engine YAMAHA GRIZZLY 125 2013 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: GRIZZLY 125, Model: YAMAHA GRIZZLY 125 2013Pages: 134, PDF Size: 3.93 MB

Page 108 of 134

8-37

86. Tighten the hub stopper bolt and hub stopper

bolt locknut to the specified torques.

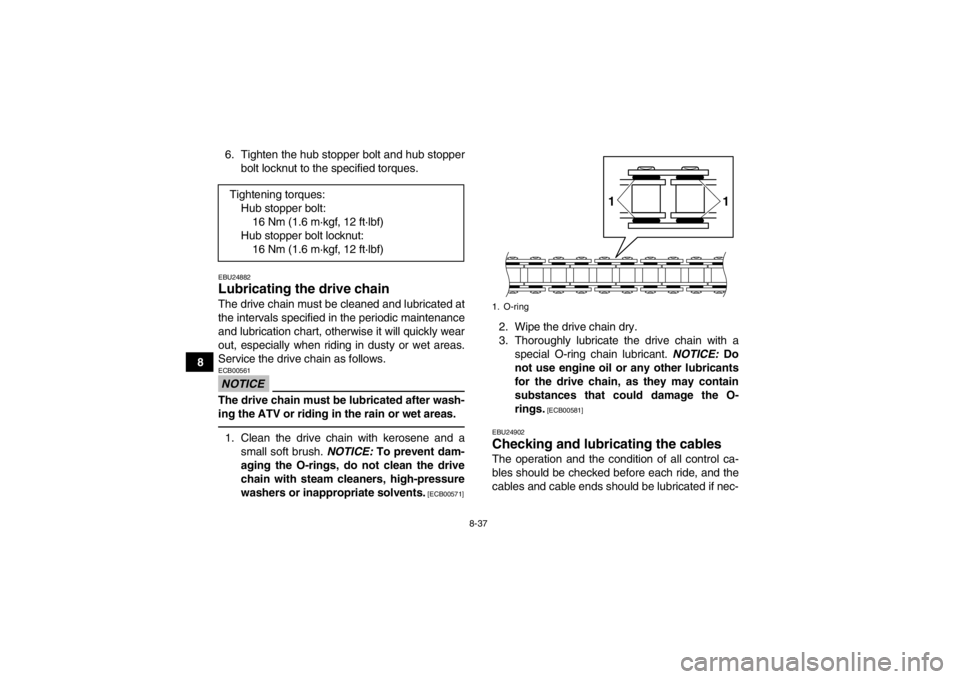

EBU24882Lubricating the drive chain The drive chain must be cleaned and lubricated at

the intervals specified in the periodic maintenance

and lubrication chart, otherwise it will quickly wear

out, especially when riding in dusty or wet areas.

Service the drive chain as follows.NOTICEECB00561The drive chain must be lubricated after wash-

ing the ATV or riding in the rain or wet areas.1. Clean the drive chain with kerosene and asmall soft brush. NOTICE: To prevent dam-

aging the O-rings, do not clean the drive

chain with steam cleaners, high-pressure

washers or inappropriate solvents.

[ECB00571]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain lubricant. NOTICE: Do

not use engine oil or any other lubricants

for the drive chain, as they may contain

substances that could damage the O-

rings.

[ECB00581]

EBU24902

Checking and lubric ating the cables The operation and the condition of all control ca-

bles should be checked before each ride, and the

cables and cable ends should be lubricated if nec-

Tightening torques:

Hub stopper bolt:16 Nm (1.6 m·kgf, 12 ft·lbf)

Hub stopper bolt locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)1. O-ring

1

1

U1PY61E0.book Page 37 Wednesday, March 14, 2012 5:22 PM

Page 109 of 134

8-38

8

essary. If a cable is damaged or does not move

smoothly, have a Yamaha dealer check or replace

it.

WARNING

EWB02581●Inspect cables frequently and replace if dam-

aged. Corrosion can result when the cable

sheaths become damaged, and cables can

also become frayed or kinked, which could

restrict the operation of controls and lead to

an accident or injury.●Always make sure all control cables work

smoothly before you begin riding in cold

weather. If the control cables are frozen or do

not work smoothly, you could be unable to

control the ATV, which could lead to an acci-

dent or collision.

EBU28702Checking and lubric

ating the front and

rear brake levers The operation of the front and rear brake levers

should be checked before each ride, and the lever

pivots should be lubricated if necessary.

Front brake lever

Recommended lubricant:

Yamaha Chain and Cable Lube or engine oilRecommended lubricant: Lithium-soap-based grease

U1PY61E0.book Page 38 Wednesday, March 14, 2012 5:22 PM

Page 122 of 134

8-51

8

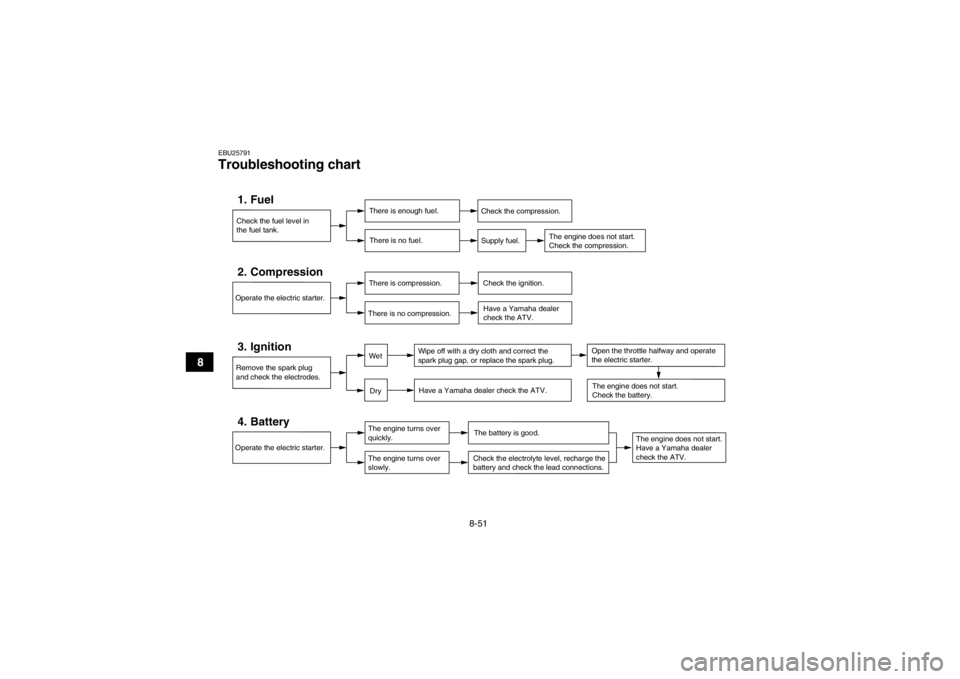

EBU25791Troubleshooting chart

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.There is no fuel.

Check the compression.

Supply fuel.

The engine does not start.

Check the compression.

Operate the electric starter.2. Compression

There is compression.

There is no compression.

Check the ignition. Have a Yamaha dealer

check the ATV.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the ATV.

The engine does not start.

Have a Yamaha dealer

check the ATV.

The engine does not start.

Check the battery.

Operate the electric starter.4. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check the electrolyte level, recharge the

battery and check the lead connections.

DryWet

Open the throttle halfway and operate

the electric starter.

U1PY61E0.book Page 51 Wednesday, March 14, 2012 5:22 PM

Page 123 of 134

9-1

9

EBU25860

CLEANING AND STORAGE

EBU25902Cleaning Frequent, thorough cleaning of your ATV will not

only enhance its appearance but will improve its

general performance and extend the useful life of

many components.1. Before cleaning the ATV: a. Block off the end of the exhaust pipe toprevent water entry. A plastic bag and

strong rubber band may be used.

b. Make sure the spark plug and all filler caps are properly installed.

2. If the engine case is excessively greasy, apply degreaser with a paint brush. Do not apply de-

greaser to the chain, sprockets or wheel ax-

les.

3. Rinse the dirt and degreaser off with a garden hose. Use only enough pressure to do the job.

WARNING! Wet brakes may have reduced stopping ability, increasing the chance of

an accident. Test the brakes after washing.

Apply the brakes several times at slow

speeds to let friction dry out the linings.

[EWB02311]

NOTICE: Excessive water pressure may cause water seepage and deteriora-

tion of wheel bearings, brakes, transmis-

sion seals and electrical devices. Many

expensive repair bills have resulted from

improper high-pressure detergent applica-

tions such as those available in coin-oper-

ated car washers.

[ECB00711]

4. Once most of the dirt has been hosed off,

wash all surfaces with warm water and mild,

detergent-type soap. An old toothbrush or bot-

tle brush is handy for hard-to-reach places.

5. Rinse the ATV off immediately with clean wa- ter and dry all surfaces with a chamois, clean

towel or soft absorbing cloth.

6. Dry the chain and lubricate it to prevent it from rusting.

7. Clean the seat with a vinyl upholstery cleaner to keep the cover pliable and glossy.

8. Automotive type wax may be applied to all painted and chrome plated surfaces. Avoid

combination cleaner-waxes. Many contain

abrasives which may mar the paint or protec-

tive finish. When finished cleaning, start the

engine and let it idle for several minutes.

U1PY61E0.book Page 1 Wednesday, March 14, 2012 5:22 PM

Page 124 of 134

9-2

9

EBU30360Storage Short-term

Always store your ATV in a cool, dry place and, if

necessary, protect it against dust with a porous

cover. NOTICE: Storing the ATV in a poorly ven-

tilated room or covering it with a tarp while it is

still wet, will allow water and humidity to seep

in and cause rust. To prevent corrosion, avoid

damp cellars, stables (because of the presence

of ammonia) and areas where strong chemi-

cals are stored.

[ECB00721]

Long-term

Before storing your ATV for several months: 1. Follow all the instructions in the “Cleaning” section of this chapter.

2. Turn the fuel cock lever to “OFF”.

3. Drain the carburetor float chamber by loosen- ing the drain bolt; this will prevent fuel deposits

from building up. Pour the drained fuel into the

fuel tank.

4. Fill up the fuel tank and add fuel stabilizer (if available) to prevent the fuel from deteriorat-

ing. 5. Perform the following steps to protect the cyl-

inder, piston rings, etc. from corrosion.a. Remove the spark plug cap and spark plug.

b. Pour a teaspoonful of engine oil into the spark plug bore.

c. Install the spark plug cap onto the spark plug, and then place the spark plug on the

cylinder head so that the electrodes are

grounded. (This will limit sparking during

the next step.)

d. Turn the engine over several times with the starter. (This will coat the cylinder wall with

oil.)

e. Remove the spark plug cap from the spark plug, and then install the spark plug and

the spark plug cap.

6. Lubricate all control cables and the pivoting points of all levers.

7. Check and, if necessary, correct the tire air pressure, and then block up the ATV so that

all of its wheels are off the ground. Alternative-

Specified amount:

7.5 ml of stabilizer to each liter of fuel (or 1

oz of stabilizer to each gallon of fuel)U1PY61E0.book Page 2 Wednesday, March 14, 2012 5:22 PM

Page 126 of 134

10-1

10

EBU25961

SPECIFICATIONS

Dimensions:Overall length:1700 mm (66.9 in)

Overall width: 990 mm (39.0 in)

Overall height:

980 mm (38.6 in)

Seat height: 685 mm (27.0 in)

Wheelbase: 1080 mm (42.5 in)

Ground clearance:

145 mm (5.7 in)

Minimum turning radius: 2900 mm (114 in)Weight:With oil and fuel:

152.0 kg (335 lb)Noise and vibration level:Noise level (77/311/EEC):78.0 dB(A)@3500 r/min

Vibration on seat (EN1032, ISO5008):

Will not exceed 0.5 m/s²

Vibration on handlebar (EN1032, ISO5008): Will not exceed 2.5 m/s²Engine:Engine type:

Air cooled 4-stroke, SOHC Cylinder arrangement:

Single cylinder

Displacement: 124 cm³

Bore × stroke:

49.0 × 66.0 mm (1.93 × 2.60 in)

Compression ratio:

9.00 : 1

Starting system: Electric starter

Lubrication system: Wet sump

Engine oil:Recommended brand:YAMALUBE

U1PY61E0.book Page 1 Wednesday, March 14, 2012 5:22 PM

Page 127 of 134

10-2

10

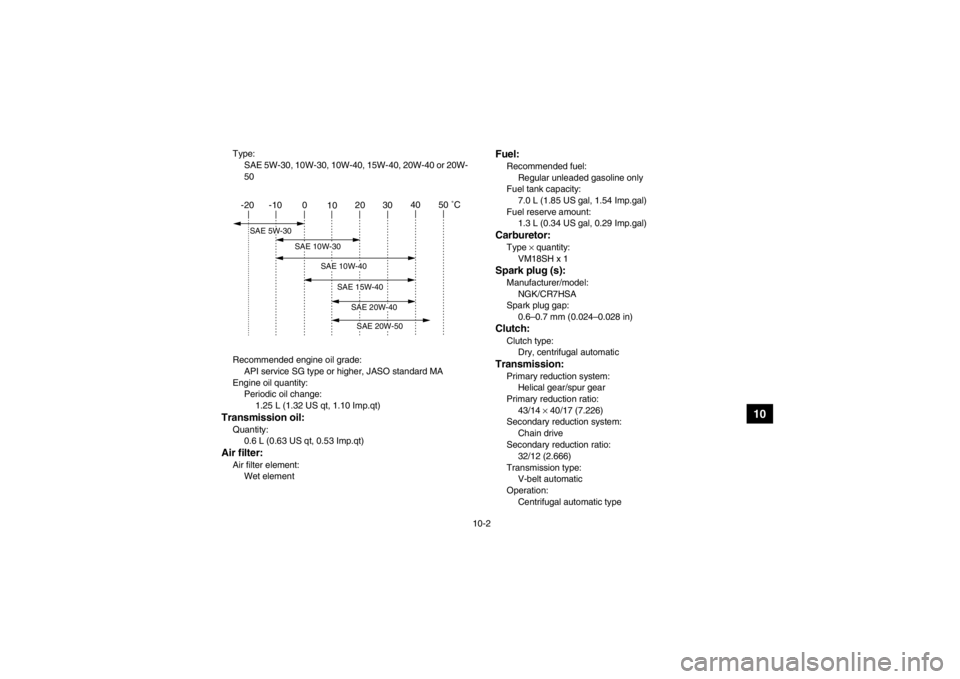

Type:SAE 5W-30, 10W-30, 10W-40, 15W-40, 20W-40 or 20W-

50

Recommended engine oil grade: API service SG type or higher, JASO standard MA

Engine oil quantity: Periodic oil change:

1.25 L (1.32 US qt, 1.10 Imp.qt)Transmission oil:Quantity:0.6 L (0.63 US qt, 0.53 Imp.qt)Air filter:Air filter element:Wet element

Fuel:Recommended fuel:Regular unleaded gasoline only

Fuel tank capacity:

7.0 L (1.85 US gal, 1.54 Imp.gal)

Fuel reserve amount: 1.3 L (0.34 US gal, 0.29 Imp.gal)Carburetor:Type × quantity:

VM18SH x 1Spark plug (s):Manufacturer/model: NGK/CR7HSA

Spark plug gap:

0.6–0.7 mm (0.024–0.028 in)Clutch:Clutch type:Dry, centrifugal automaticTransmission:Primary reduction system:Helical gear/spur gear

Primary reduction ratio: 43/14 × 40/17 (7.226)

Secondary reduction system:

Chain drive

Secondary reduction ratio: 32/12 (2.666)

Transmission type: V-belt automatic

Operation:

Centrifugal automatic type

-20 -10 0 1020 30

4050 �C

SAE 15W-40

SAE 20W-40SAE 20W-50

SAE 10W-40

SAE 5W-30

SAE 10W-30

U1PY61E0.book Page 2 Wednesday, March 14, 2012 5:22 PM

Page 132 of 134

INDEX

AAccessories and loading ................................................ 6-6

Air filter elements, engine and V-belt filter cleaning ..... 8-17BBattery ................................................................... 5-6, 8-41

Brake lever free play, adjusting the front ...................... 8-29

Brake lever free play (rear), adjusting .......................... 8-33

Brake lever, front ............................................................ 4-4

Brake lever, rear ............................................................. 4-5

Brake levers, checking and lubricating ......................... 8-38

Brakes .......................................................................... 8-28

Brakes, front and rear .................................................... 5-3

Brake shoes, checking the front and rear .................... 8-28CCables, checking and lubricating ................................. 8-37

Carburetor, adjusting .................................................... 8-25

Carrier, front ................................................................. 4-11

Carrier, rear .................................................................. 4-11

Chassis fasteners ........................................................... 5-6

Cleaning ......................................................................... 9-1DDrive chain ..................................................................... 5-3

Drive chain, lubricating ................................................. 8-37

Drive chain slack .......................................................... 8-34

Drive select lever ............................................................ 4-6

Drive select lever and driving in reverse ........................ 6-3EEngine break-in .............................................................. 6-4 Engine, cold start ........................................................... 6-1

Engine idling speed ...................................................... 8-26

Engine oil .............................................................. 5-3, 8-11

Engine, starting a warm ................................................. 6-3

Engine stop switch ......................................................... 4-2

FFront knuckle pivots, lubricating ................................... 8-40

Fuel ......................................................................... 4-7, 5-3

Fuel cock ........................................................................ 4-8

Fuel tank cap .................................................................. 4-7

Fuse, replacing ............................................................. 8-44HHandlebar switches ........................................................ 4-2

Headlight beam, adjusting ............................................ 8-47

Headlight bulb, replacing .............................................. 8-45

Horn switch .................................................................... 4-3IIdentification numbers .................................................. 11-1

Indicator lights ................................................................ 4-2

Instruments, lights and switches .................................... 5-6LLabel locations ............................................................... 1-1

Light switch .................................................................... 4-3MMain switch .................................................................... 4-1

Maintenance and lubrication chart ................................. 8-5

Maintenance chart, emission control system ................. 8-3

Model label ................................................................... 11-1

U1PY61E0.book Page 1 Wednesday, March 14, 2012 5:22 PM