engine YAMAHA TTR125 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR125, Model: YAMAHA TTR125 2001Pages: 508, PDF Size: 16.81 MB

Page 208 of 508

3 - 29

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

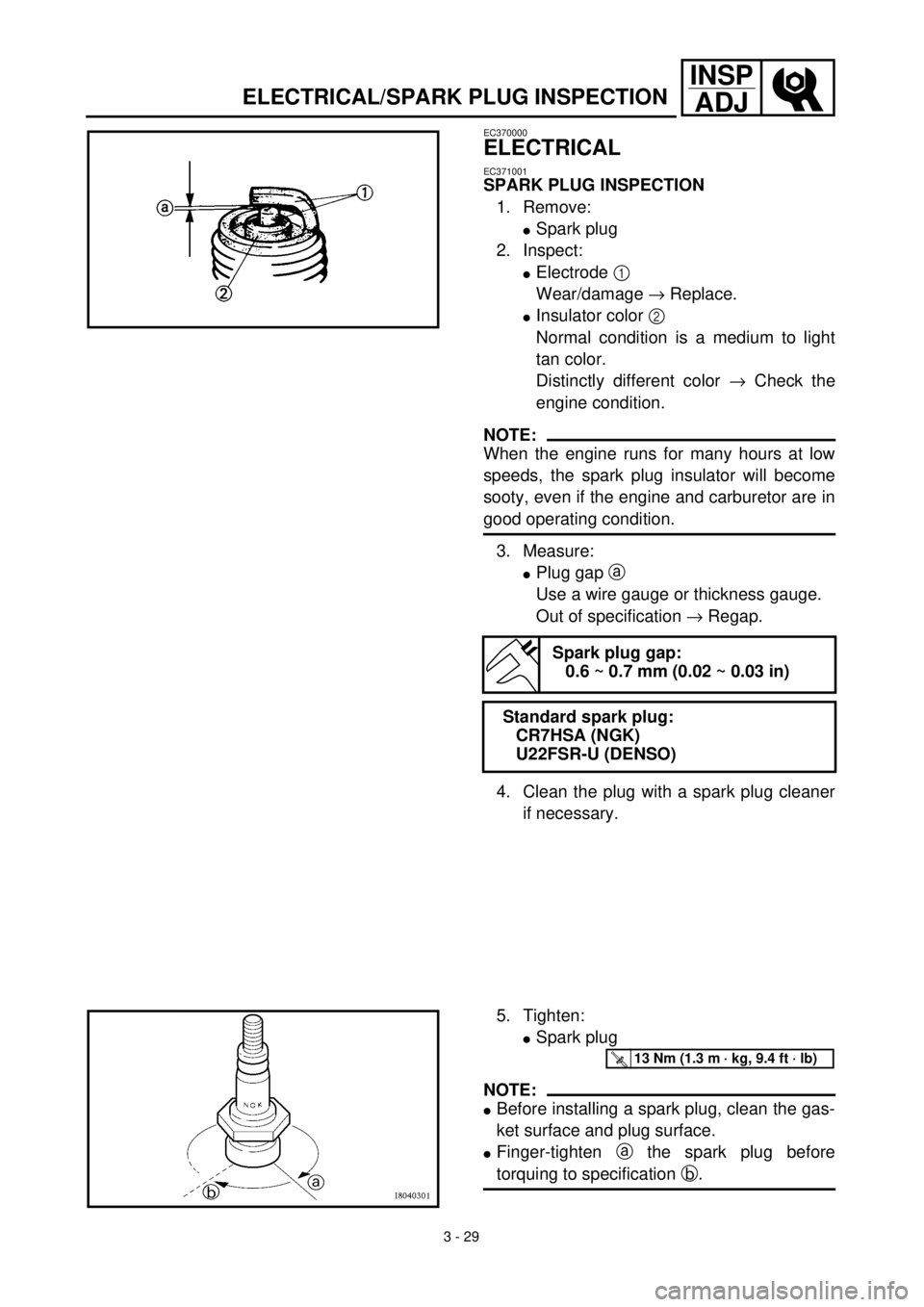

SPARK PLUG INSPECTION

1. Remove:

lSpark plug

2. Inspect:

lElectrode 1

Wear/damage ® Replace.

lInsulator color 2

Normal condition is a medium to light

tan color.

Distinctly different color ® Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

lPlug gap a

Use a wire gauge or thickness gauge.

Out of specification ® Regap.

4. Clean the plug with a spark plug cleaner

if necessary.

Spark plug gap:

0.6 ~ 0.7 mm (0.02 ~ 0.03 in)

Standard spark plug:

CR7HSA (NGK)

U22FSR-U (DENSO)

5. Tighten:

lSpark plug

NOTE:

lBefore installing a spark plug, clean the gas-

ket surface and plug surface.

lFinger-tighten a the spark plug before

torquing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 210 of 508

4 - 1

ENG

EC400000

ENGINE

EC4R0000

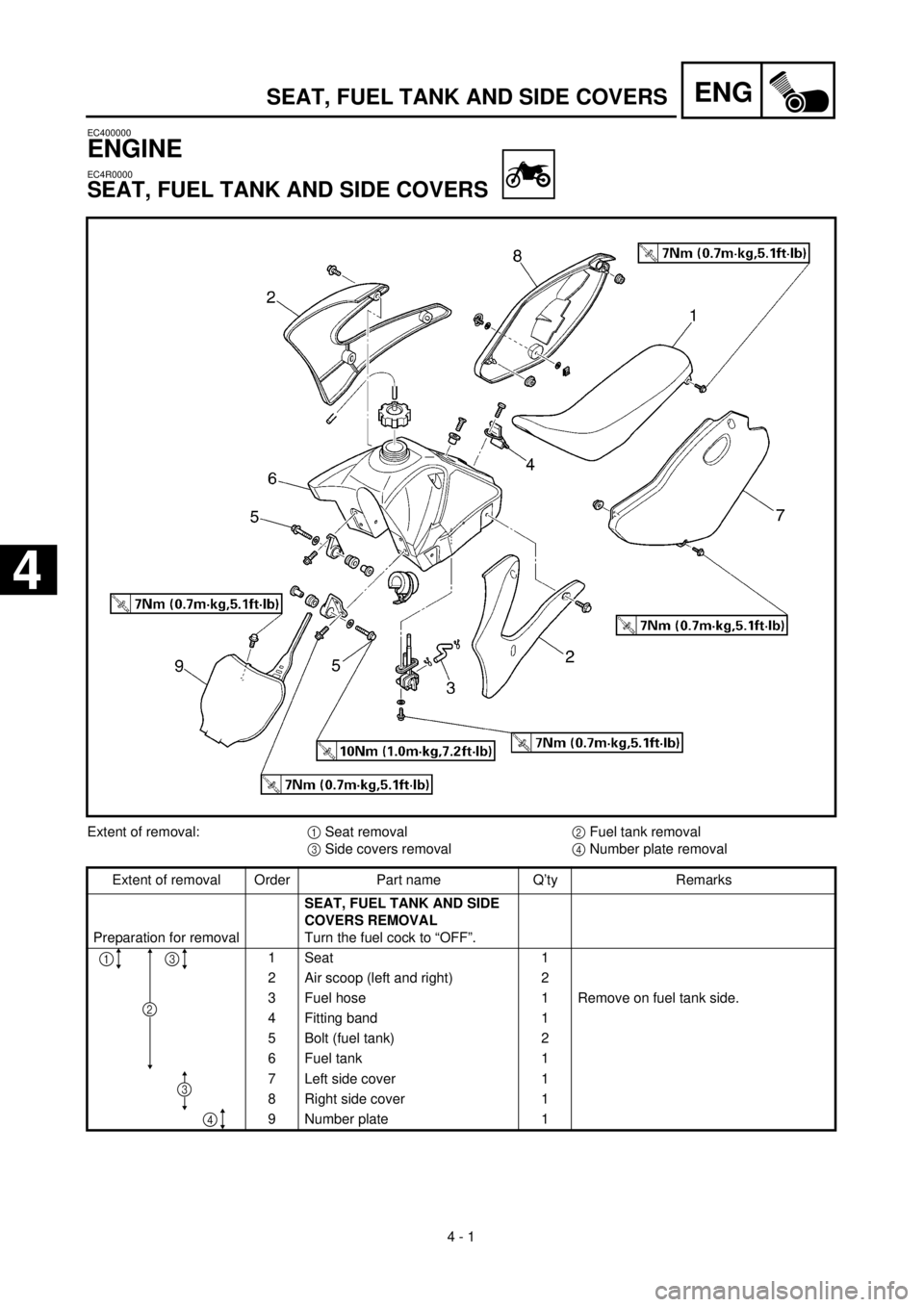

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1

Seat removal

2

Fuel tank removal

3

Side covers removal

4

Number plate removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

SEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Turn the fuel cock to “OFF”.

1 Seat 1

2 Air scoop (left and right) 2

3 Fuel hose 1 Remove on fuel tank side.

4 Fitting band 1

5 Bolt (fuel tank) 2

6 Fuel tank 1

7 Left side cover 1

8 Right side cover 1

9Number plate

1

13

4

2

3

SEAT, FUEL TANK AND SIDE COVERS

4

Page 218 of 508

4 - 5

ENG

CARBURETOR

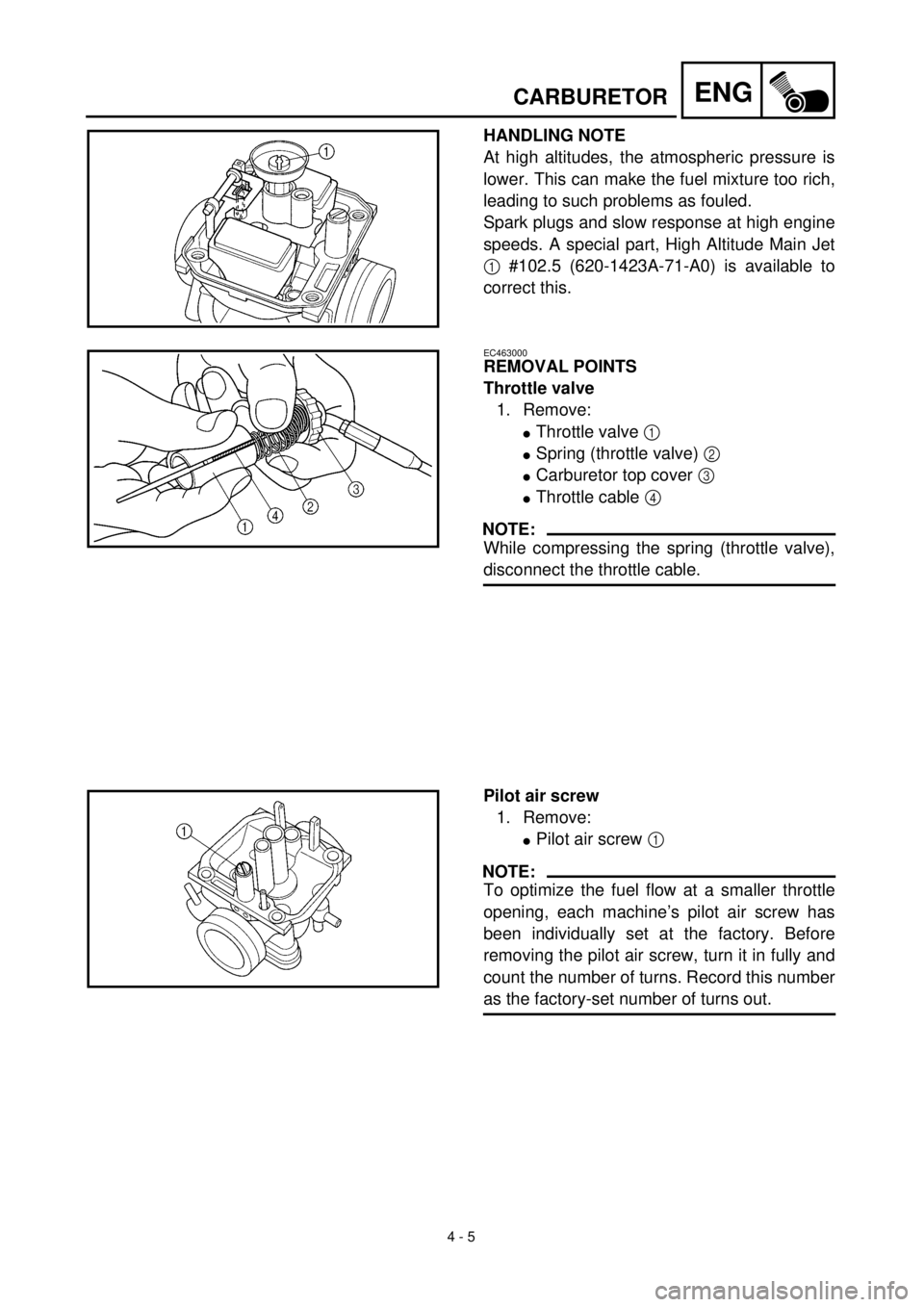

HANDLING NOTE

At high altitudes, the atmospheric pressure is

lower. This can make the fuel mixture too rich,

leading to such problems as fouled.

Spark plugs and slow response at high engine

speeds. A special part, High Altitude Main Jet

1

#102.5 (620-1423A-71-A0) is available to

correct this.

EC463000

REMOVAL POINTS

Throttle valve

1. Remove:

l

Throttle valve

1

l

Spring (throttle valve)

2

l

Carburetor top cover

3

l

Throttle cable

4

NOTE:

While compressing the spring (throttle valve),

disconnect the throttle cable.

Pilot air screw

1. Remove:

l

Pilot air screw

1

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot air screw has

been individually set at the factory. Before

removing the pilot air screw, turn it in fully and

count the number of turns. Record this number

as the factory-set number of turns out.

Page 230 of 508

4 - 11

ENG

CARBURETOR

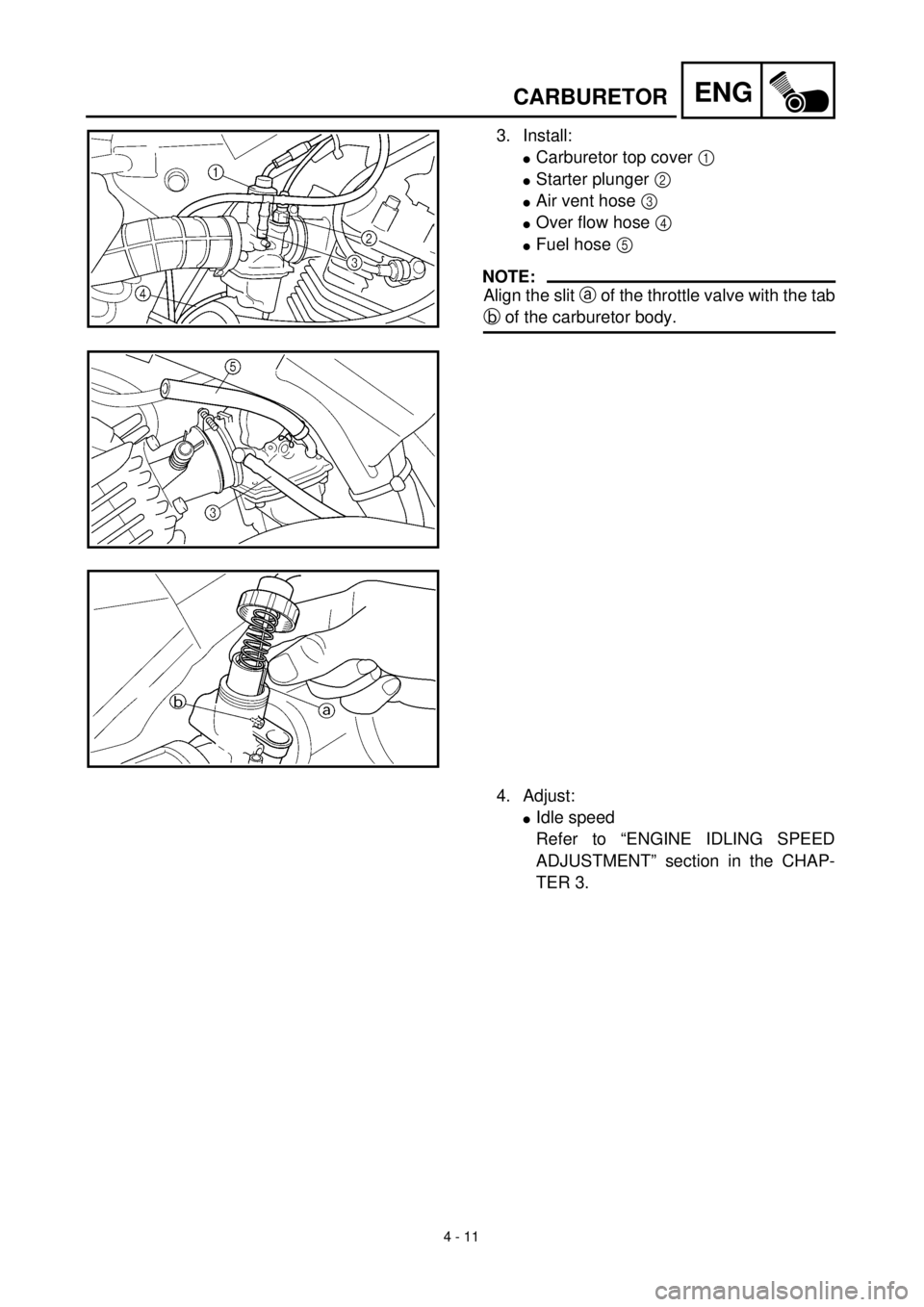

3. Install:

l

Carburetor top cover

1

l

Starter plunger

2

l

Air vent hose

3

l

Over flow hose

4

l

Fuel hose

5

NOTE:

Align the slit

a

of the throttle valve with the tab

b

of the carburetor body.

4. Adjust:

l

Idle speed

Refer to “ENGINE IDLING SPEED

ADJUSTMENT” section in the CHAP-

TER 3.

Page 232 of 508

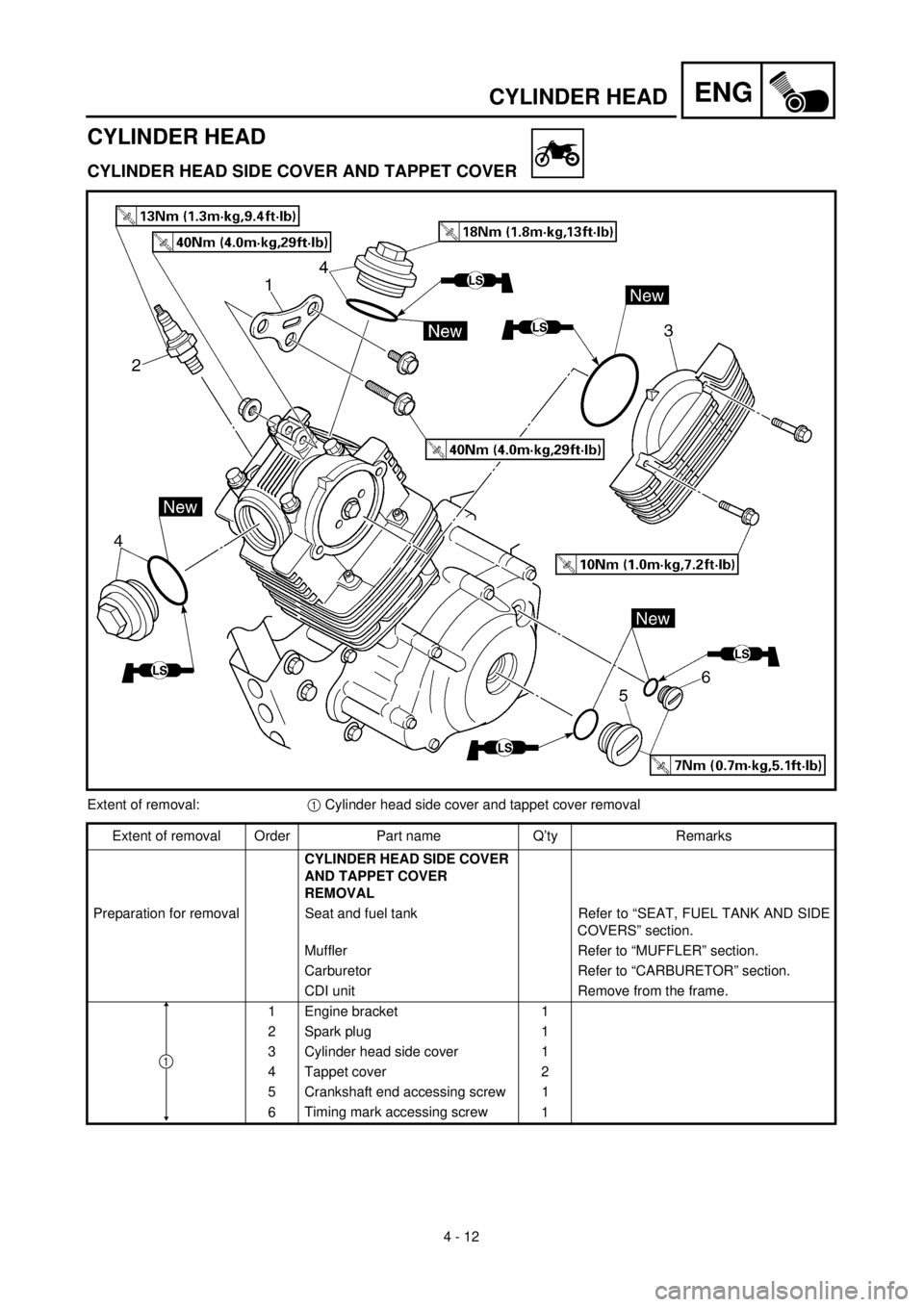

4 - 12

ENG

CYLINDER HEAD

CYLINDER HEAD

CYLINDER HEAD SIDE COVER AND TAPPET COVER

Extent of removal:

1

Cylinder head side cover and tappet cover removal

Extent of removal Order Part name Q’ty Remarks

CYLINDER HEAD SIDE COVER

AND TAPPET COVER

REMOVAL

Preparation for removal Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Muffler Refer to “MUFFLER” section.

Carburetor Refer to “CARBURETOR” section.

CDI unit Remove from the frame.

1 Engine bracket 1

2 Spark plug 1

3 Cylinder head side cover 1

4 Tappet cover 2

5 Crankshaft end accessing screw 1

6Timing mark accessing screw

1

1

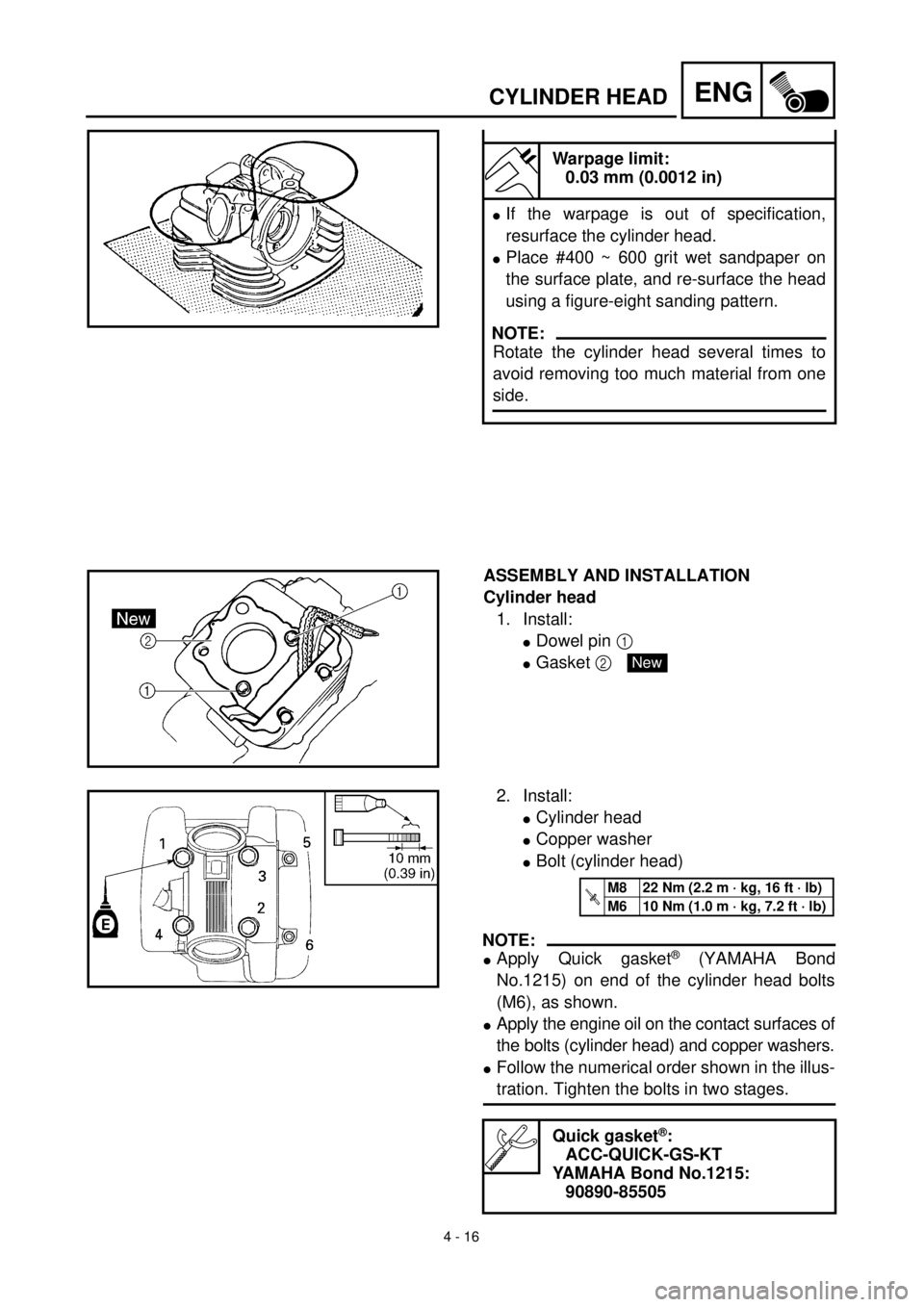

Page 240 of 508

4 - 16

ENG

CYLINDER HEAD

Warpage limit:

0.03 mm (0.0012 in)

l

If the warpage is out of specification,

resurface the cylinder head.

l

Place #400 ~ 600 grit wet sandpaper on

the surface plate, and re-surface the head

using a figure-eight sanding pattern.

NOTE:

Rotate the cylinder head several times to

avoid removing too much material from one

side.

ASSEMBLY AND INSTALLATION

Cylinder head

1. Install:

l

Dowel pin

1

lGasket 2 New

2. Install:

lCylinder head

lCopper washer

lBolt (cylinder head)

NOTE:

lApply Quick gasket® (YAMAHA Bond

No.1215) on end of the cylinder head bolts

(M6), as shown.

lApply the engine oil on the contact surfaces of

the bolts (cylinder head) and copper washers.

lFollow the numerical order shown in the illus-

tration. Tighten the bolts in two stages.

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No.1215:

90890-85505

T R..M8 22 Nm (2.2 m · kg, 16 ft · lb)

M6 10 Nm (1.0 m · kg, 7.2 ft · lb)

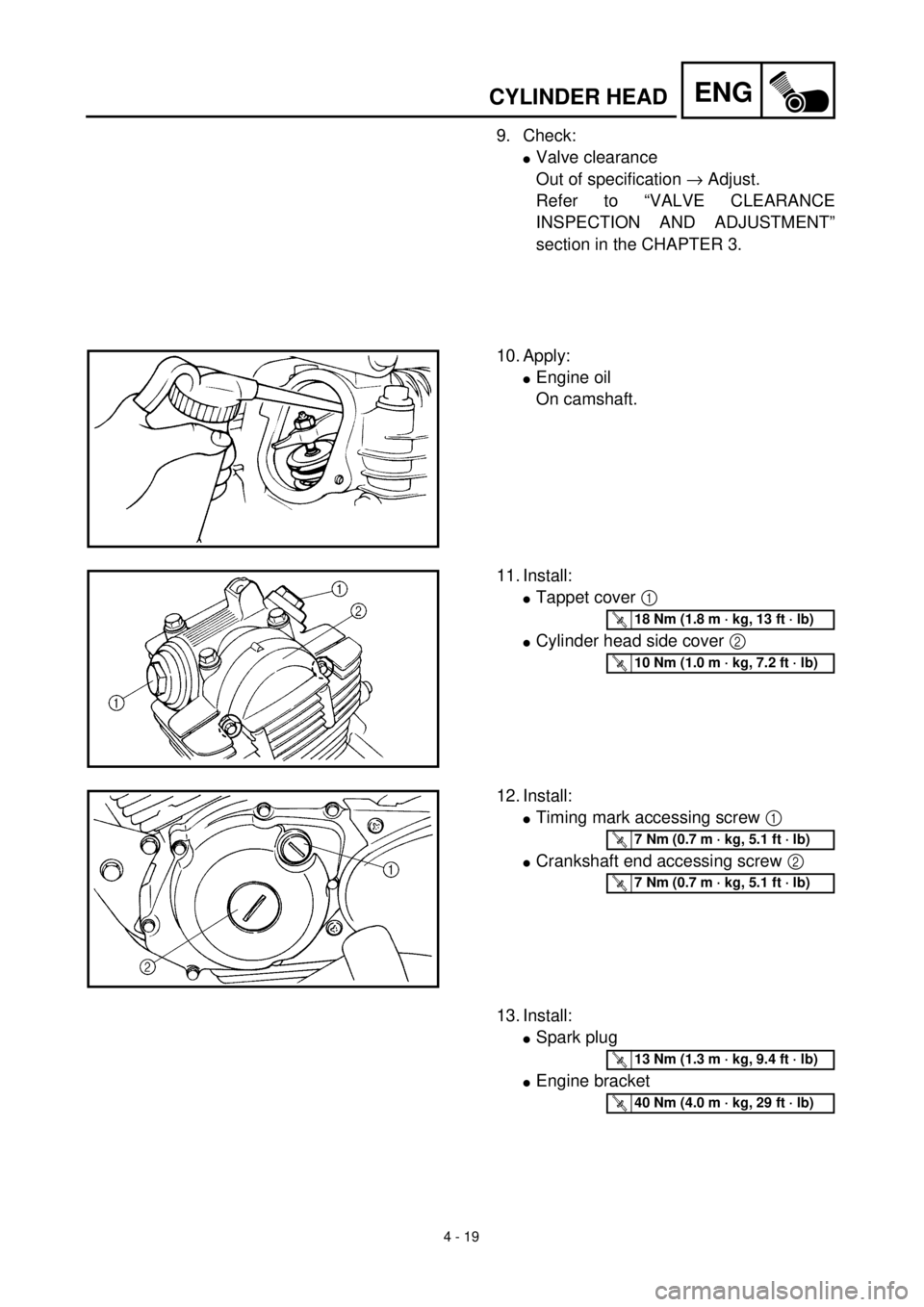

Page 246 of 508

4 - 19

ENGCYLINDER HEAD

9. Check:

lValve clearance

Out of specification ® Adjust.

Refer to “VALVE CLEARANCE

INSPECTION AND ADJUSTMENT”

section in the CHAPTER 3.

10. Apply:

lEngine oil

On camshaft.

11. Install:

lTappet cover 1

lCylinder head side cover 2

T R..18 Nm (1.8 m · kg, 13 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

12. Install:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

13. Install:

lSpark plug

lEngine bracket

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

T R..40 Nm (4.0 m · kg, 29 ft · lb)

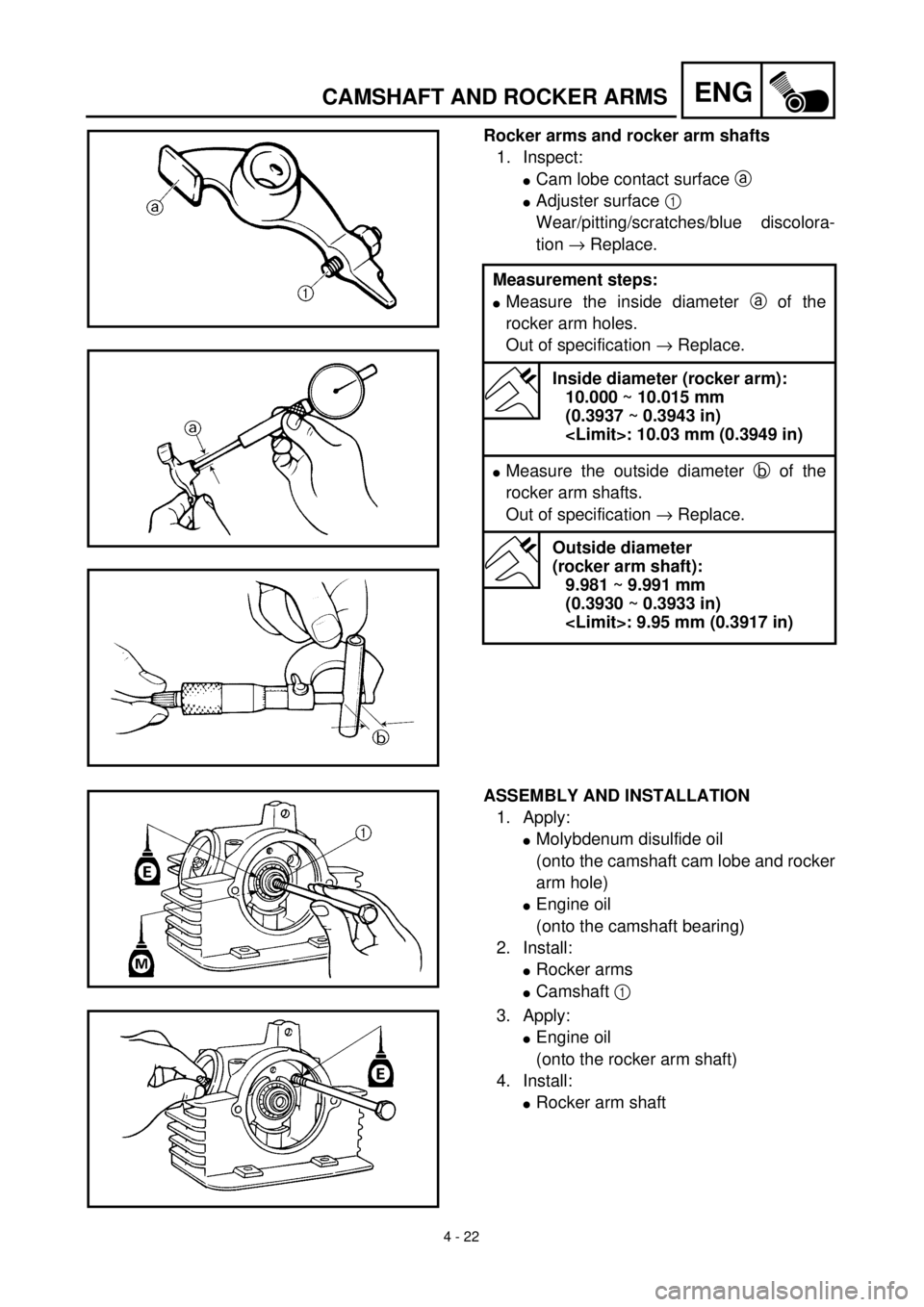

Page 252 of 508

4 - 22

ENG

CAMSHAFT AND ROCKER ARMS

Rocker arms and rocker arm shafts

1. Inspect:

l

Cam lobe contact surface

a

l

Adjuster surface

1

Wear/pitting/scratches/blue discolora-

tion

®

Replace.

Measurement steps:

l

Measure the inside diameter

a

of the

rocker arm holes.

Out of specification

®

Replace.

Inside diameter (rocker arm):

10.000 ~ 10.015 mm

(0.3937 ~ 0.3943 in)

l

Measure the outside diameter

b

of the

rocker arm shafts.

Out of specification

®

Replace.

Outside diameter

(rocker arm shaft):

9.981 ~ 9.991 mm

(0.3930 ~ 0.3933 in)

ASSEMBLY AND INSTALLATION

1. Apply:

l

Molybdenum disulfide oil

(onto the camshaft cam lobe and rocker

arm hole)

l

Engine oil

(onto the camshaft bearing)

2. Install:

l

Rocker arms

l

Camshaft

1

3. Apply:

l

Engine oil

(onto the rocker arm shaft)

4. Install:

l

Rocker arm shaft

Page 284 of 508

4 - 38

ENGCYLINDER AND PISTON

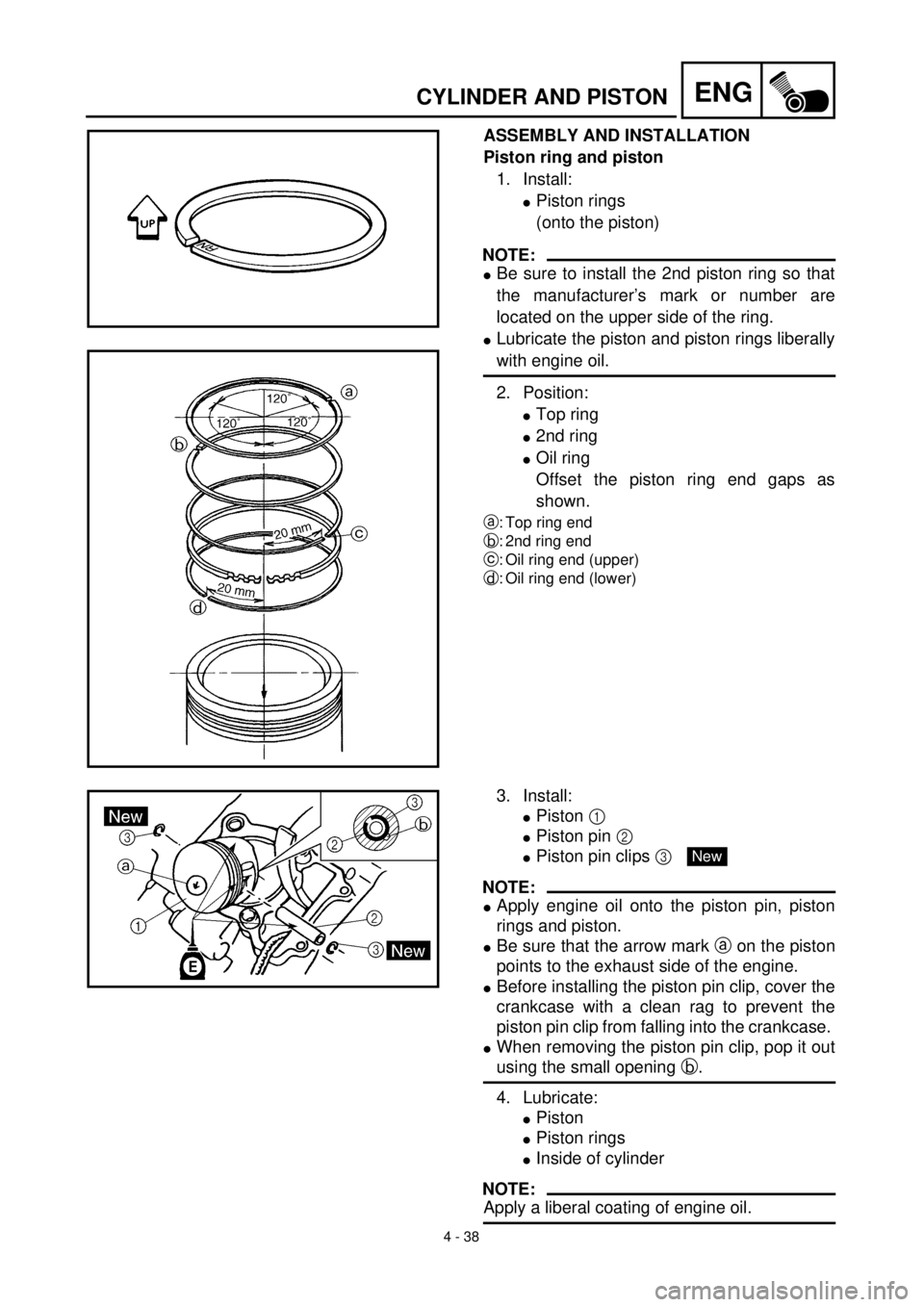

ASSEMBLY AND INSTALLATION

Piston ring and piston

1. Install:

lPiston rings

(onto the piston)

NOTE:

lBe sure to install the 2nd piston ring so that

the manufacturer’s mark or number are

located on the upper side of the ring.

lLubricate the piston and piston rings liberally

with engine oil.

2. Position:

lTop ring

l2nd ring

lOil ring

Offset the piston ring end gaps as

shown.

a: Top ring end

b: 2nd ring end

c: Oil ring end (upper)

d: Oil ring end (lower)

3. Install:

lPiston 1

lPiston pin 2

lPiston pin clips 3

NOTE:

lApply engine oil onto the piston pin, piston

rings and piston.

lBe sure that the arrow mark a on the piston

points to the exhaust side of the engine.

lBefore installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase.

lWhen removing the piston pin clip, pop it out

using the small opening b.

4. Lubricate:

lPiston

lPiston rings

lInside of cylinder

NOTE:

Apply a liberal coating of engine oil.

New

Page 288 of 508

4 - 40

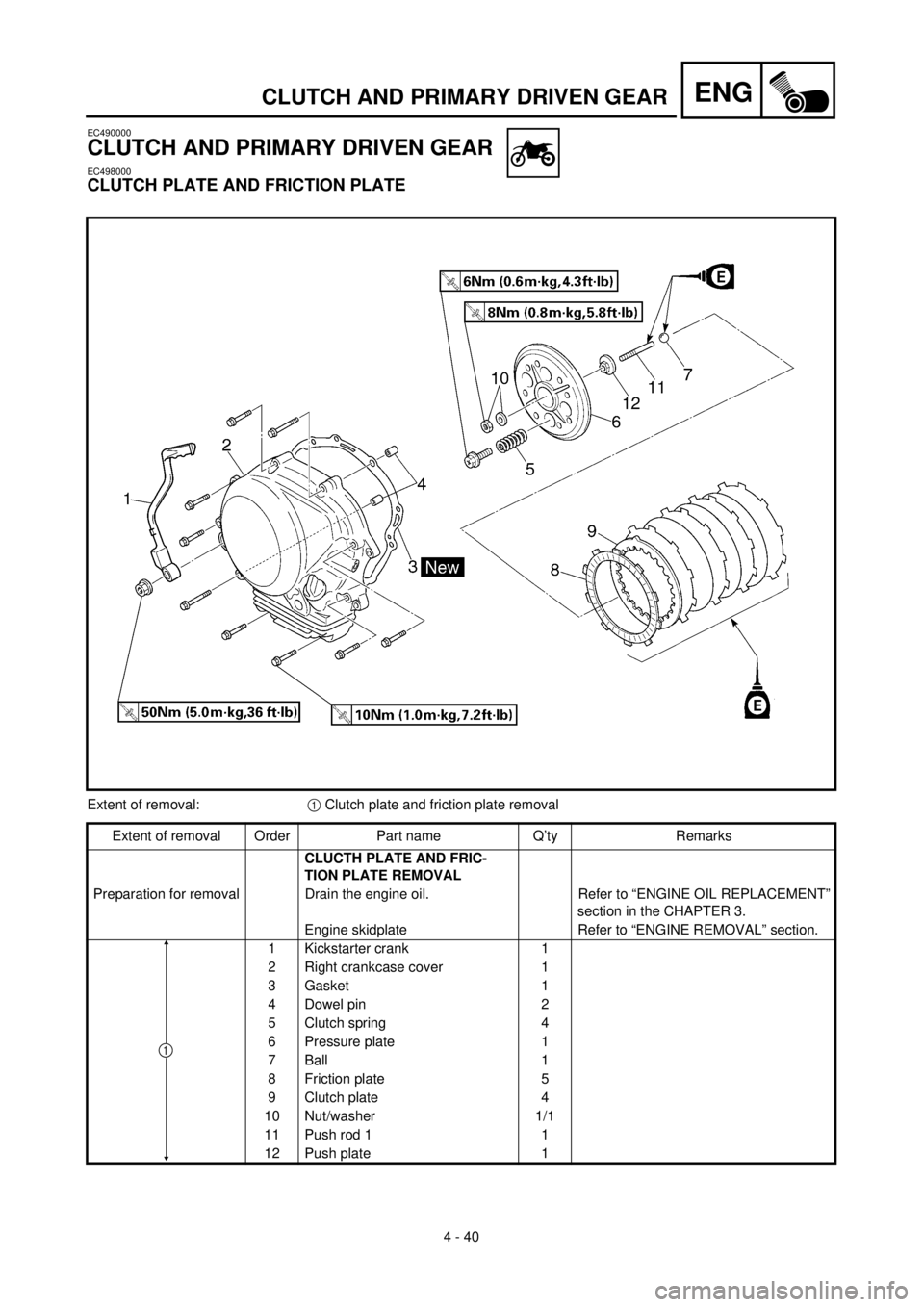

ENGCLUTCH AND PRIMARY DRIVEN GEAR

EC490000

CLUTCH AND PRIMARY DRIVEN GEAR

EC498000

CLUTCH PLATE AND FRICTION PLATE

Extent of removal:1 Clutch plate and friction plate removal

Extent of removal Order Part name Q’ty Remarks

CLUCTH PLATE AND FRIC-

TION PLATE REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Engine skidplate Refer to “ENGINE REMOVAL” section.

1 Kickstarter crank 1

2 Right crankcase cover 1

3 Gasket 1

4 Dowel pin 2

5 Clutch spring 4

6 Pressure plate 1

7 Ball 1

8 Friction plate 5

9 Clutch plate 4

10 Nut/washer 1/1

11 Push rod 1 1

12 Push plate 1

1