engine YAMAHA TTR50 2006 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 28 of 390

1 - 2

GEN

INFO

MACHINE IDENTIFICATION

EC120001

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the

number to your Yamaha dealer for positive

identification of the model you own.

2. If your machine is stolen, the authorities will need the number to search for and identify

your machine.

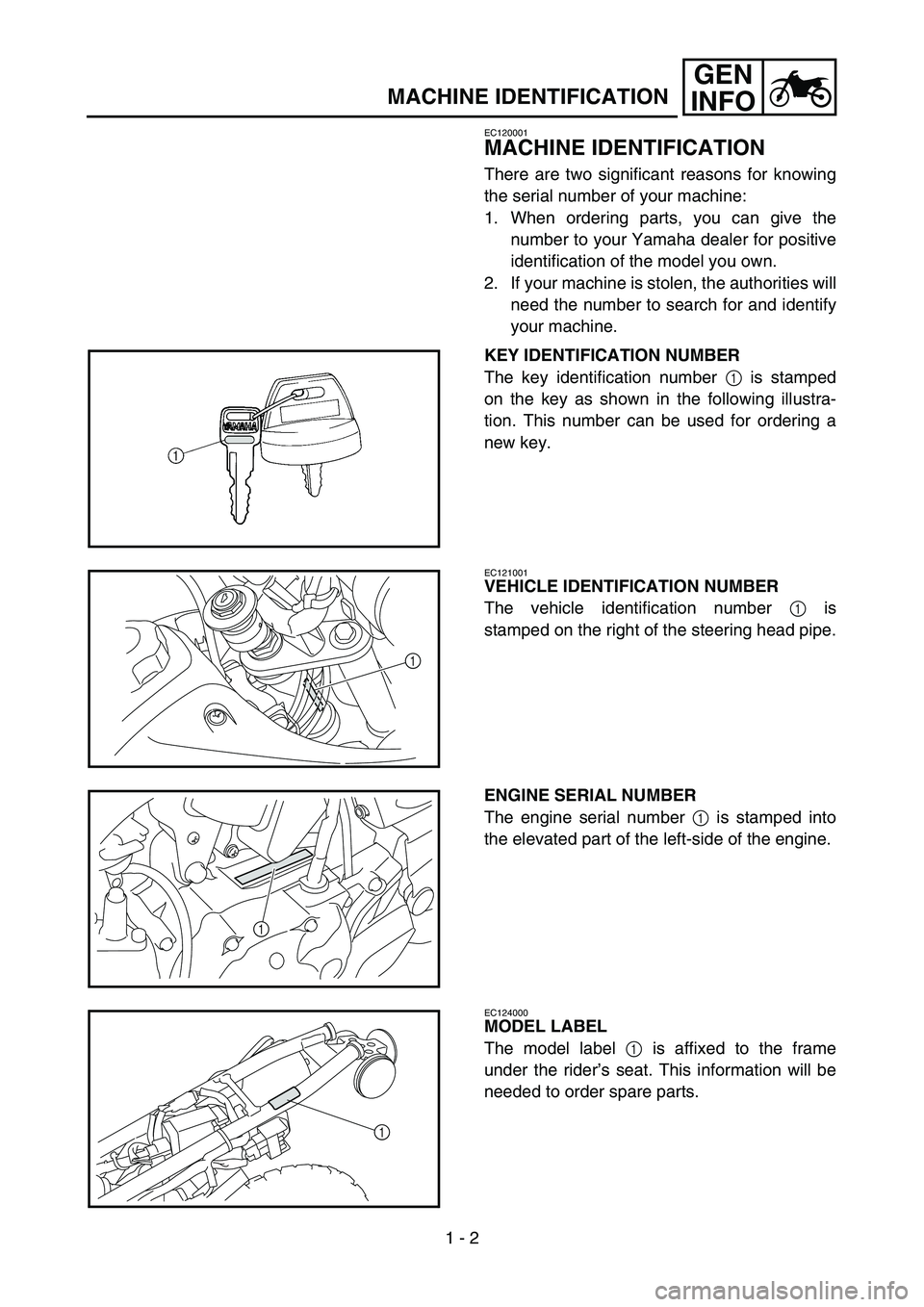

KEY IDENTIFICATION NUMBER

The key identification number 1 is stamped

on the key as shown in the following illustra-

tion. This number can be used for ordering a

new key.

EC121001

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped on the right of the steering head pipe.

1

ENGINE SERIAL NUMBER

The engine serial number 1 is stamped into

the elevated part of the left-side of the engine.

1

EC124000

MODEL LABEL

The model label 1 is affixed to the frame

under the rider ’s seat. This information will be

needed to order spare parts.

1

Page 32 of 390

1 - 4

GEN

INFO

IMPORTANT INFORMATION

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings shouldbe replaced when an engine is overhauled.

All gasket surfaces, oil seal lips, and O-

rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

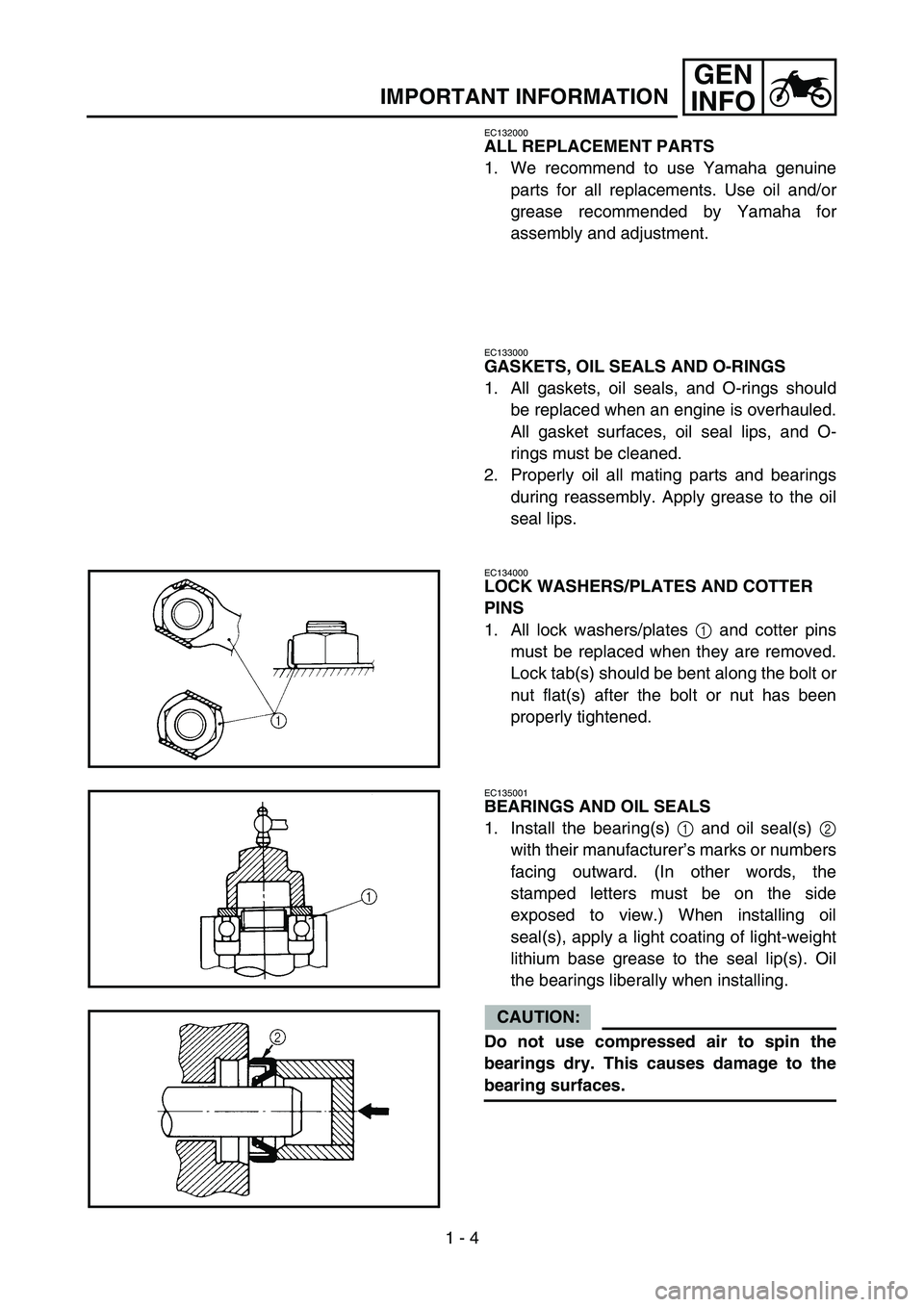

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1 and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s) 1 and oil seal(s) 2

with their manufacturer ’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-weight

lithium base grease to the seal lip(s). Oil

the bearings liberally when installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

Page 42 of 390

1 - 8

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

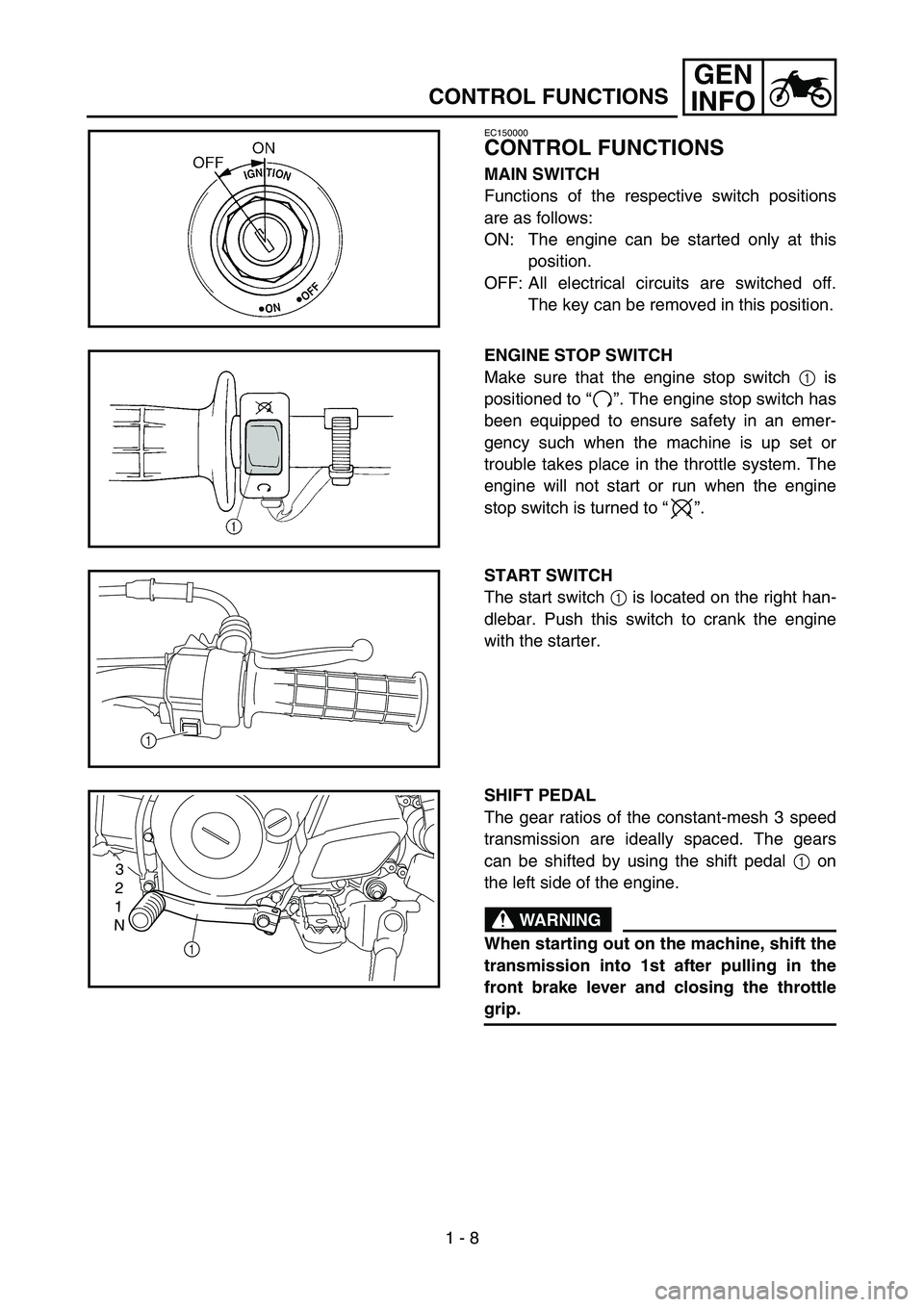

MAIN SWITCH

Functions of the respective switch positions

are as follows:

ON: The engine can be started only at this

position.

OFF: All electrical circuits are switched off. The key can be removed in this position.

ENGINE STOP SWITCH

Make sure that the engine stop switch 1 is

positioned to “”. The engine stop switch has

been equipped to ensure safety in an emer-

gency such when the machine is up set or

trouble takes place in the throttle system. The

engine will not start or run when the engine

stop switch is turned to “”.

START SWITCH

The start switch 1 is located on the right han-

dlebar. Push this switch to crank the engine

with the starter.

1

SHIFT PEDAL

The gear ratios of the constant-mesh 3 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

WARNING

When starting out on the machine, shift the

transmission into 1st after pulling in the

front brake lever and closing the throttle

grip.

3

2

1

N

1

Page 44 of 390

1 - 9

GEN

INFO

CONTROL FUNCTIONS

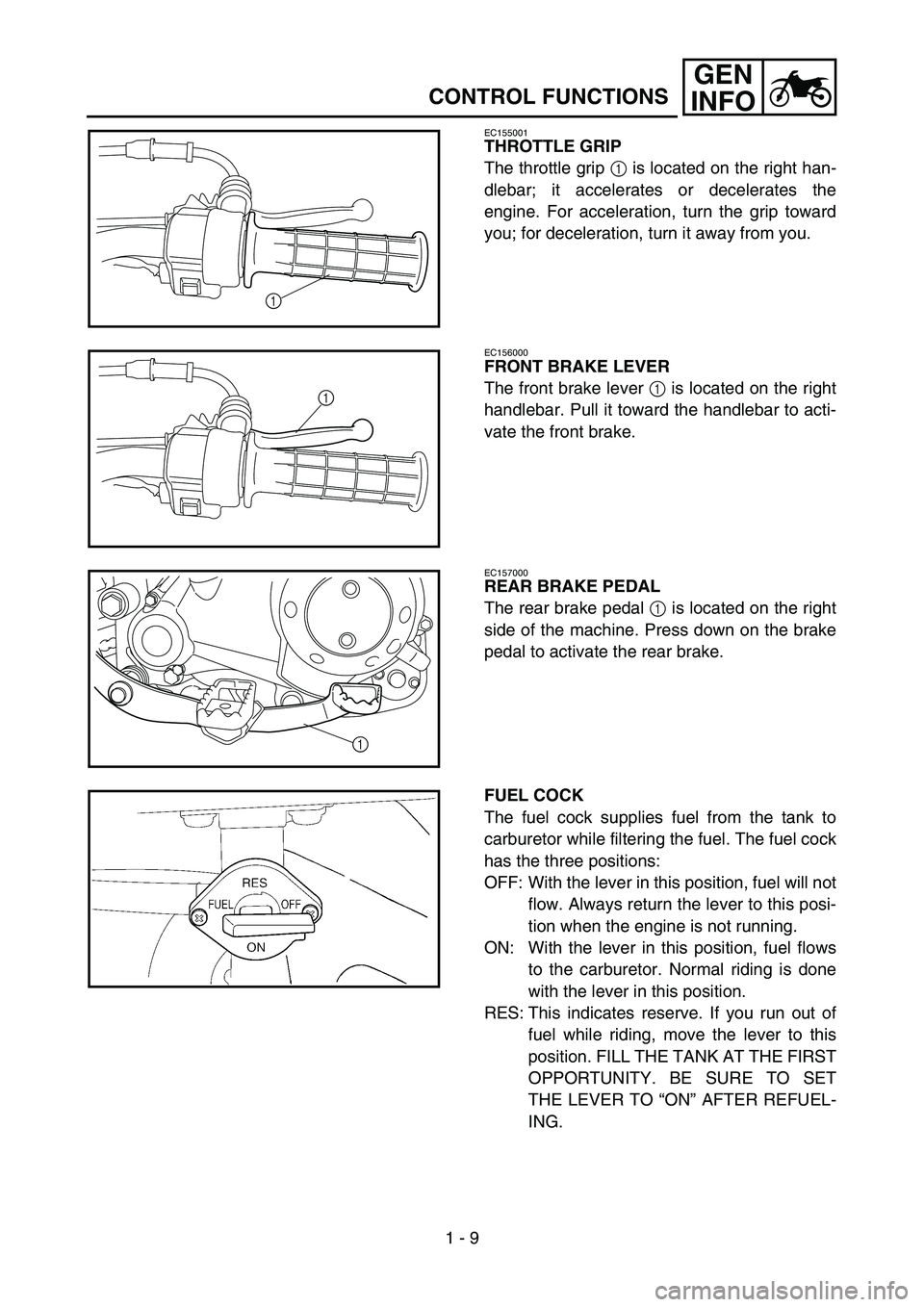

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

1

EC156000

FRONT BRAKE LEVER

The front brake lever 1 is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

1

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1 is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

1

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor while filtering the fuel. The fuel cock

has the three positions:

OFF: With the lever in this position, fuel will not flow. Always return the lever to this posi-

tion when the engine is not running.

ON: With the lever in this position, fuel flows to the carburetor. Normal riding is done

with the lever in this position.

RES: This indicates reserve. If you run out of fuel while riding, move the lever to this

position. FILL THE TANK AT THE FIRST

OPPORTUNITY. BE SURE TO SET

THE LEVER TO “ON ” AFTER REFUEL-

ING.

Page 46 of 390

1 - 10

GEN

INFO

CONTROL FUNCTIONS

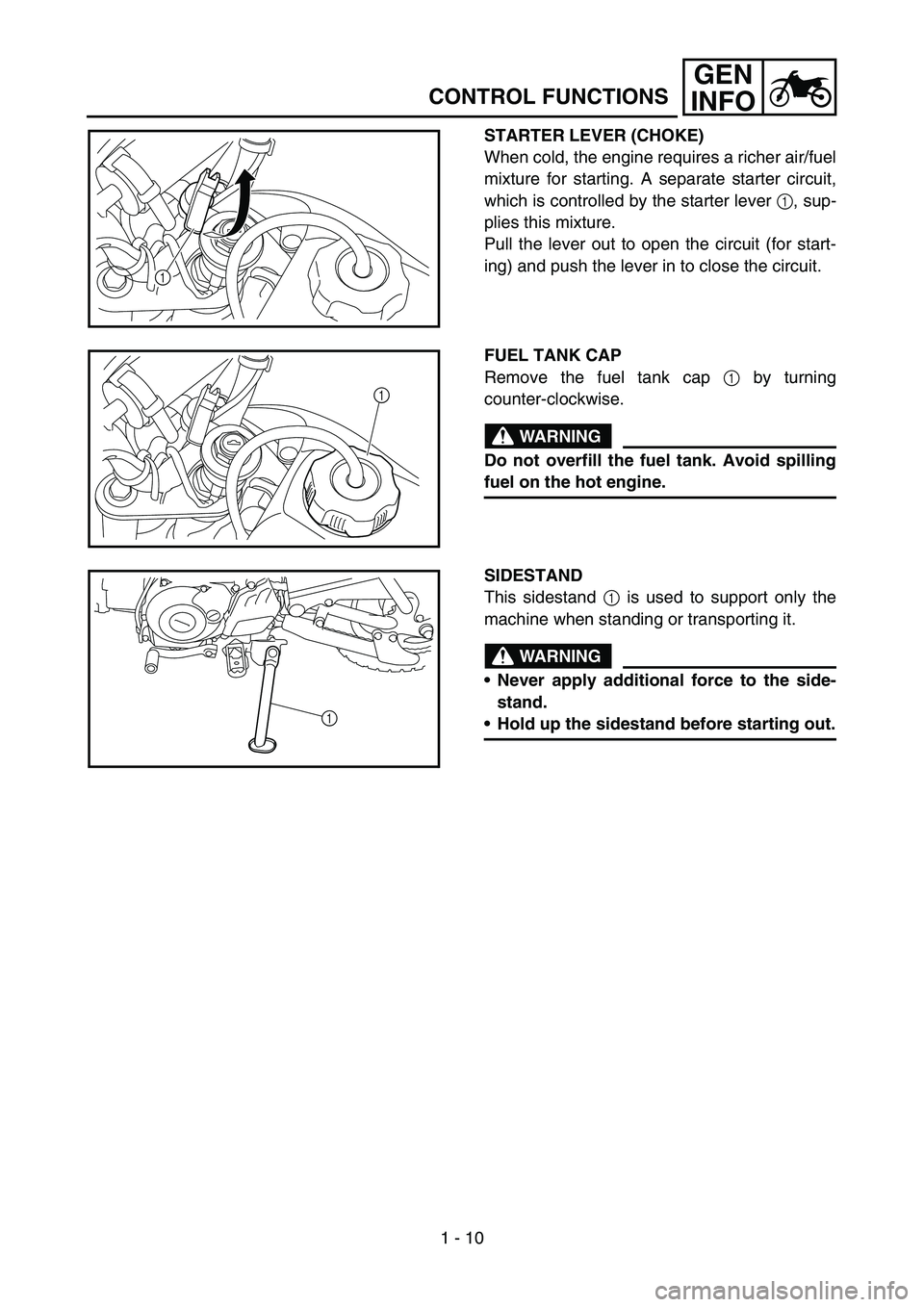

STARTER LEVER (CHOKE)

When cold, the engine requires a richer air/fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter lever 1, sup-

plies this mixture.

Pull the lever out to open the circuit (for start-

ing) and push the lever in to close the circuit.

1

FUEL TANK CAP

Remove the fuel tank cap 1 by turning

counter-clockwise.

WARNING

Do not overfill the fuel tank. Avoid spilling

fuel on the hot engine.

1

SIDESTAND

This sidestand 1 is used to support only the

machine when standing or transporting it.

WARNING

Never apply additional force to the side-

stand.

Hold up the sidestand before starting out.1

Page 48 of 390

1 - 11

GEN

INFO

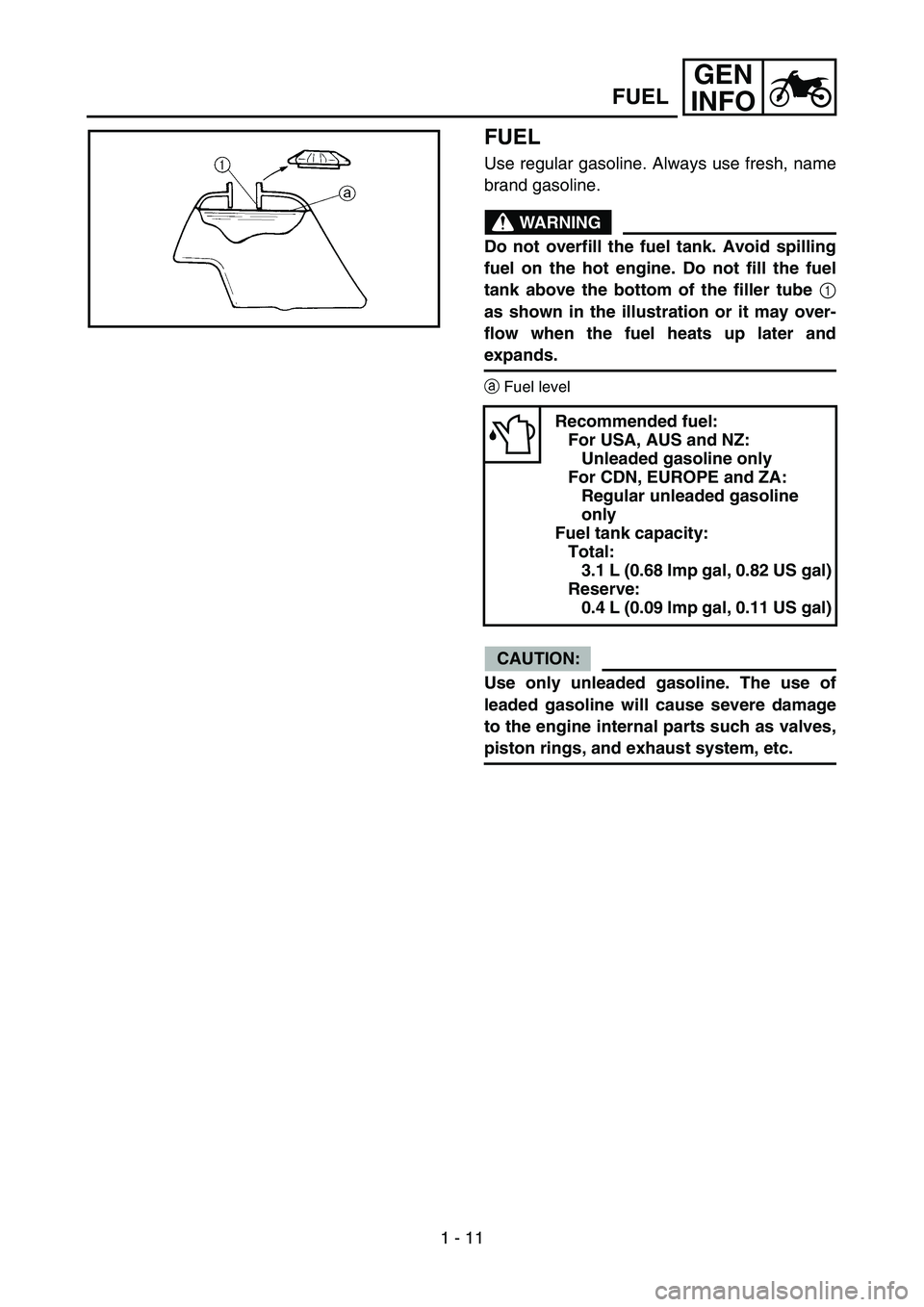

FUEL

Use regular gasoline. Always use fresh, name

brand gasoline.

WARNING

Do not overfill the fuel tank. Avoid spilling

fuel on the hot engine. Do not fill the fuel

tank above the bottom of the filler tube 1

as shown in the illustration or it may over-

flow when the fuel heats up later and

expands.

a Fuel level

CAUTION:

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

Recommended fuel: For USA, AUS and NZ: Unleaded gasoline only

For CDN, EUROPE and ZA: Regular unleaded gasoline

only

Fuel tank capacity: Total: 3.1 L (0.68 Imp gal, 0.82 US gal)

Reserve: 0.4 L (0.09 lmp gal, 0.11 US gal)

FUEL

Page 50 of 390

GEN

INFO

1 - 12

STARTING AND OPERATION

STARTING AND OPERATION

CAUTION:

Prior to operating the machine, perform

steps listed in pre-operation check list.

WARNING

Never start your engine or let it run for any

length of time in a closed area. The exhaust

fumes are poisonous and can cause loss of

consciousness and death within a short

time. Always operate your machine in an

area with adequate ventilation.

STARTING A COLD ENGINE

WARNING

Before starting the engine, be sure to shift

the transmission into neutral.

NOTE:

This model is equipped with an ignition cir-

cuit cut-off system. In case of electric start-

ing, the engine can be started only when the

transmission is in neutral.

If the engine fails to start by pushing the start

switch, release the switch, wait a few sec-

onds, and then try again. Each starting

attempt should be as short as possible to

preserve the battery. Do not crank the

engine more than 10 seconds on any one

attempt.

1. Turn the fuel cock to “ON ”.

2. Turn the main switch to “ON ”.

3. Shift the transmission into neutral.

4. Operate the starter (choke) and completely close the throttle grip.

5. Slide the “engine stop ” switch to the “”.

6. Start the engine by pushing the start switch.

7. After the engine starts, warm up for one or

two minutes. Make sure the stater (choke) is

returned to the original position before riding. STARTING A WARM ENGINE

To start a warm engine, refer to the

“START-

ING A COLD ENGINE ” section. The starter

(choke) should not be used. The throttle

should be opened slightly.

CAUTION:

See “Engine break-in Section ” prior to

operating engine for the first time.

WARMING UP

To get maximum engine life, always “warm-up ”

the engine before starting off. Never accelerate

hard with a cold engine! To see whether or not

the engine is warm, see if it responds to throttle

normally with the stater (choke) turned off.

WARNING

Before starting off, be sure to turn up or

remove the side stand.

Failure to retract the side stand completely

can result in a serious accident when you

try to turn a corner.

ENGINE BREAK-IN

Break-in is important to better fit the moving

and sliding parts as well as the installed parts.

It is also important to accustom the rider to the

machine better.

Avoid full-throttle run on a new machine for the

first 5 hours.

After the trial run, check for loose parts, oil

leakage and other problems.

Make full inspection and adjustment especially of

slack cables and drive chain and loose spokes.

CAUTION:

After the break-in period, check every fit-

ting and fastener for looseness.

If any loose is found, retighten it securely.

Page 53 of 390

GEN

INFO

1 - 13

CLEANING AND STORAGE

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will

enhance its appearance, maintain good overall

performance, and extend the life of many com-

ponents.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering.

2. If the engine is excessively greasy, apply some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprock-

ets, or wheel axles.

3. Rinse the dirt and degreaser off with a gar- den hose; use only enough pressure to do

the job.

CAUTION:

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been hosed off, wash all surfaces with warm

water and a mild detergent. Use an old

toothbrush to clean hard-to-reach places.

5. Rinse the machine off immediately with clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess water from the chain with a paper towel

and lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery cleaner to keep the cover pliable and

glossy.

8. Automotive wax may be applied to all

painted or chromed surfaces. Avoid combi-

nation cleaner-waxes, as they may contain

abrasives.

9. After completing the above, start the engine and allow it to idle for several min-

utes.

EC182001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. Set the engine

stop switch to “”, turn the engine over

several times with starter. (This will coat

the cylinder walls with oil.)

3. Remove the drive chain, clean it thoroughly with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.

Page 56 of 390

SPEC

2 - 1

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: TT-R50EV (USA, CDN, AUS, NZ)TT-R50E (Europe, ZA)

Model code number: 1P61 (USA) 1P62 (CDN)

1P63 (Europe, AUS, NZ, ZA)

Dimensions: Overall length 1,305 mm (51.4 in)

Overall width 595 mm (23.4 in)

Overall height 775 mm (30.5 in)

Seat height 555 mm (21.9 in)

Wheelbase 925 mm (36.4 in)

Minimum ground clearance 135 mm (5.31 in)

Dry weight: Without oil and fuel 54.0 kg (119 lb)

Engine: Engine type Air cooled 4-stroke, SOHC

Cylinder arrangement Forward-inclined single cylinder

Displacement 49.5 cm

3 (3.02 cu.in)

Bore × stroke 36.0 × 48.6 mm (1.42 × 1.91 in)

Compression ratio 9.5 : 1

Compression pressure (STD) 1,300 kPa (13 kg/cm

2, 185 psi) at 600 r/min

Starting system Electric starter

Lubrication system: Wet sump

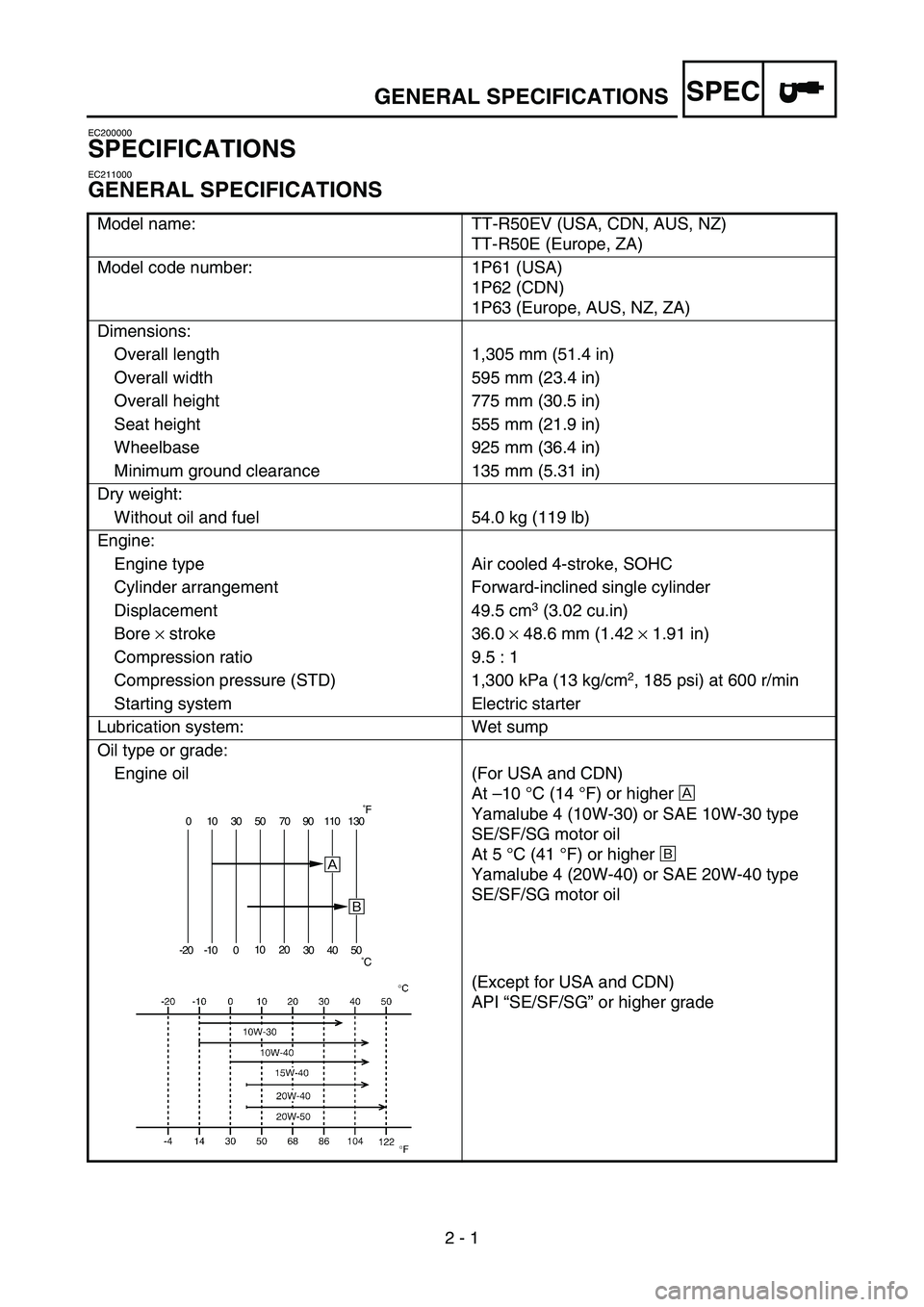

Oil type or grade: Engine oil

(For USA and CDN)

At –10 °C (14 °F) or higher È

Yamalube 4 (10W-30) or SAE 10W-30 type

SE/SF/SG motor oil

At 5 °C (41 °F) or higher É

Yamalube 4 (20W-40) or SAE 20W-40 type

SE/SF/SG motor oil

(Except for USA and CDN)

API “SE/SF/SG ” or higher grade

0 10 30 50 70 90 110 130

-20 -10 0 10

20

30 40 50

È

É

˚F

˚C

GENERAL SPECIFICATIONS

Page 57 of 390

SPEC

2 - 2

Oil capacity:

Engine oil Periodic oil change 0.8 L (0.70 Imp qt, 0.85 US qt)

Total amount 1.0 L (0.88 Imp qt, 1.06 US qt)

Air filter: Wet element

Fuel: Type Unleaded gasoline only (USA, AUS and NZ) Regular unleaded gasoline only

(CDN, Europe and ZA)

Tank capacity 3.1 L (0.68 Imp gal, 0.82 US gal)

Reserve amount 0.4 L (0.09 Imp gal, 0.11 US gal)

Carburetor: Type VM11

Manufacturer MIKUNI

Spark plug: Type CR7HSA

Manufacturer NGK

Gap 0.6 ~ 0.7 mm (0.024 ~ 0.028 in)

Clutch type: Wet, multiple-disc and centrifugal automatic

Transmission: Primary reduction system Spur gear

Primary reduction ratio 67/18 (3.722)

Secondary reduction system Chain drive

Secondary reduction ratio 37/13 (2.846)

Transmission type Constant mesh, 3-speed

Operation Left foot operation

Gear ratio: 1st 39/12 (3.250) 2nd 33/19 (1.736)

3rd 28/23 (1.217)

Chassis: Frame type Steel tube backbone

Caster angle 25.50 °

Trail 34.0 mm (1.34 in)

Tire: Type With tube

Size (front) 2.50-10 4PR

Size (rear) 2.50-10 4PR

Manufacturer (front and rear) CHENG SHIN

Type (front and rear) KNOBBY

Tire pressure (front and rear) 100 kPa (1.00 kgf/cm

2, 14.2 psi)

Brake: Front brake type Drum brake

Operation Right hand operation

Rear brake type Drum brake

Operation Right foot operation

GENERAL SPECIFICATIONS

1

2

3

4

5

6