lock YAMAHA TDM 900 2009 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: TDM 900, Model: YAMAHA TDM 900 2009Pages: 94, PDF Size: 3.75 MB

Page 29 of 94

INSTRUMENT AND CONTROL FUNCTIONS

3-13

2

34

5

6

7

8

9

EAU13091

Fuel tank cap

To open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/8 turn clockwise. The lock will be re-

leased and the fuel tank cap can be

opened.

To close the fuel tank cap

1. Push the fuel tank cap into position

with the key inserted in the lock.

2. Turn the key counterclockwise to

the original position, remove it, and

then close the lock cover.

TIP

The fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11091

Make sure that the fuel tank cap is

properly closed after filling fuel.

Leaking fuel is a fire hazard.

1. Rear wheel hub

1

1. Fuel tank cap lock cover

2. Unlock.

1

2

Page 31 of 94

INSTRUMENT AND CONTROL FUNCTIONS

3-15

2

34

5

6

7

8

9

or premium unleaded fuel. Use of un-

leaded fuel will extend spark plug life

and reduce maintenance costs.

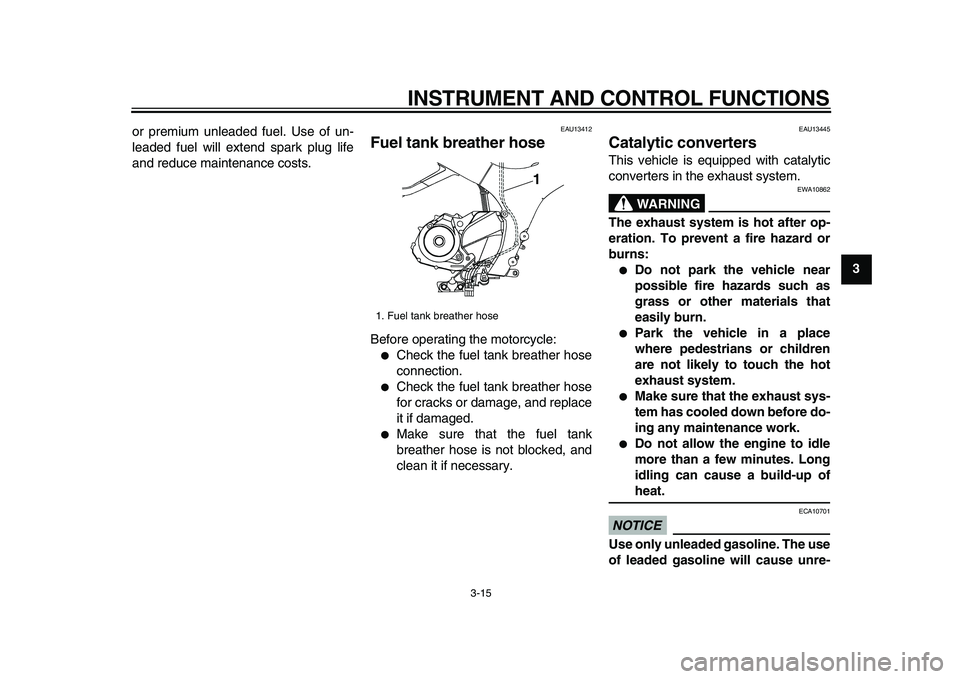

EAU13412

Fuel tank breather hose

Before operating the motorcycle:

●

Check the fuel tank breather hose

connection.

●

Check the fuel tank breather hose

for cracks or damage, and replace

it if damaged.

●

Make sure that the fuel tank

breather hose is not blocked, and

clean it if necessary.

EAU13445

Catalytic converters

This vehicle is equipped with catalytic

converters in the exhaust system.

WARNING

EWA10862

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:

●

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

●

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

●

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

●

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up of

heat.

NOTICE

ECA10701

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

1. Fuel tank breather hose

1

Page 32 of 94

INSTRUMENT AND CONTROL FUNCTIONS

3-16

1

2

3

4

5

6

7

8

9pairable damage to the catalytic

converter.

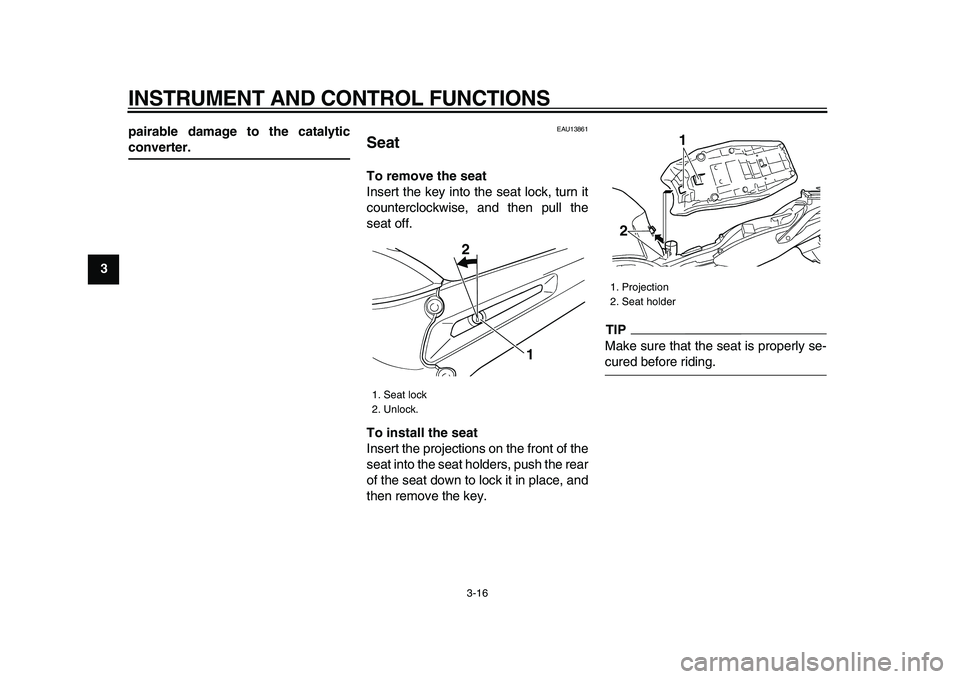

EAU13861

Seat

To remove the seat

Insert the key into the seat lock, turn it

counterclockwise, and then pull the

seat off.

To install the seat

Insert the projections on the front of the

seat into the seat holders, push the rear

of the seat down to lock it in place, and

then remove the key.

TIP

Make sure that the seat is properly se-

cured before riding.

1. Seat lock

2. Unlock.

1

2

1. Projection

2. Seat holder

1

2

Page 33 of 94

INSTRUMENT AND CONTROL FUNCTIONS

3-17

2

34

5

6

7

8

9

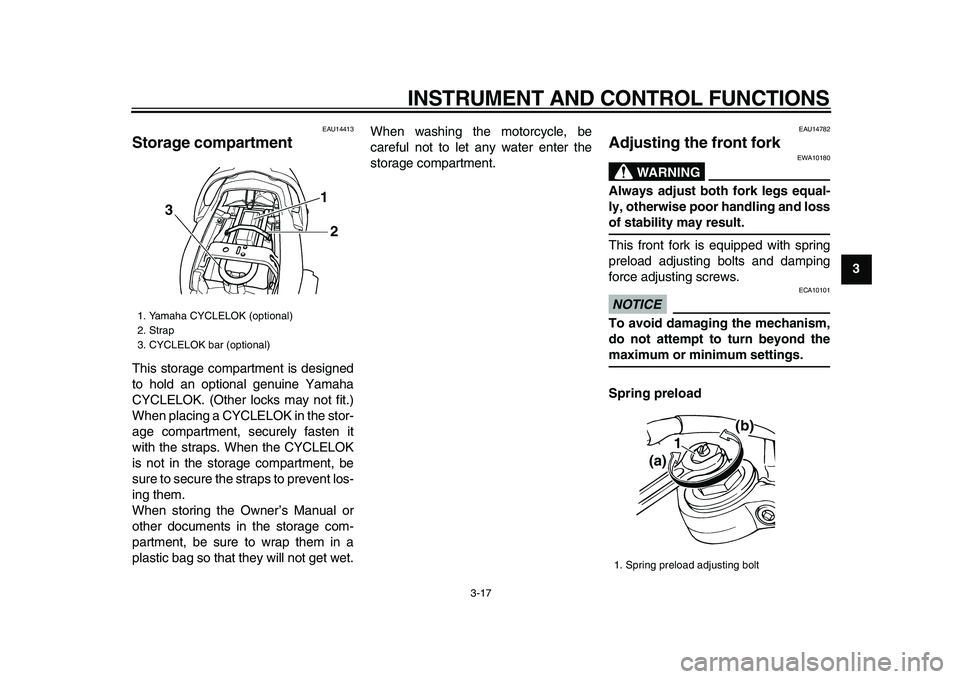

EAU14413

Storage compartment

This storage compartment is designed

to hold an optional genuine Yamaha

CYCLELOK. (Other locks may not fit.)

When placing a CYCLELOK in the stor-

age compartment, securely fasten it

with the straps. When the CYCLELOK

is not in the storage compartment, be

sure to secure the straps to prevent los-

ing them.

When storing the Owner’s Manual or

other documents in the storage com-

partment, be sure to wrap them in a

plastic bag so that they will not get wet.When washing the motorcycle, be

careful not to let any water enter the

storage compartment.

EAU14782

Adjusting the front fork

WARNING

EWA10180

Always adjust both fork legs equal-

ly, otherwise poor handling and loss

of stability may result.

This front fork is equipped with spring

preload adjusting bolts and damping

force adjusting screws.

NOTICE

ECA10101

To avoid damaging the mechanism,

do not attempt to turn beyond the

maximum or minimum settings.

Spring preload

1. Yamaha CYCLELOK (optional)

2. Strap

3. CYCLELOK bar (optional)

3

2 1

1. Spring preload adjusting bolt

1

(a)(b)

Page 63 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-18

2

3

4

5

67

8

9

EAU21960

Cast wheels

To maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

●

The wheel rims should be checked

for cracks, bends or warpage be-

fore each ride. If any damage is

found, have a Yamaha dealer re-

place the wheel. Do not attempt

even the smallest repair to the

wheel. A deformed or cracked

wheel must be replaced.

●

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

●

Ride at moderate speeds after

changing a tire since the tire sur-

face must first be “broken in” for it

to develop its optimal characteris-

tics.

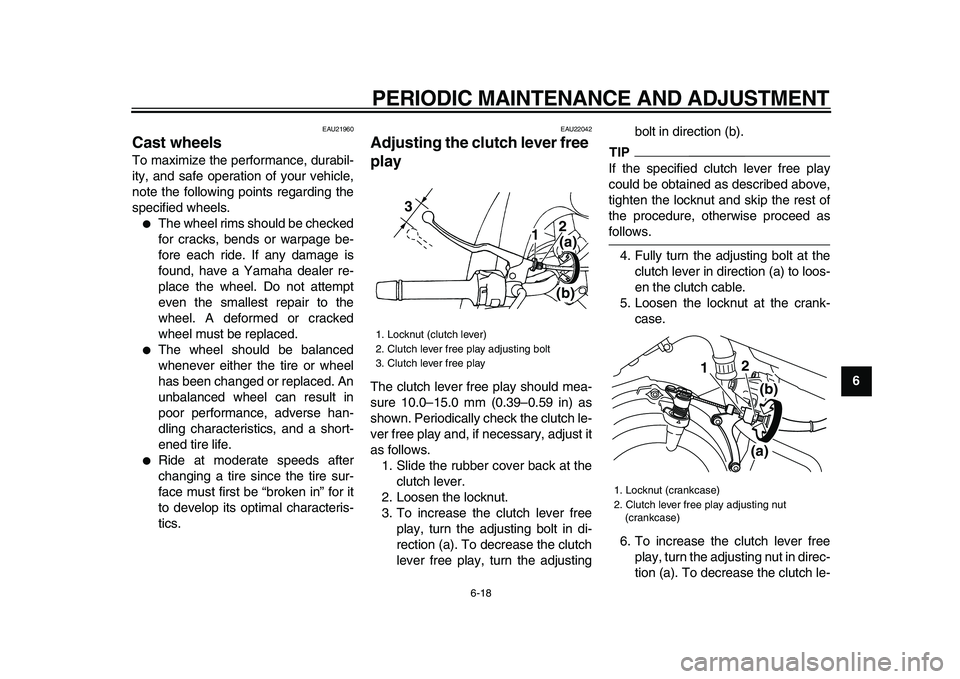

EAU22042

Adjusting the clutch lever free

play

The clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch le-

ver free play and, if necessary, adjust it

as follows.

1. Slide the rubber cover back at the

clutch lever.

2. Loosen the locknut.

3. To increase the clutch lever free

play, turn the adjusting bolt in di-

rection (a). To decrease the clutch

lever free play, turn the adjustingbolt in direction (b).

TIP

If the specified clutch lever free play

could be obtained as described above,

tighten the locknut and skip the rest of

the procedure, otherwise proceed as

follows.

4. Fully turn the adjusting bolt at the

clutch lever in direction (a) to loos-

en the clutch cable.

5. Loosen the locknut at the crank-

case.

6. To increase the clutch lever free

play, turn the adjusting nut in direc-

tion (a). To decrease the clutch le-

1. Locknut (clutch lever)

2. Clutch lever free play adjusting bolt

3. Clutch lever free play

12

3

(a)

(b)

1. Locknut (crankcase)

2. Clutch lever free play adjusting nut

(crankcase)

12

(a)(b)

Page 64 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

1

2

3

4

5

6

7

8

9

ver free play, turn the adjusting nut

in direction (b).

7. Tighten the locknut at the clutch le-

ver and the crankcase.

8. Slide the rubber cover to its origi-

nal position.

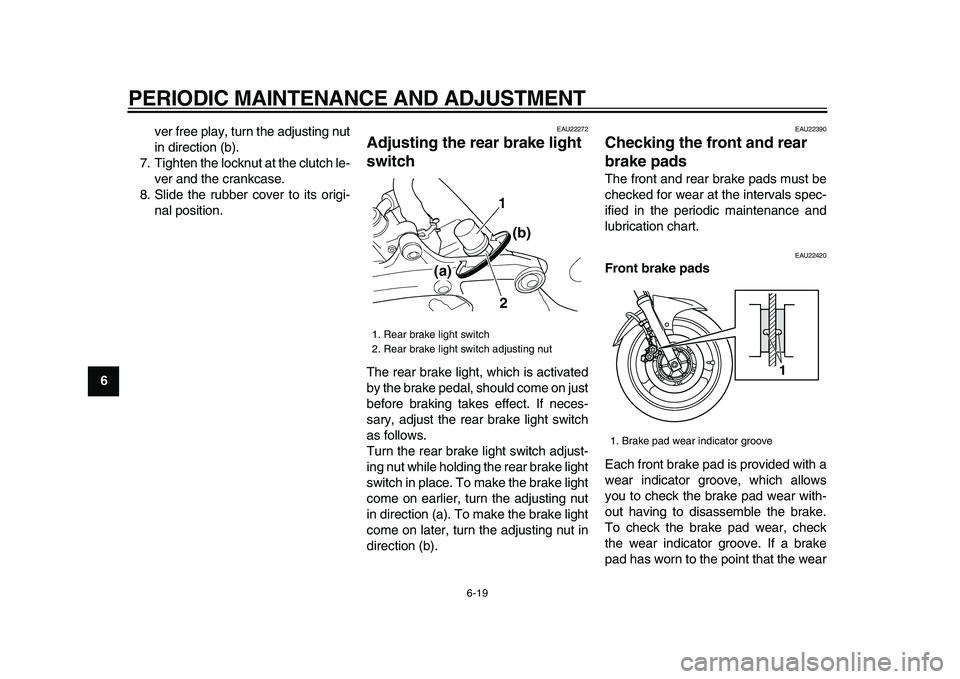

EAU22272

Adjusting the rear brake light

switch

The rear brake light, which is activated

by the brake pedal, should come on just

before braking takes effect. If neces-

sary, adjust the rear brake light switch

as follows.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake light

switch in place. To make the brake light

come on earlier, turn the adjusting nut

in direction (a). To make the brake light

come on later, turn the adjusting nut in

direction (b).

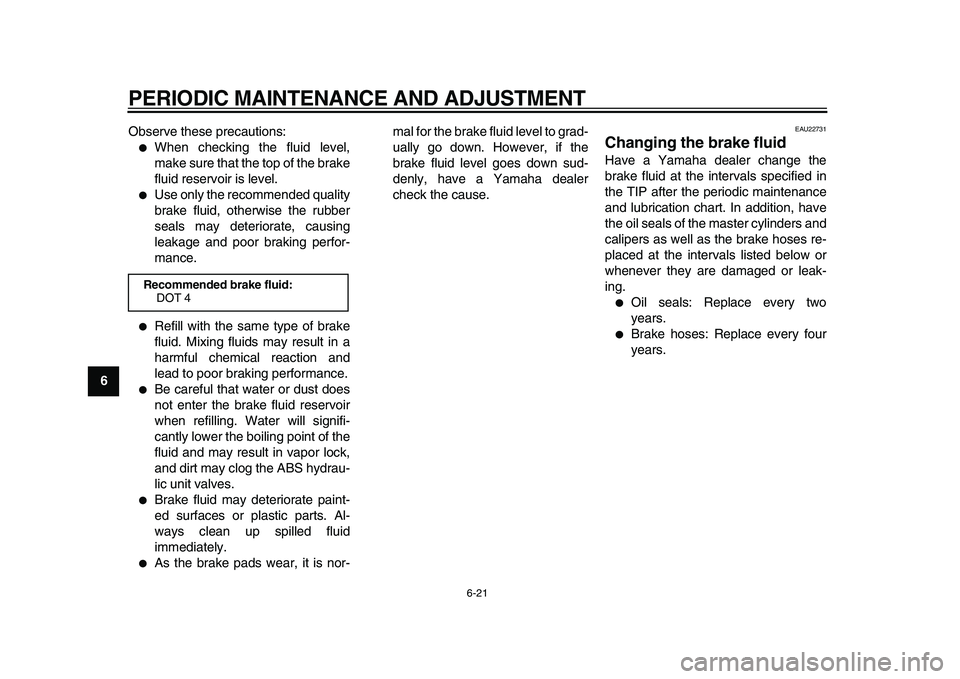

EAU22390

Checking the front and rear

brake pads

The front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU22420

Front brake pads

Each front brake pad is provided with a

wear indicator groove, which allows

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator groove. If a brake

pad has worn to the point that the wear

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2 (a)(b)

1. Brake pad wear indicator groove

1

Page 66 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

1

2

3

4

5

6

7

8

9

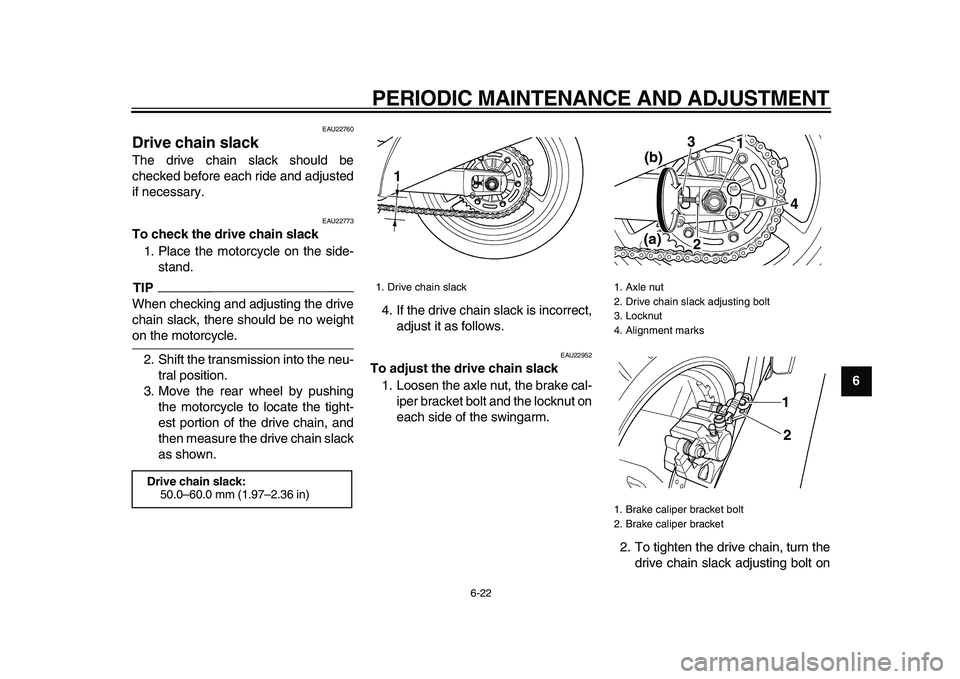

Observe these precautions:

●

When checking the fluid level,

make sure that the top of the brake

fluid reservoir is level.

●

Use only the recommended quality

brake fluid, otherwise the rubber

seals may deteriorate, causing

leakage and poor braking perfor-

mance.

●

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

●

Be careful that water or dust does

not enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of the

fluid and may result in vapor lock,

and dirt may clog the ABS hydrau-

lic unit valves.

●

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

●

As the brake pads wear, it is nor-mal for the brake fluid level to grad-

ually go down. However, if the

brake fluid level goes down sud-

denly, have a Yamaha dealer

check the cause.

EAU22731

Changing the brake fluid

Have a Yamaha dealer change the

brake fluid at the intervals specified in

the TIP after the periodic maintenance

and lubrication chart. In addition, have

the oil seals of the master cylinders and

calipers as well as the brake hoses re-

placed at the intervals listed below or

whenever they are damaged or leak-

ing.

●

Oil seals: Replace every two

years.

●

Brake hoses: Replace every four

years.

Recommended brake fluid:

DOT 4

Page 67 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

2

3

4

5

67

8

9

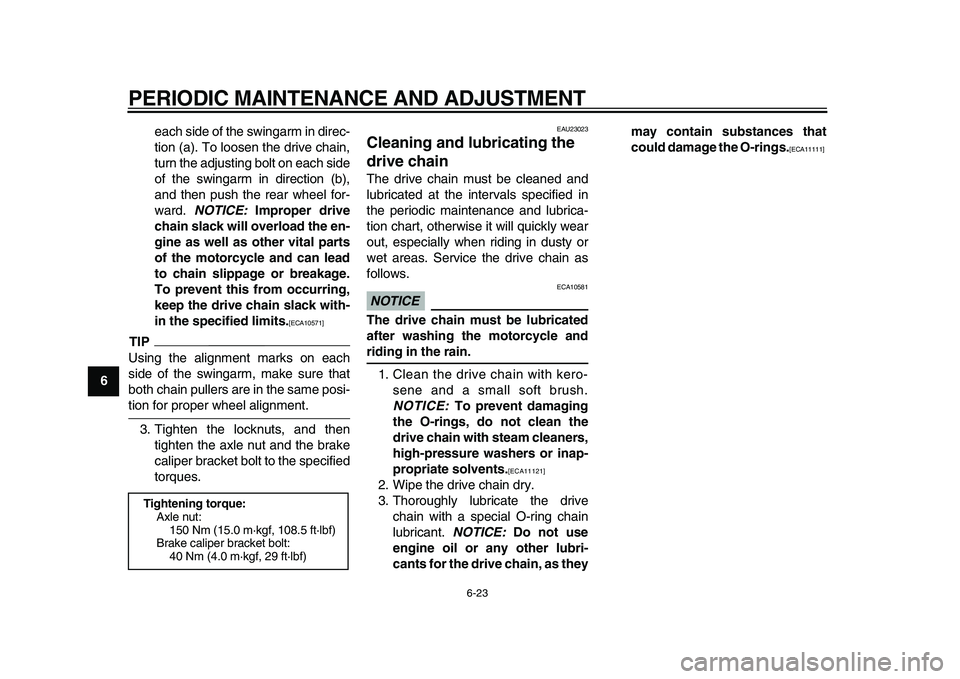

EAU22760

Drive chain slack

The drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22773

To check the drive chain slack

1. Place the motorcycle on the side-

stand.

TIP

When checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.

2. Shift the transmission into the neu-

tral position.

3. Move the rear wheel by pushing

the motorcycle to locate the tight-

est portion of the drive chain, and

then measure the drive chain slack

as shown.4. If the drive chain slack is incorrect,

adjust it as follows.

EAU22952

To adjust the drive chain slack

1. Loosen the axle nut, the brake cal-

iper bracket bolt and the locknut on

each side of the swingarm.

2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

Drive chain slack:

50.0–60.0 mm (1.97–2.36 in)

1. Drive chain slack

1

1. Axle nut

2. Drive chain slack adjusting bolt

3. Locknut

4. Alignment marks

1. Brake caliper bracket bolt

2. Brake caliper bracket

3

4 1

2 (b)

(a)

1

2

Page 68 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

1

2

3

4

5

6

7

8

9

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

NOTICE:

Improper drive

chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

TIP

Using the alignment marks on each

side of the swingarm, make sure that

both chain pullers are in the same posi-

tion for proper wheel alignment.

3. Tighten the locknuts, and then

tighten the axle nut and the brake

caliper bracket bolt to the specified

torques.

EAU23023

Cleaning and lubricating the

drive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.

NOTICE

ECA10581

The drive chain must be lubricated

after washing the motorcycle and

riding in the rain.

1.Clean the drive chain with kero-

sene and a small soft brush.

NOTICE:

To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11121]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant.

NOTICE:

Do not use

engine oil or any other lubri-

cants for the drive chain, as theymay contain substances that

could damage the O-rings.

[ECA11111]

Tightening torque:

Axle nut:

150 Nm (15.0 m·kgf, 108.5 ft·lbf)

Brake caliper bracket bolt:

40 Nm (4.0 m·kgf, 29 ft·lbf)

Page 73 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

2

3

4

5

67

8

9 To charge the battery

Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to

have discharged. Keep in mind that the

battery tends to discharge more quickly

if the vehicle is equipped with optional

electrical accessories.

NOTICE

ECA16520

To charge a VRLA (Valve Regulated

Lead Acid) battery, a special (con-

stant-voltage) battery charger is re-

quired. Using a conventional battery

charger will damage the battery. If

you do not have access to a con-

stant-voltage battery charger, have a

Yamaha dealer charge your battery.

To store the battery

1.If the vehicle will not be used for

more than one month, remove

the battery, fully charge it, and

then place it in a cool, dry place.

NOTICE:

When removing the

battery, be sure the key is turned

to “OFF”, then disconnect the

negative lead before discon-

necting the positive lead.

[ECA16302]

2. If the battery will be stored for more

than two months, check it at least

once a month and fully charge it if

necessary.

3. Fully charge the battery before in-

stallation.

4. After installation, make sure that

the battery leads are properly con-

nected to the battery terminals.

NOTICE

ECA16530

Always keep the battery charged.

Storing a discharged battery can

cause permanent battery damage.

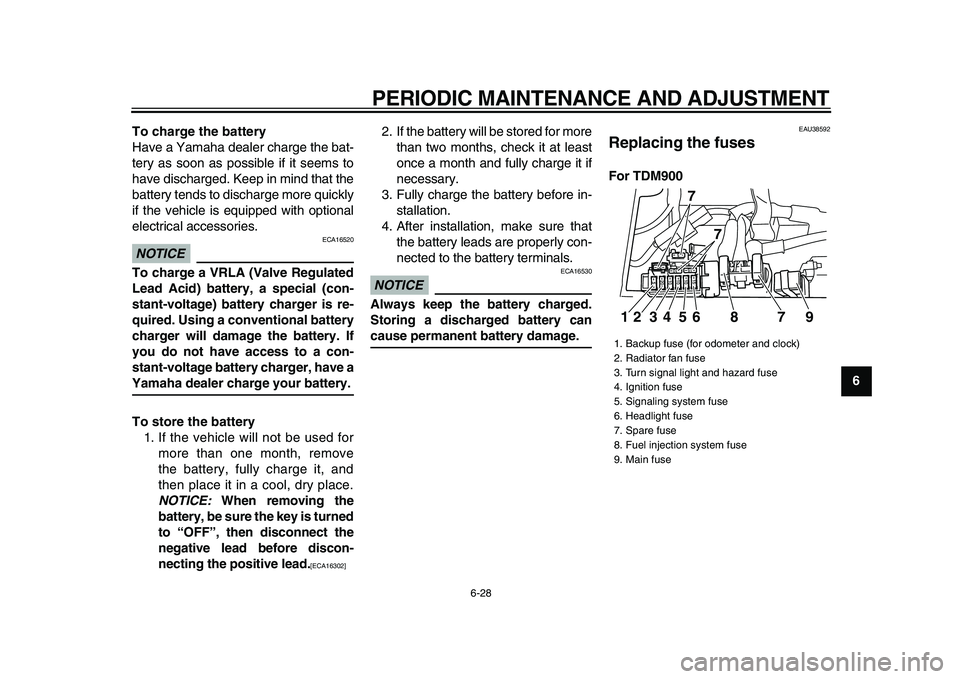

EAU38592

Replacing the fuses

For TDM900

1. Backup fuse (for odometer and clock)

2. Radiator fan fuse

3. Turn signal light and hazard fuse

4. Ignition fuse

5. Signaling system fuse

6. Headlight fuse

7. Spare fuse

8. Fuel injection system fuse

9. Main fuse

12 34 5 6 7 97

7

8