ECU YAMAHA SUPERJET 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: SUPERJET, Model: YAMAHA SUPERJET 2013Pages: 78, PDF Size: 3.29 MB

Page 56 of 78

Care and storage

50

EJU41191

Post-operation care

WARNING

EWJ00320

Always turn the fuel cock knob to “OFF”

when storing the watercraft, otherwise

fuel could leak out into the engine or en-

gine compartment, which would create a

fire hazard.

After using the watercraft, always take it out of

the water, clean it, and store it. Leaving the

watercraft in the water for extended periods

will accelerate the rate of normal deterioration

of the jet pump and hull. Marine organisms

and corrosion are some of the conditions that

can shorten the life of many watercraft com-

ponents.

EJU33518Flushing the cooling water passages

NOTICE

ECJ01360

Do not run the engine for more than 15

seconds on land without supplying water,

otherwise the engine could overheat.

Flush the cooling water passages to prevent

them from clogging with salt, sand, or dirt.

(1) Place the watercraft in a horizontal posi-tion.

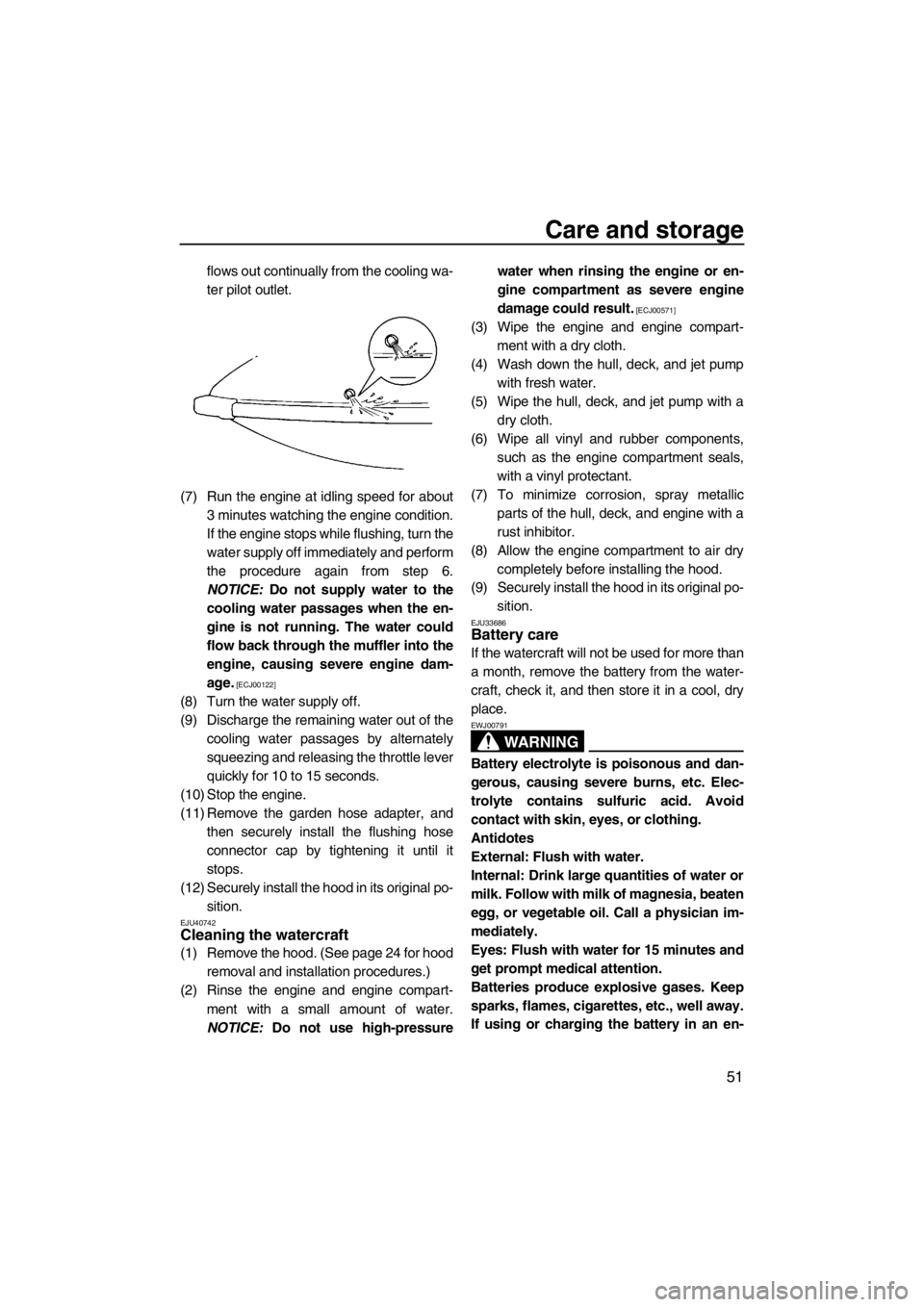

(2) Remove the hood. (See page 24 for hood removal and installation procedures.) (3) Connect the garden hose adapter to a

garden hose.

(4) Loosen the flushing hose connector cap and remove it. Insert the garden hose

adapter into the flushing hose connector

and turn it until it is securely connected.

(5) Connect the garden hose to a water tap.

(6) Make sure that the area around the wa- tercraft is clear, and then start the engine.

Immediately after the engine starts, turn

the water supply on gradually until water

1Garden hose adapter

1 Flushing hose connector

2 Flushing hose connector cap

3 Garden hose adapter

UF2F75E0.book Page 50 Thursday, July 5, 2012 8:50 AM

Page 57 of 78

Care and storage

51

flows out continually from the cooling wa-

ter pilot outlet.

(7) Run the engine at idling speed for about 3 minutes watching the engine condition.

If the engine stops while flushing, turn the

water supply off immediately and perform

the procedure again from step 6.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00122]

(8) Turn the water supply off.

(9) Discharge the remaining water out of the cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(10) Stop the engine.

(11) Remove the garden hose adapter, and then securely install the flushing hose

connector cap by tightening it until it

stops.

(12) Securely install the hood in its original po- sition.

EJU40742Cleaning the watercraft

(1) Remove the hood. (See page 24 for hoodremoval and installation procedures.)

(2) Rinse the engine and engine compart-

ment with a small amount of water.

NOTICE: Do not use high-pressure water when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00571]

(3) Wipe the engine and engine compart-

ment with a dry cloth.

(4) Wash down the hull, deck, and jet pump with fresh water.

(5) Wipe the hull, deck, and jet pump with a dry cloth.

(6) Wipe all vinyl and rubber components, such as the engine compartment seals,

with a vinyl protectant.

(7) To minimize corrosion, spray metallic parts of the hull, deck, and engine with a

rust inhibitor.

(8) Allow the engine compartment to air dry completely before installing the hood.

(9) Securely install the hood in its original po- sition.

EJU33686Battery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

WARNING

EWJ00791

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg, or vegetable oil. Call a physician im-

mediately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flames, cigarettes, etc., well away.

If using or charging the battery in an en-

UF2F75E0.book Page 51 Thursday, July 5, 2012 8:50 AM

Page 59 of 78

Care and storage

53

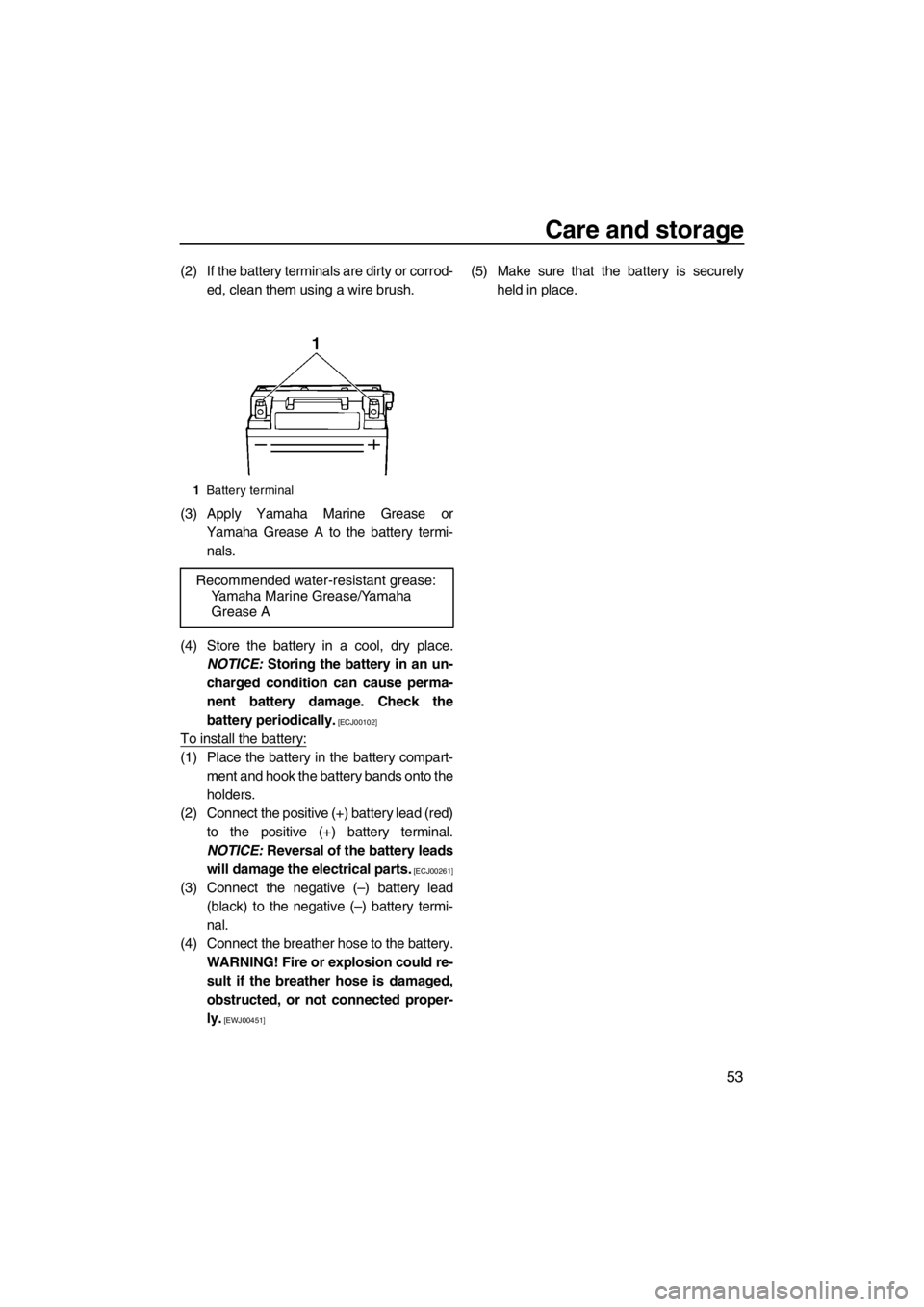

(2) If the battery terminals are dirty or corrod-ed, clean them using a wire brush.

(3) Apply Yamaha Marine Grease or Yamaha Grease A to the battery termi-nals.

(4) Store the battery in a cool, dry place. NOTICE: Storing the battery in an un-

charged condition can cause perma-

nent battery damage. Check the

battery periodically.

[ECJ00102]

To install the battery:

(1) Place the battery in the battery compart- ment and hook the battery bands onto the

holders.

(2) Connect the positive (+) battery lead (red) to the positive (+) battery terminal.

NOTICE: Reversal of the battery leads

will damage the electrical parts.

[ECJ00261]

(3) Connect the negative (–) battery lead (black) to the negative (–) battery termi-

nal.

(4) Connect the breather hose to the battery. WARNING! Fire or explosion could re-sult if the breather hose is damaged,

obstructed, or not connected proper-

ly.

[EWJ00451]

(5) Make sure that the battery is securely held in place.

1Battery terminal

Recommended water-resistant grease:

Yamaha Marine Grease/Yamaha

Grease A

UF2F75E0.book Page 53 Thursday, July 5, 2012 8:50 AM

Page 60 of 78

Care and storage

54

EJU33483

Long-term storage

WARNING

EWJ00320

Always turn the fuel cock knob to “OFF”

when storing the watercraft, otherwise

fuel could leak out into the engine or en-

gine compartment, which would create a

fire hazard.

Storage for long periods of time, such as win-

ter storage, requires preventive maintenance

to ensure against deterioration. It is advisable

to have the watercraft serviced by a Yamaha

dealer prior to storage.

However, the following procedures can be

performed easily by the owner.

EJU40762Cleaning

(1) Flush the cooling water passages. (Seepage 50 for information on flushing the

cooling water passages.)

TIP:

If you will be storing the watercraft for a pro-

longed period, such as winter storage, top off

the fuel tank with fresh gasoline and add fuel

stabilizer and conditioner to the fuel tank ac-

cording to the manufacturer’s instruction be-

fore starting the engine.

(2) Clean the watercraft. (See page 51 for in-formation on cleaning the watercraft.)

Wax the hull with a non-abrasive wax.

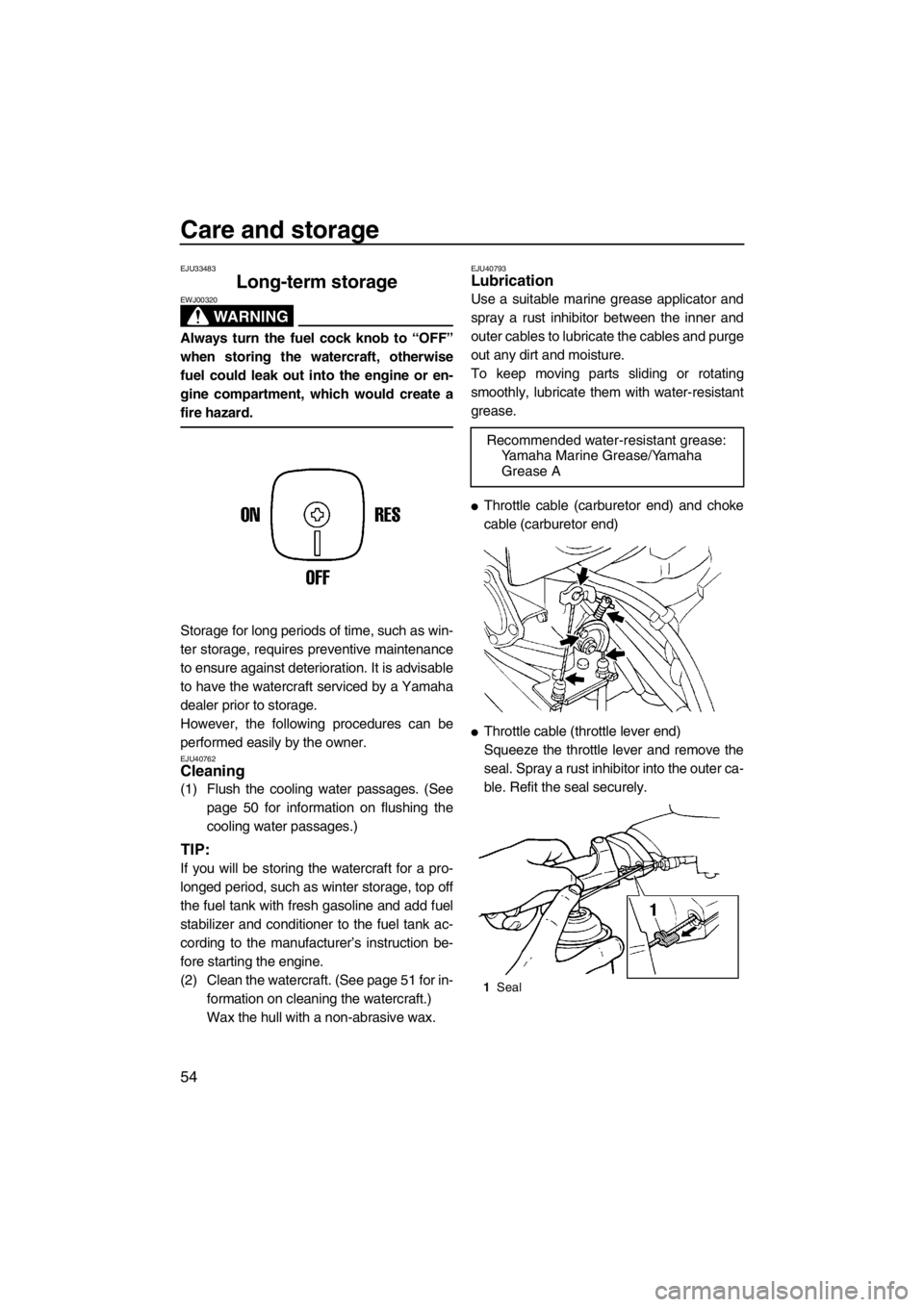

EJU40793Lubrication

Use a suitable marine grease applicator and

spray a rust inhibitor between the inner and

outer cables to lubricate the cables and purge

out any dirt and moisture.

To keep moving parts sliding or rotating

smoothly, lubricate them with water-resistant

grease.

●Throttle cable (carburetor end) and choke

cable (carburetor end)

●Throttle cable (throttle lever end)

Squeeze the throttle lever and remove the

seal. Spray a rust inhibitor into the outer ca-

ble. Refit the seal securely.

Recommended water-resistant grease:Yamaha Marine Grease/Yamaha

Grease A

1 Seal

UF2F75E0.book Page 54 Thursday, July 5, 2012 8:50 AM

Page 61 of 78

Care and storage

55

●Steering cable ball joint (handlebar end)

and steering cable inner wire (handlebar

end)

To access the steering cable ball joint (han-

dlebar end) and steering cable inner wire

(handlebar end), remove the steering pole

cover. (See step 1 in “Adjusting the jet

thrust nozzle angle” on page 57 for informa-

tion on removing the steering pole cover.)

●Steering cable ball joint (jet thrust nozzle

end) and steering cable inner wire (jet thrust

nozzle end)

EJU40943Rustproofing

NOTICE

ECJ01360

Do not run the engine for more than 15

seconds on land without supplying water,

otherwise the engine could overheat.

Spray metallic parts of the hull and engine

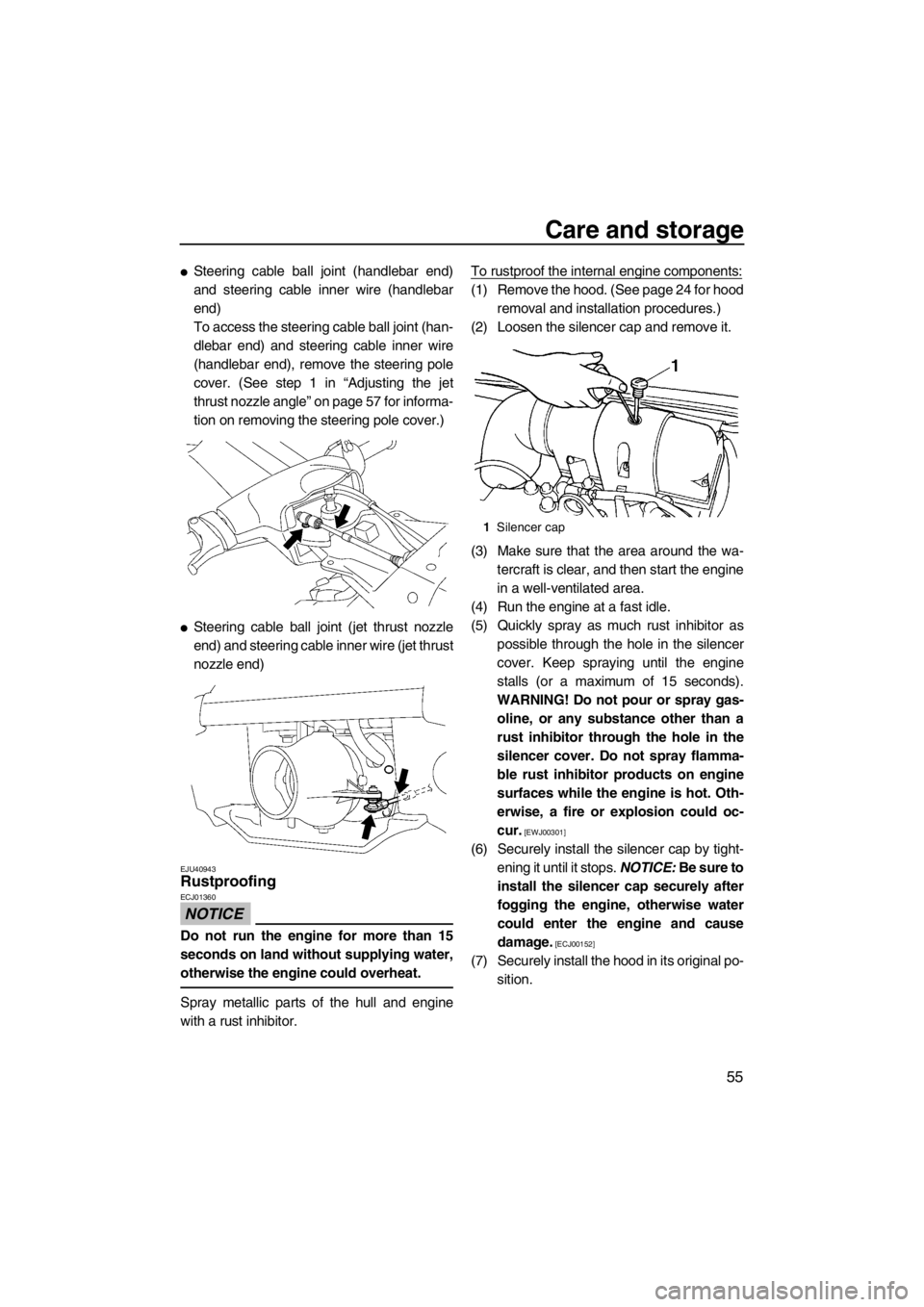

with a rust inhibitor.To rustproof the internal engine components:

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Loosen the silencer cap and remove it.

(3) Make sure that the area around the wa- tercraft is clear, and then start the engine

in a well-ventilated area.

(4) Run the engine at a fast idle.

(5) Quickly spray as much rust inhibitor as possible through the hole in the silencer

cover. Keep spraying until the engine

stalls (or a maximum of 15 seconds).

WARNING! Do not pour or spray gas- oline, or any substance other than a

rust inhibitor through the hole in the

silencer cover. Do not spray flamma-

ble rust inhibitor products on engine

surfaces while the engine is hot. Oth-

erwise, a fire or explosion could oc-

cur.

[EWJ00301]

(6) Securely install the silencer cap by tight- ening it until it stops. NOTICE: Be sure to

install the silencer cap securely after

fogging the engine, otherwise water

could enter the engine and cause

damage.

[ECJ00152]

(7) Securely install the hood in its original po- sition.

1Silencer cap

UF2F75E0.book Page 55 Thursday, July 5, 2012 8:50 AM

Page 63 of 78

Maintenance

57

(2) Remove the four screws, and then re-move the handlebar cover.

(3) Turn the handlebars so that the left han- dlebar grip is facing down.

(4) Loosen the locknut.

(5) Tighten or loosen the adjusting nut until the desired amount of friction is obtained.

(6) While holding the adjusting nut with a wrench, tighten the locknut to the speci-

fied torque.

(7) Securely install the handlebar cover and four screws in their original positions. (8) While holding the steering pole, move the

lock pin to the stowed position, and then

lower the steering pole.

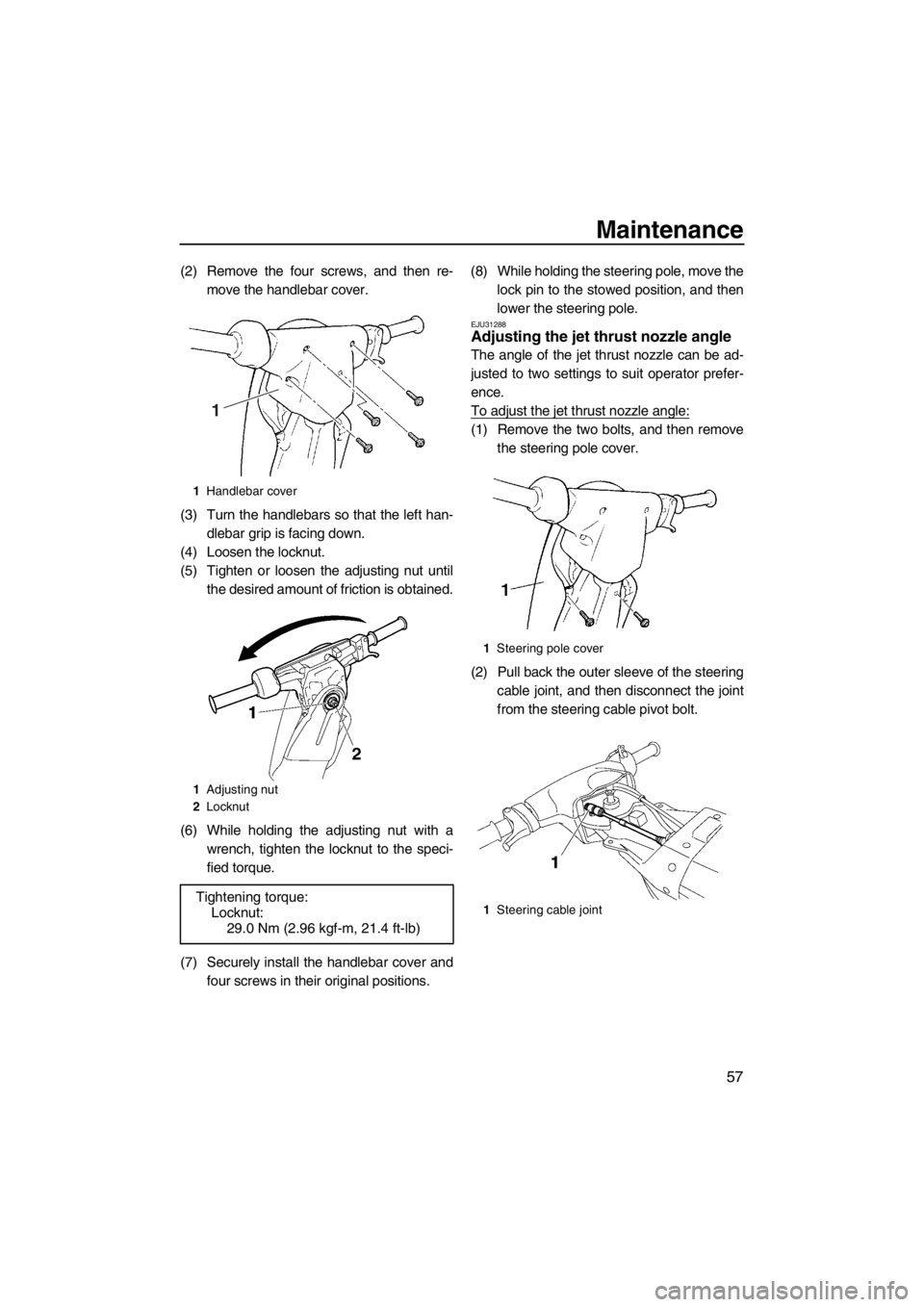

EJU31288Adjusting the jet thrust nozzle angle

The angle of the jet thrust nozzle can be ad-

justed to two settings to suit operator prefer-

ence.

To adjust the jet thrust nozzle angle:

(1) Remove the two bolts, and then removethe steering pole cover.

(2) Pull back the outer sleeve of the steering cable joint, and then disconnect the joint

from the steering cable pivot bolt.

1Handlebar cover

1 Adjusting nut

2 Locknut

Tightening torque:

Locknut:29.0 Nm (2.96 kgf-m, 21.4 ft-lb)

1

1Steering pole cover

1 Steering cable joint

UF2F75E0.book Page 57 Thursday, July 5, 2012 8:50 AM

Page 64 of 78

Maintenance

58

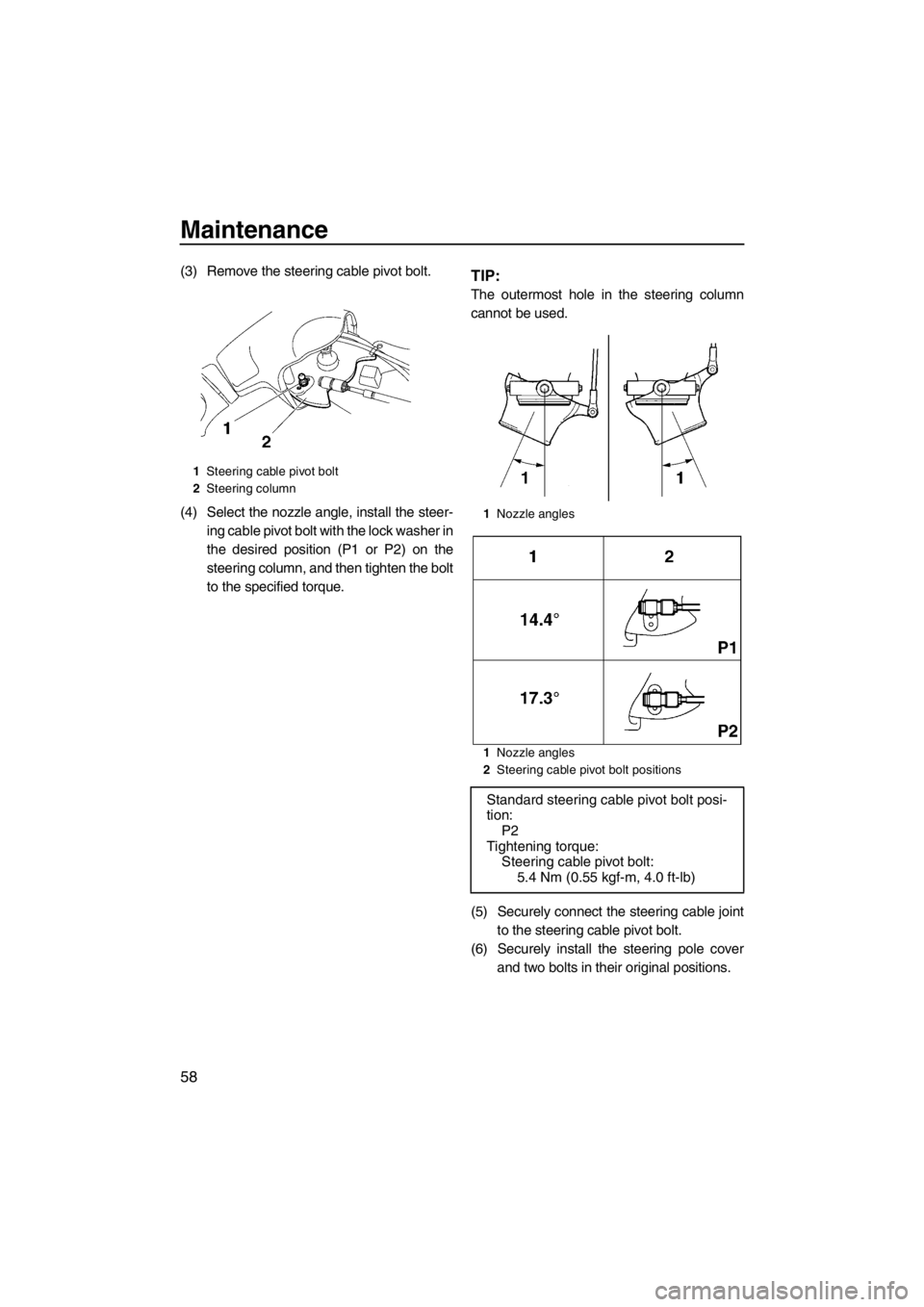

(3) Remove the steering cable pivot bolt.

(4) Select the nozzle angle, install the steer-ing cable pivot bolt with the lock washer in

the desired position (P1 or P2) on the

steering column, and then tighten the bolt

to the specified torque.TIP:

The outermost hole in the steering column

cannot be used.

(5) Securely connect the steering cable jointto the steering cable pivot bolt.

(6) Securely install the steering pole cover and two bolts in their original positions.

1Steering cable pivot bolt

2 Steering column

1Nozzle angles

1 Nozzle angles

2 Steering cable pivot bolt positions

Standard steering cable pivot bolt posi-

tion:

P2

Tightening torque: Steering cable pivot bolt: 5.4 Nm (0.55 kgf-m, 4.0 ft-lb)

UF2F75E0.book Page 58 Thursday, July 5, 2012 8:50 AM

Page 67 of 78

Maintenance

61

the correct torque is 1/4 turn to 1/2 turn past

finger tight using the spark plug wrench in-

cluded in the tool kit. Have the spark plug ad-

justed to the correct torque with a torque

wrench as soon as possible.

(3) Wipe off any water or dirt inside the sparkplug cap.

(4) Install the spark plug cap by pushing it down until it is securely installed in its

original position.

(5) Securely install the hood in its original po- sition.

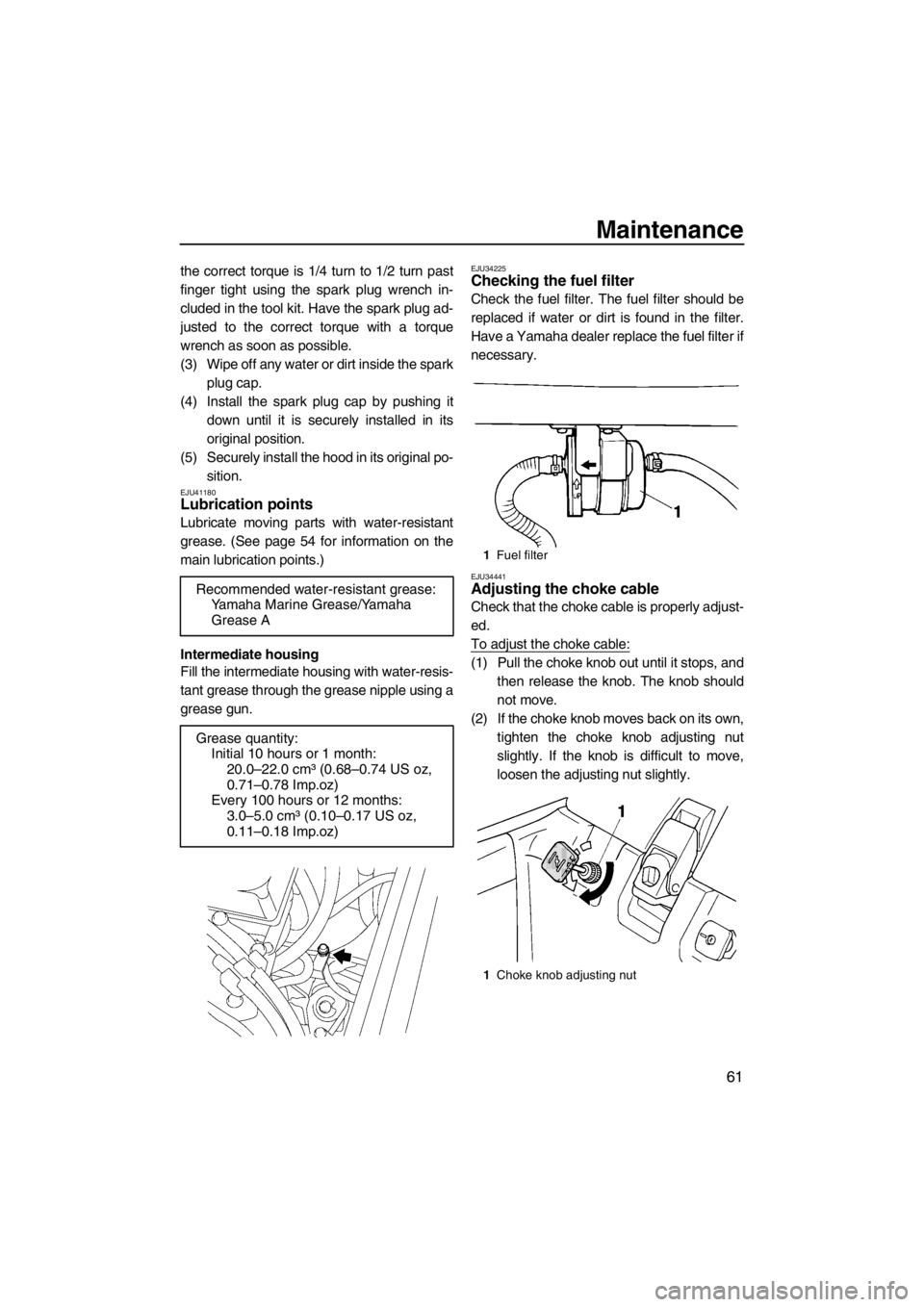

EJU41180Lubrication points

Lubricate moving parts with water-resistant

grease. (See page 54 for information on the

main lubrication points.)

Intermediate housing

Fill the intermediate housing with water-resis-

tant grease through the grease nipple using a

grease gun.

EJU34225Checking the fuel filter

Check the fuel filter. The fuel filter should be

replaced if water or dirt is found in the filter.

Have a Yamaha dealer replace the fuel filter if

necessary.

EJU34441Adjusting the choke cable

Check that the choke cable is properly adjust-

ed.

To adjust the choke cable:

(1) Pull the choke knob out until it stops, andthen release the knob. The knob should

not move.

(2) If the choke knob moves back on its own, tighten the choke knob adjusting nut

slightly. If the knob is difficult to move,

loosen the adjusting nut slightly.

Recommended water-resistant grease:

Yamaha Marine Grease/Yamaha

Grease A

Grease quantity: Initial 10 hours or 1 month:

20.0–22.0 cm³ (0.68–0.74 US oz,

0.71–0.78 Imp.oz)

Every 100 hours or 12 months:

3.0–5.0 cm³ (0.10–0.17 US oz,

0.11–0.18 Imp.oz)

1Fuel filter

1 Choke knob adjusting nut

UF2F75E0.book Page 61 Thursday, July 5, 2012 8:50 AM

Page 74 of 78

Trouble recovery

68

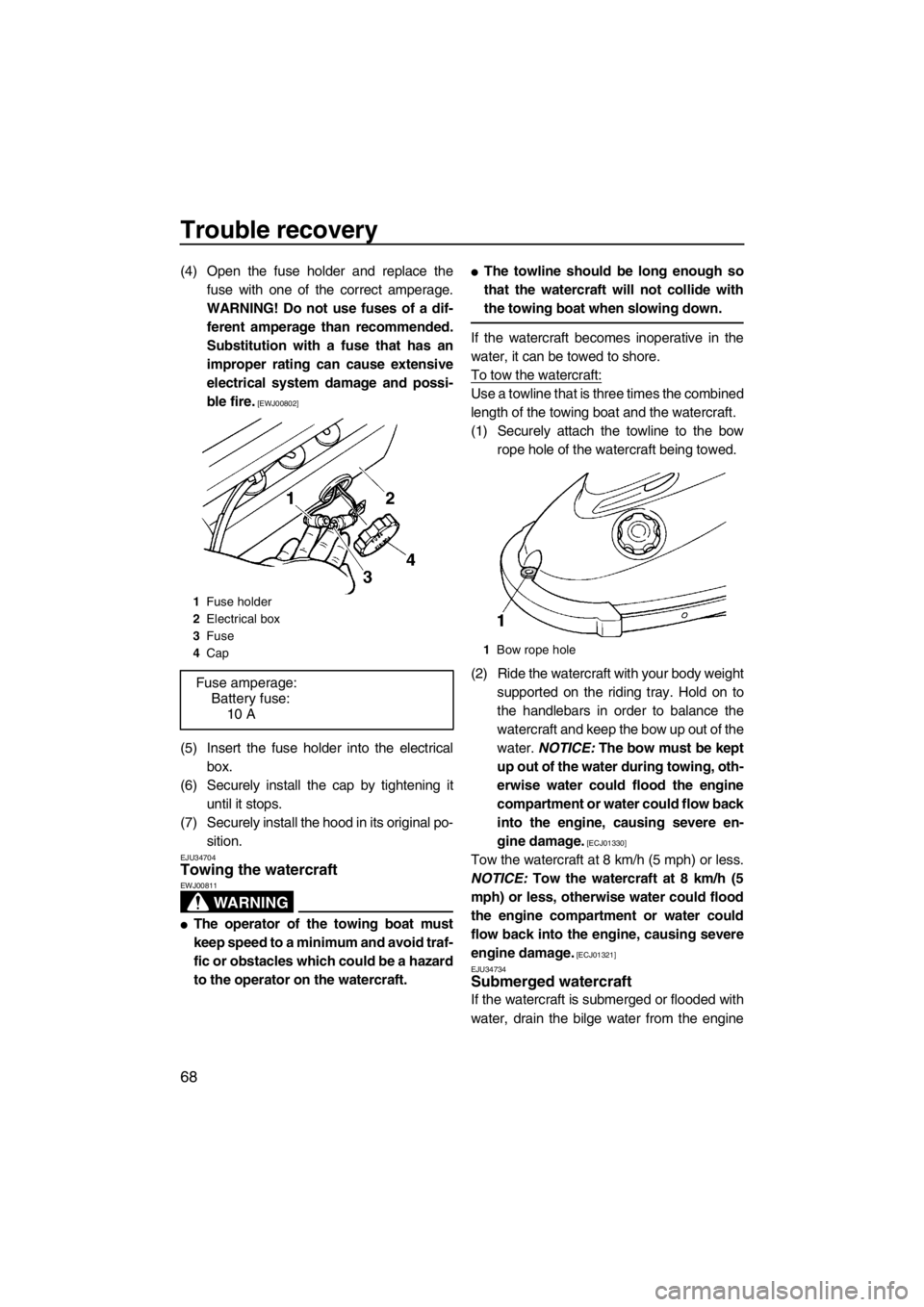

(4) Open the fuse holder and replace thefuse with one of the correct amperage.

WARNING! Do not use fuses of a dif- ferent amperage than recommended.

Substitution with a fuse that has an

improper rating can cause extensive

electrical system damage and possi-

ble fire.

[EWJ00802]

(5) Insert the fuse holder into the electrical box.

(6) Securely install the cap by tightening it until it stops.

(7) Securely install the hood in its original po- sition.

EJU34704Towing the watercraft

WARNING

EWJ00811

●The operator of the towing boat must

keep speed to a minimum and avoid traf-

fic or obstacles which could be a hazard

to the operator on the watercraft.

●The towline should be long enough so

that the watercraft will not collide with

the towing boat when slowing down.

If the watercraft becomes inoperative in the

water, it can be towed to shore.

To tow the watercraft:

Use a towline that is three times the combined

length of the towing boat and the watercraft.

(1) Securely attach the towline to the bowrope hole of the watercraft being towed.

(2) Ride the watercraft with your body weight supported on the riding tray. Hold on to

the handlebars in order to balance the

watercraft and keep the bow up out of the

water. NOTICE: The bow must be kept

up out of the water during towing, oth-

erwise water could flood the engine

compartment or water could flow back

into the engine, causing severe en-

gine damage.

[ECJ01330]

Tow the watercraft at 8 km/h (5 mph) or less.

NOTICE: Tow the watercraft at 8 km/h (5

mph) or less, otherwise water could flood

the engine compartment or water could

flow back into the engine, causing severe

engine damage.

[ECJ01321]

EJU34734

Submerged watercraft

If the watercraft is submerged or flooded with

water, drain the bilge water from the engine

1 Fuse holder

2 Electrical box

3 Fuse

4 Cap

Fuse amperage:

Battery fuse:10 A

1Bow rope hole

UF2F75E0.book Page 68 Thursday, July 5, 2012 8:50 AM