engine YAMAHA TTR125 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR125, Model: YAMAHA TTR125 2001Pages: 508, PDF Size: 16.81 MB

Page 298 of 508

4 - 45

ENG

CLUTCH AND PRIMARY DRIVEN GEAR

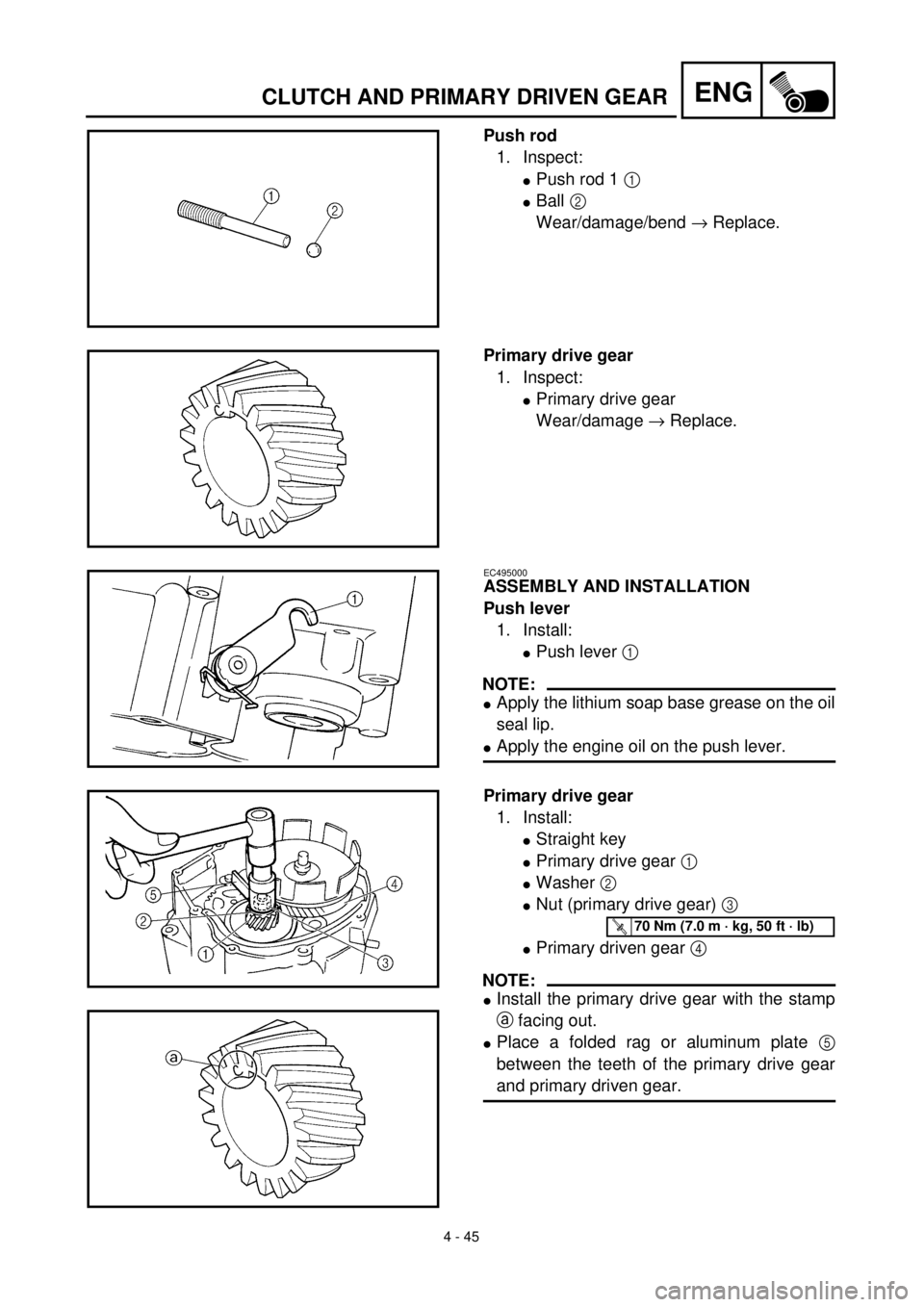

Push rod

1. Inspect:

l

Push rod 1

1

l

Ball

2

Wear/damage/bend

®

Replace.

Primary drive gear

1. Inspect:

l

Primary drive gear

Wear/damage

®

Replace.

EC495000

ASSEMBLY AND INSTALLATION

Push lever

1. Install:

l

Push lever

1

NOTE:

lApply the lithium soap base grease on the oil

seal lip.

lApply the engine oil on the push lever.

Primary drive gear

1. Install:

lStraight key

lPrimary drive gear 1

lWasher 2

lNut (primary drive gear) 3

lPrimary driven gear 4

NOTE:

lInstall the primary drive gear with the stamp

a facing out.

lPlace a folded rag or aluminum plate 5

between the teeth of the primary drive gear

and primary driven gear.

T R..70 Nm (7.0 m · kg, 50 ft · lb)

Page 300 of 508

4 - 46

ENGCLUTCH AND PRIMARY DRIVEN GEAR

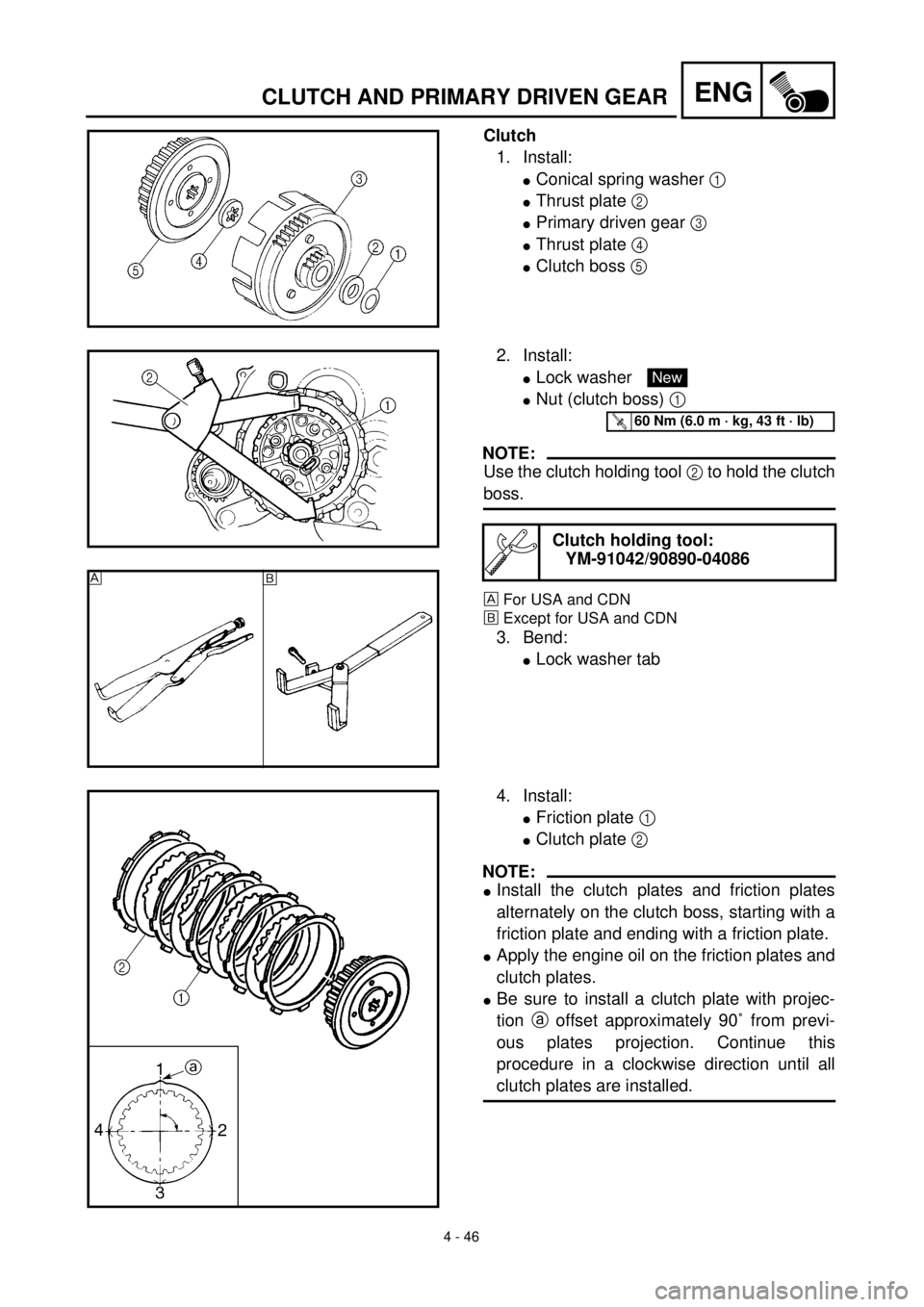

Clutch

1. Install:

lConical spring washer 1

lThrust plate 2

lPrimary driven gear 3

lThrust plate 4

lClutch boss 5

2. Install:

lLock washer

lNut (clutch boss) 1

NOTE:

Use the clutch holding tool 2 to hold the clutch

boss.

For USA and CDN

õExcept for USA and CDN

3. Bend:

lLock washer tab

Clutch holding tool:

YM-91042/90890-04086

New

T R..60 Nm (6.0 m · kg, 43 ft · lb)

õ

4. Install:

lFriction plate 1

lClutch plate 2

NOTE:

lInstall the clutch plates and friction plates

alternately on the clutch boss, starting with a

friction plate and ending with a friction plate.

lApply the engine oil on the friction plates and

clutch plates.

lBe sure to install a clutch plate with projec-

tion a offset approximately 90˚ from previ-

ous plates projection. Continue this

procedure in a clockwise direction until all

clutch plates are installed.

Page 302 of 508

4 - 47

ENGCLUTCH AND PRIMARY DRIVEN GEAR

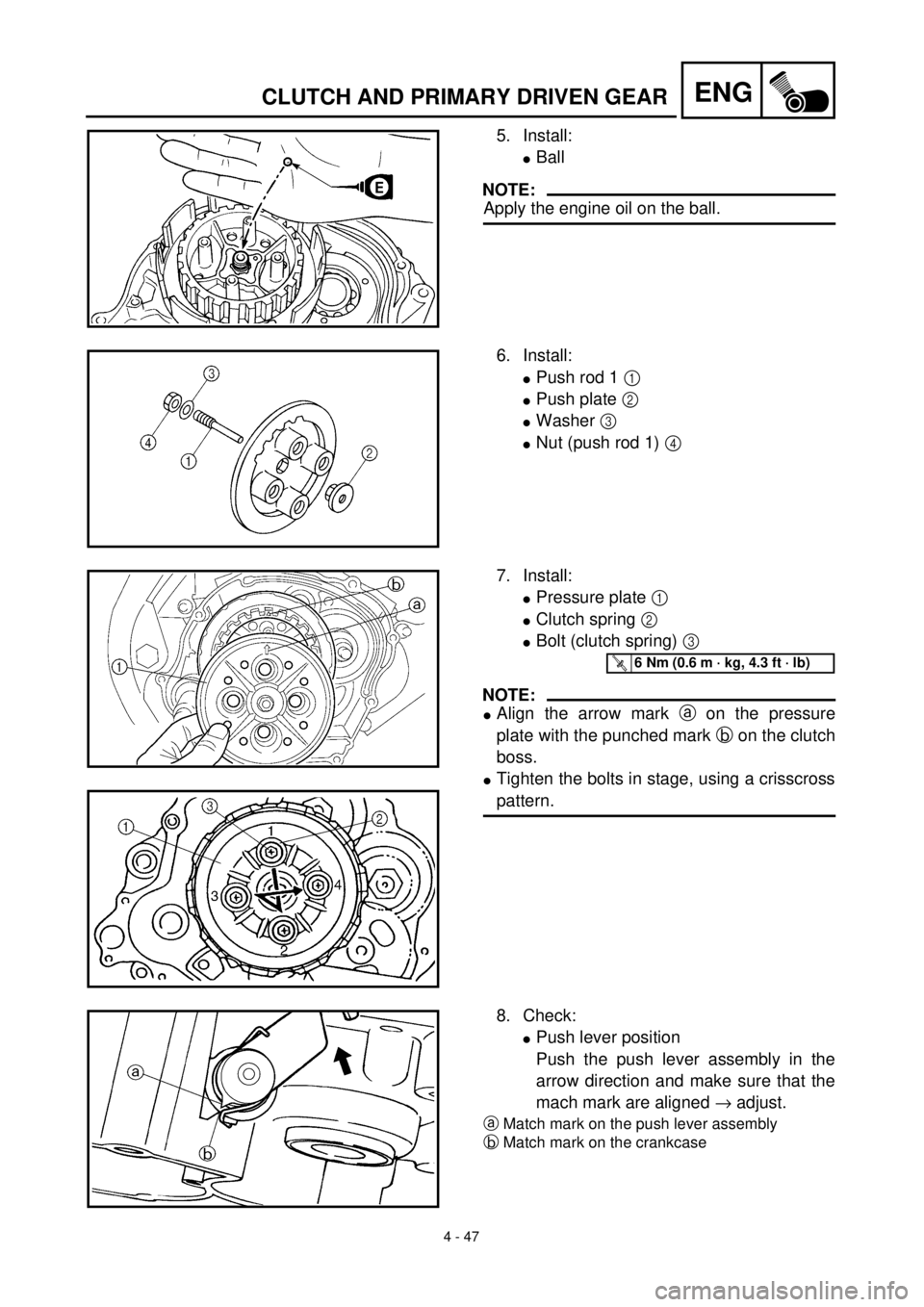

5. Install:

lBall

NOTE:

Apply the engine oil on the ball.

6. Install:

lPush rod 1 1

lPush plate 2

lWasher 3

lNut (push rod 1) 4

7. Install:

lPressure plate 1

lClutch spring 2

lBolt (clutch spring) 3

NOTE:

lAlign the arrow mark a on the pressure

plate with the punched mark b on the clutch

boss.

lTighten the bolts in stage, using a crisscross

pattern.

T R..6 Nm (0.6 m · kg, 4.3 ft · lb)

8. Check:

lPush lever position

Push the push lever assembly in the

arrow direction and make sure that the

mach mark are aligned ® adjust.

aMatch mark on the push lever assembly

bMatch mark on the crankcase

Page 312 of 508

4 - 52

ENG

OIL PUMP

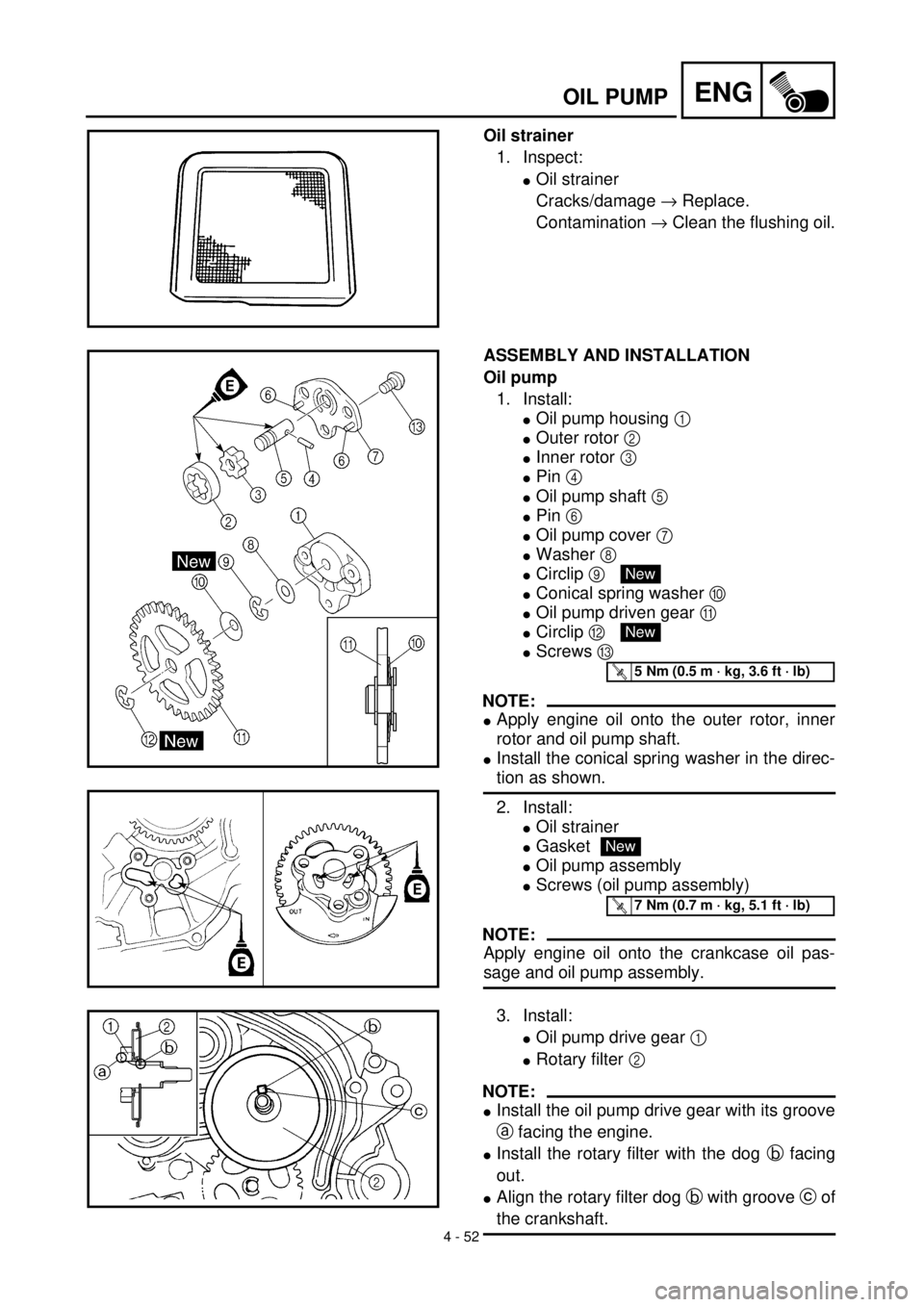

Oil strainer

1. Inspect:

l

Oil strainer

Cracks/damage

®

Replace.

Contamination

®

Clean the flushing oil.

ASSEMBLY AND INSTALLATION

Oil pump

1. Install:

l

Oil pump housing

1

l

Outer rotor

2

l

Inner rotor

3

l

Pin

4

l

Oil pump shaft

5

l

Pin

6

l

Oil pump cover

7

l

Washer

8

l

Circlip

9

l

Conical spring washer

0

l

Oil pump driven gear

A

l

Circlip

B

l

Screws

C

NOTE:

l

Apply engine oil onto the outer rotor, inner

rotor and oil pump shaft.

l

Install the conical spring washer in the direc-

tion as shown.

2. Install:

l

Oil strainer

l

Gasket

l

Oil pump assembly

l

Screws (oil pump assembly)

NOTE:

Apply engine oil onto the crankcase oil pas-

sage and oil pump assembly.

New

New

T R..5 Nm (0.5 m · kg, 3.6 ft · lb)

New

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

3. Install:

l

Oil pump drive gear

1

lRotary filter 2

NOTE:

lInstall the oil pump drive gear with its groove

a facing the engine.

lInstall the rotary filter with the dog b facing

out.

lAlign the rotary filter dog b with groove c of

the crankshaft.

Page 314 of 508

4 - 53

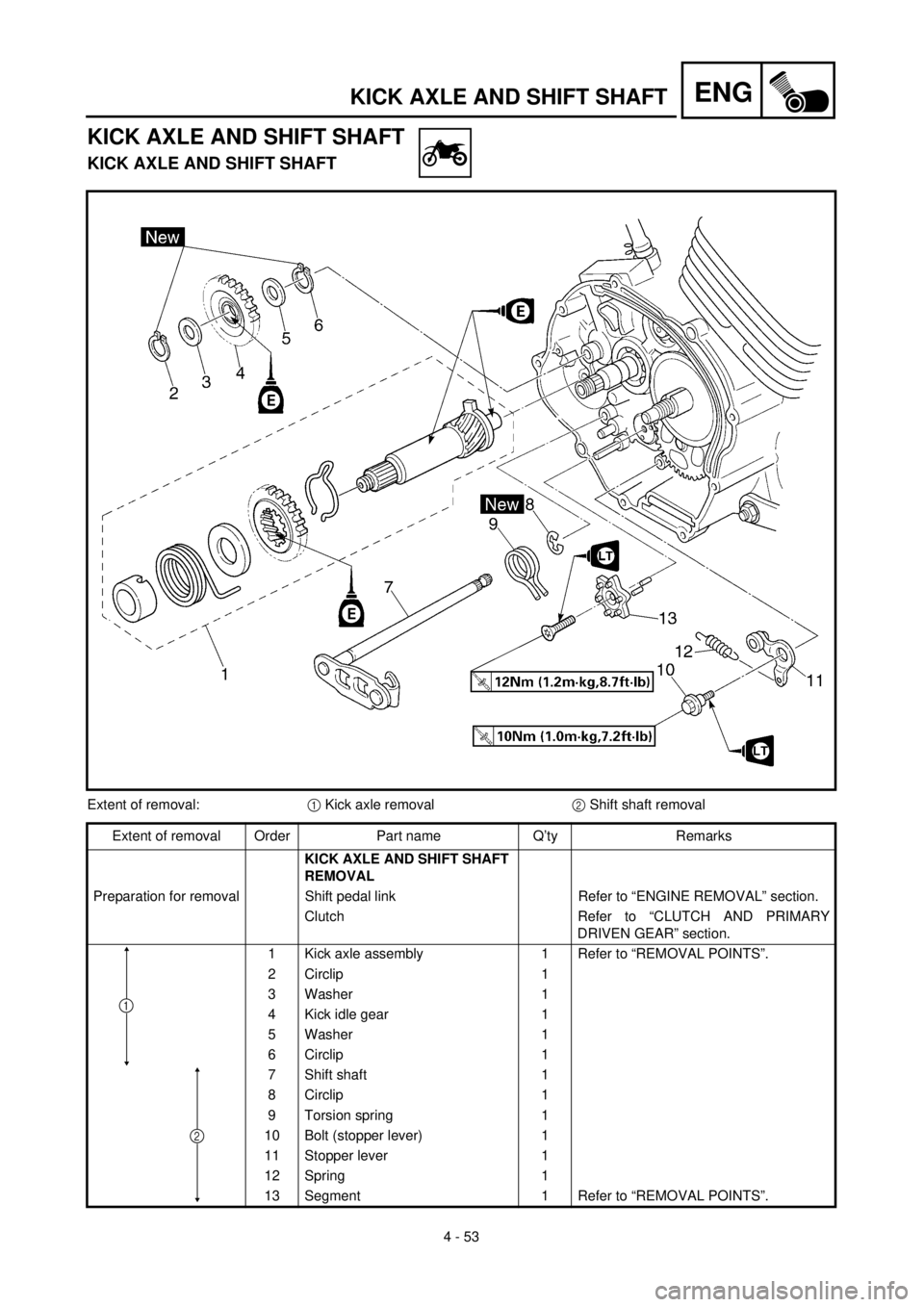

ENGKICK AXLE AND SHIFT SHAFT

KICK AXLE AND SHIFT SHAFT

KICK AXLE AND SHIFT SHAFT

Extent of removal:1 Kick axle removal2 Shift shaft removal

Extent of removal Order Part name Q’ty Remarks

KICK AXLE AND SHIFT SHAFT

REMOVAL

Preparation for removal Shift pedal link Refer to “ENGINE REMOVAL” section.

Clutch Refer to “CLUTCH AND PRIMARY

DRIVEN GEAR” section.

1 Kick axle assembly 1 Refer to “REMOVAL POINTS”.

2 Circlip 1

3 Washer 1

4 Kick idle gear 1

5 Washer 1

6 Circlip 1

7 Shift shaft 1

8 Circlip 1

9 Torsion spring 1

10 Bolt (stopper lever) 1

11 Stopper lever 1

12 Spring 1

13 Segment 1 Refer to “REMOVAL POINTS”.

1

2

Page 320 of 508

4 - 56

ENGKICK AXLE AND SHIFT SHAFT

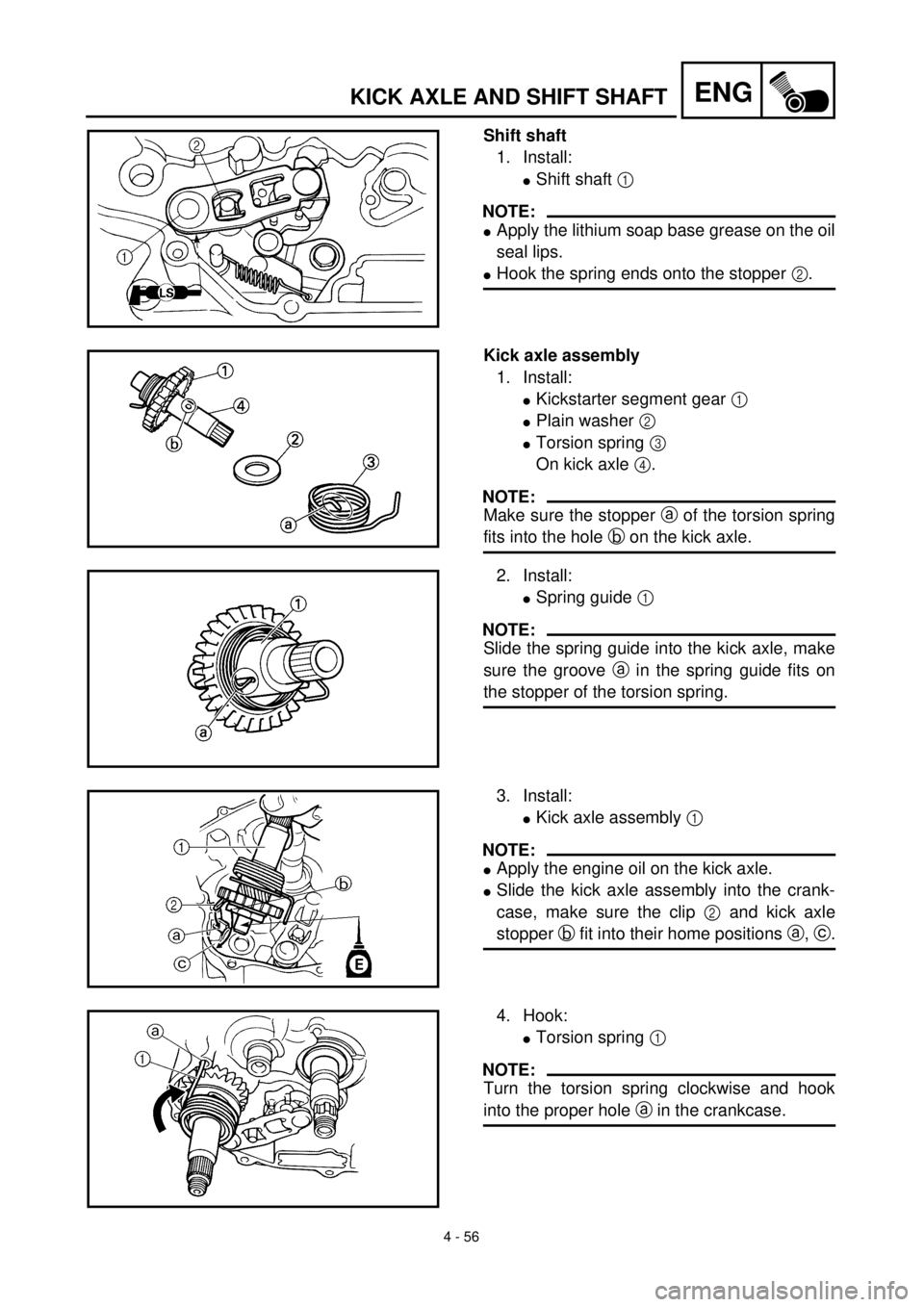

Shift shaft

1. Install:

lShift shaft 1

NOTE:

lApply the lithium soap base grease on the oil

seal lips.

lHook the spring ends onto the stopper 2.

Kick axle assembly

1. Install:

lKickstarter segment gear 1

lPlain washer 2

lTorsion spring 3

On kick axle 4.

NOTE:

Make sure the stopper a of the torsion spring

fits into the hole b on the kick axle.

2. Install:

lSpring guide 1

NOTE:

Slide the spring guide into the kick axle, make

sure the groove a in the spring guide fits on

the stopper of the torsion spring.

3. Install:

lKick axle assembly 1

NOTE:

lApply the engine oil on the kick axle.

lSlide the kick axle assembly into the crank-

case, make sure the clip 2 and kick axle

stopper b fit into their home positions a, c.

4. Hook:

lTorsion spring 1

NOTE:

Turn the torsion spring clockwise and hook

into the proper hole a in the crankcase.

Page 322 of 508

4 - 57

ENGKICK AXLE AND SHIFT SHAFT

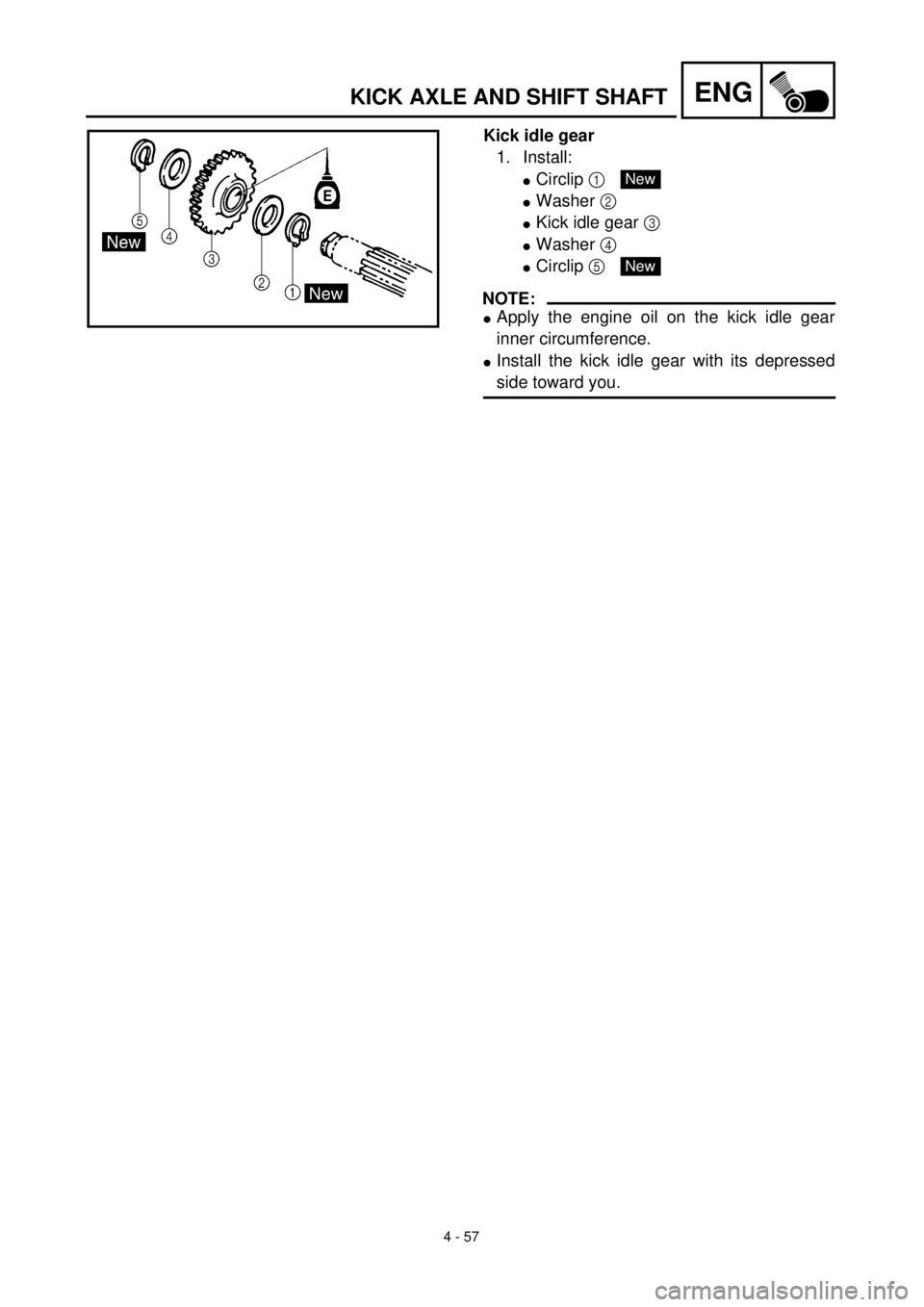

Kick idle gear

1. Install:

lCirclip 1

lWasher 2

lKick idle gear 3

lWasher 4

lCirclip 5

NOTE:

lApply the engine oil on the kick idle gear

inner circumference.

lInstall the kick idle gear with its depressed

side toward you.

New

New

Page 324 of 508

4 - 58

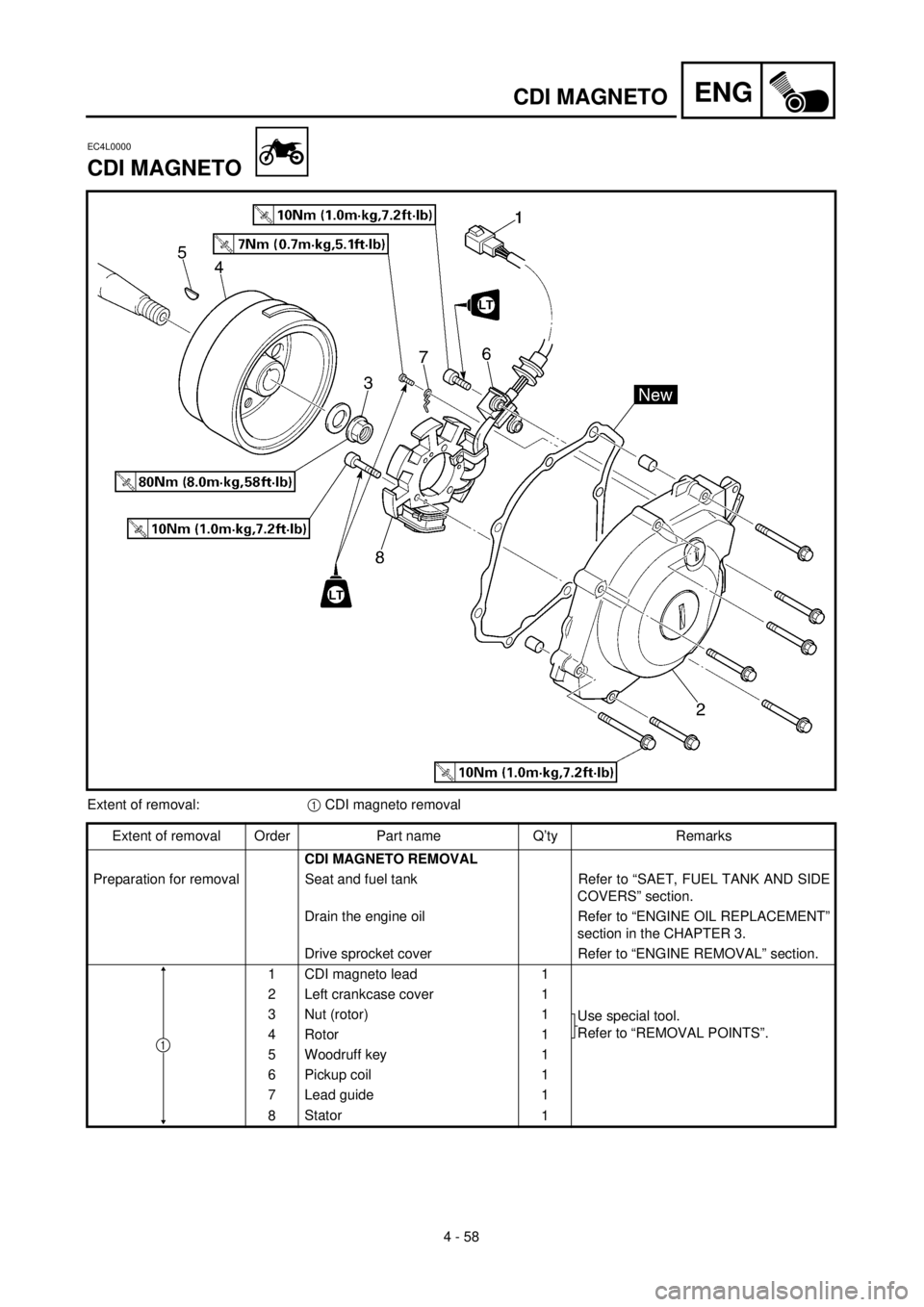

ENGCDI MAGNETO

EC4L0000

CDI MAGNETO

Extent of removal:1 CDI magneto removal

Extent of removal Order Part name Q’ty Remarks

CDI MAGNETO REMOVAL

Preparation for removal Seat and fuel tank Refer to “SAET, FUEL TANK AND SIDE

COVERS” section.

Drain the engine oil Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Drive sprocket cover Refer to “ENGINE REMOVAL” section.

1 CDI magneto lead 1

2 Left crankcase cover 1

3 Nut (rotor) 1

Use special tool.

Refer to “REMOVAL POINTS”.

4 Rotor 1

5 Woodruff key 1

6 Pickup coil 1

7 Lead guide 1

8Stator

1

1

Page 330 of 508

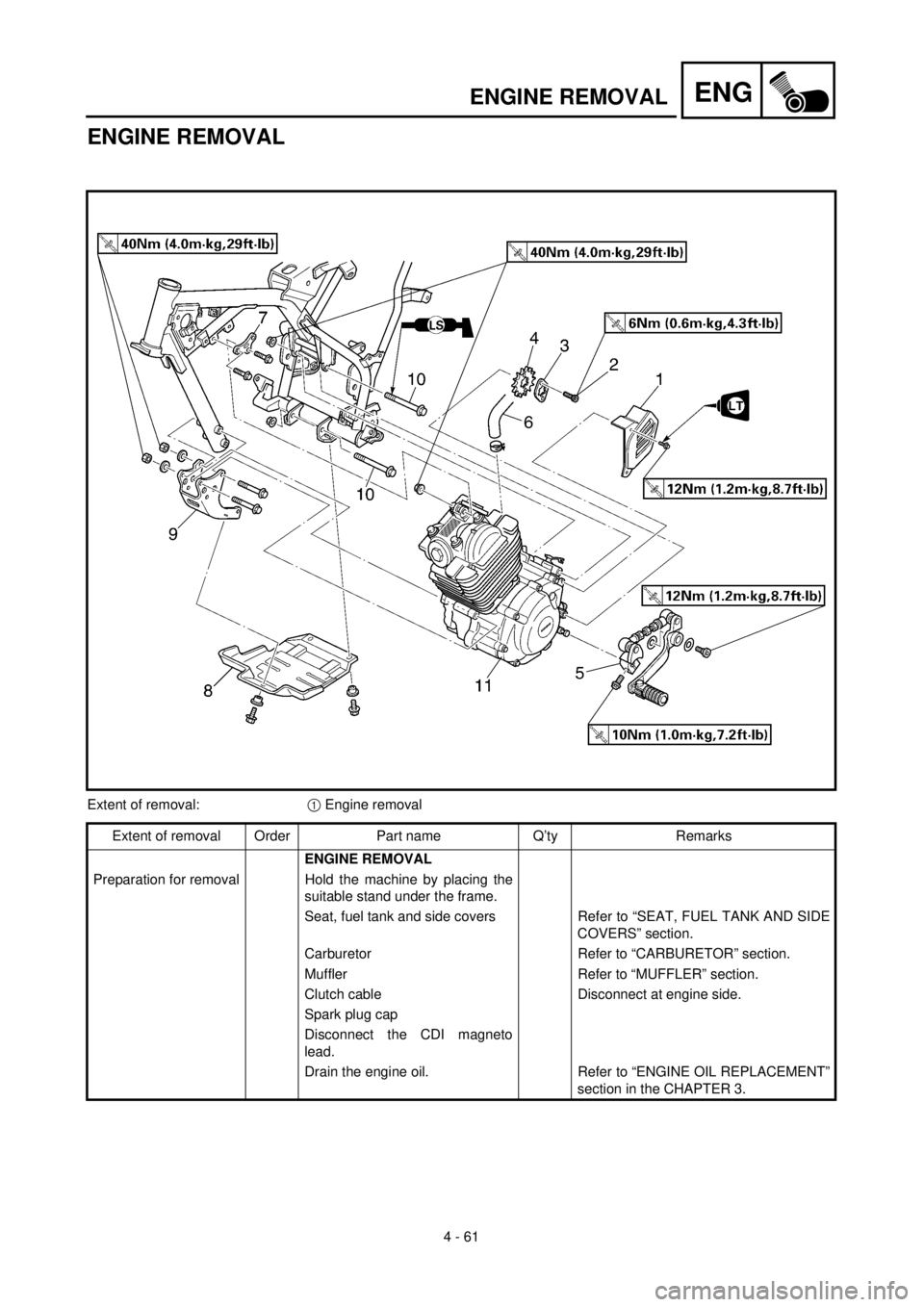

4 - 61

ENG

ENGINE REMOVAL

ENGINE REMOVAL

Extent of removal:

1

Engine removal

Extent of removal Order Part name Q’ty Remarks

ENGINE REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the frame.

Seat, fuel tank and side covers Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Carburetor Refer to “CARBURETOR” section.

Muffler Refer to “MUFFLER” section.

Clutch cable Disconnect at engine side.

Spark plug cap

Disconnect the CDI magneto

lead.

Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

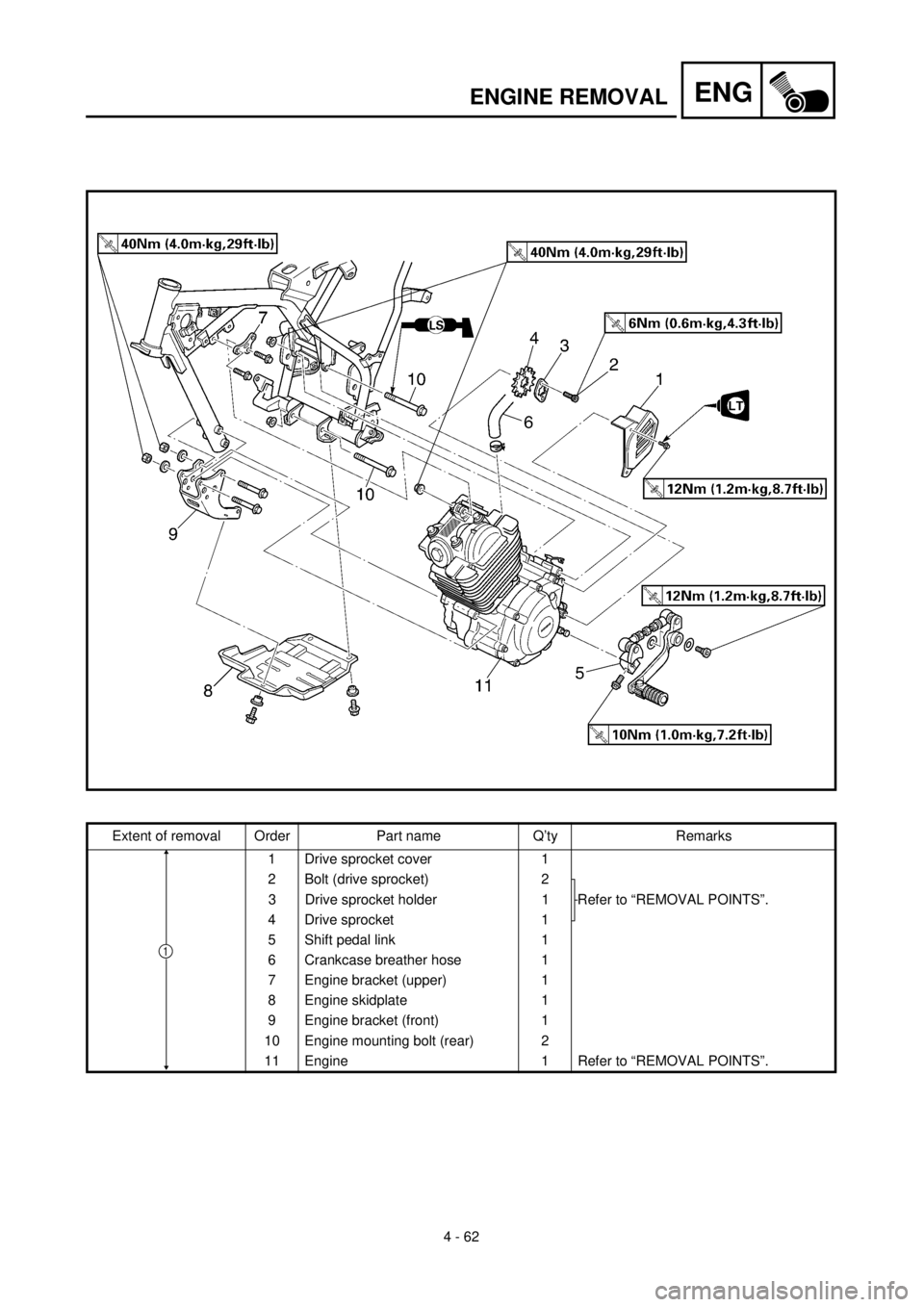

Page 332 of 508

4 - 62

ENG

ENGINE REMOVAL

Extent of removal Order Part name Q’ty Remarks

1 Drive sprocket cover 1

2 Bolt (drive sprocket) 2

Refer to “REMOVAL POINTS”. 3 Drive sprocket holder 1

4 Drive sprocket 1

5 Shift pedal link 1

6 Crankcase breather hose 1

7 Engine bracket (upper) 1

8 Engine skidplate 1

9 Engine bracket (front) 1

10 Engine mounting bolt (rear) 2

11Engine

1Refer to “REMOVAL POINTS”.

1