf)

Axle holding bolts (lower):

60 Nm (6.0 m0kgf)

1C5-9-61-08 9/4/04 9:30 AM Page 8-66

Page 304 of 362

8-75

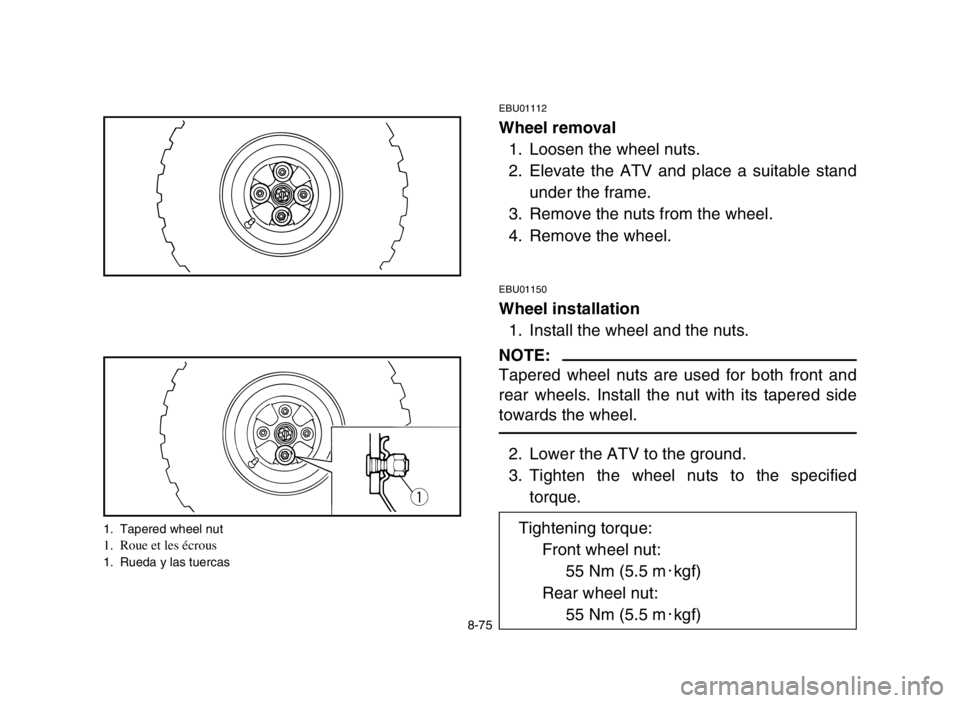

EBU01112

Wheel removal

1. Loosen the wheel nuts.

2. Elevate the ATV and place a suitable stand

under the frame.

3. Remove the nuts from the wheel.

4. Remove the wheel.

EBU01150

Wheel installation

1. Install the wheel and the nuts.

NOTE:

Tapered wheel nuts are used for both front and

rear wheels. Install the nut with its tapered side

towards the wheel.

2. Lower the ATV to the ground.

3. Tighten the wheel nuts to the specified

torque.

q

1. Tapered wheel nut1. Roue et les écrous1. Rueda y las tuercas

Tightening torque:

Front wheel nut:

55 Nm (5.5 m0kgf)

Rear wheel nut:

55 Nm (5.5 m0kgf)

1C5-9-61-08 9/4/04 9:30 AM Page 8-76

Page 358 of 362

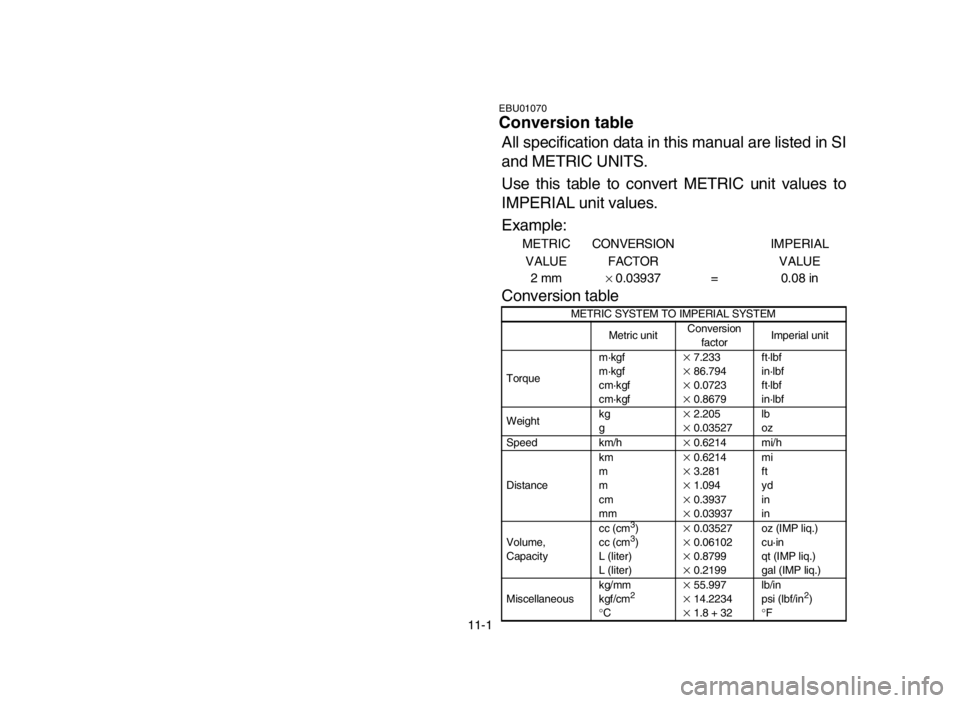

All specification data in this manual are listed in SI

and METRIC UNITS.

Use this table to convert METRIC unit values to

IMPERIAL unit values.

Example:

METRIC

VALUECONVERSION

FACTORIMPERIAL

VALUE

2 mm× 0.03937 = 0.08 in

Conversion tableMETRIC SYSTEM TO IMPERIAL SYSTEM

Metric unitConversion

factorImperial unit

Torquem·kgf

m·kgf

cm·kgf

cm·kgf

× 7.233× 86.794× 0.0723× 0.8679ft·lbf

in·lbf

ft·lbf

in·lbf

Weightkg

g× 2.205× 0.03527lb

oz

Speed km/h× 0.6214 mi/h

Distancekm

m

m

cm

mm× 0.6214× 3.281× 1.094× 0.3937× 0.03937mi

ft

yd

in

in

Volume,

Capacitycc (cm3)

cc (cm3)

L (liter)

L (liter)× 0.03527× 0.06102× 0.8799× 0.2199oz (IMP liq.)

cu·in

qt (IMP liq.)

gal (IMP liq.)

Miscellaneouskg/mm

kgf/cm

2

°C

× 55.997× 14.2234× 1.8 + 32 lb/in

psi (lbf/in

2)

°F

EBU01070Conversion table

11-1

1C5-9-61-09~11 9/4/04 9:29 AM Page 28