YAMAHA VMAX 2001 Owner's Manual

Manufacturer: YAMAHA, Model Year: 2001, Model line: VMAX, Model: YAMAHA VMAX 2001Pages: 110, PDF Size: 11.88 MB

Page 21 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-6

3

EAU00157

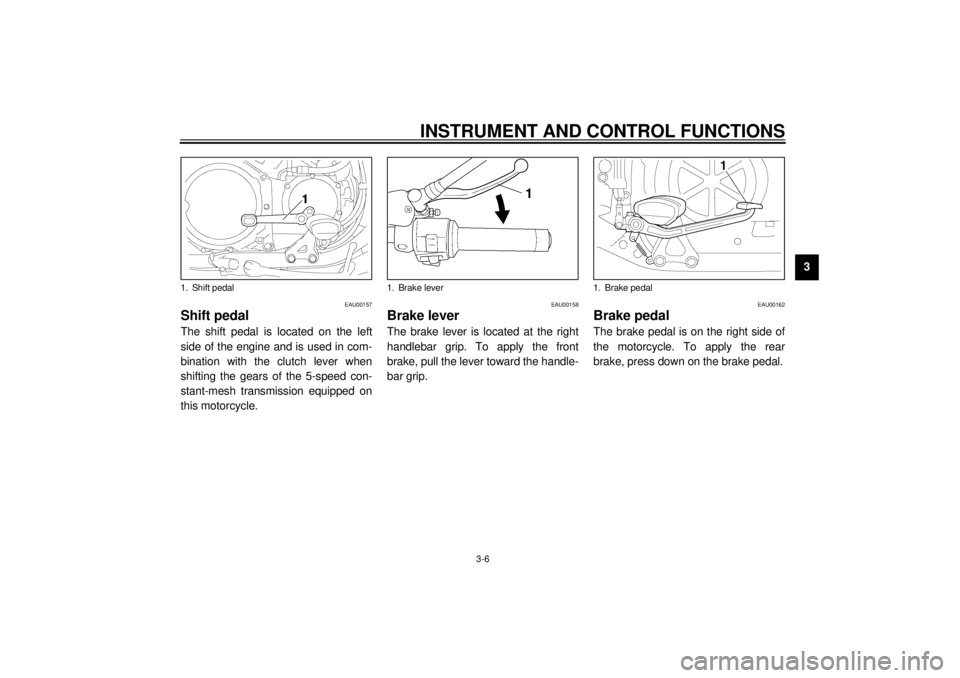

Shift pedal The shift pedal is located on the left

side of the engine and is used in com-

bination with the clutch lever when

shifting the gears of the 5-speed con-

stant-mesh transmission equipped on

this motorcycle.

EAU00158

Brake lever The brake lever is located at the right

handlebar grip. To apply the front

brake, pull the lever toward the handle-

bar grip.

EAU00162

Brake pedal The brake pedal is on the right side of

the motorcycle. To apply the rear

brake, press down on the brake pedal.

1. Shift pedal

1. Brake lever

1. Brake pedal

E_3lr.book Page 6 Wednesday, November 22, 2000 4:10 PM

Page 22 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-7

3

EAU01654

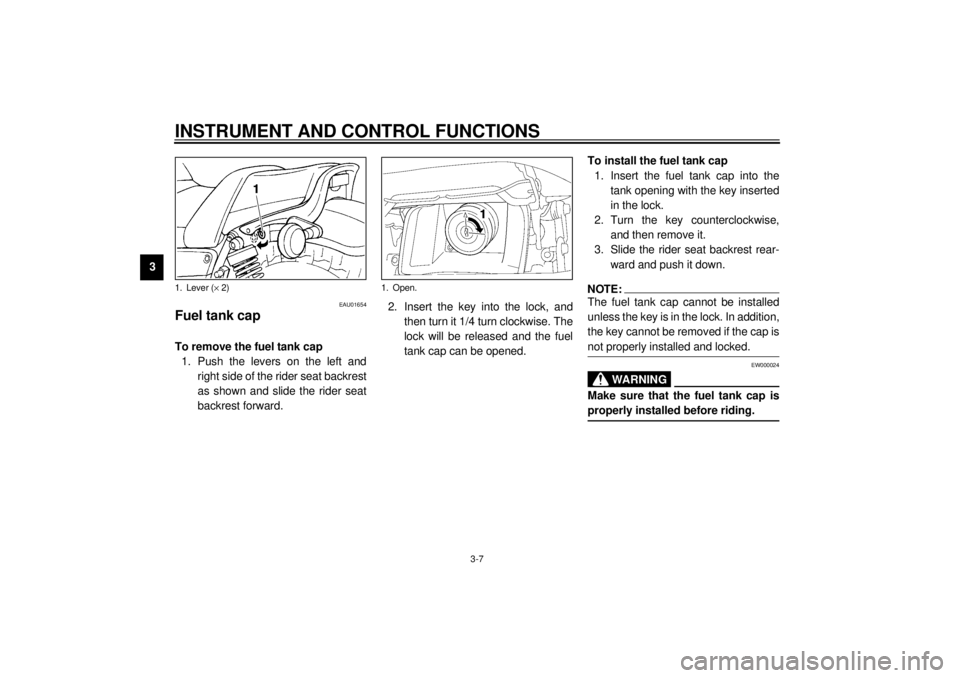

Fuel tank cap To remove the fuel tank cap

1. Push the levers on the left and

right side of the rider seat backrest

as shown and slide the rider seat

backrest forward.2. Insert the key into the lock, and

then turn it 1/4 turn clockwise. The

lock will be released and the fuel

tank cap can be opened.To install the fuel tank cap

1. Insert the fuel tank cap into the

tank opening with the key inserted

in the lock.

2. Turn the key counterclockwise,

and then remove it.

3. Slide the rider seat backrest rear-

ward and push it down.

NOTE:@ The fuel tank cap cannot be installed

unless the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly installed and locked. @

EW000024

WARNING

@ Make sure that the fuel tank cap is

properly installed before riding. @

1. Lever (´ 2)

1. Open.

E_3lr.book Page 7 Wednesday, November 22, 2000 4:10 PM

Page 23 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-8

3

EAU01183

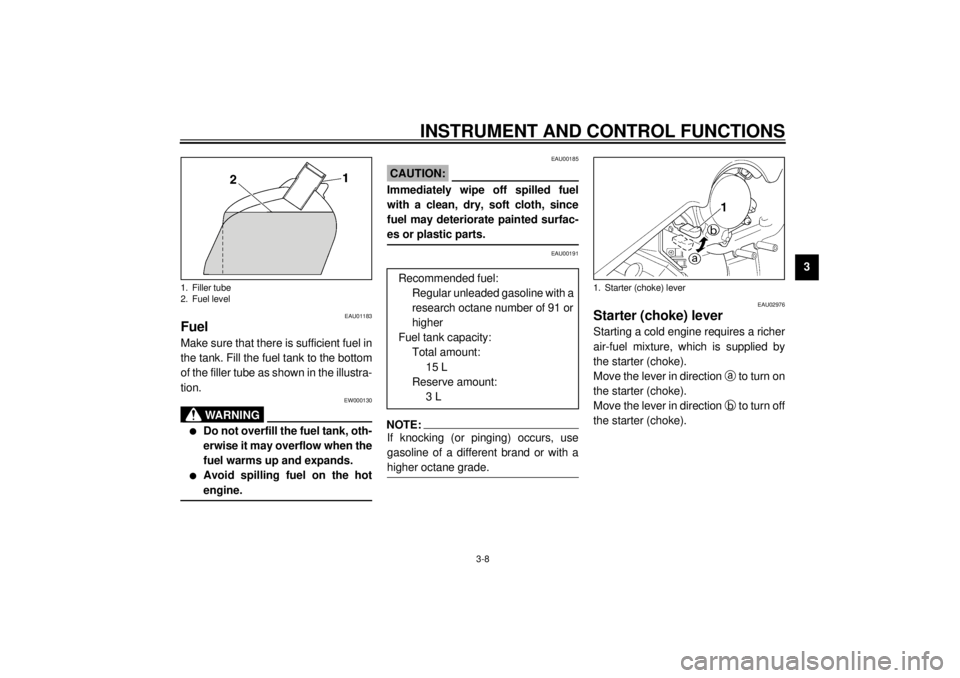

Fuel Make sure that there is sufficient fuel in

the tank. Fill the fuel tank to the bottom

of the filler tube as shown in the illustra-

tion.

EW000130

WARNING

@ l

Do not overfill the fuel tank, oth-

erwise it may overflow when the

fuel warms up and expands.

l

Avoid spilling fuel on the hot

engine.

@

EAU00185

CAUTION:@ Immediately wipe off spilled fuel

with a clean, dry, soft cloth, since

fuel may deteriorate painted surfac-

es or plastic parts. @

EAU00191

NOTE:@ If knocking (or pinging) occurs, use

gasoline of a different brand or with a

higher octane grade. @

EAU02976

Starter (choke) lever Starting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the lever in direction

a to turn on

the starter (choke).

Move the lever in direction

b to turn off

the starter (choke).

1. Filler tube

2. Fuel level

Recommended fuel:

Regular unleaded gasoline with a

research octane number of 91 or

higher

Fuel tank capacity:

Total amount:

15 L

Reserve amount:

3 L

1. Starter (choke) lever

E_3lr.book Page 8 Wednesday, November 22, 2000 4:10 PM

Page 24 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-9

3

EAU03342

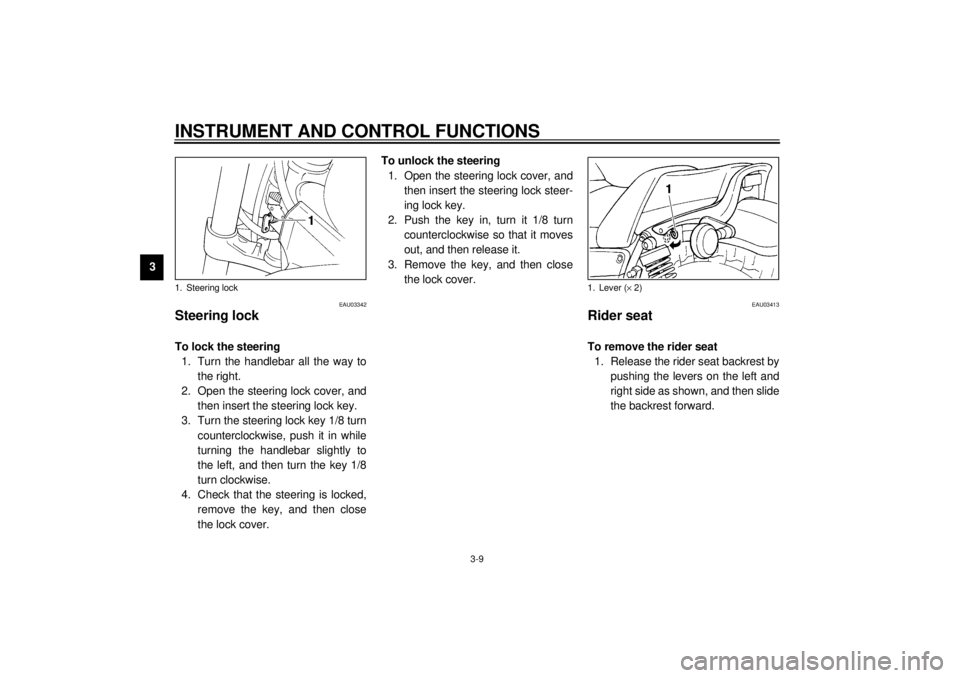

Steering lock To lock the steering

1. Turn the handlebar all the way to

the right.

2. Open the steering lock cover, and

then insert the steering lock key.

3. Turn the steering lock key 1/8 turn

counterclockwise, push it in while

turning the handlebar slightly to

the left, and then turn the key 1/8

turn clockwise.

4. Check that the steering is locked,

remove the key, and then close

the lock cover.To unlock the steering

1. Open the steering lock cover, and

then insert the steering lock steer-

ing lock key.

2. Push the key in, turn it 1/8 turn

counterclockwise so that it moves

out, and then release it.

3. Remove the key, and then close

the lock cover.

EAU03413

Rider seat To remove the rider seat

1. Release the rider seat backrest by

pushing the levers on the left and

right side as shown, and then slide

the backrest forward.

1. Steering lock

1. Lever (´ 2)

E_3lr.book Page 9 Wednesday, November 22, 2000 4:10 PM

Page 25 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-10

3

2. Remove the bolts and screws, and

then pull the rider seat off.To install the rider seat

1. Insert the projection on the front of

the rider seat into the seat holder

as shown.

2. Place the rider seat in the original

position, and then tighten the bolts

and screws.

NOTE:@ Make sure that the seat is properly se-

cured before riding. @3. Return the rider seat backrest to

the original position.

EAU00260

Helmet holder To open the helmet holder, insert the

key into the lock, and then turn the key

as shown.

To lock the helmet holder, place it in

the original position, and then remove

the key.

EW000030

WARNING

@ Never ride with a helmet attached to

the helmet holder, since the helmet

may hit objects, causing loss of

control and possibly an accident. @

1. Bolt (´ 2)

2. Screw (´ 2)

1. Projection

2. Seat holder

1. Helmet holder

2. Open.

E_3lr.book Page 10 Wednesday, November 22, 2000 4:10 PM

Page 26 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-11

3

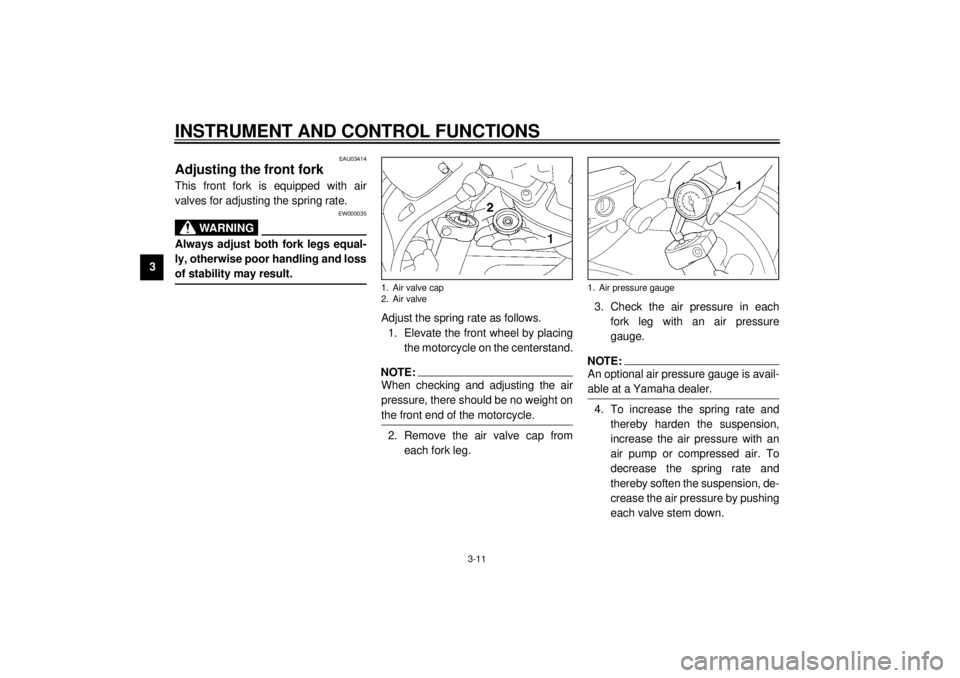

EAU03414

Adjusting the front fork This front fork is equipped with air

valves for adjusting the spring rate.

EW000035

WARNING

@ Always adjust both fork legs equal-

ly, otherwise poor handling and loss

of stability may result. @

Adjust the spring rate as follows.

1. Elevate the front wheel by placing

the motorcycle on the centerstand.NOTE:@ When checking and adjusting the air

pressure, there should be no weight on

the front end of the motorcycle. @2. Remove the air valve cap from

each fork leg.3. Check the air pressure in each

fork leg with an air pressure

gauge.

NOTE:@ An optional air pressure gauge is avail-

able at a Yamaha dealer. @4. To increase the spring rate and

thereby harden the suspension,

increase the air pressure with an

air pump or compressed air. To

decrease the spring rate and

thereby soften the suspension, de-

crease the air pressure by pushing

each valve stem down.

1. Air valve cap

2. Air valve

1. Air pressure gauge

E_3lr.book Page 11 Wednesday, November 22, 2000 4:10 PM

Page 27 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

EC000012

CAUTION:@ Never exceed the maximum air pres-

sure, otherwise the front fork oil

seals may become damaged. @

EWA00037

WARNING

@ There must be no difference in air

pressure between the left and right

fork legs, otherwise poor handling

and loss of stability may result. @5. Securely install the air valve caps.

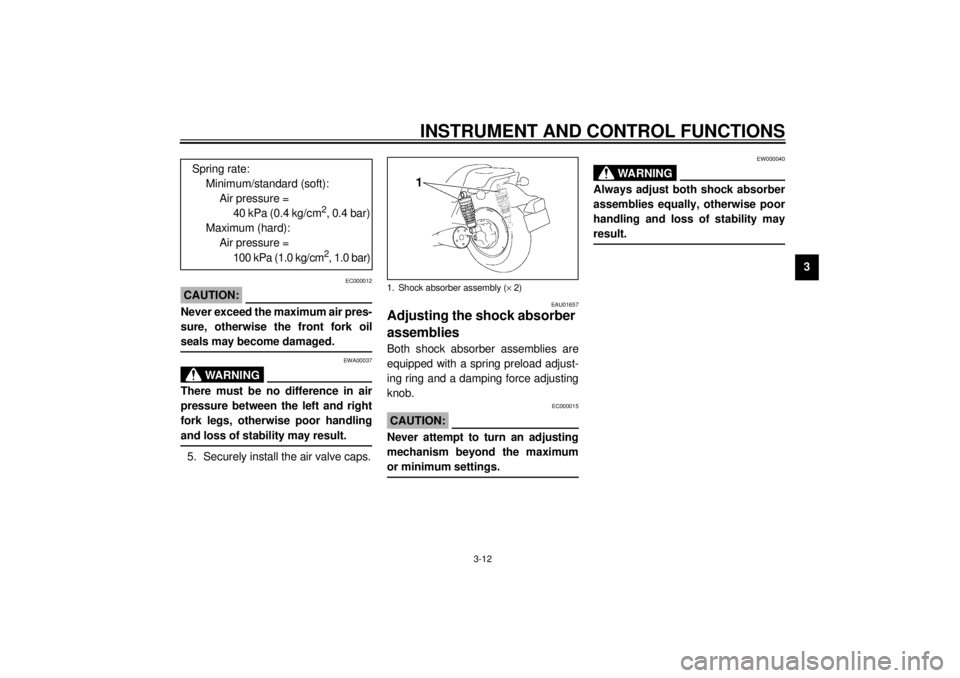

EAU01657

Adjusting the shock absorber

assemblies Both shock absorber assemblies are

equipped with a spring preload adjust-

ing ring and a damping force adjusting

knob.

EC000015

CAUTION:@ Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings. @

EW000040

WARNING

@ Always adjust both shock absorber

assemblies equally, otherwise poor

handling and loss of stability may

result. @

Spring rate:

Minimum/standard (soft):

Air pressure =

40 kPa (0.4 kg/cm

2, 0.4 bar)

Maximum (hard):

Air pressure =

100 kPa (1.0 kg/cm2, 1.0 bar)

1. Shock absorber assembly (´ 2)

E_3lr.book Page 12 Wednesday, November 22, 2000 4:10 PM

Page 28 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-13

3

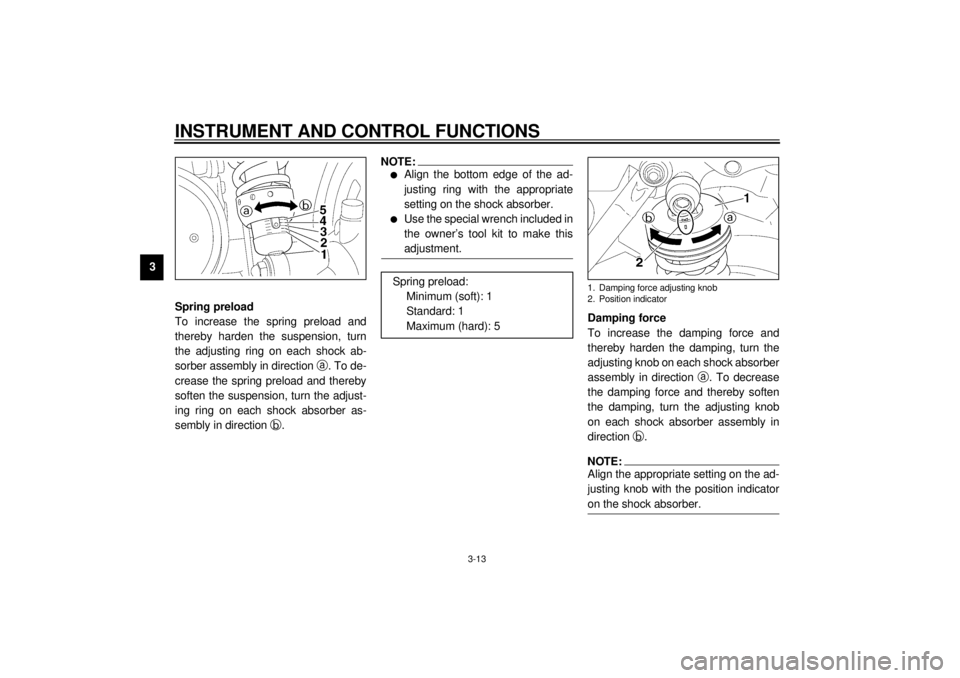

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring on each shock ab-

sorber assembly in direction

a. To de-

crease the spring preload and thereby

soften the suspension, turn the adjust-

ing ring on each shock absorber as-

sembly in direction

b.

NOTE:@ l

Align the bottom edge of the ad-

justing ring with the appropriate

setting on the shock absorber.

l

Use the special wrench included in

the owner’s tool kit to make this

adjustment.

@

Damping force

To increase the damping force and

thereby harden the damping, turn the

adjusting knob on each shock absorber

assembly in direction

a. To decrease

the damping force and thereby soften

the damping, turn the adjusting knob

on each shock absorber assembly in

direction

b.NOTE:@ Align the appropriate setting on the ad-

justing knob with the position indicator

on the shock absorber. @

Spring preload:

Minimum (soft): 1

Standard: 1

Maximum (hard): 5

1. Damping force adjusting knob

2. Position indicator

E_3lr.book Page 13 Wednesday, November 22, 2000 4:10 PM

Page 29 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-14

3 Damping force:

Minimum (soft): 1

Standard: 1

Maximum (hard): 4

E_3lr.book Page 14 Wednesday, November 22, 2000 4:10 PM

Page 30 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

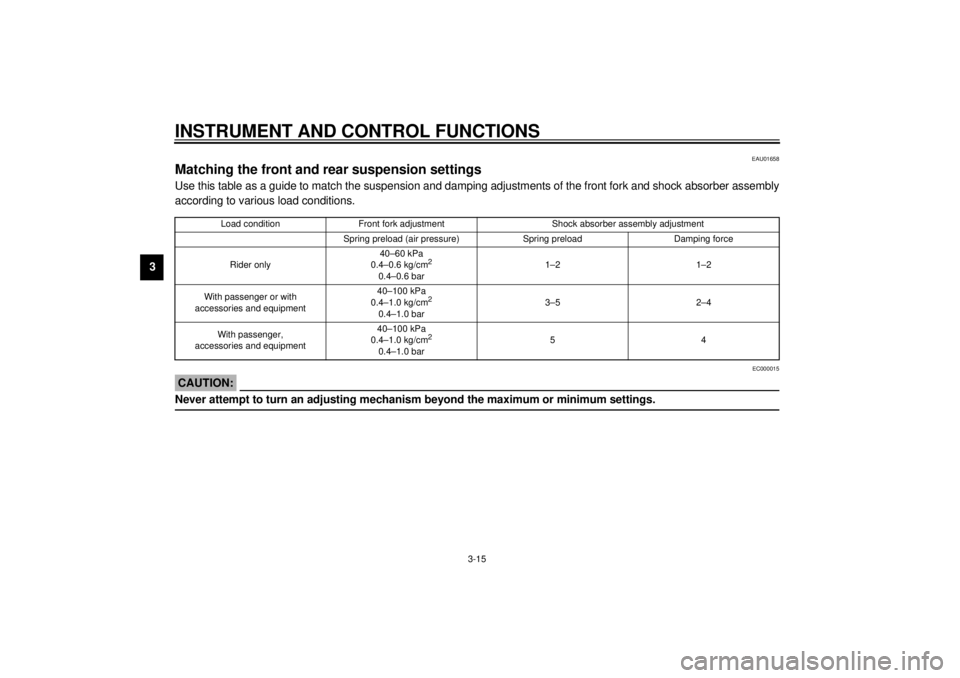

EAU01658

Matching the front and rear suspension settings Use this table as a guide to match the suspension and damping adjustments of the front fork and shock absorber assembly

according to various load conditions.CI-06E

EC000015CAUTION:@ Never attempt to turn an adjusting mechanism beyond the maximum or minimum settings. @

Load condition Front fork adjustment Shock absorber assembly adjustment

Spring preload (air pressure) Spring preload Damping force

Rider only40–60 kPa

0.4–0.6 kg/cm

2

0.4–0.6 bar1–2 1–2

With passenger or with

accessories and equipment40–100 kPa

0.4–1.0 kg/cm

2

0.4–1.0 bar3–5 2–4

With passenger,

accessories and equipment40–100 kPa

0.4–1.0 kg/cm

2

0.4–1.0 bar54

E_3lr.book Page 15 Wednesday, November 22, 2000 4:10 PM