service YAMAHA TRACER 900 GT 2021 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: TRACER 900 GT, Model: YAMAHA TRACER 900 GT 2021Pages: 116, PDF Size: 4.35 MB

Page 43 of 116

Instrument and control functions

4-21

4

This module allows you to set the

clock.

When the clock module is selected, the

hours will be highlighted.

Set the hours by rotating the wheel

switch. Push the switch to confirm and

highlight the minutes.

After confirming the minutes, you will

be returned to the top MENU screen.

“SUS. Sensor Cali

bration”

After any service to the rear suspen-

sion, a sensor calibration must be per-

formed using this module.

Select “Execute” and within approx. 10

seconds the result of the calibration

(success/failed) will be displayed.

TIPWhen performing the sensor calibra-

tion, place the motorcycle on the cen-

terstand and there should be no weight

on the motorcycle.“All Reset”

This module resets all settings items

(except the odometers, Clock and

SUS. Sensor Calibration) to their de-

fault or factory presets.

Select YES to reset all items. After se-

lecting YES, all items will be reset and

the screen will automatically return to

the top MENU screen.

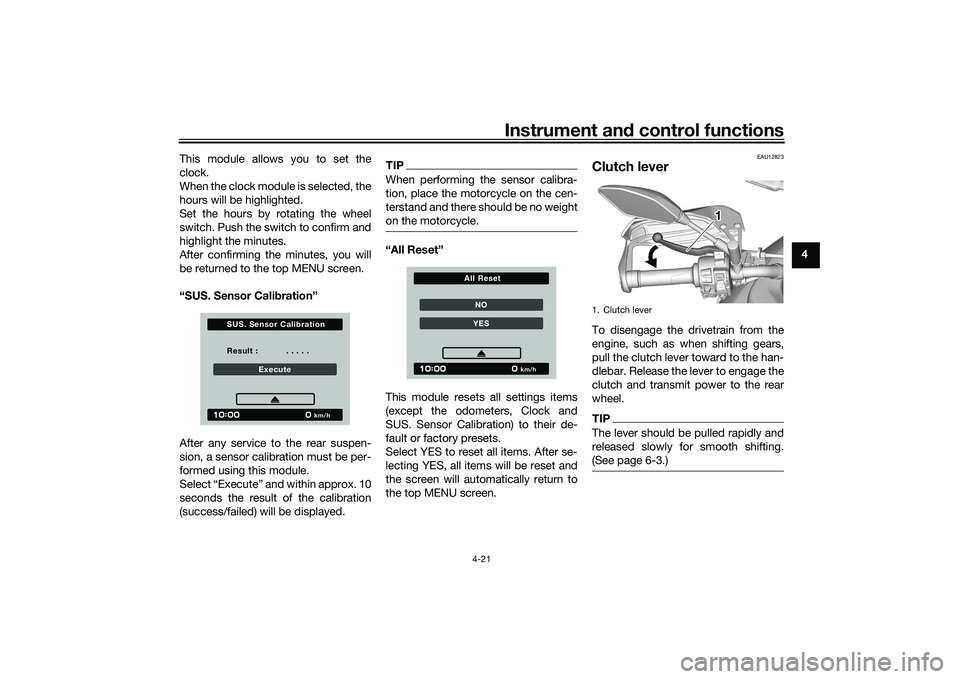

EAU12823

Clutch leverTo disengage the drivetrain from the

engine, such as when shifting gears,

pull the clutch lever toward to the han-

dlebar. Release the lever to engage the

clutch and transmit power to the rear

wheel.TIPThe lever should be pulled rapidly and

released slowly for smooth shifting.

(See page 6-3.)

Result : . . . . .

Execute

km/h

S U S. S ensor Calibration

NOYES

km/h

All Reset

1. Clutch lever

111

UBAPE0E0.book Page 21 Thursday, December 24, 2020 9:14 AM

Page 55 of 116

Instrument and control functions

4-33

4

EAU92782

A djustin g the front an d rear

suspensionThis model is equipped with an elec-

tronically controlled suspension damp-

ing system (KADS). See pages 3-4,

4-13 for more information on KADS

and SUS-MODE.TIPAfter any service to the rear suspen-

sion, a sensor calibration must be per-

formed via the settings MENU. See

page 4-21 for more information on

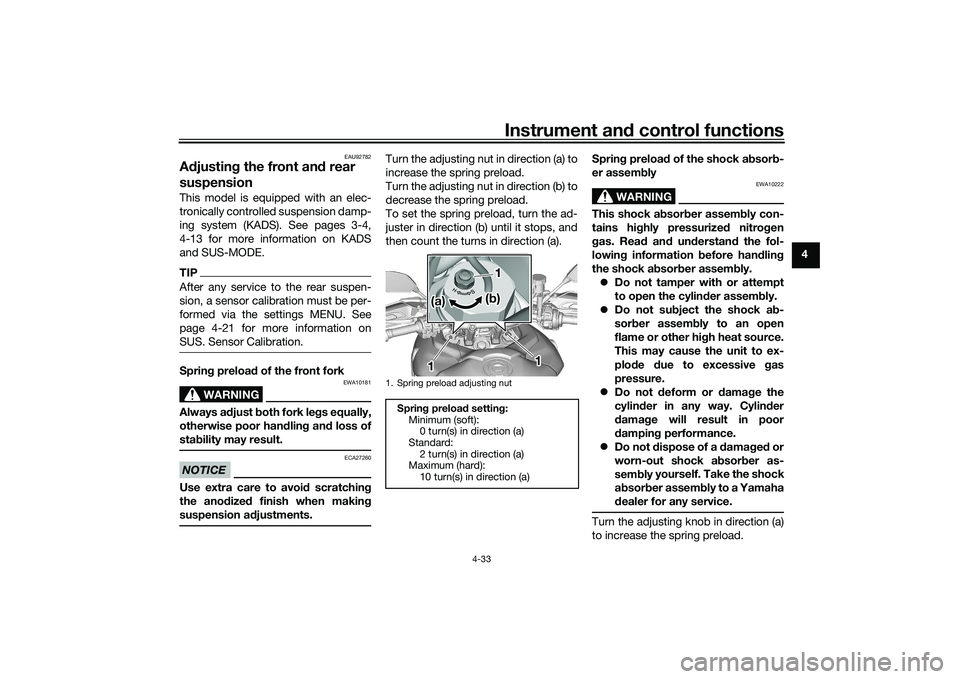

SUS. Sensor Calibration.Sprin g preloa d of the front fork

WARNING

EWA10181

Always a djust both fork le gs equally,

otherwise poor han dlin g an d loss of

sta bility may result.NOTICE

ECA27260

Use extra care to avoi d scratching

the anod ized finish when makin g

suspension a djustments.

Turn the adjusting nut in direction (a) to

increase the spring preload.

Turn the adjusting nut in direction (b) to

decrease the spring preload.

To set the spring preload, turn the ad-

juster in direction (b) until it stops, and

then count the turns in direction (a). Sprin

g preloa d of the shock a bsor b-

er assem bly

WARNING

EWA10222

This shock a bsor ber assem bly con-

tains hig hly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylind er assembly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not deform or damag e the

cylin der in any way. Cylin der

d ama ge will result in poor

d ampin g performance.

Do not dispose of a d amaged or

worn-out shock a bsor ber as-

sem bly yo

u

rself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

Turn the adjusting knob in direction (a)

to increase the spring preload.

1. Spring preload adjusting nut

Sprin g preloa d settin g:

Minimum (soft): 0 turn(s) in direction (a)

Standard: 2 turn(s) in direction (a)

Maximum (hard):

10 turn(s) in direction (a)

1 11

11

11(a) (a) (a)

(b) (b) (b)

UBAPE0E0.book Page 33 Thursday, December 24, 2020 9:14 AM

Page 68 of 116

Periodic maintenance an d a djustment

7-1

7

EAU17246

Periodic inspection, adjustment, and

lubrication will keep your vehicle in the

safest and most efficient condition

possible. Safety is an obligation of the

vehicle owner/operator. The most im-

portant points of vehicle inspection,

adjustment, and lubrication are ex-

plained on the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performin g maintenance ac-

tivities incorrectly may increase

your risk of injury or death durin g

service or while usin g the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha d ealer perform

service.

WARNING

EWA15123

Turn off the en gine when performin g

maintenance unless otherwise

specified .

A runnin g en gine has movin g

parts that can catch on body

parts or clothin g an d electrical

parts that can cause shocks or

fires.

Runnin g the en gine while ser-

vicin g can lead to eye injury,

b urns, fire, or car bon monoxi de

poisonin g – possi bly lea din g to

d eath. See pag e 1-3 for more in-

formation a bout car bon monox-

i d e.

WARNING

EWA15461

Brake discs, calipers, drums, and

linin gs can b ecome very hot d uring

use. To avoi d possi ble burns, let

b rake components cool before

touchin g them.

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replace-

ment, or repair of the emission control

devices and systems may be per-

formed by any repair establishment or

individual that is certified (if applicable).

Yamaha dealers are trained and equipped to perform these particular

services.

UBAPE0E0.book Page 1 Thursday, December 24, 2020 9:14 AM

Page 75 of 116

Periodic maintenance an d a djustment

7-8

7

EAU72800

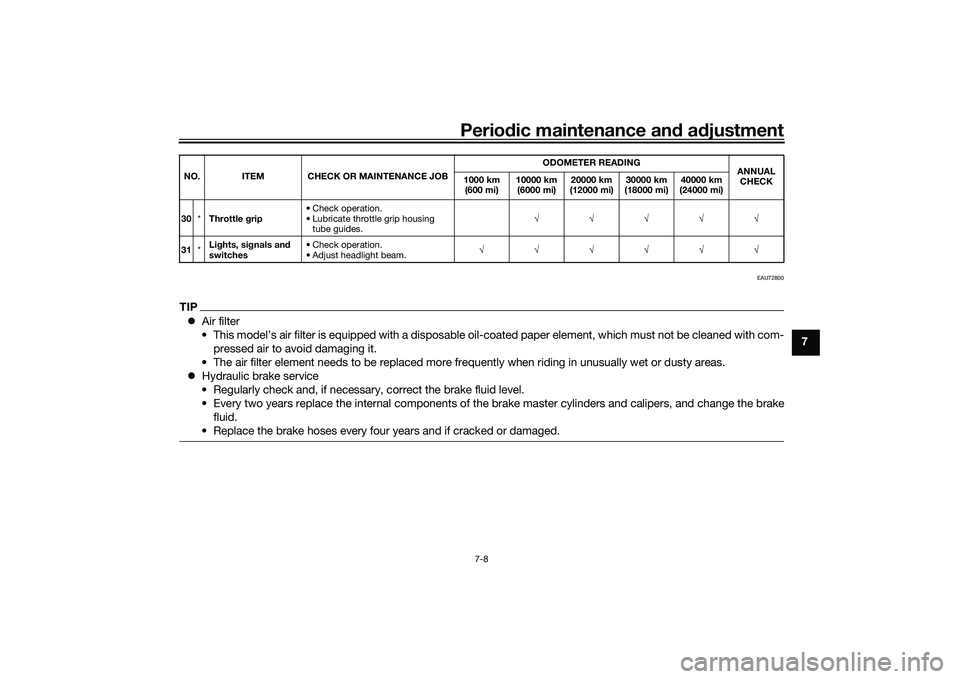

TIP Air filter

• This model’s air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with com- pressed air to avoid damaging it.

• The air filter element needs to be replaced more frequently when riding in unusually wet or dusty areas.

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.30 *Throttle g rip • Check operation.

• Lubricate throttle grip housing

tube guides. √√√√√

31 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

UBAPE0E0.book Page 8 Thursday, December 24, 2020 9:14 AM

Page 82 of 116

Periodic maintenance an d a djustment

7-15

7

EAU21403

Valve clearanceThe valves are an important engine

component, and since valve clearance

changes with use, they must be

checked and adjusted at the intervals

specified in the periodic maintenance

chart. Unadjusted valves can result in

improper air-fuel mixture, engine

noise, and eventually engine damage.

To prevent this from occurring, have

your Yamaha dealer check and adjust

the valve clearance at regular intervals.TIPThis service must be performed when

the engine is cold.

EAU64412

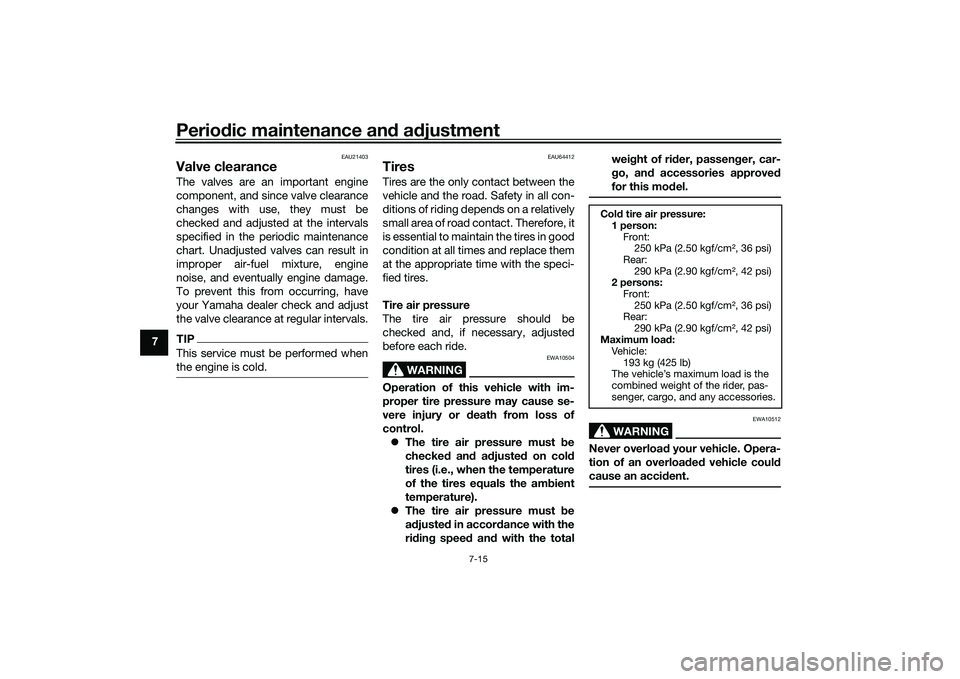

TiresTires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA10504

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control. The tire air pressure must be

checked and a djuste d on col d

tires (i.e., when the temperature

of the tires equals the amb ient

temperature).

The tire air pressure must be

a d juste d in accor dance with the

ri din g speed and with the total wei

ght of ri der, passen ger, car-

g o, an d accessories approve d

for this mo del.

WARNING

EWA10512

Never overloa d your vehicle. Opera-

tion of an overload ed vehicle coul d

cause an acci dent.Col d tire air pressure:

1 person: Front:250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

2 persons:

Front:250 kPa (2.50 kgf/cm², 36 psi)

Rear:

290 kPa (2.90 kgf/cm², 42 psi)

Maximum load :

Vehicle:

193 kg (425 lb)

The vehicle’s maximum load is the

combined weight of the rider, pas-

senger, cargo, and any accessories.

UBAPE0E0.book Page 15 Thursday, December 24, 2020 9:14 AM

Page 86 of 116

Periodic maintenance an d a djustment

7-19

7 b

rakin g performance, which may re-

sult in loss of control and an acci-

d ent.

EAU36505

Brake li ght switchesThe brake light should come on just

before braking takes effect. The brake

light is activated by switches connect-

ed to the brake lever and brake pedal.

Since the brake light switches are

components of the anti-lock brake sys-

tem, they should only be serviced by a

Yamaha dealer.

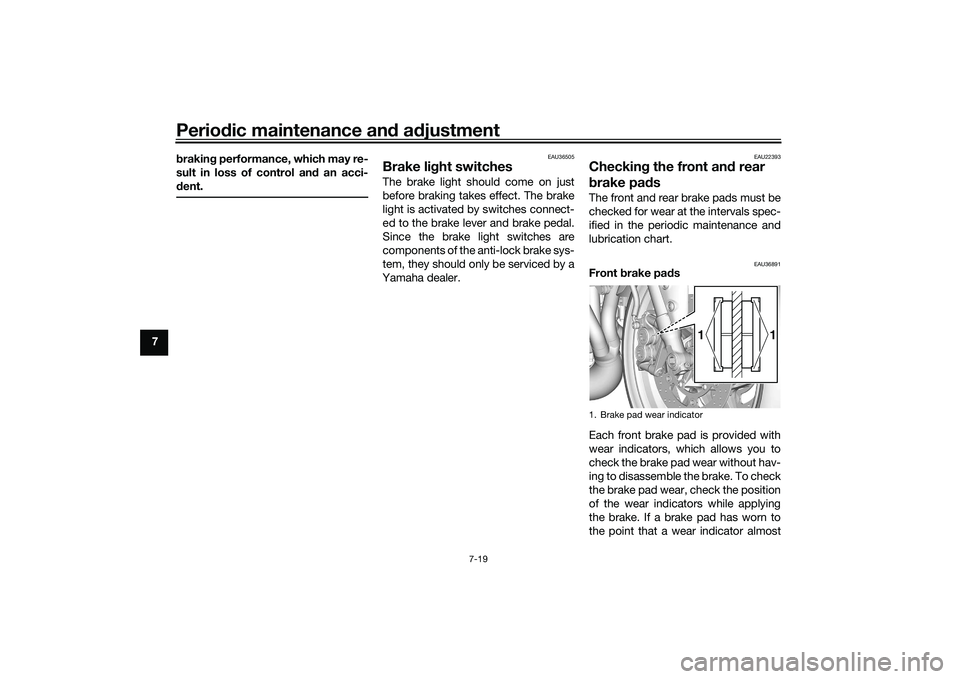

EAU22393

Checkin g the front an d rear

b rake pa dsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU36891

Front brake pa ds

Each front brake pad is provided with

wear indicators, which allows you to

check the brake pad wear without hav-

ing to disassemble the brake. To check

the brake pad wear, check the position

of the wear indicators while applying

the brake. If a brake pad has worn to

the point that a wear indicator almost1. Brake pad wear indicator

1

1

UBAPE0E0.book Page 19 Thursday, December 24, 2020 9:14 AM

Page 90 of 116

Periodic maintenance an d a djustment

7-23

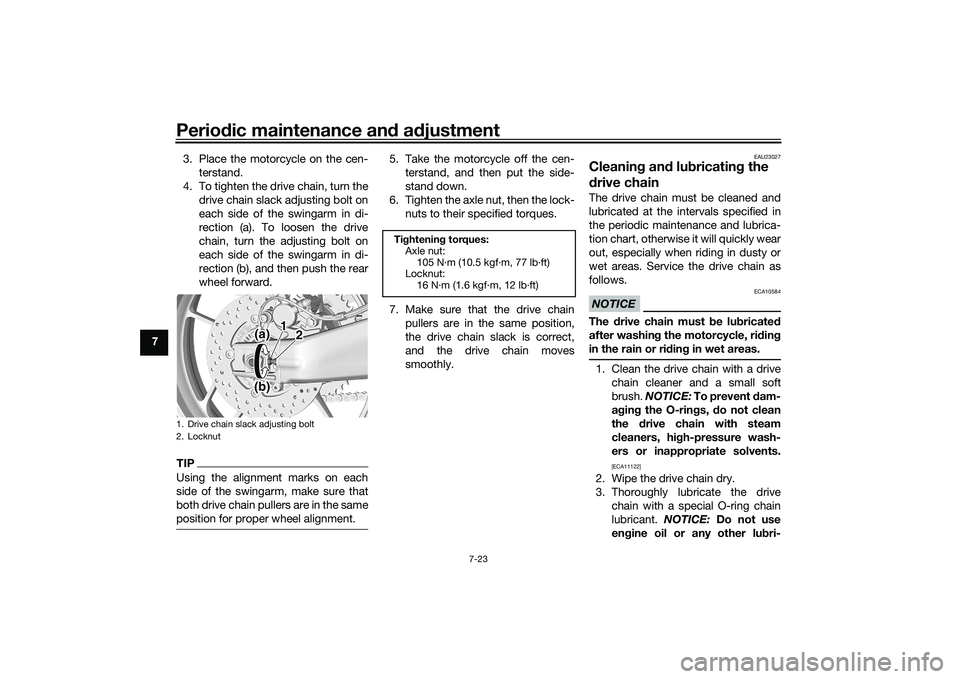

7 3. Place the motorcycle on the cen-

terstand.

4. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward.

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

5. Take the motorcycle off the cen-terstand, and then put the side-

stand down.

6. Tighten the axle nut, then the lock- nuts to their specified torques.

7. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23027

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with a drive

chain cleaner and a small soft

brush. NOTICE: To prevent d am-

a g in g the O-rin gs, do not clean

the drive chain with steam

cleaners, hi gh-pressure wash-

ers or inappropriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

1. Drive chain slack adjusting bolt

2. Locknut

(a) 1

2

(b)

Ti ghtenin g torques:

Axle nut: 105 N·m (10.5 kgf·m, 77 lb·ft)

Locknut:

16 N·m (1.6 kgf·m, 12 lb·ft)

UBAPE0E0.book Page 23 Thursday, December 24, 2020 9:14 AM

Page 100 of 116

Periodic maintenance an d a djustment

7-33

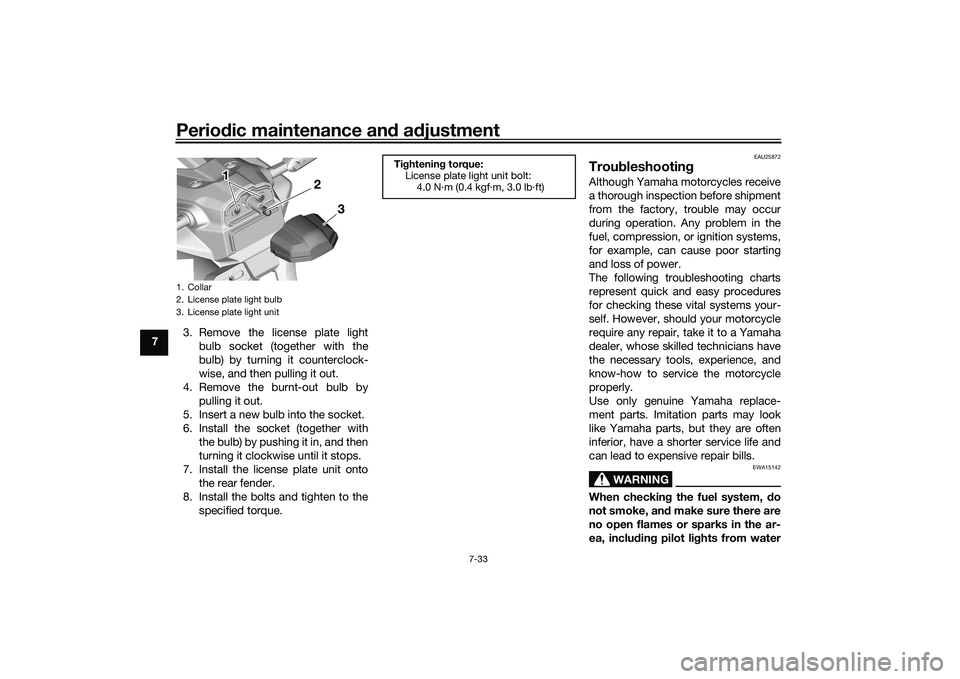

7 3. Remove the license plate light

bulb socket (together with the

bulb) by turning it counterclock-

wise, and then pulling it out.

4. Remove the burnt-out bulb by pulling it out.

5. Insert a new bulb into the socket.

6. Install the socket (together with the bulb) by pushing it in, and then

turning it clockwise until it stops.

7. Install the license plate unit onto the rear fender.

8. Install the bolts and tighten to the specified torque.

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, do

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

1. Collar

2. License plate light bulb

3. License plate light unit

3

2

1 1 1

Ti

ghtenin g torque:

License plate light unit bolt:

4.0 N·m (0.4 kgf·m, 3.0 lb·ft)

UBAPE0E0.book Page 33 Thursday, December 24, 2020 9:14 AM

Page 108 of 116

Specifications

9-1

9

Dimensions:Overall length:2175 mm (85.6 in)

Overall width:

885 mm (34.8 in)

Overall height: 1430/1470 mm (56.3/57.9 in)

Seat height: 810/825 mm (31.9/32.5 in)

Wheelbase:

1500 mm (59.1 in)

Ground clearance: 135 mm (5.31 in)

Minimum turning radius: 3.1 m (10.17 ft)Wei ght:Curb weight:

220 kg (485 lb)Engine:Combustion cycle:

4-stroke

Cooling system: Liquid cooled

Valve train: DOHC

Cylinder arrangement:

Inline

Number of cylinders: 3-cylinder

Displacement: 890 cm³

Bore × stroke:

78.0 × 62.1 mm (3.07 × 2.44 in) Starting system:

Electric starter

Engine oil:Recommended brand:

SAE viscosity grades:

10W-40

Recommended engine oil grade:

API service SG type or higher, JASO

standard MA

Engine oil quantity:

Oil change: 2.80 L (2.96 US qt, 2.46 Imp.qt)

With oil filter removal:

3.20 L (3.38 US qt, 2.82 Imp.qt)Coolant quantity:Coolant reservoir (up to the maximum level

mark):0.28 L (0.30 US qt, 0.25 Imp.qt)

Radiator (including all routes): 1.72 L (1.82 US qt, 1.51 Imp.qt)Fuel:Recommended fuel:Unleaded gasoline (E10 acceptable)

Octane number (RON): 95

Fuel tank capacity:

19 L (5.0 US gal, 4.2 Imp.gal)

Fuel reserve amount: 3.0 L (0.79 US gal, 0.66 Imp.gal)

Fuel injection:Throttle body:ID mark: B7N1Drivetrain:Gear ratio:

1st:2.571 (36/14)

2nd:

1.947 (37/19)

3rd: 1.619 (34/21)

4th: 1.381 (29/21)

5th:

1.190 (25/21)

6th: 1.037 (28/27)Front tire:Type:

Tubeless

Size: 120/70ZR17M/C (58W)

Manufacturer/model: BRIDGESTONE/BATTLAX SPORT

TOURING T32FRear tire:Type:

Tubeless

Size: 180/55ZR17M/C (73W)

Manufacturer/model: BRIDGESTONE/BATTLAX SPORT

TOURING T32R

UBAPE0E0.book Page 1 Thursday, December 24, 2020 9:14 AM

Page 111 of 116

Consumer information

10-2

10

The model label is affixed to the frame

under the rider seat. (See page 4-28.)

Record the information on this label in

the space provided. This information

will be needed when ordering spare

parts from a Yamaha dealer.

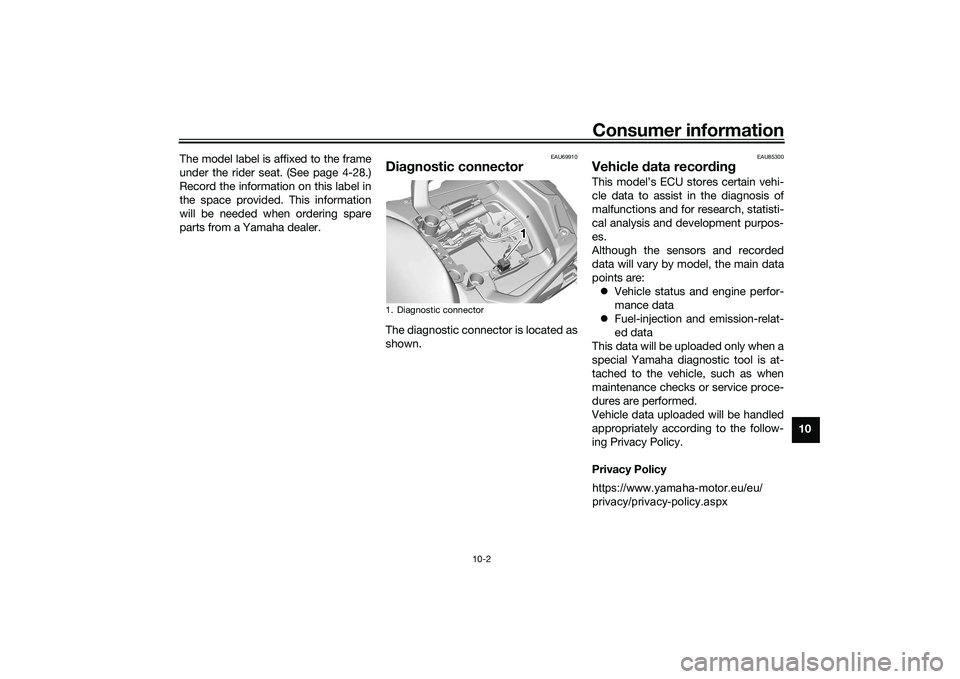

EAU69910

Dia

gnostic connectorThe diagnostic connector is located as

shown.

EAU85300

Vehicle data recor din gThis model’s ECU stores certain vehi-

cle data to assist in the diagnosis of

malfunctions and for research, statisti-

cal analysis and development purpos-

es.

Although the sensors and recorded

data will vary by model, the main data

points are:

Vehicle status and engine perfor-

mance data

Fuel-injection and emission-relat-

ed data

This data will be uploaded only when a

special Yamaha diagnostic tool is at-

tached to the vehicle, such as when

maintenance checks or service proce-

dures are performed.

Vehicle data uploaded will be handled

appropriately according to the follow-

ing Privacy Policy.

Privacy Policy

1. Diagnostic connector

111

https://www.yamaha-motor.eu/eu/

privacy/privacy-policy.aspx

UBAPE0E0.book Page 2 Thursday, December 24, 2020 9:14 AM