YAMAHA TT600RE 2004 Service Manual

TT600RE 2004

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/57493/w960_57493-0.png

YAMAHA TT600RE 2004 Service Manual

Trending: seat adjustment, ABS, air bleeding, checking oil, tow, brake light, high beam

Page 211 of 382

ENGENGINE DISASSEMBLY

5-7

7. Remove:

•Gasket (1) (cylinder head)

•Pins (2)

•Cylinder (3)

•Gasket (4) (cylinder)

8. Remove:

•Pins (1)

9. Remove:

•Pin ring (1)

NOTE:

Before removing the pin ring, cover the crankcase

with a clean cloth to prevent the ring falling into

the crankcase cavity.

10. Remove:

•Pin (1)

•Piston (2)

NOTE:

Before removing the pin, burr the pin housing

groove. If it is hard to pull out the pin even with the

groove burred, use the pin puller.

ProCarManuals.com

Page 212 of 382

ENGINE DISASSEMBLY

5-8

ENG

Avoid using the hammer to pull the pin out.

CAUTION: Piston pin puller set:

P/N. 90890-01304

3. Remove:

•Neutral gear switch cable (1)

2. Remove:

•Intermediate starter gear (1)

•Bearing (2)

•Distributor shaft (3)

INTERMEDIATE STARTER GEAR, CRANKCASE

COVER (L) AND GENERATOR STATOR

NOTE:

With the engine installed, maintenance of the inter-

mediate starter gear and the crankcase cover (L)

may be performed by removing the following parts.

•Exhaust pipe

•Starter

•Sprocket cover

1. Remove:

•Cover (1) intermediate starter gear

•Centring pins

•Gasket

ProCarManuals.com

Page 213 of 382

ENGENGINE DISASSEMBLY

5-9

4. Remove:

•Crankcase cover gasket (1) (L)

•Centring pins

•Seal ring and O-ring

•Gasket

6. Remove:

•Cable clamp (1)

•Coil (2)

•Stator (3)

CRANKCASE COVER (R), CLUTCH, PRIMARY

DRIVE GEAR AND BALANCER SHAFT GEAR

NOTE:

The clutch, the primary gear and the balance gear

may be inspected with the engine installed by

removing the following parts.

•Footrest (R)

•Oil delivery hose screw

5. Remove:

•Intermediate starter gear (1)

•Bearing (2)

•Distributor shaft (3)

ProCarManuals.com

Page 214 of 382

ENGINE DISASSEMBLY

5-10

ENG

2. Remove:

•Compression spring (1)

•Pressure plate (2)

•Ball (3)

•Friction plate (4)

•Clutch plate (5)

•Clutch boss spring (6)

•Clutch boss (7)

•Thrust plate (8)

•Clutch shroud (9)

•Push rod (10)

1. Remove:

•Engine oil delivery hose screw

•Copper washer

•Oil filter cover (1)

•Oil filter

•Seal ring and O-Ring

•Crankcase cover (2) (R)

NOTE:

•Before loosening the nut (11) (clutch shroud),

straighten the washer lock tab.

•To loosen the nut (clutch boss), block the

clutch boss using the special tool (12).

Clutch holding tool: P/N. 90890-04086

ProCarManuals.com

Page 215 of 382

ENGENGINE DISASSEMBLY

5-11

3. Remove

•Primary drive gear (1)

•Disc (2)

•Balancer drive gear (3)

•Disc (4)

•Key (5)

•Disc washer (6)

•Disc (7)

•Balancer gear (8)

•Straight key (9)

NOTE:

Before loosening the nut (9) (primary drive gear)

and nut (10) (balancer gear), straighten the wash

lock tab.

NOTE:

To loosen nuts (9) and (10), hold the rotor (CA

magneto) firmly in place using special tool (11).

Sheave holder: P/N. 90890-01701

Be careful not to touch jutting edges (12) on

the rotor with the sheave holder.

CAUTION:

4. Remove:

•Push lever (1)

•Spring

•Flat washer

NOTE:

Loosen the screw to remove the push rod.

ProCarManuals.com

Page 216 of 382

ENGINE DISASSEMBLY

5-12

ENG

OIL PUMP AND SHIFT LEVER

NOTE:

The oil pump and shift lever may be checked with

the engine installed by removing the following

parts:

•Footrest (R)

•Oil delivery hose screw

•Crankcase (R)

•Clutch

1. Remove:

•Circlip (1)

•Oil pump gear (2)

•Oil pump (3)

•O-rings (4)

2. Remove:

•Circlip (1) (from drive shaft)

•Ring (2)

•Circlip (3)

3. Remove:

•Circlip (1)

•Shift lever (2)

•Spring (3)

•Flat washer (4)

4. Remove:

•Stopper lever (1)

•Ring (2)

•Spring (3)

ProCarManuals.com

Page 217 of 382

ENGENGINE DISASSEMBLY

5-13

AC GENERATOR AND TIMING CHAIN

NOTE:

The AC generator may be inspected with the

engine installed by removing the following parts:

•Crankcase (L)

1. Remove:

•Nut (1)

•Washer (2)

•Rotor (3) (with starter gear)

•Bearing (4)

•Shim adjustment washer (5)

•Key (6)

NOTE:

To loosen the nut (rotor), lock the rotor with the

special tool (7).

Sheave holder: P/N. 90890-01701

Flywheel puller:P/N. 90890-01362

Be careful not to touch the jutting edges (8) on

the rotor with the special tool.

CAUTION:

NOTE:

Remove the rotor with the puller (1).

2. Remove:

•Chain guide (1)

•Timing chain (2)

ProCarManuals.com

Page 218 of 382

ENGINE DISASSEMBLY

5-14

ENG

CRANKCASE (R)

1. Remove:

•Crankcase (R)

NOTE:

•Loosen nuts starting from the one with the

highest number.

•Loosen all by 1/4 turn and then remove.

Removal procedure:

•Set the crankcase separating tool (1) in place.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Crankcase separating tool: P/N. 90890-01135

NOTE:

When tightening the support bolts of the separat-

ing tool, be sure to keep the tool body parallel to

the engine crankcase. If necessary, a screw may

be slightly loosened to put the tool body on level.

•Applying pressure, strike the front engine

assembly flange, the drive shafts and the gear

cam plate with a rubber hammer. Then

remove the crankcase.

NOTE:

•If the crankcase fails come out, lever at points

(2), being careful not to damage the

crankcase.

•Turn the gear cam plate as shown in the fig-

ure to prevent it interfering with the crankcase.

ProCarManuals.com

Page 219 of 382

ENGENGINE DISASSEMBLY

5-15

•Be careful not to damage surfaces in con-

tact with the crankcase.

•Use a soft hammer to hit the engine

crankcase. Only hit the reinforced parts.

Do not hit the surface in contact with the

gasket. Work slowly and carefully. Be care-

ful to perform the separation uniformly. If

one end locks, remove pressure from the

thrust screw, realign and recommence. If it

is impossible to separate the crankcase,

check that all screws and components

have been disassembled. Do not use force.

CAUTION:

ProCarManuals.com

Page 220 of 382

ENGINE DISASSEMBLY

5-16

ENG

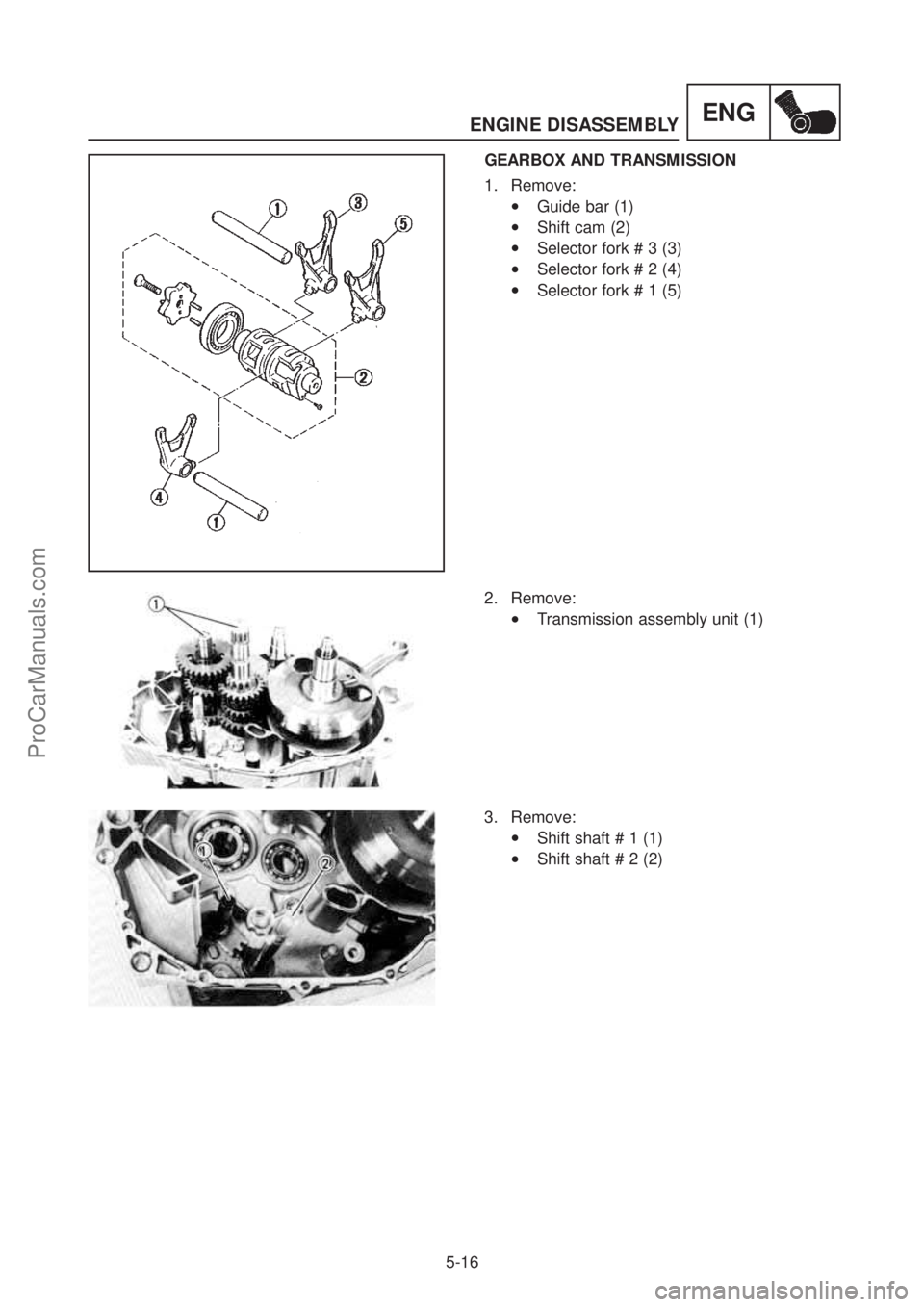

GEARBOX AND TRANSMISSION

1. Remove:

•Guide bar (1)

•Shift cam (2)

•Selector fork # 3 (3)

•Selector fork # 2 (4)

•Selector fork # 1 (5)

2. Remove:

•Transmission assembly unit (1)

3. Remove:

•Shift shaft # 1 (1)

•Shift shaft # 2 (2)

ProCarManuals.com

Trending: wiring, remove seats, engine oil, fuel, maintenance, clock setting, wheel size