lock YAMAHA MT-10 2020 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: MT-10, Model: YAMAHA MT-10 2020Pages: 108, PDF Size: 9.22 MB

Page 36 of 108

Instrument and control functions

4-15

1

2

34

5

6

7

8

9

10

11

12

On - the indicator light will come

on when activated. (This setting

is selected when the indicator

light stays on.)

Flash - the indicator light will

flash when activated. (This set-

ting is selected when the indica-

tor light flashes four times per

second.)

Off - the indicator light is deacti-

vated; in other words, it will not

come on or flash. (This setting

is selected when the indicator

light flashes once every two

seconds.)

2. Push the “CLOCK” button to con- firm the selected indicator light ac-

tivity. The control mode changes to

the shift indicator light on r/min

function.

To set the shift indicator light on r/min

TIPThe shift indicator light can be set be-

tween 7000 r/min and 13000 r/min in in-crements of 200 r/min. 1. Push the “RESET” button to select the desired engine speed for acti- vating the indicator light.

2. Push the “CLOCK” button to con- firm the selected engine speed.

The control mode changes to the

shift indicator light off r/min func-

tion.

To set the shift indicator light off r/min

TIP

The shift indicator light can be

set between 7000 r/min and

13000 r/min in increments of 200

r/min.

Be sure to set the off r/min to a

higher engine speed than the on

r/min setting, otherwise the shiftindicator light will not come on.

1. Push the “RESET” button to select the desired engine speed for deac-

tivating the indicator light.

2. Push the “CLOCK” button to con- firm the selected engine speed.

The control mode changes to the

shift indicator light brightness func-

tion. To adjust the brightness of the shift in-

dicator light1. Push the “RESET” button to select

the desired indicator light bright-

ness level.

2. Push the “CLOCK” button to con- firm the selected indicator light

brightness level and exit the bright-

ness and shift indicator light con-

trol mode.

B67-9-E4.book 15 ページ 2019年7月19日 金曜日 午後4時23分

Page 38 of 108

Instrument and control functions

4-17

1

2

34

5

6

7

8

9

10

11

12 the brake lever.

EAU12944

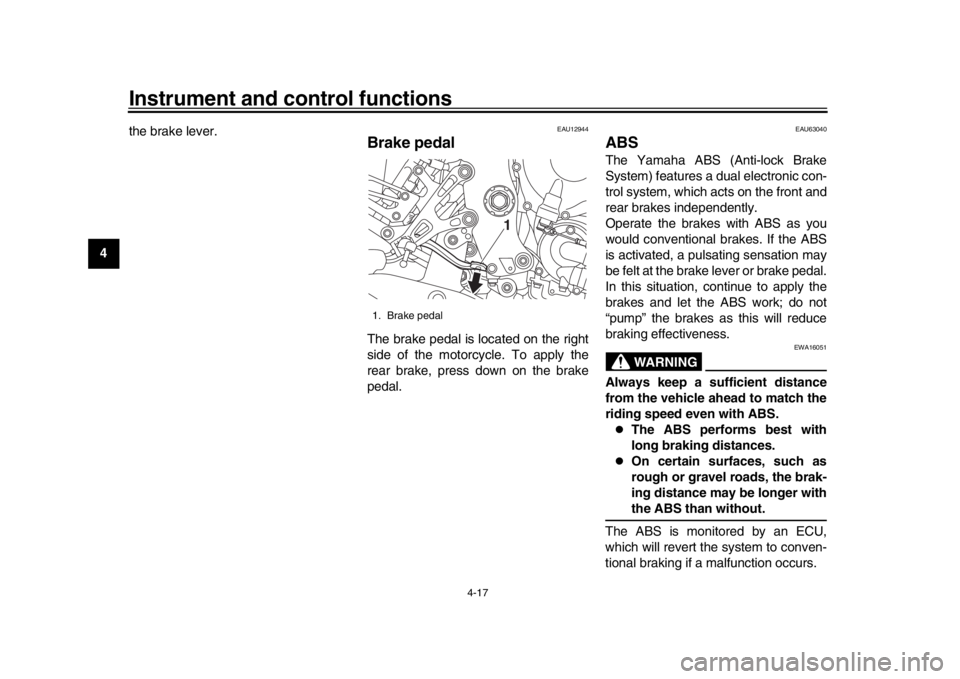

Brake pedalThe brake pedal is located on the right

side of the motorcycle. To apply the

rear brake, press down on the brake

pedal.

EAU63040

ABSThe Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake pedal.

In this situation, continue to apply the

brakes and let the ABS work; do not

“pump” the brakes as this will reduce

braking effectiveness.

WARNING

EWA16051

Always keep a sufficient distance

from the vehicle ahead to match the

riding speed even with ABS.

The ABS performs best with

long braking distances.

On certain surfaces, such as

rough or gravel roads, the brak-

ing distance may be longer withthe ABS than without.

The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

1. Brake pedal

1

B67-9-E4.book 17 ページ 2019年7月19日 金曜日 午後4時23分

Page 39 of 108

Instrument and control functions

4-18

1

2

345

6

7

8

9

10

11

12

TIP

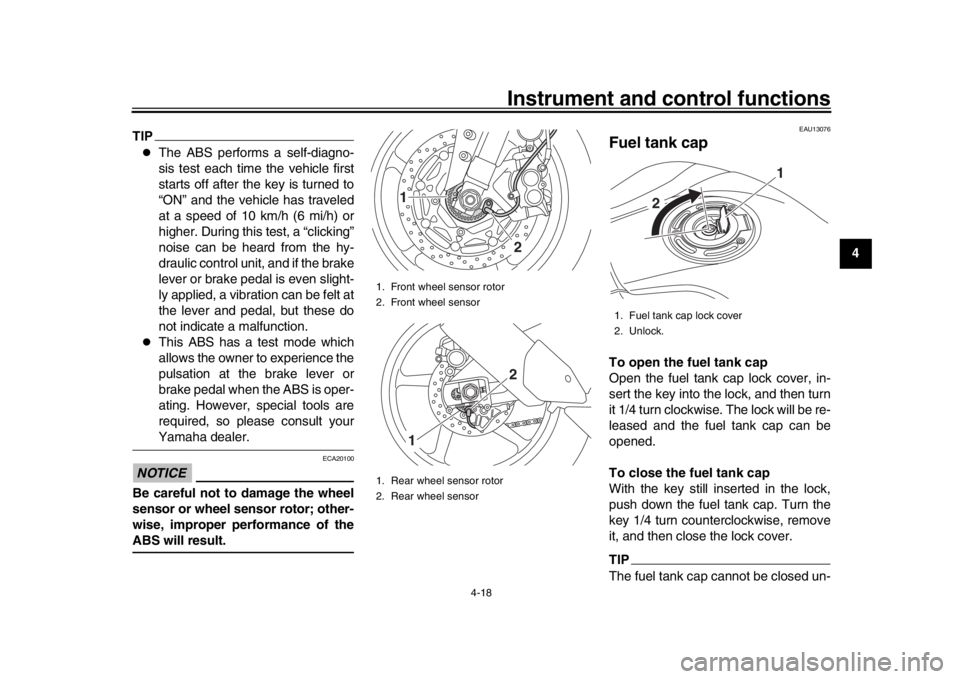

The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “clicking”

noise can be heard from the hy-

draulic control unit, and if the brake

lever or brake pedal is even slight-

ly applied, a vibration can be felt at

the lever and pedal, but these do

not indicate a malfunction.

This ABS has a test mode which

allows the owner to experience the

pulsation at the brake lever or

brake pedal when the ABS is oper-

ating. However, special tools are

required, so please consult yourYamaha dealer.

NOTICE

ECA20100

Be careful not to damage the wheel

sensor or wheel sensor rotor; other-

wise, improper performance of theABS will result.

EAU13076

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be re-

leased and the fuel tank cap can be

opened.

To close the fuel tank cap

With the key still inserted in the lock,

push down the fuel tank cap. Turn the

key 1/4 turn counterclockwise, remove

it, and then close the lock cover.TIPThe fuel tank cap cannot be closed un-

1. Front wheel sensor rotor

2. Front wheel sensor

1. Rear wheel sensor rotor

2. Rear wheel sensor

2

12

1

1. Fuel tank cap lock cover

2. Unlock.

1

2

B67-9-E4.book 18 ページ 2019年7月19日 金曜日 午後4時23分

Page 40 of 108

Instrument and control functions

4-19

1

2

34

5

6

7

8

9

10

11

12 less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly closed after filling fuel.Leaking fuel is a fire hazard.

EAU13222

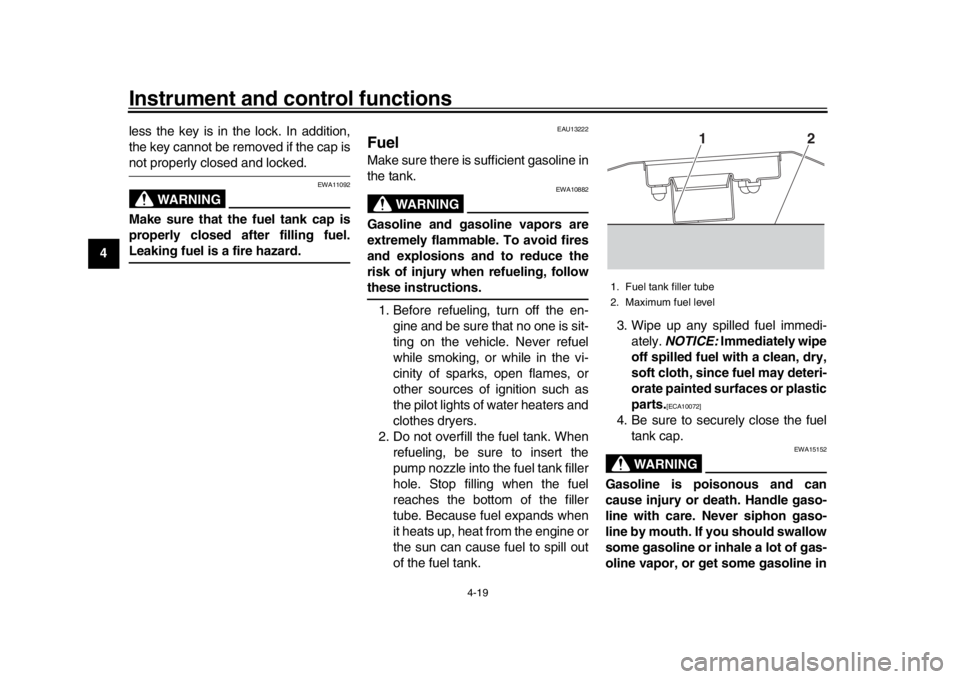

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline and gasoline vapors are

extremely flammable. To avoid fires

and explosions and to reduce the

risk of injury when refueling, followthese instructions.

1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters and

clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank. 3. Wipe up any spilled fuel immedi-

ately. NOTICE: Immediately wipe

off spilled fuel with a clean, dry,

soft cloth, since fuel may deteri-

orate painted surfaces or plastic

parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous and can

cause injury or death. Handle gaso-

line with care. Never siphon gaso-

line by mouth. If you should swallow

some gasoline or inhale a lot of gas-

oline vapor, or get some gasoline in1. Fuel tank filler tube

2. Maximum fuel level

2

1

B67-9-E4.book 19 ページ 2019年7月19日 金曜日 午後4時23分

Page 42 of 108

Instrument and control functions

4-21

1

2

34

5

6

7

8

9

10

11

12

EAU72972

Fuel tank overflow hoseBefore operating the vehicle:

Check the overflow hose connec-

tion and for damage.

Confirm the overflow hose is not

blocked and is routed through the

clamp.

TIPSee page 7-10 for canister information.

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up ofheat.

NOTICE

ECA10702

Use only unleaded gasoline. The use

of leaded gasoline will cause unre- pairable damage to the catalytic

converter.

1. Clamp

2. Fuel tank overflow hose

1

2

B67-9-E4.book 21 ページ 2019年7月19日 金曜日 午後4時23分

Page 43 of 108

Instrument and control functions

4-22

1

2

345

6

7

8

9

10

11

12

EAU57992

SeatTo remove the seat 1. Open the seat lock cover, insert the key into the seat lock, and then

turn the key counterclockwise.

2. While holding the key in that posi- tion, slide the seat backward and

then lift the rear of the seat up, and

then pull the seat off.

To install the seat 1. Insert the projections into the seat holders as shown. 2. Push the rear of the seat down to

lock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-cured before riding.

EAU70412

Adjusting the front forkThis model is equipped with adjustable

suspension. The spring preload, re-

bound damping force, and compres-

sion damping force of each leg can be

adjusted.

WARNING

EWA10181

Always adjust both fork legs equal-

ly, otherwise poor handling and lossof stability may result.NOTICE

ECA22471

Use extra care to avoid scratch-

ing the gold-anodized finish

when making suspension ad-

justments.

To avoid damaging the suspen-

sion’s internal mechanisms, do

not attempt to turn beyond themaximum or minimum settings.

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting nut on each fork in direc-

tion (a). To decrease the spring preload

1. Seat lock cover

2. Seat lock

3. Unlock.

2 3

1

1. Projection

2. Seat holder

2

2 1

B67-9-E4.book 22 ページ 2019年7月19日 金曜日 午後4時23分

Page 45 of 108

Instrument and control functions

4-24

1

2

345

6

7

8

9

10

11

12

may turn or click beyond the stated

minimum settings, such adjust-

ments are ineffective and may

damage the suspension.

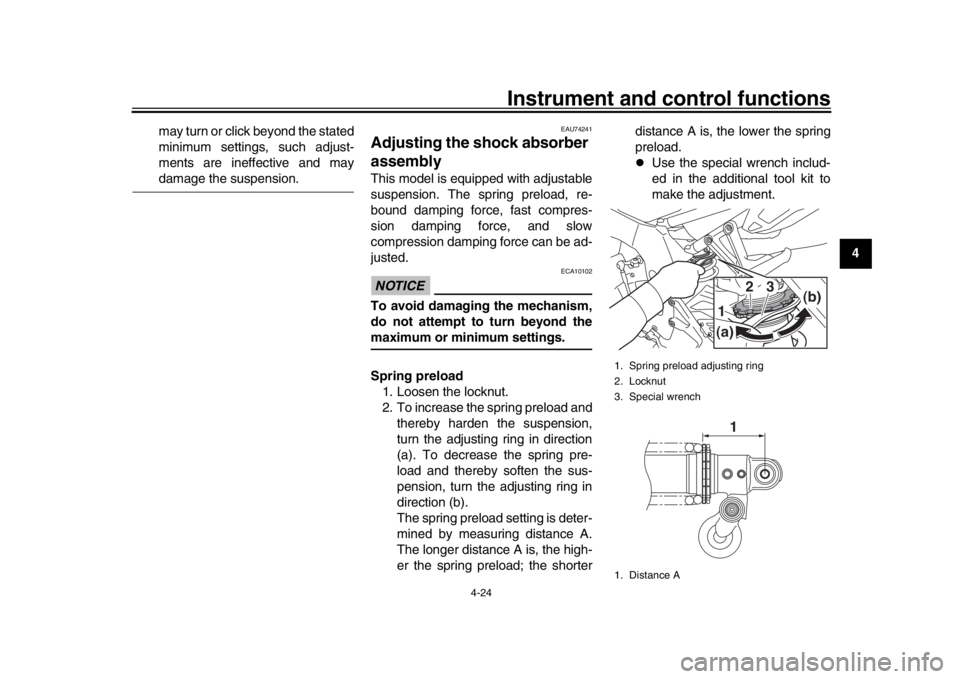

EAU74241

Adjusting the shock absorber

assemblyThis model is equipped with adjustable

suspension. The spring preload, re-

bound damping force, fast compres-

sion damping force, and slow

compression damping force can be ad-

justed.NOTICE

ECA10102

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

Spring preload

1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspension,

turn the adjusting ring in direction

(a). To decrease the spring pre-

load and thereby soften the sus-

pension, turn the adjusting ring in

direction (b).

The spring preload setting is deter-

mined by measuring distance A.

The longer distance A is, the high-

er the spring preload; the shorter distance A is, the lower the spring

preload.

Use the special wrench includ-

ed in the additional tool kit to

make the adjustment.

1. Spring preload adjusting ring

2. Locknut

3. Special wrench

1. Distance A

(a)

(b)1

2

3

1

B67-9-E4.book 24 ページ 2019年7月19日 金曜日 午後4時23分

Page 46 of 108

Instrument and control functions

4-25

1

2

34

5

6

7

8

9

10

11

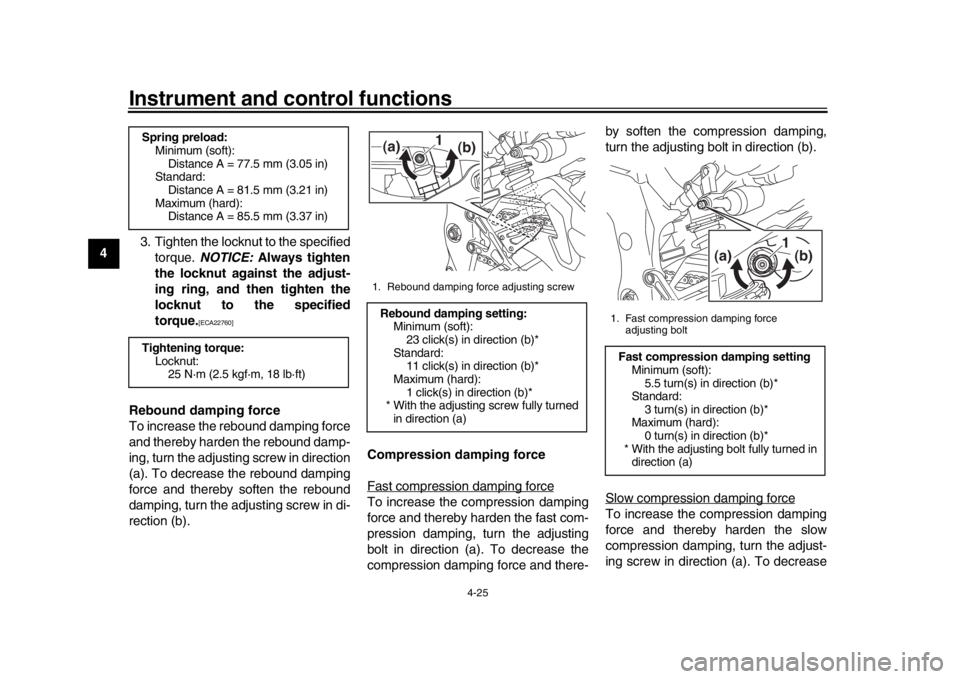

12 3. Tighten the locknut to the specified

torque. NOTICE: Always tighten

the locknut against the adjust-

ing ring, and then tighten the

locknut to the specified

torque.

[ECA22760]

Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting screw in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in di-

rection (b). Compression damping force

Fast compression damping force

To increase the compression damping

force and thereby harden the fast com-

pression damping, turn the adjusting

bolt in direction (a). To decrease the

compression damping force and there-by soften the compression damping,

turn the adjusting bolt in direction (b).

Slow compression damping force

To increase the compression damping

force and thereby harden the slow

compression damping, turn the adjust-

ing screw in direction (a). To decrease

Spring preload:

Minimum (soft):Distance A = 77.5 mm (3.05 in)

Standard:

Distance A = 81.5 mm (3.21 in)

Maximum (hard): Distance A = 85.5 mm (3.37 in)

Tightening torque: Locknut:25 N·m (2.5 kgf·m, 18 lb·ft)

1. Rebound damping force adjusting screwRebound damping setting: Minimum (soft):

23 click(s) in direction (b)*

Standard: 11 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned

in direction (a)(a) (b)

1

1. Fast compression damping force

adjusting bolt Fast compression damping settingMinimum (soft):

5.5 turn(s) in direction (b)*

Standard: 3 turn(s) in direction (b)*

Maximum (hard): 0 turn(s) in direction (b)*

* With the adjusting bolt fully turned in

direction (a)

(a) (b)

1

B67-9-E4.book 25 ページ 2019年7月19日 金曜日 午後4時23分

Page 68 of 108

Periodic maintenance and adjustment

7-10

1

2

3

4

5

67

8

9

10

11

12

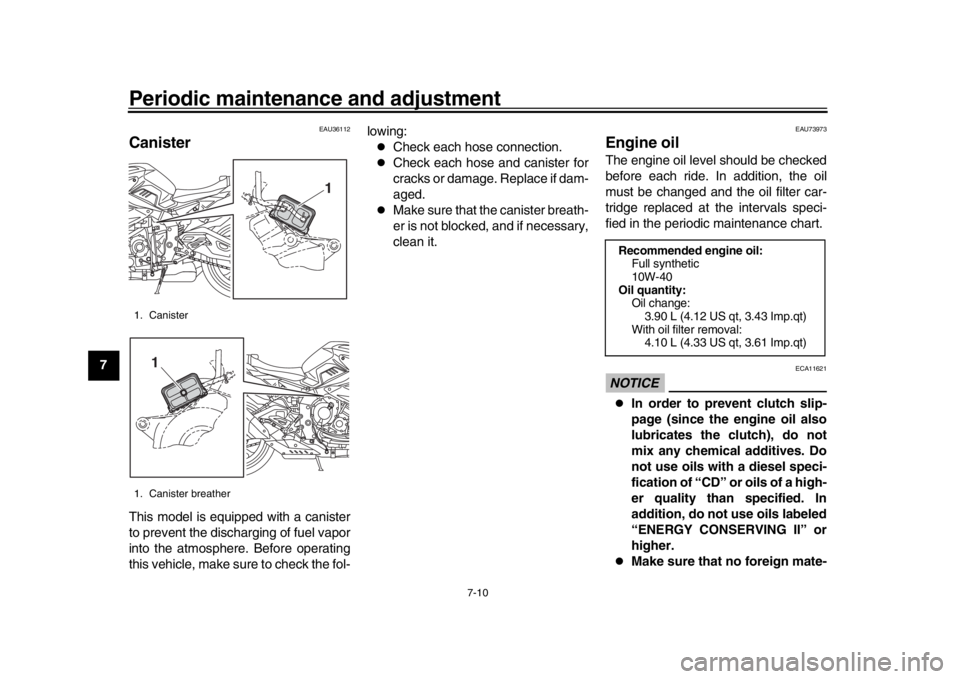

EAU36112

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the fol- lowing:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if dam-

aged.

Make sure that the canister breath-

er is not blocked, and if necessary,

clean it.

EAU73973

Engine oilThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance chart.NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-

1. Canister

1. Canister breather

1

1

Recommended engine oil:

Full synthetic

10W-40

Oil quantity: Oil change:

3.90 L (4.12 US qt, 3.43 Imp.qt)

With oil filter removal: 4.10 L (4.33 US qt, 3.61 Imp.qt)

B67-9-E4.book 10 ページ 2019年7月19日 金曜日 午後4時23分

Page 78 of 108

Periodic maintenance and adjustment

7-20

1

2

3

4

5

67

8

9

10

11

12

TIPIf the specified clutch lever free play

cannot be obtained as describedabove, proceed as follows. 1. Fully turn the adjusting bolt at the clutch lever in direction (a) to loos-

en the clutch cable.

2. Loosen the locknut further down the clutch cable.

3. To increase the clutch lever free play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free play,

turn the adjusting nut in direction

(b).

4. Tighten the locknut.

EAU37914

Checking the brake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spongy feeling in the brake

lever can indicate the presence of air

in the hydraulic system. If there is air

in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the vehicle. Air in the

hydraulic system will diminish the

braking performance, which may re- sult in loss of control and an acci-

dent.

1. Locknut

2. Clutch lever free play adjusting nut

(b)

1

2

(a)

1. No brake lever free play

1

B67-9-E4.book 20 ページ 2019年7月19日 金曜日 午後4時23分