engine YAMAHA TTR125 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR125, Model: YAMAHA TTR125 2001Pages: 508, PDF Size: 16.81 MB

Page 334 of 508

4 - 63

ENG

ENGINE REMOVAL

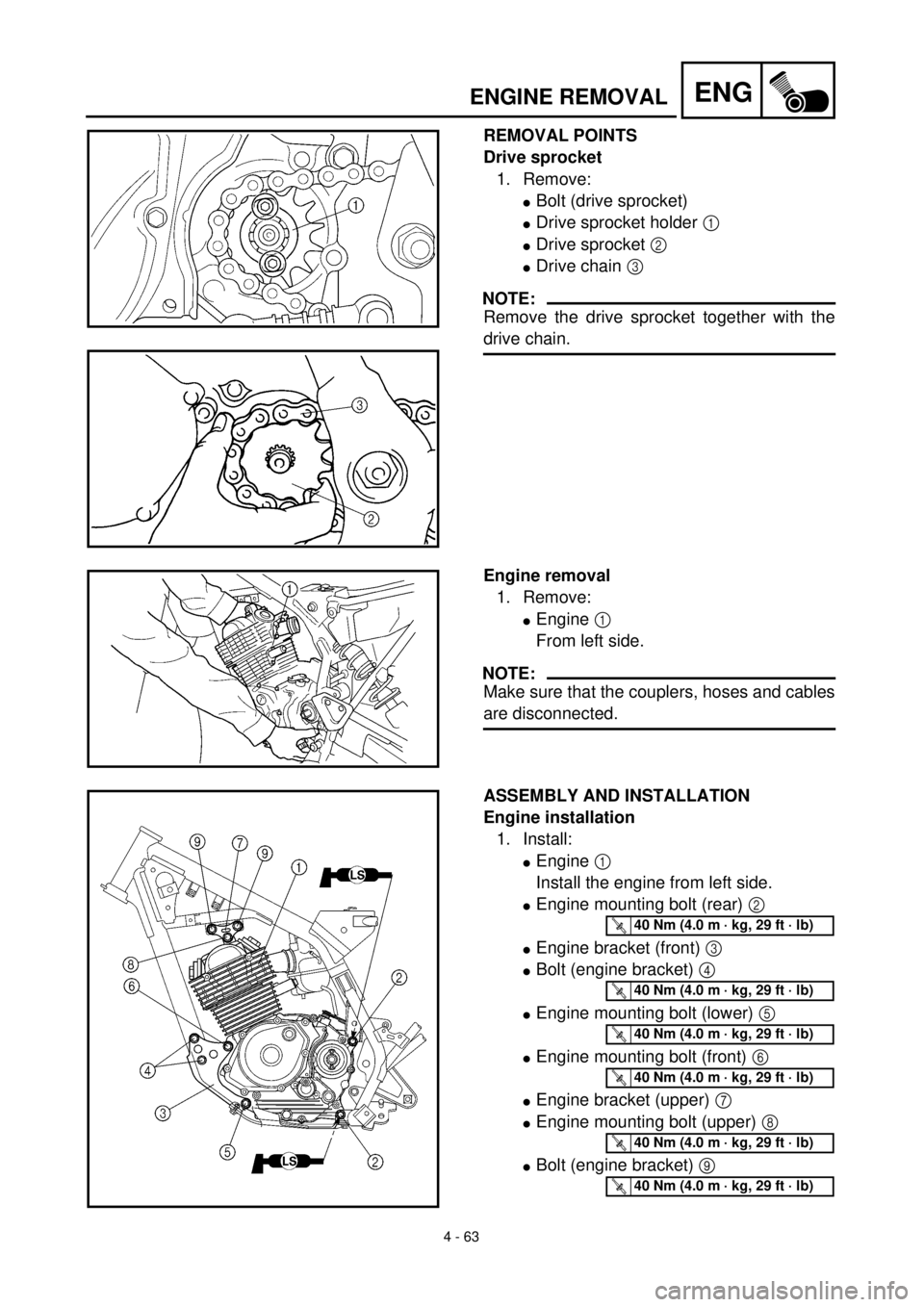

REMOVAL POINTS

Drive sprocket

1. Remove:

l

Bolt (drive sprocket)

l

Drive sprocket holder

1

l

Drive sprocket

2

l

Drive chain

3

NOTE:

Remove the drive sprocket together with the

drive chain.

Engine removal

1. Remove:

l

Engine

1

From left side.

NOTE:

Make sure that the couplers, hoses and cables

are disconnected.

ASSEMBLY AND INSTALLATION

Engine installation

1. Install:

l

Engine

1

Install the engine from left side.

l

Engine mounting bolt (rear)

2

l

Engine bracket (front)

3

l

Bolt (engine bracket)

4

l

Engine mounting bolt (lower)

5

l

Engine mounting bolt (front)

6

l

Engine bracket (upper)

7

l

Engine mounting bolt (upper)

8

l

Bolt (engine bracket)

9

T R..40 Nm (4.0 m · kg, 29 ft · lb)

T R..40 Nm (4.0 m · kg, 29 ft · lb)

T R..40 Nm (4.0 m · kg, 29 ft · lb)

T R..40 Nm (4.0 m · kg, 29 ft · lb)

T R..40 Nm (4.0 m · kg, 29 ft · lb)

T R..40 Nm (4.0 m · kg, 29 ft · lb)

Page 336 of 508

4 - 64

ENG

ENGINE REMOVAL

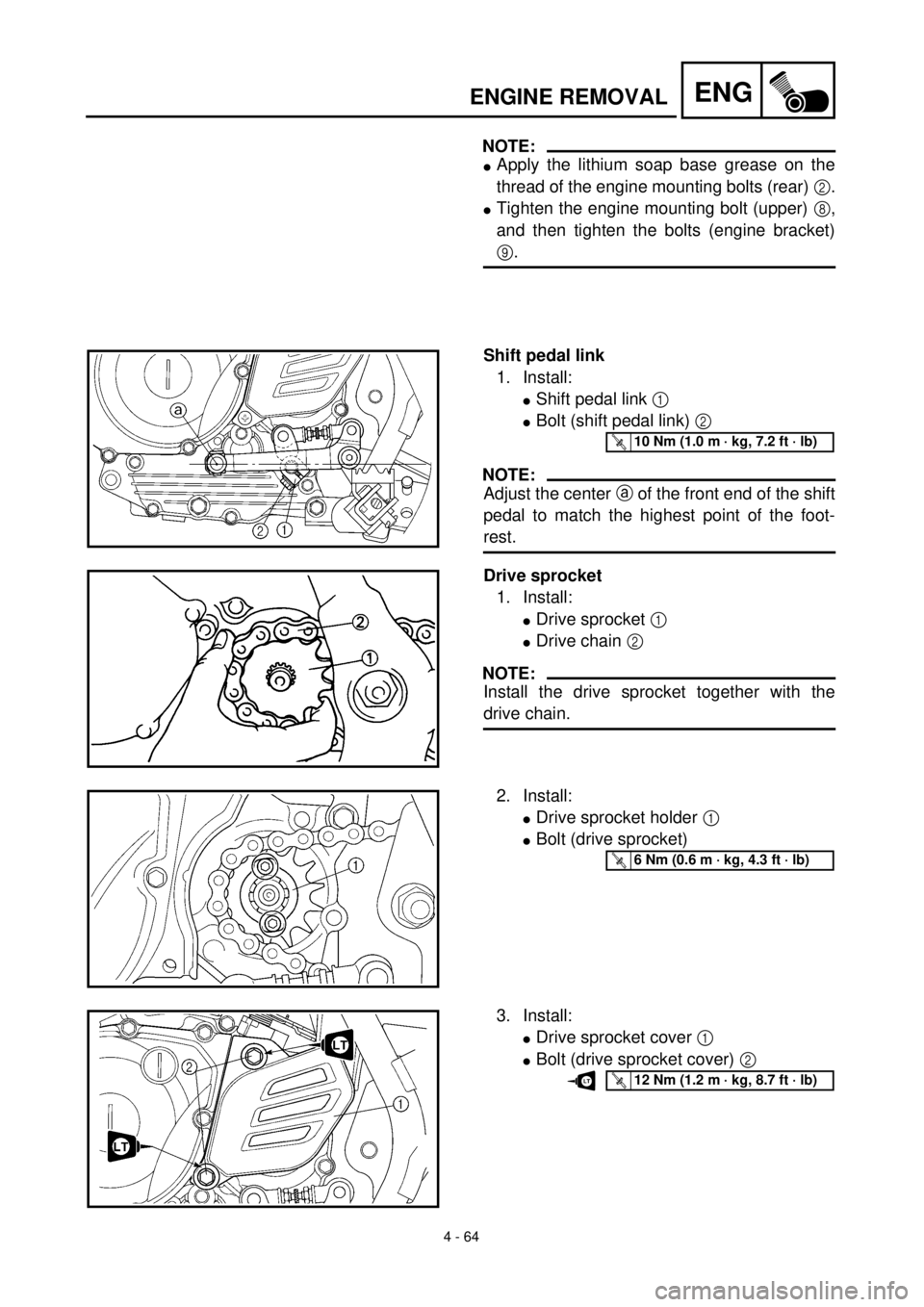

NOTE:

l

Apply the lithium soap base grease on the

thread of the engine mounting bolts (rear)

2

.

l

Tighten the engine mounting bolt (upper)

8

,

and then tighten the bolts (engine bracket)

9

.

Shift pedal link

1. Install:

l

Shift pedal link

1

l

Bolt (shift pedal link)

2

NOTE:

Adjust the center

a

of the front end of the shift

pedal to match the highest point of the foot-

rest.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Drive sprocket

1. Install:

l

Drive sprocket

1

l

Drive chain

2

NOTE:

Install the drive sprocket together with the

drive chain.

2. Install:

l

Drive sprocket holder

1

l

Bolt (drive sprocket)

T R..6 Nm (0.6 m · kg, 4.3 ft · lb)

3. Install:

l

Drive sprocket cover 1

lBolt (drive sprocket cover) 2

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)LT

Page 338 of 508

4 - 65

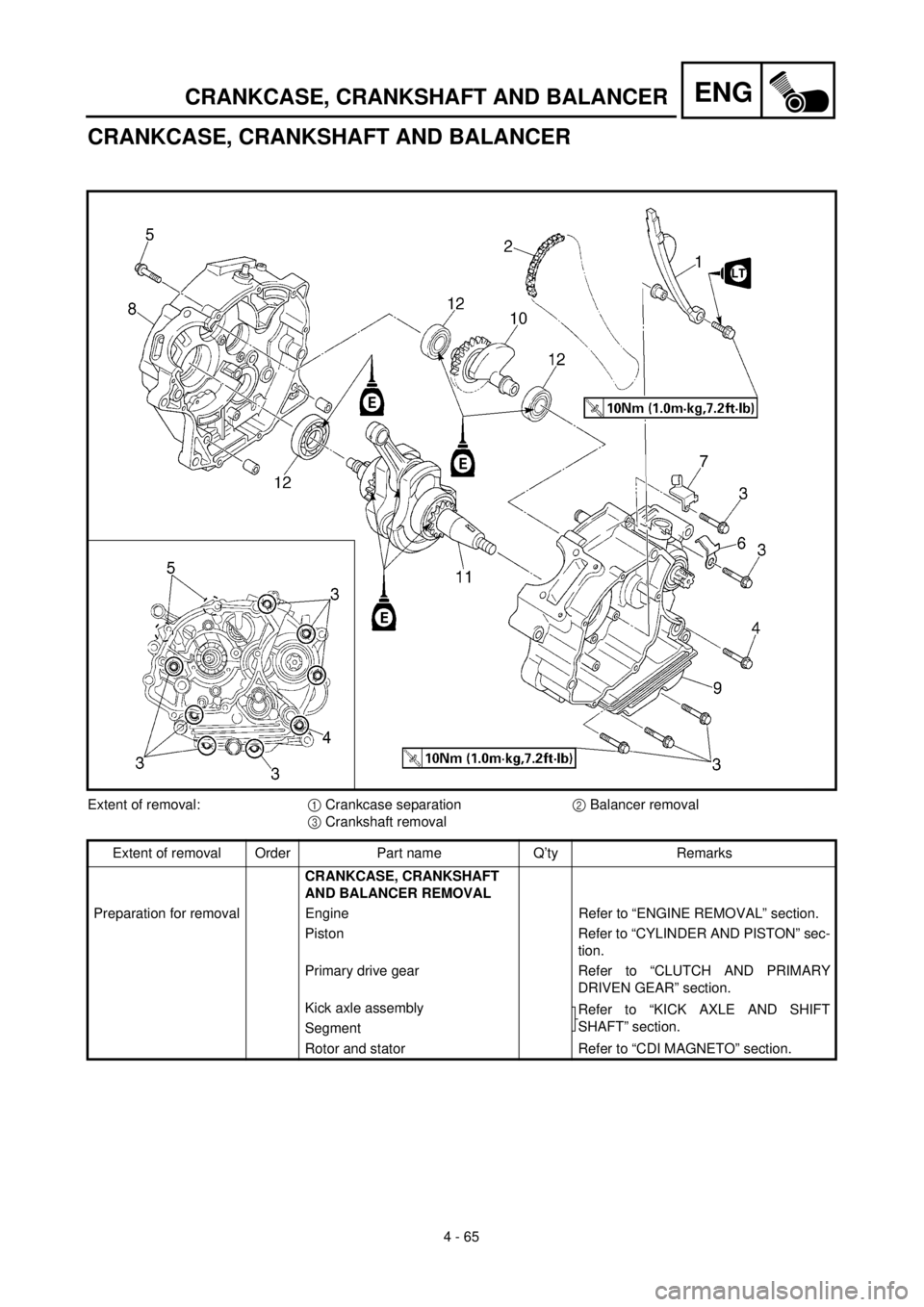

ENGCRANKCASE, CRANKSHAFT AND BALANCER

CRANKCASE, CRANKSHAFT AND BALANCER

Extent of removal:1 Crankcase separation2 Balancer removal

3 Crankshaft removal

Extent of removal Order Part name Q’ty Remarks

CRANKCASE, CRANKSHAFT

AND BALANCER REMOVAL

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Piston Refer to “CYLINDER AND PISTON” sec-

tion.

Primary drive gear Refer to “CLUTCH AND PRIMARY

DRIVEN GEAR” section.

Kick axle assembly

Refer to “KICK AXLE AND SHIFT

SHAFT” section.

Segment

Rotor and stator Refer to “CDI MAGNETO” section.

Page 342 of 508

4 - 67

ENGCRANKCASE, CRANKSHAFT AND BALANCER

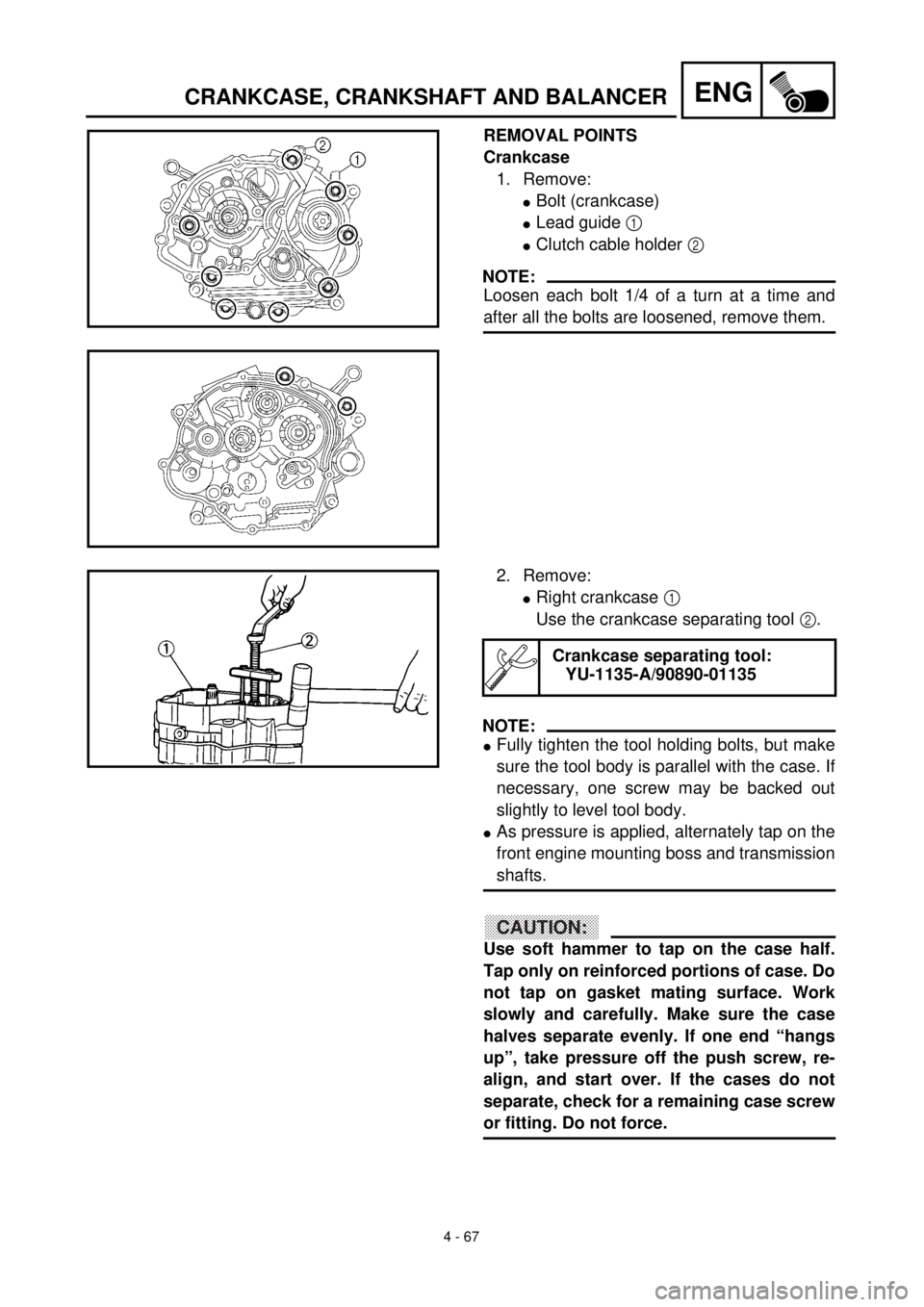

REMOVAL POINTS

Crankcase

1. Remove:

lBolt (crankcase)

lLead guide 1

lClutch cable holder 2

NOTE:

Loosen each bolt 1/4 of a turn at a time and

after all the bolts are loosened, remove them.

2. Remove:

lRight crankcase 1

Use the crankcase separating tool 2.

NOTE:

lFully tighten the tool holding bolts, but make

sure the tool body is parallel with the case. If

necessary, one screw may be backed out

slightly to level tool body.

lAs pressure is applied, alternately tap on the

front engine mounting boss and transmission

shafts.

CAUTION:

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If one end “hangs

up”, take pressure off the push screw, re-

align, and start over. If the cases do not

separate, check for a remaining case screw

or fitting. Do not force.

Crankcase separating tool:

YU-1135-A/90890-01135

Page 346 of 508

4 - 69

ENGCRANKCASE, CRANKSHAFT AND BALANCER

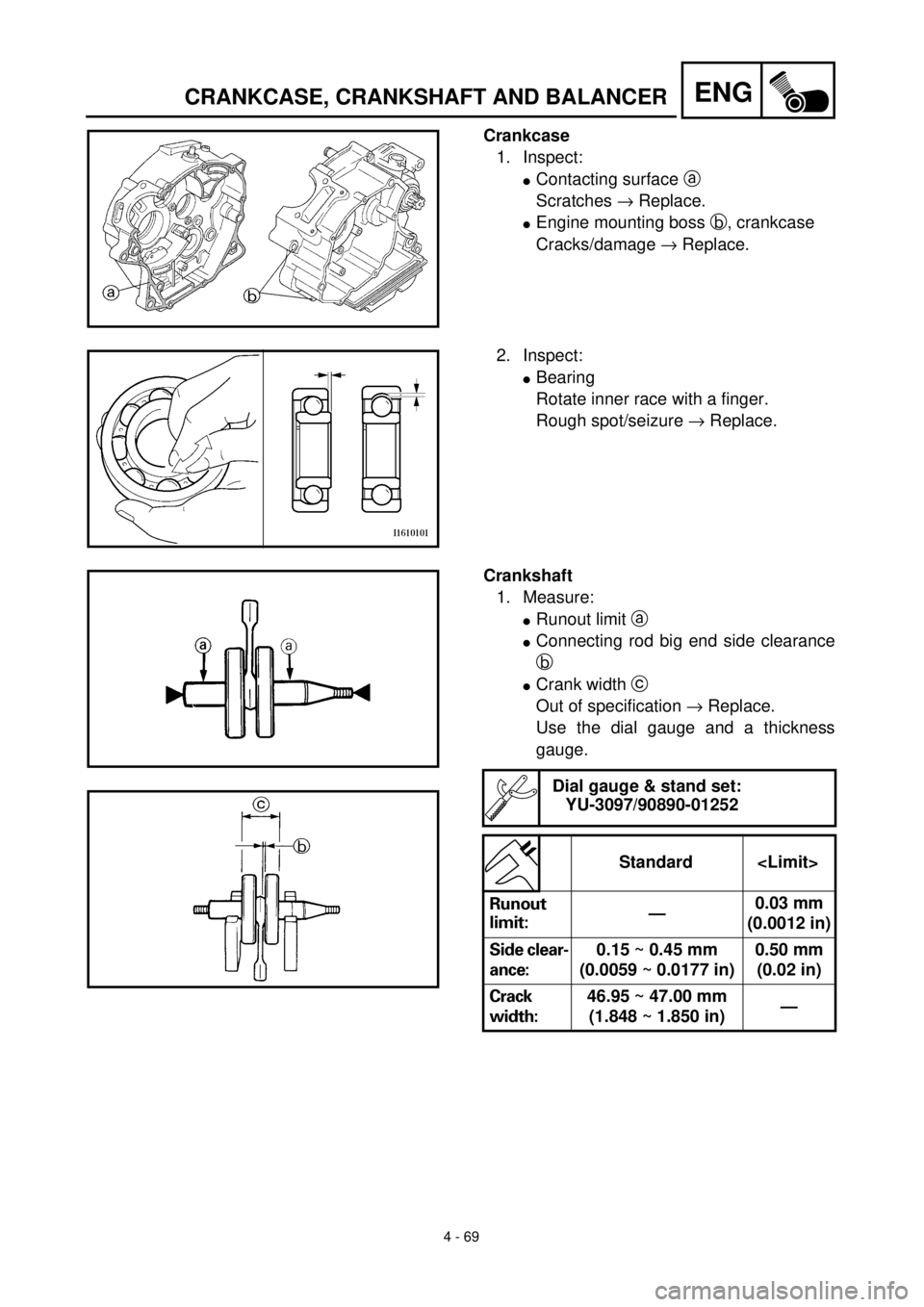

Crankcase

1. Inspect:

lContacting surface a

Scratches ® Replace.

lEngine mounting boss b, crankcase

Cracks/damage ® Replace.

2. Inspect:

lBearing

Rotate inner race with a finger.

Rough spot/seizure ® Replace.

Crankshaft

1. Measure:

lRunout limit a

lConnecting rod big end side clearance

b

lCrank width c

Out of specification ® Replace.

Use the dial gauge and a thickness

gauge.

Dial gauge & stand set:

YU-3097/90890-01252

Standard

Runout

limit:—0.03 mm

(0.0012 in)

Side clear-

ance:0.15 ~ 0.45 mm

(0.0059 ~ 0.0177 in)0.50 mm

(0.02 in)

Crack

width:46.95 ~ 47.00 mm

(1.848 ~ 1.850 in)—

Page 354 of 508

4 - 73

ENG

TRANSMISSION, SHIFT CAM AND SHIFT FORK

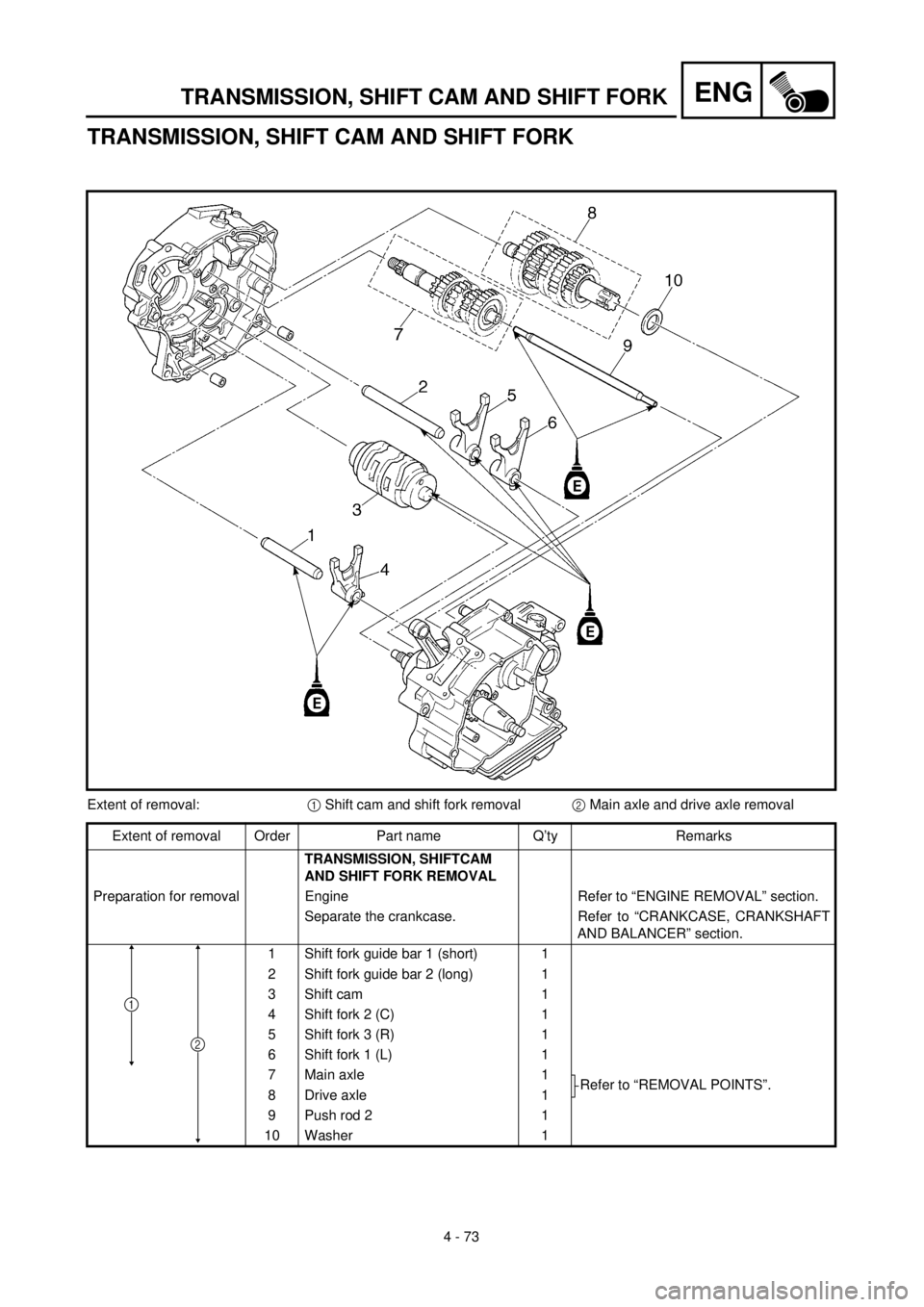

TRANSMISSION, SHIFT CAM AND SHIFT FORK

Extent of removal:

1

Shift cam and shift fork removal

2

Main axle and drive axle removal

Extent of removal Order Part name Q’ty Remarks

TRANSMISSION, SHIFTCAM

AND SHIFT FORK REMOVAL

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Separate the crankcase. Refer to “CRANKCASE, CRANKSHAFT

AND BALANCER” section.

1 Shift fork guide bar 1 (short) 1

2 Shift fork guide bar 2 (long) 1

3 Shift cam 1

4 Shift fork 2 (C) 1

5 Shift fork 3 (R) 1

6 Shift fork 1 (L) 1

7 Main axle 1

Refer to “REMOVAL POINTS”.

8 Drive axle 1

9 Push rod 2 1

10 Washer 1

1

2

Page 362 of 508

4 - 77

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

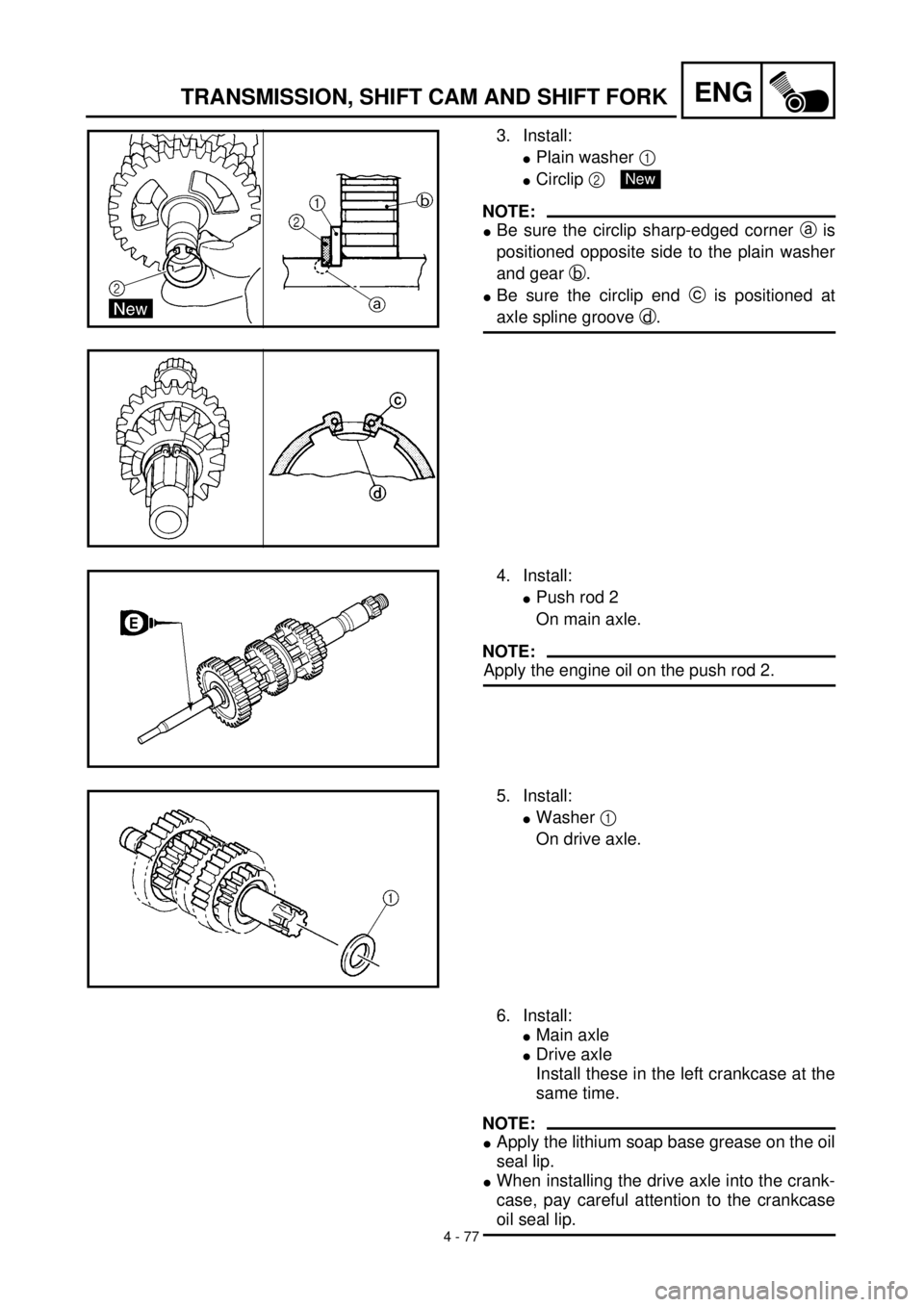

3. Install:

lPlain washer 1

lCirclip 2

NOTE:

lBe sure the circlip sharp-edged corner a is

positioned opposite side to the plain washer

and gear b.

lBe sure the circlip end c is positioned at

axle spline groove d.

New

4. Install:

lPush rod 2

On main axle.

NOTE:

Apply the engine oil on the push rod 2.

5. Install:

lWasher 1

On drive axle.

6. Install:

lMain axle

lDrive axle

Install these in the left crankcase at the

same time.

NOTE:

lApply the lithium soap base grease on the oil

seal lip.

lWhen installing the drive axle into the crank-

case, pay careful attention to the crankcase

oil seal lip.

Page 364 of 508

4 - 78

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

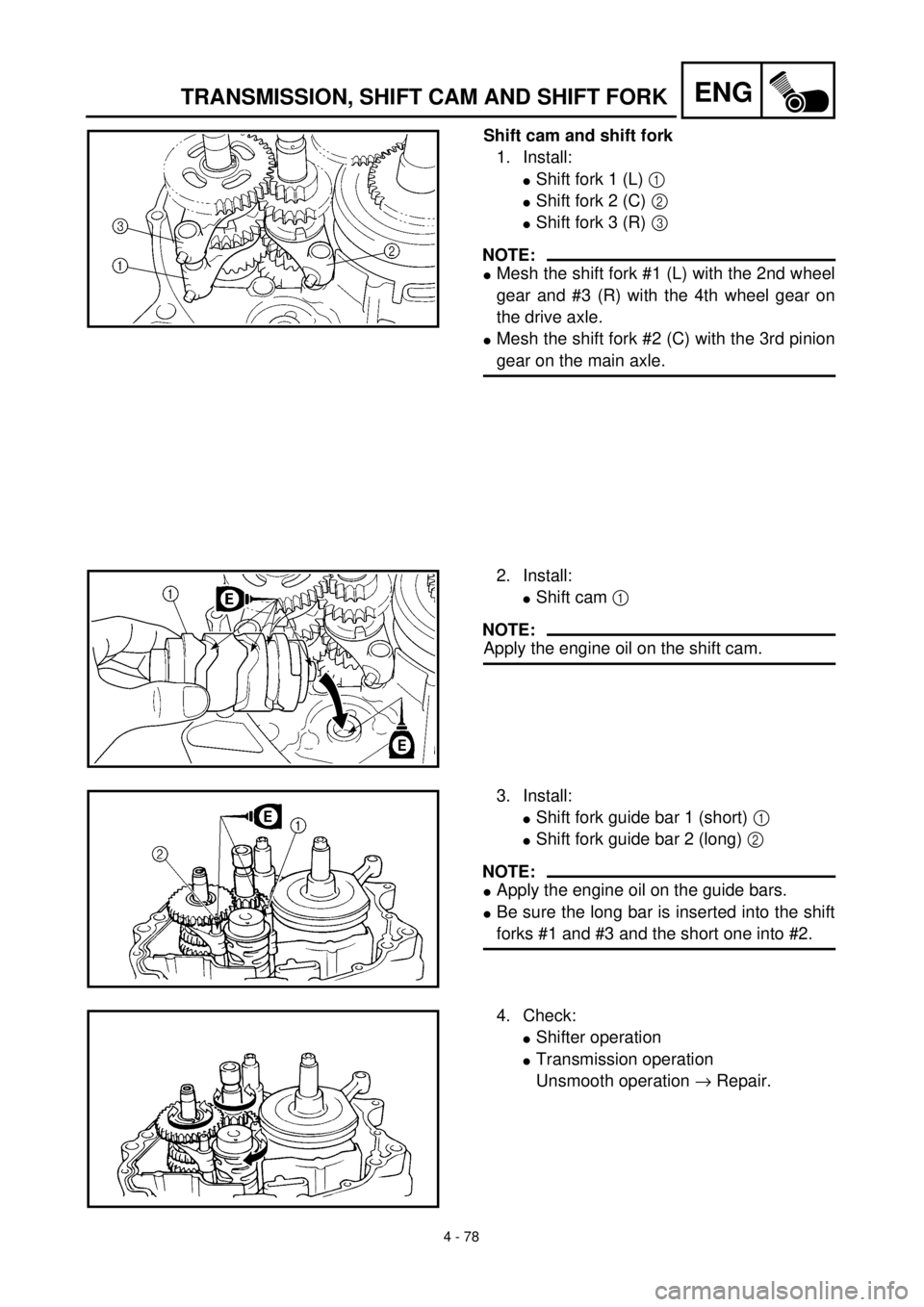

Shift cam and shift fork

1. Install:

lShift fork 1 (L) 1

lShift fork 2 (C) 2

lShift fork 3 (R) 3

NOTE:

lMesh the shift fork #1 (L) with the 2nd wheel

gear and #3 (R) with the 4th wheel gear on

the drive axle.

lMesh the shift fork #2 (C) with the 3rd pinion

gear on the main axle.

2. Install:

lShift cam 1

NOTE:

Apply the engine oil on the shift cam.

3. Install:

lShift fork guide bar 1 (short) 1

lShift fork guide bar 2 (long) 2

NOTE:

lApply the engine oil on the guide bars.

lBe sure the long bar is inserted into the shift

forks #1 and #3 and the short one into #2.

4. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

Page 366 of 508

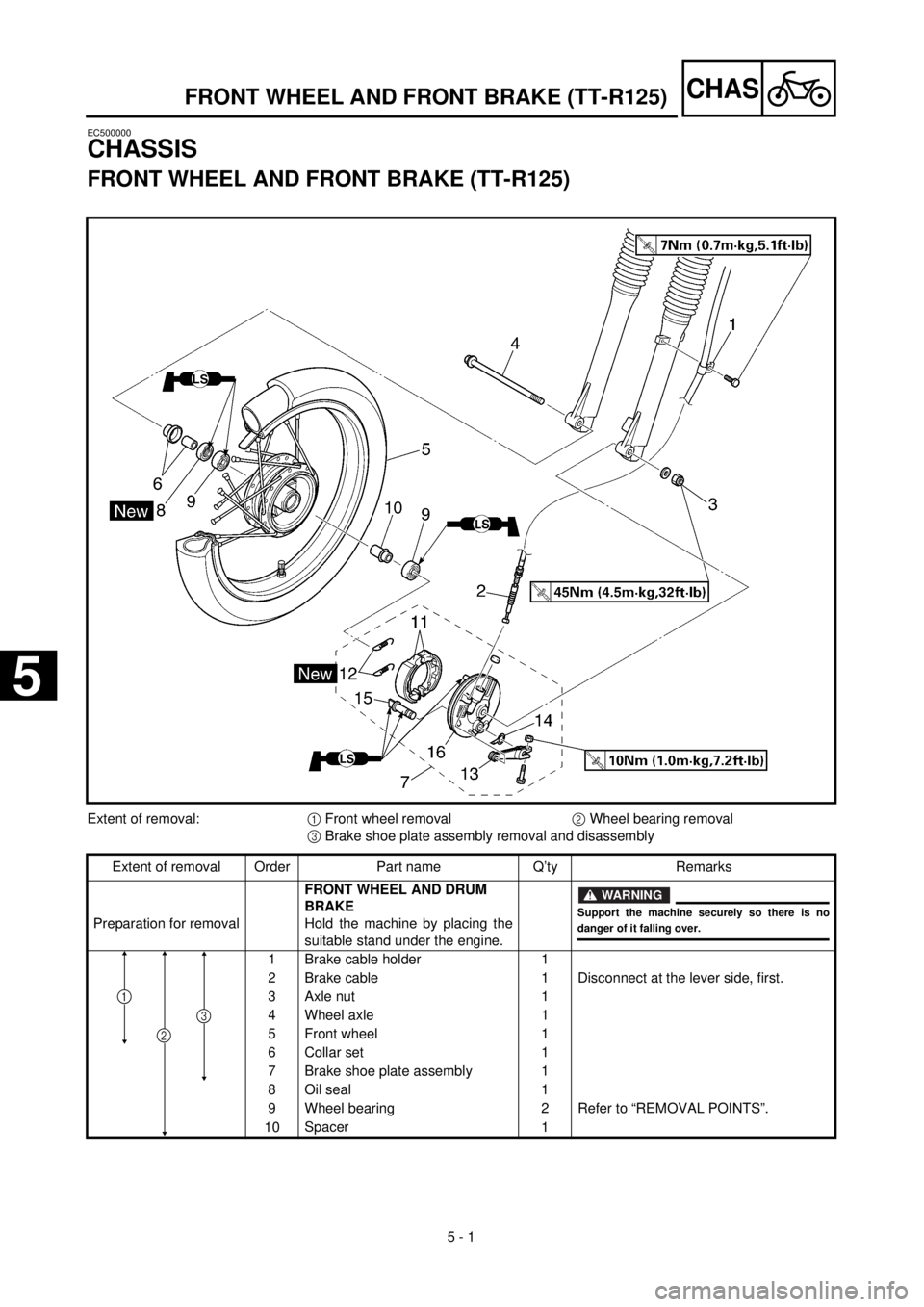

5 - 1

CHAS

FRONT WHEEL AND FRONT BRAKE (TT-R125)

EC500000

CHASSIS

FRONT WHEEL AND FRONT BRAKE (TT-R125)

Extent of removal:

1

Front wheel removal

2

Wheel bearing removal

3

Brake shoe plate assembly removal and disassembly

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

FRONT WHEEL AND DRUM

BRAKE

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Brake cable holder 1

2 Brake cable 1 Disconnect at the lever side, first.

3 Axle nut 1

4 Wheel axle 1

5 Front wheel 1

6 Collar set 1

7 Brake shoe plate assembly 1

8 Oil seal 1

9 Wheel bearing 2 Refer to “REMOVAL POINTS”.

10Spacer

1

2

3

1

5

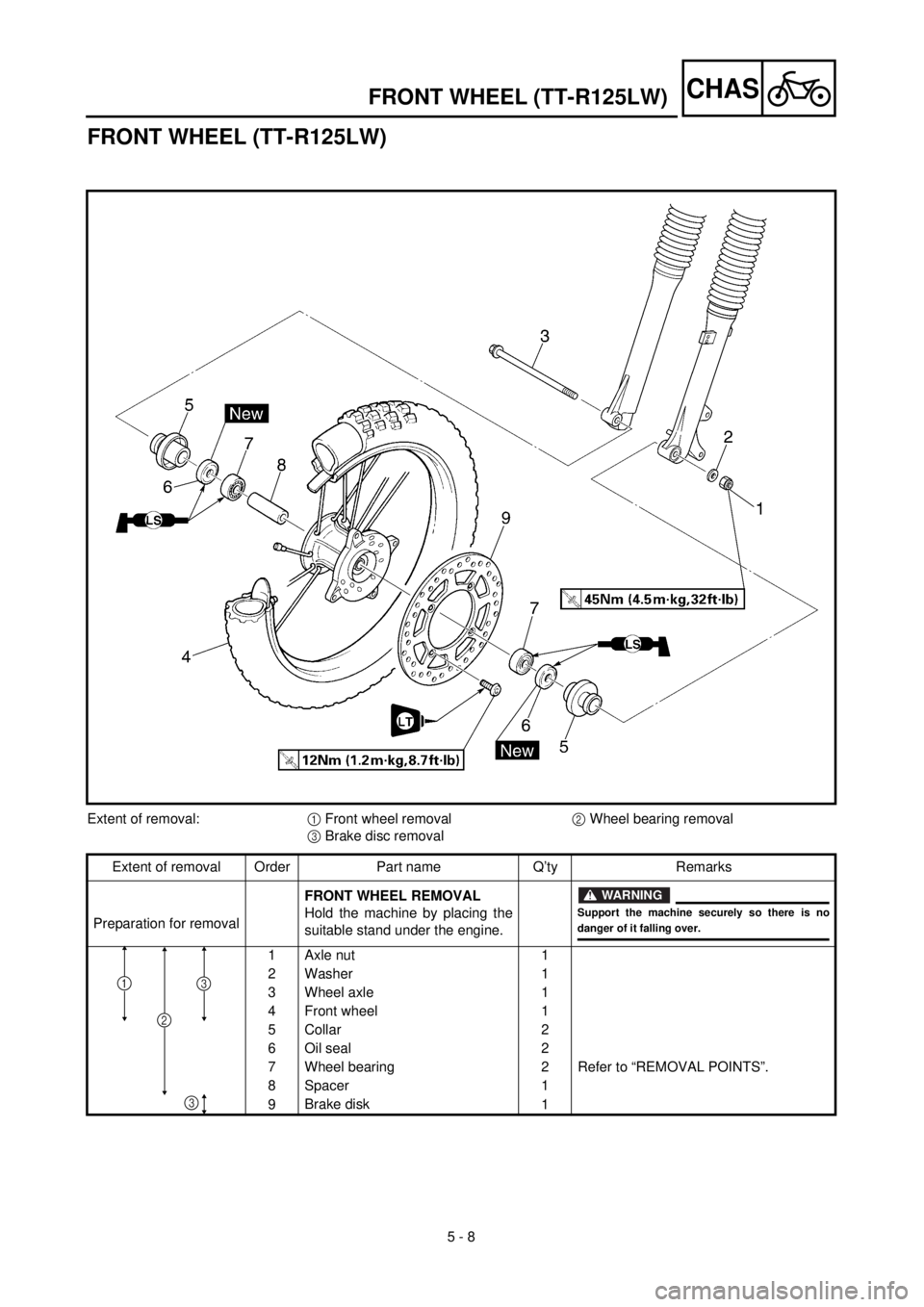

Page 380 of 508

5 - 8

CHAS

FRONT WHEEL (TT-R125LW)

Extent of removal:1 Front wheel removal2 Wheel bearing removal

3 Brake disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

1 Axle nut 1

2 Washer 1

3 Wheel axle 1

4 Front wheel 1

5 Collar 2

6 Oil seal 2

7 Wheel bearing 2 Refer to “REMOVAL POINTS”.

8 Spacer 1

9Brake disk

1

2

31

3

FRONT WHEEL (TT-R125LW)