engine YAMAHA TTR50 2006 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 121 of 390

3 - 2

INSPADJ

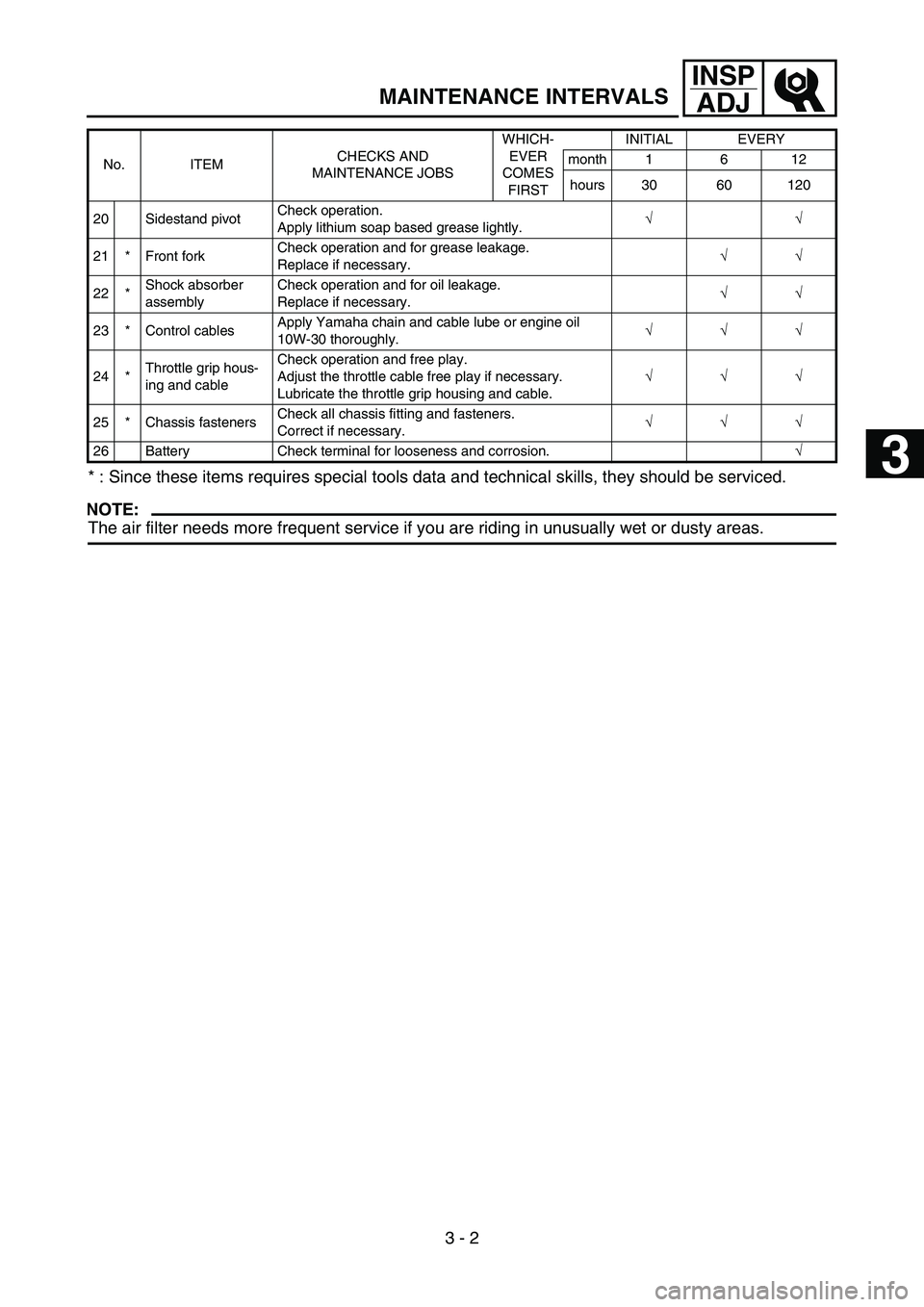

MAINTENANCE INTERVALS

* : Since these items requires special tools data and technical skills, they should be serviced.

NOTE:

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

20 Sidestand pivot Check operation.

Apply lithium soap based grease lightly.

√

√

21 * Front fork Check operation and for grease leakage.

Replace if necessary.

√

√

22 * Shock absorber

assembly Check operation and for oil leakage.

Replace if necessary.

√

√

23 * Control cables Apply Yamaha chain and cable lube or engine oil

10W-30 thoroughly.

√

√

√

24 * Throttle grip hous-

ing and cable Check operation and free play.

Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.

√

√

√

25 * Chassis fasteners Check all chassis fitting and fasteners.

Correct if necessary.

√

√

√

26 Battery Check terminal for looseness and corrosion. √

No. ITEM

CHECKS AND

MAINTENANCE JOBS WHICH-

EVER

COMES FIRST INITIAL EVERY

month 1 6 12

hours 30 60 120

1

2

3

4

5

6

Page 126 of 390

3 - 3

INSPADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

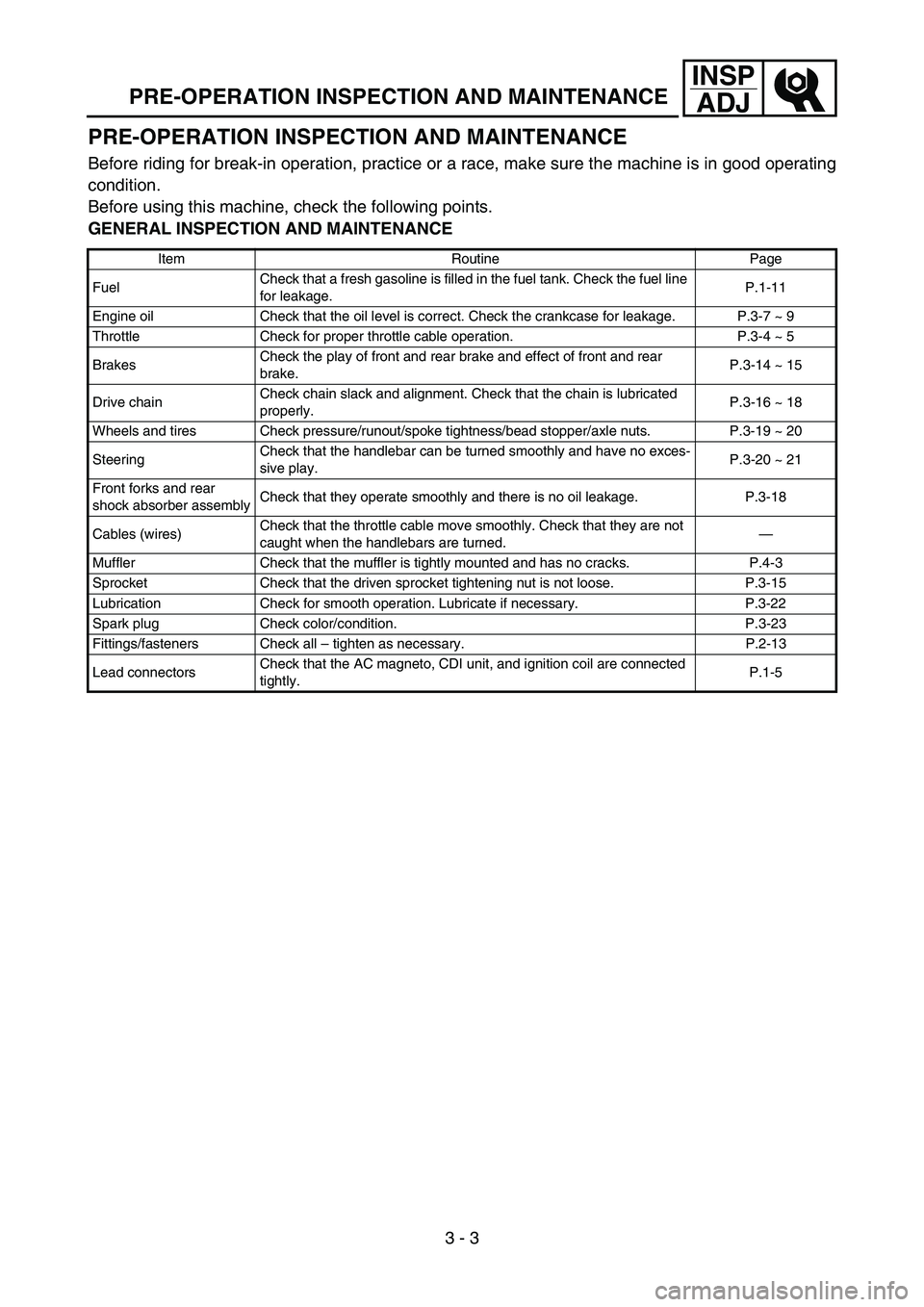

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

Fuel Check that a fresh gasoline is filled in the fuel tank. Check the fuel line

for leakage. P.1-11

Engine oil Check that the oil level is correct. Check the crankcase for leakage. P.3-7 ~ 9

Throttle Check for proper throttle cable operation. P.3-4 ~ 5

Brakes Check the play of front and rear brake and effect of front and rear

brake. P.3-14 ~ 15

Drive chain Check chain slack and alignment. Check that the chain is lubricated

properly. P.3-16 ~ 18

Wheels and tires Check pressure/runout/spoke tightness/bead stopper/axle nuts. P.3-19 ~ 20

Steering Check that the handlebar can be turned smoothly and have no exces-

sive play. P.3-20 ~ 21

Front forks and rear

shock absorber assembly Check that they operate smoothly and there is no oil leakage. P.3-18

Cables (wires) Check that the throttle cable move smoothly. Check that they are not

caught when the handlebars are turned. —

Muffler Check that the muffler is tightly mounted and has no cracks. P.4-3

Sprocket Check that the driven sprocket tightening nut is not loose. P.3-15

Lubrication Check for smooth operation. Lubricate if necessary. P.3-22

Spark plug Check color/condition. P.3-23

Fittings/fasteners Check all – tighten as necessary. P.2-13

Lead connectors Check that the AC magneto, CDI unit, and ignition coil are connected

tightly. P.1-5

Page 130 of 390

3 - 4

INSPADJ

ENGINE/THROTTLE CABLE ADJUSTMENT

EC350000

ENGINE

THROTTLE CABLE ADJUSTMENT

1. Check:

Throttle grip free play a

Out of specification → Adjust.

Throttle grip free play

a:

3 ~ 5 mm (0.12 ~ 0.20 in)

2. Adjust:

Throttle grip free play

Throttle grip free play adjustment steps:

Carburetor side

NOTE:

Before adjusting the throttle cable free play,

the engine idle speed should be adjusted.

Remove the seat assembly and air scoop

(right).

Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section in

the CHAPTER 4.

Pull back the adjuster cover.

Loosen the locknut 1 on throttle cable.

Turn the adjuster 2 in or out until the

specified free play is obtained.

Turning in b → Free play is increased.

Turning out c → Free play is decreased.

Tighten the locknut.

Slide the adjuster cover to its original posi-

tion.

Install the seat assembly and air scoop

(right).

NOTE:

If the specified throttle cable free play can-

not be obtained on the carburetor side of the

cable, use the adjusting nut on the handle-

bar side.

WARNING

After adjusting, turn the handlebar to

right and left and make sure that the

engine idling does not run faster.

c

b

1

2

Page 132 of 390

3 - 5

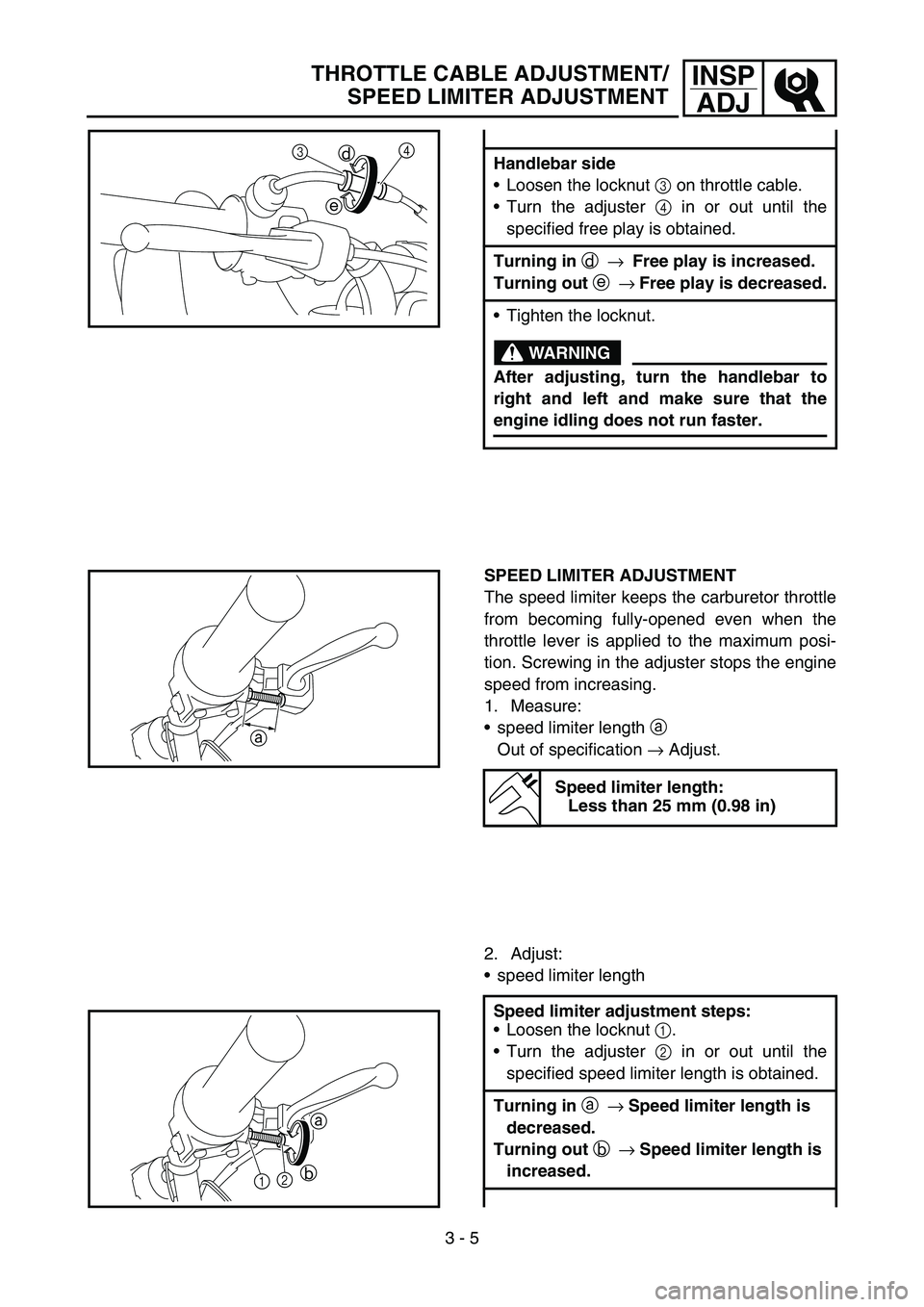

INSPADJTHROTTLE CABLE ADJUSTMENT/

SPEED LIMITER ADJUSTMENT

Handlebar side

Loosen the locknut 3 on throttle cable.

Turn the adjuster 4 in or out until the

specified free play is obtained.

Turning in d → Free play is increased.

Turning out e → Free play is decreased.

Tighten the locknut.

WARNING

After adjusting, turn the handlebar to

right and left and make sure that the

engine idling does not run faster.

4

d

e

3

SPEED LIMITER ADJUSTMENT

The speed limiter keeps the carburetor throttle

from becoming fully-opened even when the

throttle lever is applied to the maximum posi-

tion. Screwing in the adjuster stops the engine

speed from increasing.

1. Measure:

speed limiter length a

Out of specification → Adjust.

2. Adjust:

speed limiter length

Speed limiter length:

Less than 25 mm (0.98 in)

Speed limiter adjustment steps:

Loosen the locknut 1.

Turn the adjuster 2 in or out until the

specified speed limiter length is obtained.

Turning in a → Speed limiter length is

decreased.

Turning out b → Speed limiter length is

increased.

a

1 2

a

b

Page 134 of 390

3 - 6

INSPADJ

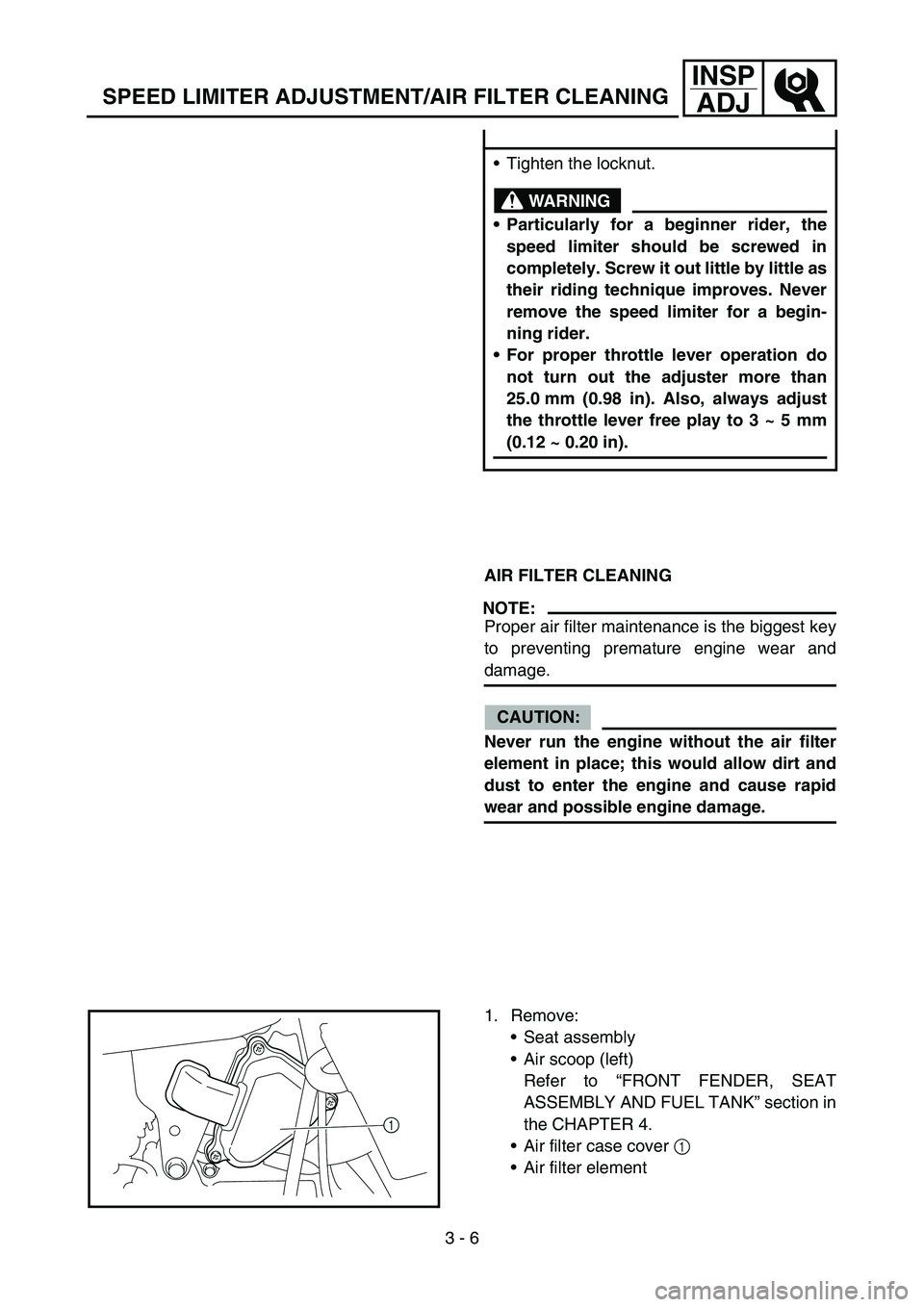

Tighten the locknut.

WARNING

Particularly for a beginner rider, the

speed limiter should be screwed in

completely. Screw it out little by little as

their riding technique improves. Never

remove the speed limiter for a begin-

ning rider.

For proper throttle lever operation do

not turn out the adjuster more than

25.0 mm (0.98 in). Also, always adjust

the throttle lever free play to 3 ~ 5 mm

(0.12 ~ 0.20 in).

AIR FILTER CLEANING

NOTE:

Proper air filter maintenance is the biggest key

to preventing premature engine wear and

damage.

CAUTION:

Never run the engine without the air filter

element in place; this would allow dirt and

dust to enter the engine and cause rapid

wear and possible engine damage.

1. Remove: Seat assembly

Air scoop (left)

Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section in

the CHAPTER 4.

Air filter case cover 1

Air filter element

1

SPEED LIMITER ADJUSTMENT/AIR FILTER CLEANING

Page 136 of 390

3 - 7

INSPADJ

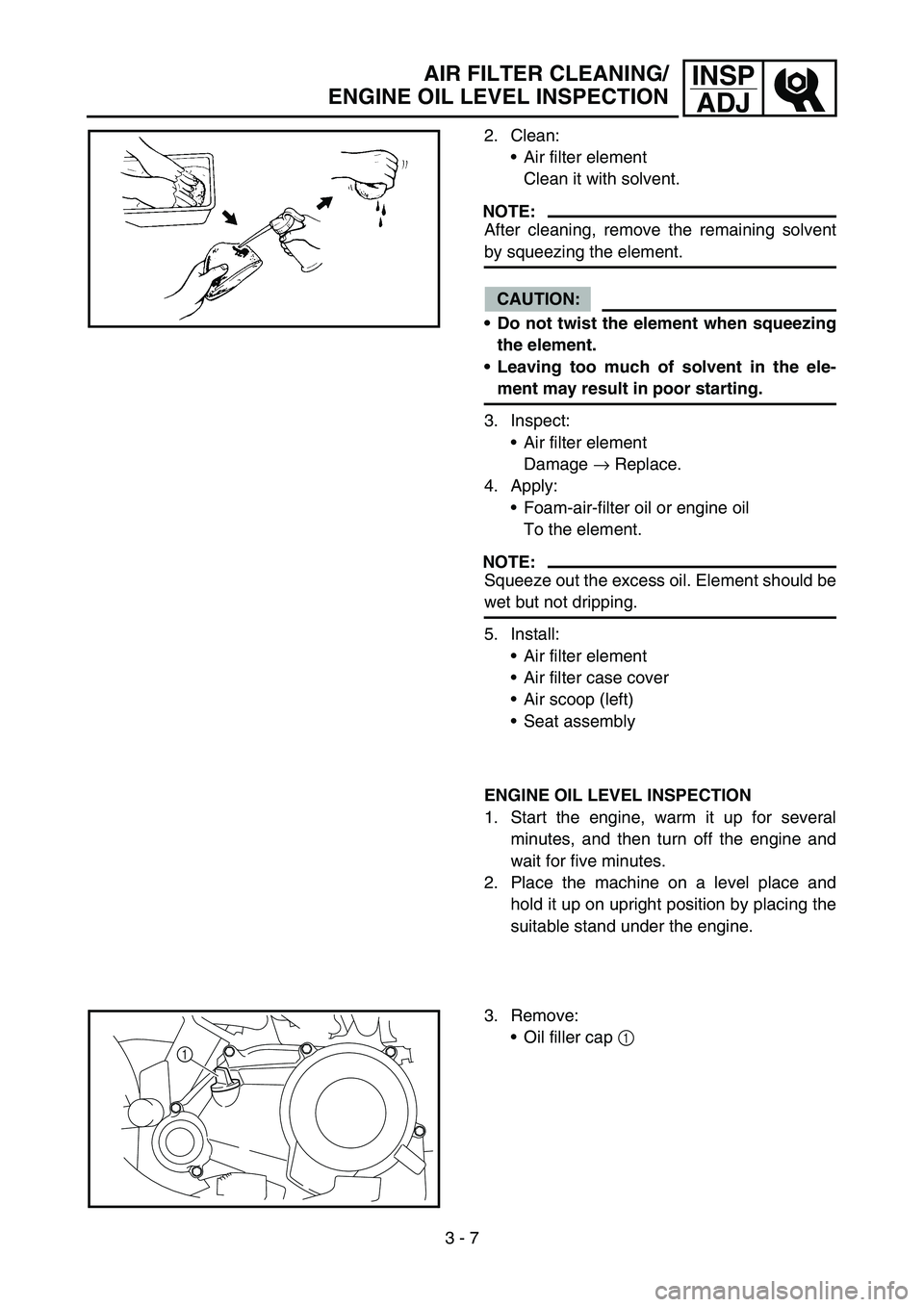

2. Clean:

Air filter element

Clean it with solvent.

NOTE:

After cleaning, remove the remaining solvent

by squeezing the element.

CAUTION:

Do not twist the element when squeezing

the element.

Leaving too much of solvent in the ele-

ment may result in poor starting.

3. Inspect: Air filter element

Damage → Replace.

4. Apply: Foam-air-filter oil or engine oil

To the element.

NOTE:

Squeeze out the excess oil. Element should be

wet but not dripping.

5. Install:

Air filter element

Air filter case cover

Air scoop (left)

Seat assembly

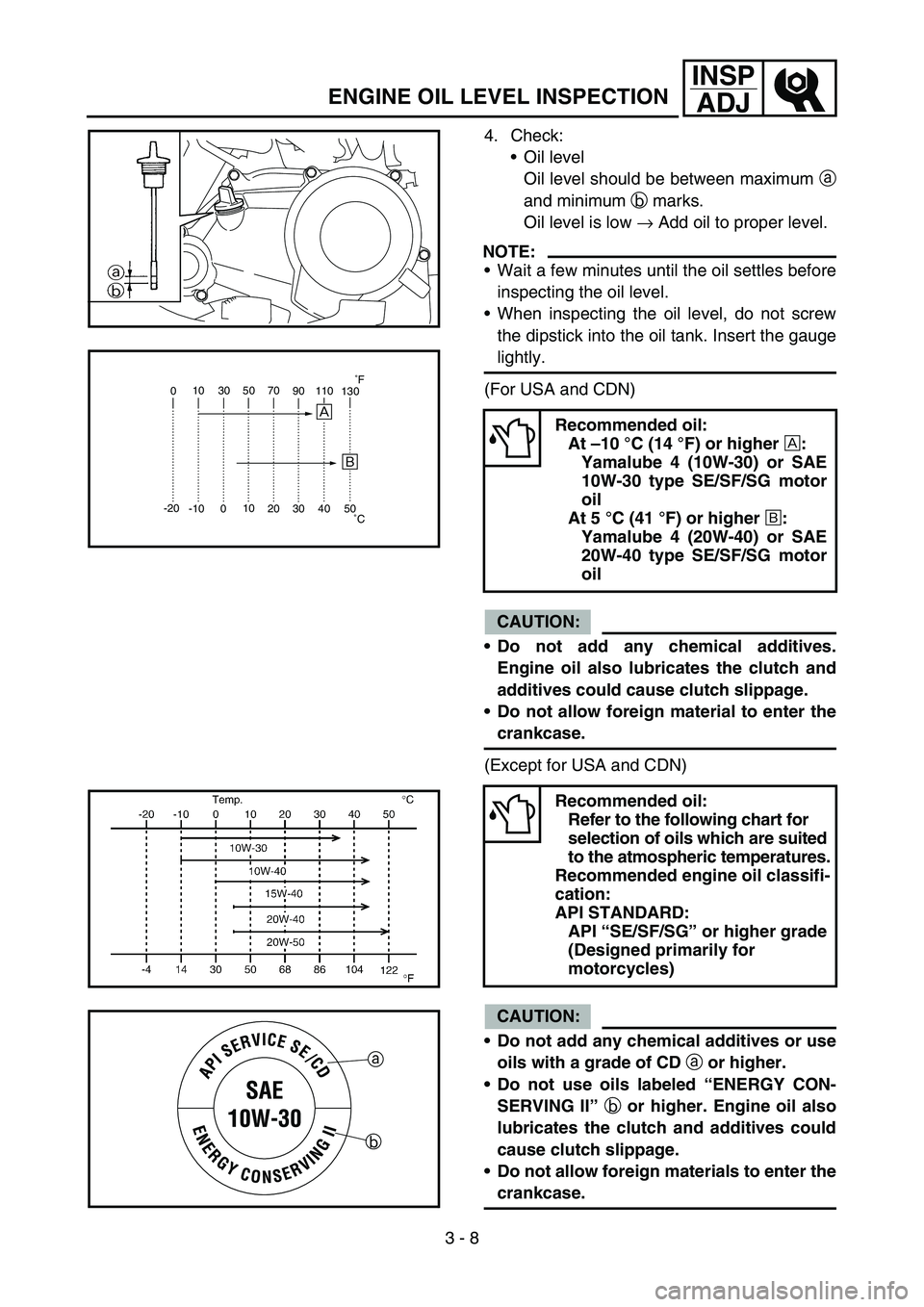

ENGINE OIL LEVEL INSPECTION

1. Start the engine, warm it up for several

minutes, and then turn off the engine and

wait for five minutes.

2. Place the machine on a level place and hold it up on upright position by placing the

suitable stand under the engine.

3. Remove: Oil filler cap 1

1

AIR FILTER CLEANING/

ENGINE OIL LEVEL INSPECTION

Page 138 of 390

3 - 8

INSPADJ

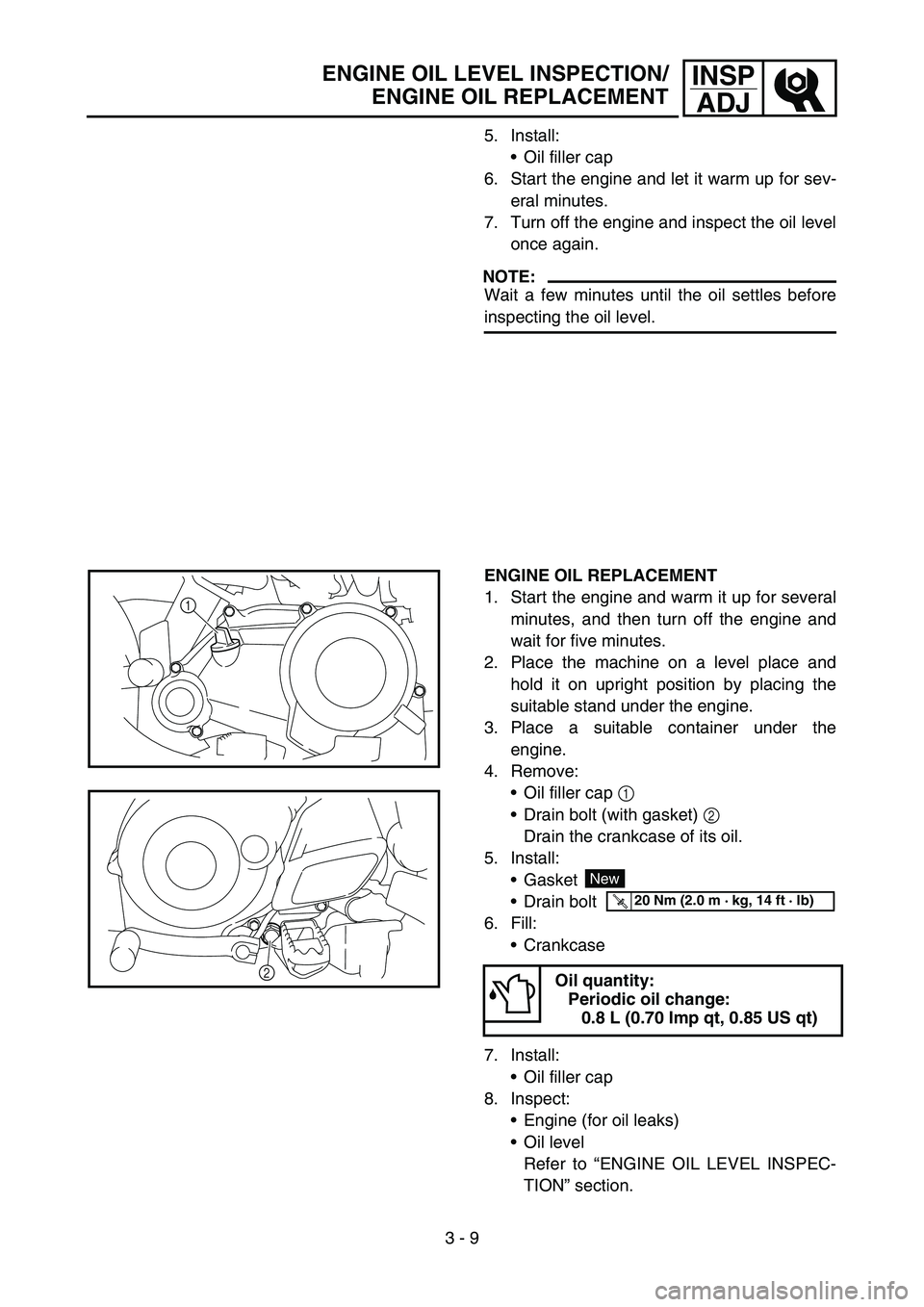

4. Check:

Oil level

Oil level should be between maximum a

and minimum b marks.

Oil level is low → Add oil to proper level.

NOTE:

Wait a few minutes until the oil settles before

inspecting the oil level.

When inspecting the oil level, do not screw

the dipstick into the oil tank. Insert the gauge

lightly.

(For USA and CDN)

CAUTION:

Do not add any chemical additives.

Engine oil also lubricates the clutch and

additives could cause clutch slippage.

Do not allow foreign material to enter the

crankcase.

(Except for USA and CDN)

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD a or higher.

Do not use oils labeled “ENERGY CON-

SERVING II ” b or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

Recommended oil:

At –10 °C (14 °F) or higher È:

Yamalube 4 (10W-30) or SAE

10W-30 type SE/SF/SG motor

oil

At 5 °C (41 °F) or higher É:

Yamalube 4 (20W-40) or SAE

20W-40 type SE/SF/SG motor

oil

Recommended oil: Refer to the following chart for

selection of oils which are suited

to the atmospheric temperatures.

Recommended engine oil classifi-

cation:

API STANDARD: API “SE/SF/SG ” or higher grade

(Designed primarily for

motorcycles)

0 10 30 50 70

90110

130

-20 -10 010

20 30 40 50

È

É

˚C

˚

F

a

b

ENGINE OIL LEVEL INSPECTION

Page 140 of 390

3 - 9

INSPADJENGINE OIL LEVEL INSPECTION/

ENGINE OIL REPLACEMENT

5. Install:

Oil filler cap

6. Start the engine and let it warm up for sev-

eral minutes.

7. Turn off the engine and inspect the oil level once again.

NOTE:

Wait a few minutes until the oil settles before

inspecting the oil level.

ENGINE OIL REPLACEMENT

1. Start the engine and warm it up for severalminutes, and then turn off the engine and

wait for five minutes.

2. Place the machine on a level place and hold it on upright position by placing the

suitable stand under the engine.

3. Place a suitable container under the engine.

4. Remove:

Oil filler cap 1

Drain bolt (with gasket) 2

Drain the crankcase of its oil.

5. Install: Gasket

Drain bolt

6. Fill: Crankcase

7. Install: Oil filler cap

8. Inspect: Engine (for oil leaks)

Oil level

Refer to “ENGINE OIL LEVEL INSPEC-

TION ” section.

Oil quantity:

Periodic oil change: 0.8 L (0.70 Imp qt, 0.85 US qt)

1

2

New

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 142 of 390

3 - 10

INSPADJIDLE SPEED ADJUSTMENT/

VALVE CLEARANCE ADJUSTMENT

IDLE SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Attach:

Tachometer

To spark plug lead.

3. Adjust:

Idle speed

Adjustment steps:

Turn the throttle stop screw 1 until the

engine runs at the lowest possible speed.

To increase idle speed → Turn the throt-

tle stop screw 1 in

a.

To decrease idle speed → Turn the throt-

tle stop screw 1 out

b.

Engine idling speed:

1,600 ~ 1,800 r/min

1

a

b

VALVE CLEARANCE ADJUSTMENT

NOTE:

The valve clearance should be adjusted

when the engine is cool to the touch.

The piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove: Spark plug cap 1

Spark plug

Tappet cover (intake side) 2

Tappet cover (exhaust side) 3

Camshaft sprocket cover 4

3

4

1

2

2. Remove:

Timing plug 1

Crankshaft end cover 2

O-rings

1

2

Page 148 of 390

3 - 13

INSPADJVALVE CLEARANCE ADJUSTMENT/

SPARK ARRESTER CLEANING (For USA)

6. Install:

Spark plug

Spark plug cap

Timing plug

Crankshaft end cover

NOTE:

Apply the engine oil on the O-ring.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

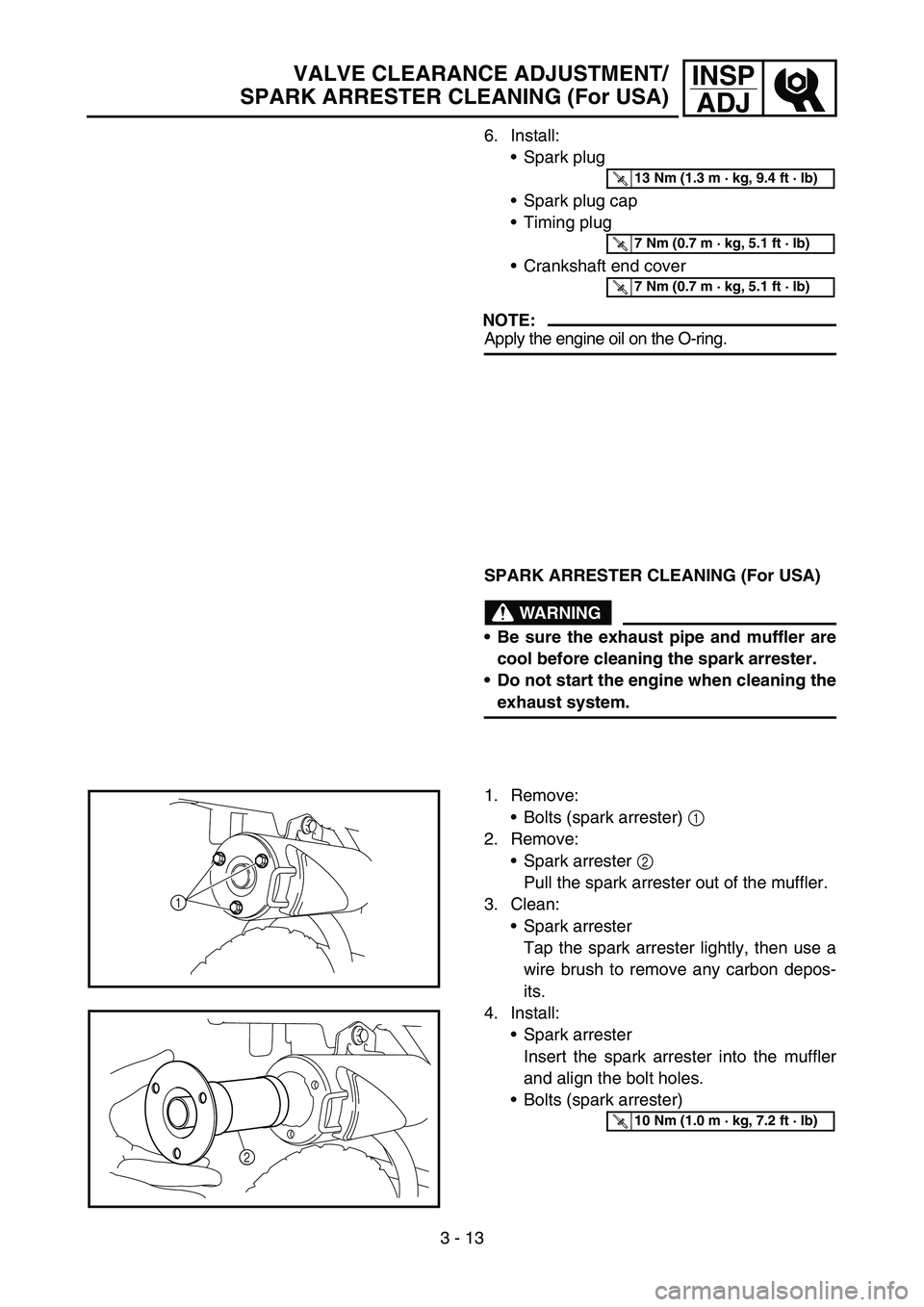

SPARK ARRESTER CLEANING (For USA)

WARNING

Be sure the exhaust pipe and muffler are

cool before cleaning the spark arrester.

Do not start the engine when cleaning the

exhaust system.

1. Remove: Bolts (spark arrester) 1

2. Remove:

Spark arrester 2

Pull the spark arrester out of the muffler.

3. Clean:

Spark arrester

Tap the spark arrester lightly, then use a

wire brush to remove any carbon depos-

its.

4. Install: Spark arrester

Insert the spark arrester into the muffler

and align the bolt holes.

Bolts (spark arrester)

1

2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)