engine YAMAHA GRIZZLY 125 2013 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: GRIZZLY 125, Model: YAMAHA GRIZZLY 125 2013Pages: 134, PDF Size: 3.93 MB

Page 86 of 134

8-15

85. Pour the recommended type of oil in the trans-

mission oil filler hole until it flows out of the

check screw hole.

6. Tighten the oil check screw to the specified torque.

7. Check the oil filler bolt gasket for damage, and replace it if necessary. 8. Install the transmission oil filler bolt and its

gasket, and then tighten the bolt to the speci-

fied torque.

To change the transmission oil 1. Place the ATV on a level surface.

2. Start the engine, warm it up for several min- utes, and then turn it off.

3. Place an oil pan under the transmission to col- lect the used oil.

4. Remove the transmission oil filler bolt, the transmission oil drain bolt and their gasket to

drain the oil from the transmission case.

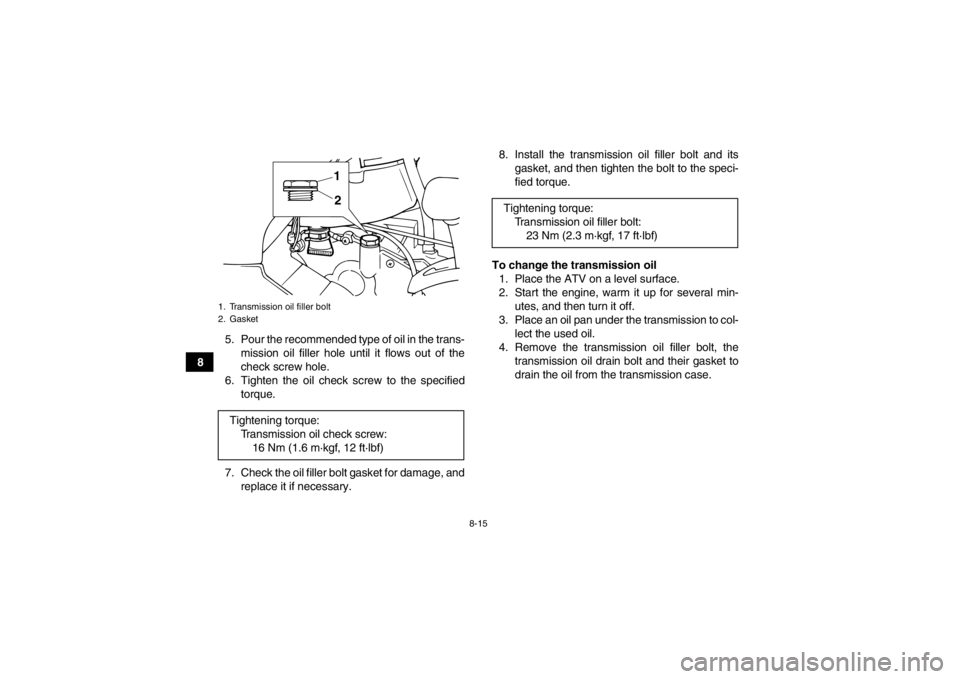

1. Transmission oil filler bolt

2. GasketTightening torque:Transmission oil check screw:16 Nm (1.6 m·kgf, 12 ft·lbf)

1

2

Tightening torque: Transmission oil filler bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

U1PY61E0.book Page 15 Wednesday, March 14, 2012 5:22 PM

Page 87 of 134

8-16

8

5. Install the drain bolt and its new gasket, and

then tighten the bolt to the specified torque.

6. Refill with the specified amount of the recom- mended transmission oil. NOTICE: Make

sure that no foreign material enters the

transmission case.

[ECB00791]

7. Check the oil filler bolt gasket for damage, and replace it if necessary.

8. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified torque.NOTICEECB01061Make sure that no oil gets on the tires or

wheels.9. Start the engine, and then let it idle for severalminutes while checking the transmission for

oil leakage. If oil is leaking, immediately turn

off the engine and check for the cause.

10. Turn the engine off, and then check the oil lev- el and correct it if necessary.

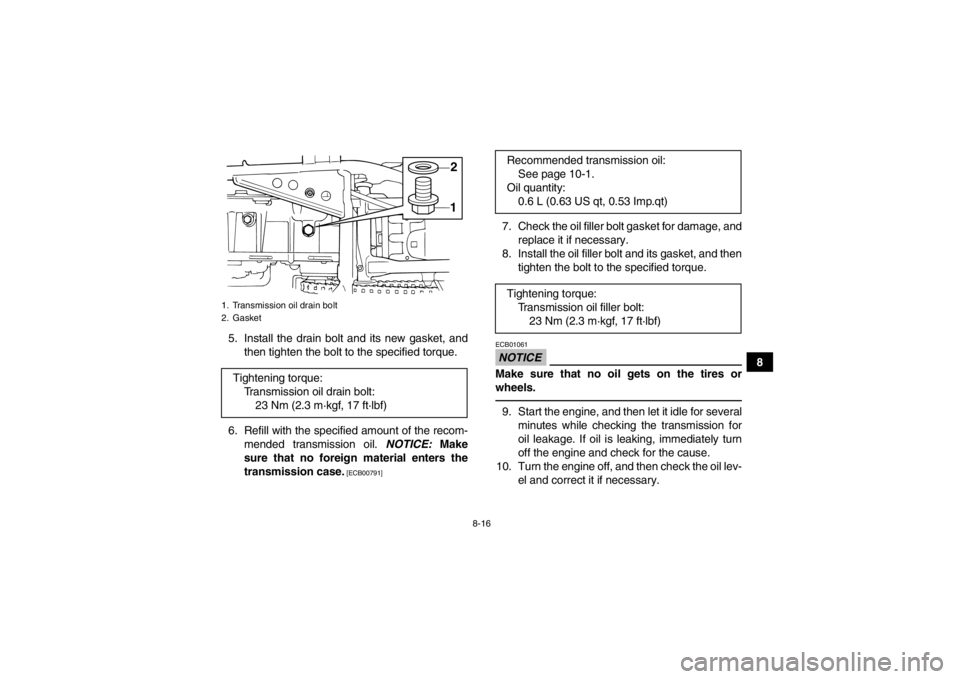

1. Transmission oil drain bolt

2. GasketTightening torque:Transmission oil drain bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

12

Recommended transmission oil: See page 10-1.

Oil quantity: 0.6 L (0.63 US qt, 0.53 Imp.qt)

Tightening torque: Transmission oil filler bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

U1PY61E0.book Page 16 Wednesday, March 14, 2012 5:22 PM

Page 88 of 134

8-17

8

EBU2384CCleaning the engine and V-belt case air

filter elements Both air filter elements should be cleaned at the

specified intervals in the periodic maintenance

chart.

Engine air filter elementTIPThere is a check hose at the bottom of the air filter

case. If dust or water collects in this hose, empty

the hose and clean the air filter element and air fil-

ter case.

1. Place the ATV on a level surface.

2. Remove the seat. (See page 4-10.)

3. Remove the breather hose by pulling it out,

and then loosen the air filter joint screw.

4. Remove the air filter case cover by removing its screws, then disconnecting the air filter

case cover from the air filter joint.

1. Air filter case check hose

1

1. Breather hose

2. Air filter joint

3. Air filter joint screw

1

3

2

U1PY61E0.book Page 17 Wednesday, March 14, 2012 5:22 PM

Page 89 of 134

8-18

8

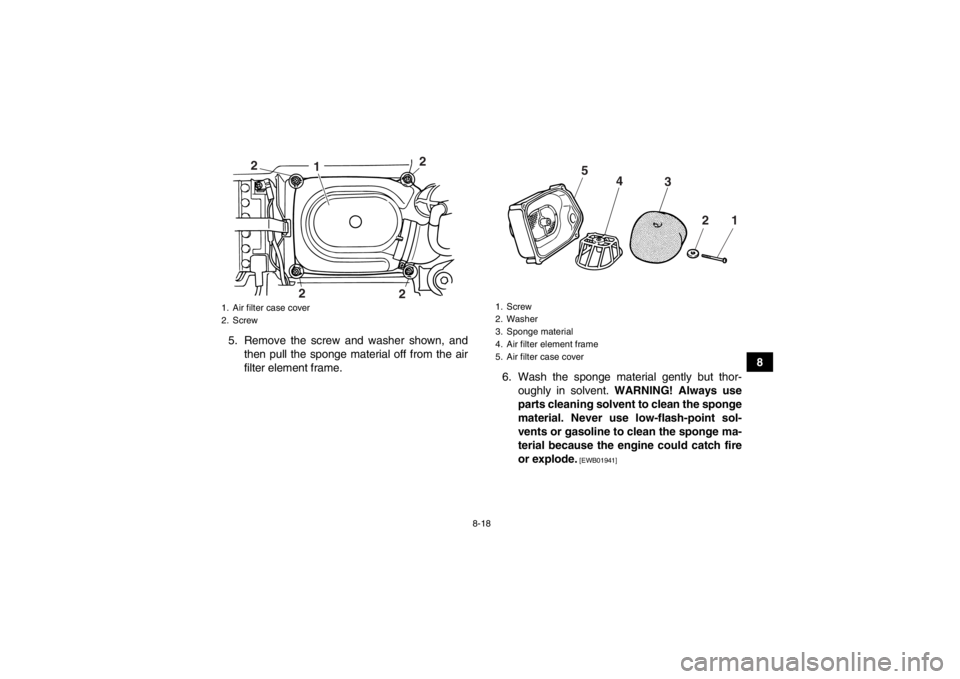

5. Remove the screw and washer shown, and

then pull the sponge material off from the air

filter element frame. 6. Wash the sponge material gently but thor-

oughly in solvent. WARNING! Always use

parts cleaning solvent to clean the sponge

material. Never use low-flash-point sol-

vents or gasoline to clean the sponge ma-

terial because the engine could catch fire

or explode.

[EWB01941]

1. Air filter case cover

2. Screw

1

2 2

2 2

1. Screw

2. Washer

3. Sponge material

4. Air filter element frame

5. Air filter case cover

3

4

21

5

U1PY61E0.book Page 18 Wednesday, March 14, 2012 5:22 PM

Page 91 of 134

8-20

8

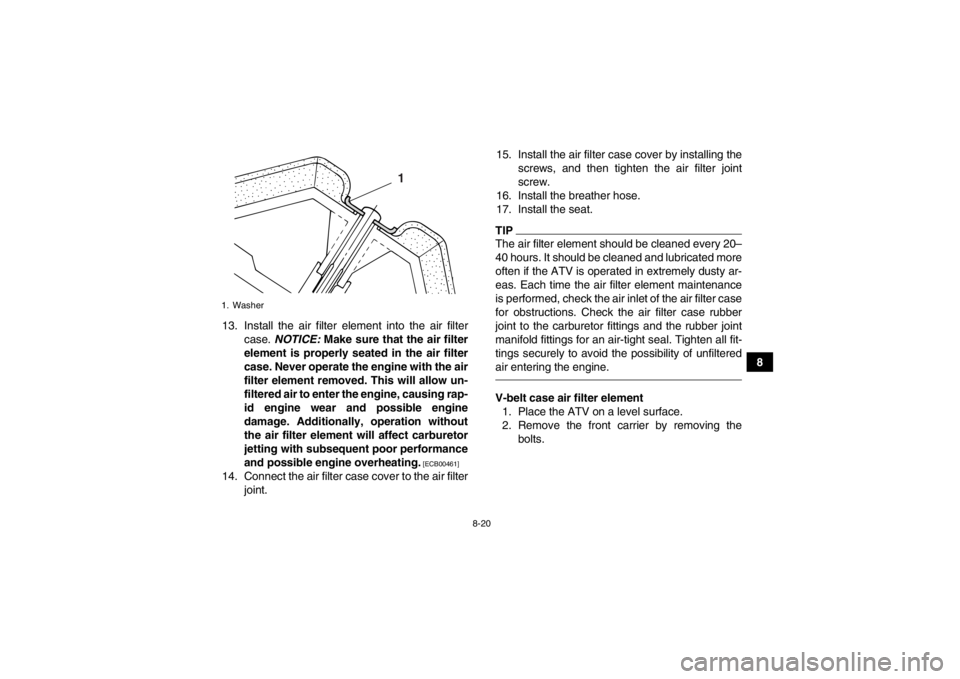

13. Install the air filter element into the air filter

case. NOTICE: Make sure that the air filter

element is properly seated in the air filter

case. Never operate the engine with the air

filter element removed. This will allow un-

filtered air to enter the engine, causing rap-

id engine wear and possible engine

damage. Additionally, operation without

the air filter element will affect carburetor

jetting with subsequent poor performance

and possible engine overheating.

[ECB00461]

14. Connect the air filter case cover to the air filter joint. 15. Install the air filter case cover by installing the

screws, and then tighten the air filter joint

screw.

16. Install the breather hose.

17. Install the seat.

TIPThe air filter element should be cleaned every 20–

40 hours. It should be cleaned and lubricated more

often if the ATV is operated in extremely dusty ar-

eas. Each time the air filter element maintenance

is performed, check the air inlet of the air filter case

for obstructions. Check the air filter case rubber

joint to the carburetor fittings and the rubber joint

manifold fittings for an air-tight seal. Tighten all fit-

tings securely to avoid the possibility of unfiltered

air entering the engine.V-belt case air filter element 1. Place the ATV on a level surface.

2. Remove the front carrier by removing the bolts.

1. Washer

1

U1PY61E0.book Page 20 Wednesday, March 14, 2012 5:22 PM

Page 95 of 134

8-24

8

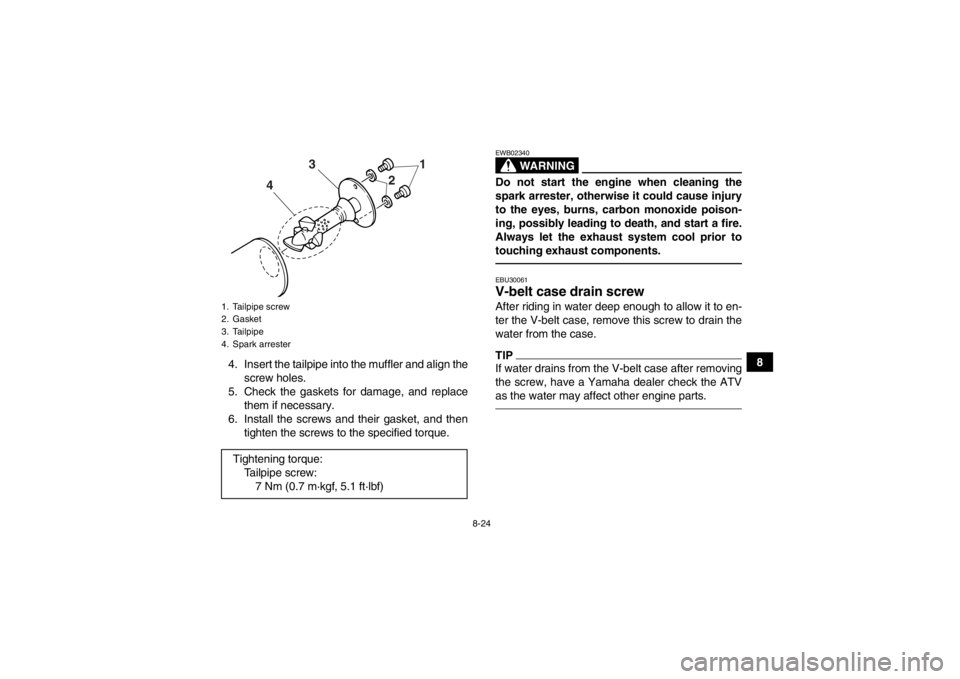

4. Insert the tailpipe into the muffler and align the

screw holes.

5. Check the gaskets for damage, and replace them if necessary.

6. Install the screws and their gasket, and then tighten the screws to the specified torque.

WARNING

EWB02340Do not start the engine when cleaning the

spark arrester, otherwise it could cause injury

to the eyes, burns, carbon monoxide poison-

ing, possibly leading to death, and start a fire.

Always let the exhaust system cool prior to

touching exhaust components.EBU30061V-belt case drain screw After riding in water deep enough to allow it to en-

ter the V-belt case, remove this screw to drain the

water from the case.TIPIf water drains from the V-belt case after removing

the screw, have a Yamaha dealer check the ATV

as the water may affect other engine parts.

1. Tailpipe screw

2. Gasket

3. Tailpipe

4. Spark arresterTightening torque:Tailpipe screw:7 Nm (0.7 m·kgf, 5.1 ft·lbf)

3

4 21

U1PY61E0.book Page 24 Wednesday, March 14, 2012 5:22 PM

Page 96 of 134

8-25

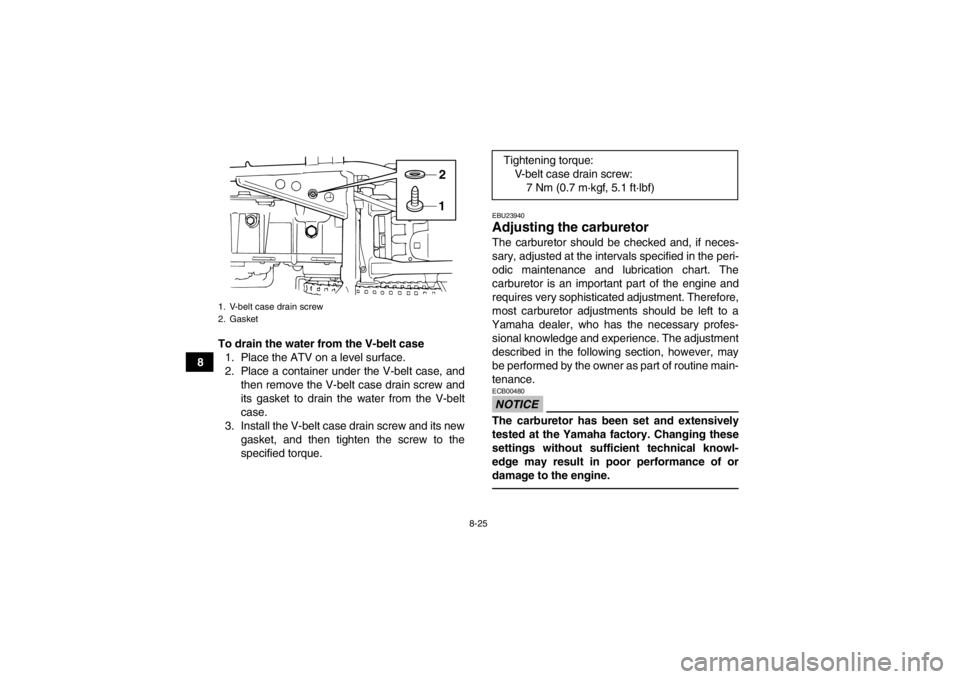

8To drain the water from the V-belt case

1. Place the ATV on a level surface.

2. Place a container under the V-belt case, and then remove the V-belt case drain screw and

its gasket to drain the water from the V-belt

case.

3. Install the V-belt case drain screw and its new gasket, and then tighten the screw to the

specified torque.

EBU23940Adjusting the carburetor The carburetor should be checked and, if neces-

sary, adjusted at the intervals specified in the peri-

odic maintenance and lubrication chart. The

carburetor is an important part of the engine and

requires very sophisticated adjustment. Therefore,

most carburetor adjustments should be left to a

Yamaha dealer, who has the necessary profes- sional knowledge and experience. The adjustment

described in the following section, however, may

be performed by the owner as part of routine main-

tenance.NOTICEECB00480The carburetor has been set and extensively

tested at the Yamaha factory. Changing these

settings without sufficient technical knowl-

edge may result in poor performance of or

damage to the engine.

1. V-belt case drain screw

2. Gasket

12

Tightening torque: V-belt case drain screw:7 Nm (0.7 m·kgf, 5.1 ft·lbf)

U1PY61E0.book Page 25 Wednesday, March 14, 2012 5:22 PM

Page 97 of 134

8-26

8

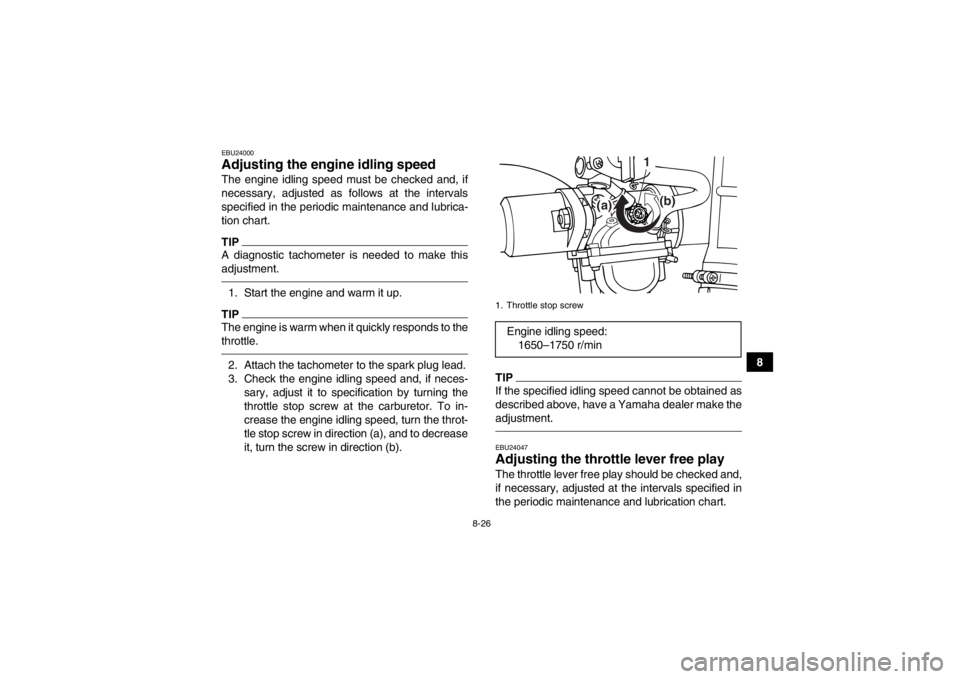

EBU24000Adjusting the engine idling speed The engine idling speed must be checked and, if

necessary, adjusted as follows at the intervals

specified in the periodic maintenance and lubrica-

tion chart.TIPA diagnostic tachometer is needed to make this

adjustment.1. Start the engine and warm it up.TIPThe engine is warm when it quickly responds to the

throttle.2. Attach the tachometer to the spark plug lead.

3. Check the engine idling speed and, if neces-sary, adjust it to specification by turning the

throttle stop screw at the carburetor. To in-

crease the engine idling speed, turn the throt-

tle stop screw in direction (a), and to decrease

it, turn the screw in direction (b).

TIPIf the specified idling speed cannot be obtained as

described above, have a Yamaha dealer make the

adjustment.EBU24047Adjusting the throttle lever free play The throttle lever free play should be checked and,

if necessary, adjusted at the intervals specified in

the periodic maintenance and lubrication chart.1. Throttle stop screwEngine idling speed:1650–1750 r/min

(a) (b)

1

U1PY61E0.book Page 26 Wednesday, March 14, 2012 5:22 PM

Page 98 of 134

8-27

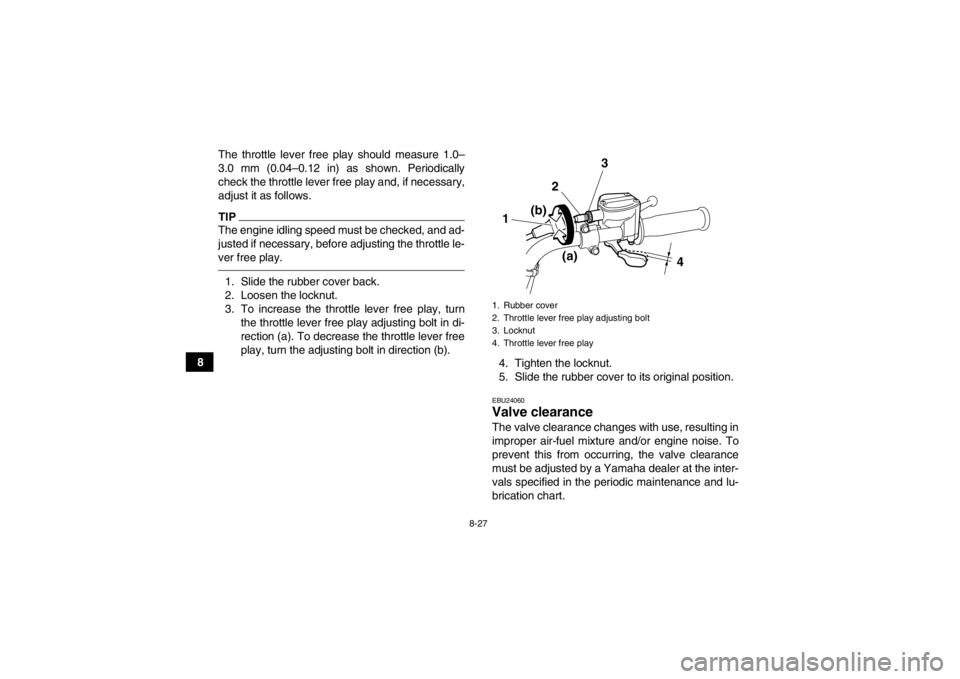

8The throttle lever free play should measure 1.0–

3.0 mm (0.04–0.12 in) as shown. Periodically

check the throttle lever free play and, if necessary,

adjust it as follows.

TIPThe engine idling speed must be checked, and ad-

justed if necessary, before adjusting the throttle le-

ver free play.1. Slide the rubber cover back.

2. Loosen the locknut.

3. To increase the throttle lever free play, turn

the throttle lever free play adjusting bolt in di-

rection (a). To decrease the throttle lever free

play, turn the adjusting bolt in direction (b). 4. Tighten the locknut.

5. Slide the rubber cover to its original position.

EBU24060Valve clearance The valve clearance changes with use, resulting in

improper air-fuel mixture and/or engine noise. To

prevent this from occurring, the valve clearance

must be adjusted by a Yamaha dealer at the inter-

vals specified in the periodic maintenance and lu-

brication chart.1. Rubber cover

2. Throttle lever free play adjusting bolt

3. Locknut

4. Throttle lever free play

4

3

2

1

(a)

(b)

U1PY61E0.book Page 27 Wednesday, March 14, 2012 5:22 PM

Page 107 of 134

8-36

8

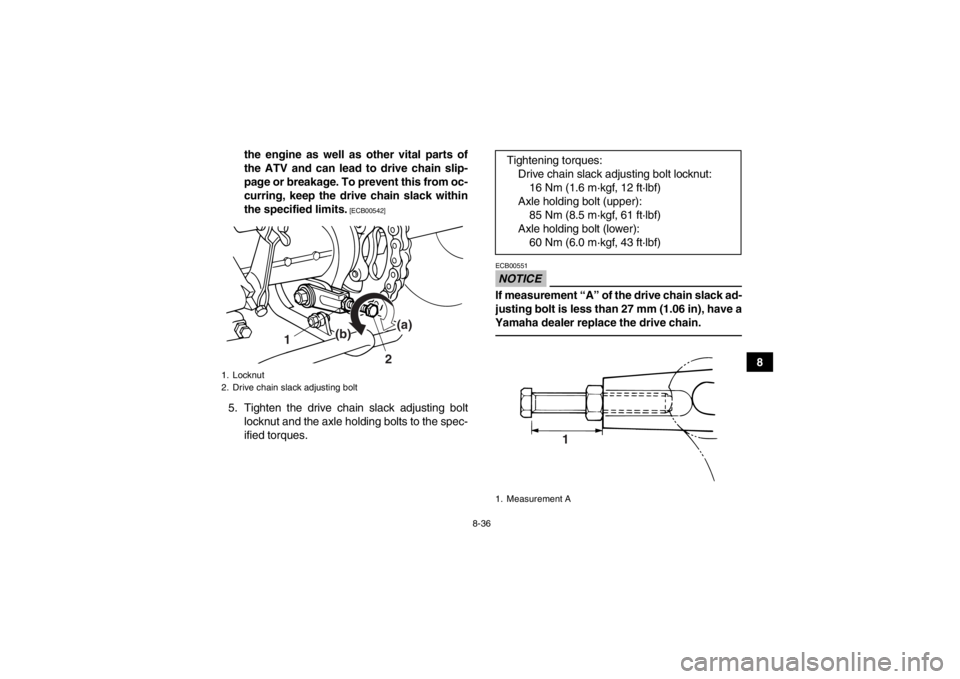

the engine as well as other vital parts of

the ATV and can lead to drive chain slip-

page or breakage. To prevent this from oc-

curring, keep the drive chain slack within

the specified limits.

[ECB00542]

5. Tighten the drive chain slack adjusting bolt

locknut and the axle holding bolts to the spec-

ified torques.

NOTICEECB00551If measurement “A” of the drive chain slack ad-

justing bolt is less than 27 mm (1.06 in), have a

Yamaha dealer replace the drive chain.

1. Locknut

2. Drive chain slack adjusting bolt

1

2

(a)

(b)

Tightening torques:

Drive chain slack adjusting bolt locknut:16 Nm (1.6 m·kgf, 12 ft·lbf)

Axle holding bolt (upper): 85 Nm (8.5 m·kgf, 61 ft·lbf)

Axle holding bolt (lower): 60 Nm (6.0 m·kgf, 43 ft·lbf)1. Measurement A

1

U1PY61E0.book Page 36 Wednesday, March 14, 2012 5:22 PM