brake YAMAHA VMAX 2001 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: VMAX, Model: YAMAHA VMAX 2001Pages: 110, PDF Size: 11.88 MB

Page 85 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-42

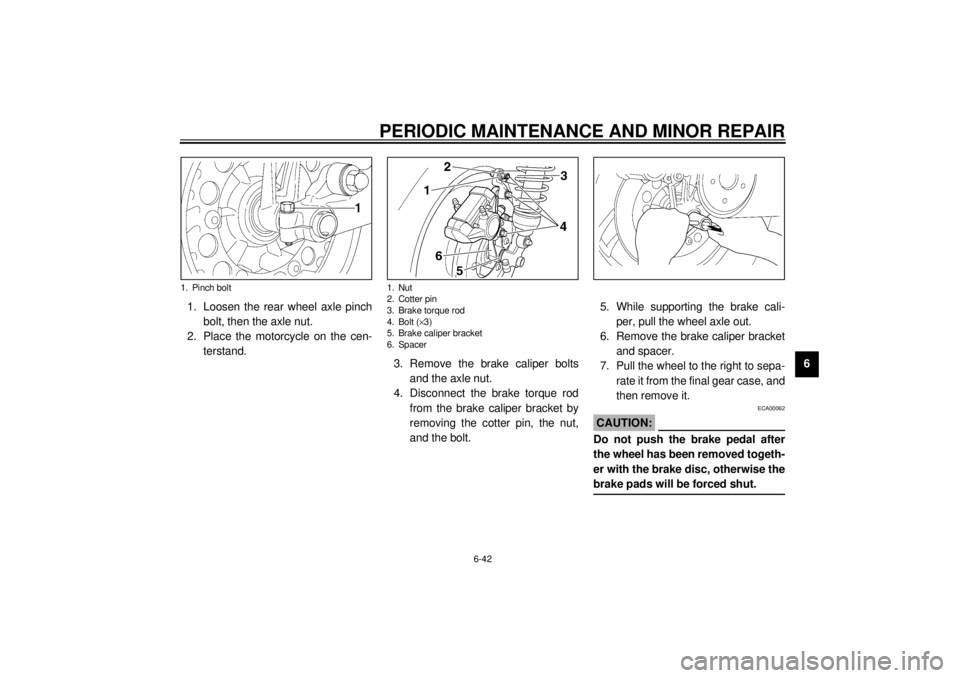

6 1. Loosen the rear wheel axle pinch

bolt, then the axle nut.

2. Place the motorcycle on the cen-

terstand.

3. Remove the brake caliper bolts

and the axle nut.

4. Disconnect the brake torque rod

from the brake caliper bracket by

removing the cotter pin, the nut,

and the bolt.5. While supporting the brake cali-

per, pull the wheel axle out.

6. Remove the brake caliper bracket

and spacer.

7. Pull the wheel to the right to sepa-

rate it from the final gear case, and

then remove it.

ECA00062

CAUTION:@ Do not push the brake pedal after

the wheel has been removed togeth-

er with the brake disc, otherwise the

brake pads will be forced shut. @

1. Pinch bolt

1. Nut

2. Cotter pin

3. Brake torque rod

4. Bolt (´3)

5. Brake caliper bracket

6. Spacer

E_3lr.book Page 42 Wednesday, November 22, 2000 4:10 PM

Page 86 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-43

6

EAU03422

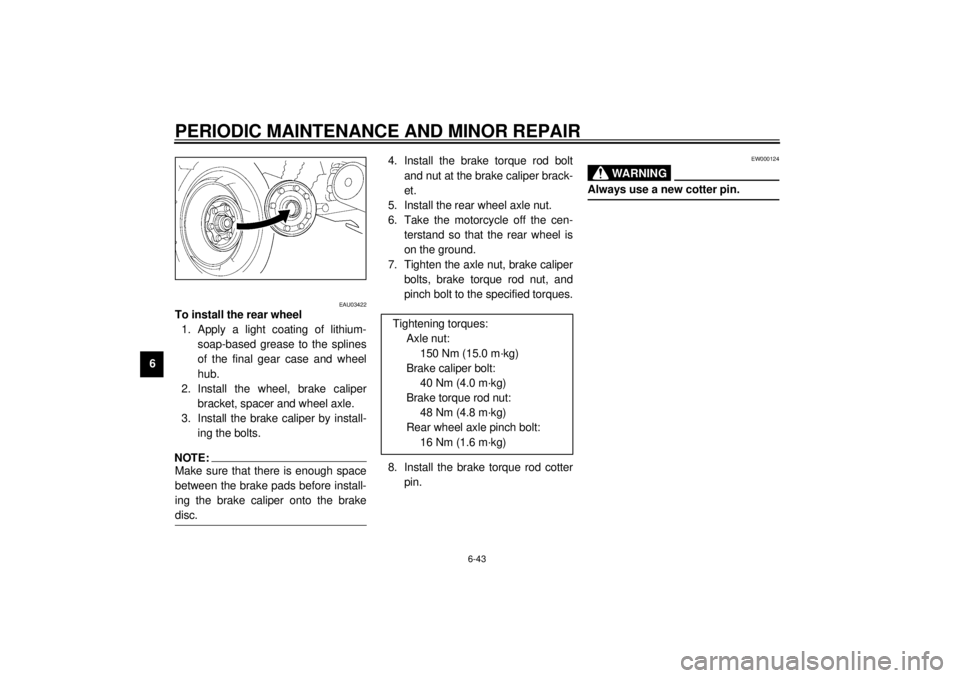

To install the rear wheel

1. Apply a light coating of lithium-

soap-based grease to the splines

of the final gear case and wheel

hub.

2. Install the wheel, brake caliper

bracket, spacer and wheel axle.

3. Install the brake caliper by install-

ing the bolts.NOTE:@ Make sure that there is enough space

between the brake pads before install-

ing the brake caliper onto the brake

disc. @

4. Install the brake torque rod bolt

and nut at the brake caliper brack-

et.

5. Install the rear wheel axle nut.

6. Take the motorcycle off the cen-

terstand so that the rear wheel is

on the ground.

7. Tighten the axle nut, brake caliper

bolts, brake torque rod nut, and

pinch bolt to the specified torques.

8. Install the brake torque rod cotter

pin.

EW000124

WARNING

@ Always use a new cotter pin. @

Tightening torques:

Axle nut:

150 Nm (15.0 m·kg)

Brake caliper bolt:

40 Nm (4.0 m·kg)

Brake torque rod nut:

48 Nm (4.8 m·kg)

Rear wheel axle pinch bolt:

16 Nm (1.6 m·kg)

E_3lr.book Page 43 Wednesday, November 22, 2000 4:10 PM

Page 93 of 110

MOTORCYCLE CARE AND STORAGE

7-2

7 thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

l

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and swing-

arm bearings, fork and brakes),

electric components (couplers,

connectors, instruments, switch-

es and lights), breather hoses

and vents.

l

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure that it does

not leave any marks. If the wind-shield is scratched, use a quali-

ty plastic polishing compound

after washing.

@After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.After riding in the rain, near the sea or

on salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive in

combination with water, carry out the

following steps after each ride in the

rain, near the sea or on salt-sprayed

roads.NOTE:@ Salt sprayed on roads in the winter may

remain well into spring. @1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

ECA00012

CAUTION:@ Do not use warm water since it in-

creases the corrosive action of the

salt. @2. After drying the motorcycle, apply

a corrosion protection spray on all

metal, including chrome- and nick-

el-plated, surfaces to prevent cor-

rosion.

E_3lr.book Page 2 Wednesday, November 22, 2000 4:10 PM

Page 94 of 110

MOTORCYCLE CARE AND STORAGE

7-3

7After cleaning

1. Dry the motorcycle with a chamois

or an absorbing cloth.

2. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

3. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

4. Use spray oil as a universal clean-

er to remove any remaining dirt.

5. Touch up minor paint damage

caused by stones, etc.

6. Wax all painted surfaces.

7. Let the motorcycle dry completely

before storing or covering it.

EWA00031

WARNING

@ l

Make sure that there is no oil or

wax on the brakes or tires.

l

If necessary, clean the brake

discs and brake linings with a

regular brake disc cleaner or ac-

etone, and wash the tires with

warm water and a mild deter-

gent. Before riding at higher

speeds, test the motorcycle’s

braking performance and cor-

nering behavior.

@

ECA00013

CAUTION:@ l

Apply spray oil and wax spar-

ingly and make sure to wipe off

any excess.

l

Never apply oil or wax to any

rubber and plastic parts, but

treat them with a suitable care

product.

l

Avoid using abrasive polishing

compounds as they will wear

away the paint.

@NOTE:@ Consult a Yamaha dealer for advice on

what products to use. @

E_3lr.book Page 3 Wednesday, November 22, 2000 4:10 PM

Page 100 of 110

SPECIFICATIONS

8-3

8

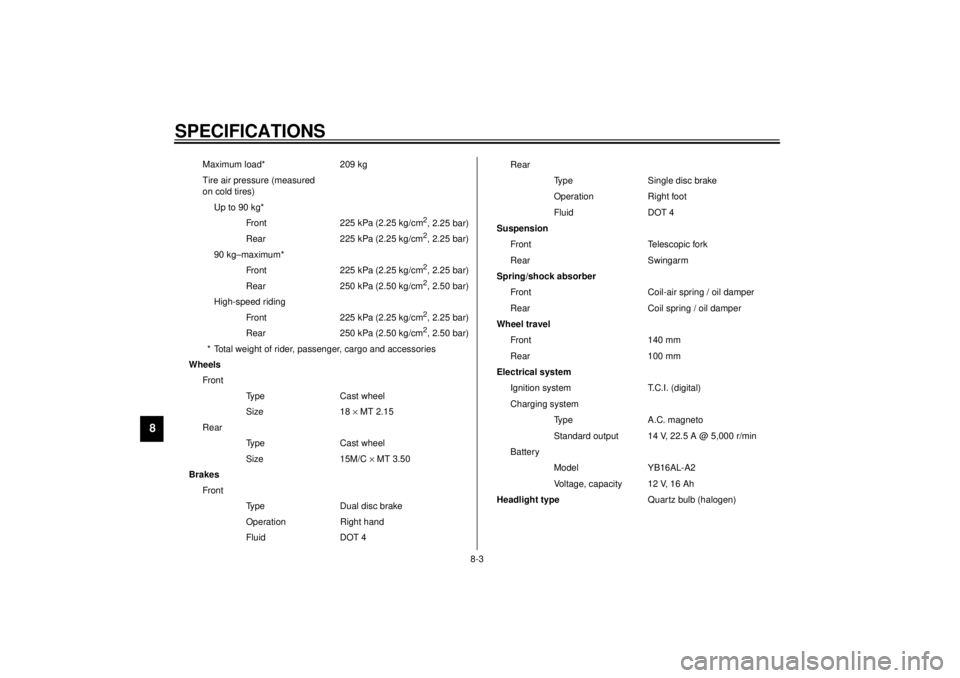

Maximum load* 209 kg

Tire air pressure (measured

on cold tires)

Up to 90 kg*

Front 225 kPa (2.25 kg/cm

2, 2.25 bar)

Rear 225 kPa (2.25 kg/cm2, 2.25 bar)

90 kg–maximum*

Front 225 kPa (2.25 kg/cm2, 2.25 bar)

Rear 250 kPa (2.50 kg/cm2, 2.50 bar)

High-speed riding

Front 225 kPa (2.25 kg/cm2, 2.25 bar)

Rear 250 kPa (2.50 kg/cm2, 2.50 bar)

* Total weight of rider, passenger, cargo and accessories

Wheels

Front

Type Cast wheel

Size 18 ´ MT 2.15

Rear

Type Cast wheel

Size 15M/C ´ MT 3.50

Brakes

Front

Type Dual disc brake

Operation Right hand

Fluid DOT 4Rear

Type Single disc brake

Operation Right foot

Fluid DOT 4

Suspension

Front Telescopic fork

Rear Swingarm

Spring/shock absorber

Front Coil-air spring / oil damper

Rear Coil spring / oil damper

Wheel travel

Front 140 mm

Rear 100 mm

Electrical system

Ignition system T.C.I. (digital)

Charging system

Type A.C. magneto

Standard output 14 V, 22.5 A @ 5,000 r/min

Battery

Model YB16AL-A2

Voltage, capacity 12 V, 16 Ah

Headlight typeQuartz bulb (halogen)

E_3lr.book Page 3 Wednesday, November 22, 2000 4:10 PM

Page 101 of 110

SPECIFICATIONS

8-4

8

Bulb voltage, wattage ´ quantity

Headlight 12 V, 60/55 W ´ 1

Tail/brake light 12 V, 5/21 W ´ 2

Turn signal light 12 V, 21 W ´ 4

Auxiliary light 12 V, 3.4 W ´ 1 (for GB)

12 V, 4 W ´ 1 (for F, B, I, P)

Meter lighting 14 V, 3 W ´ 2

Neutral indicator light 14 V, 3 W ´ 1

High beam indicator light 14 V, 3 W ´ 1

Turn signal indicator light 14 V, 3 W ´ 1

Fuel level warning light 14 V, 3 W ´ 1

Oil level warning light 14 V, 3 W ´ 1

Fuses

Main fuse 30 A

Headlight fuse 15 A

Signaling system fuse 10 A

Radiator fan fuse 10 A

Ignition fuse 10 A

E_3lr.book Page 4 Wednesday, November 22, 2000 4:10 PM

Page 106 of 110

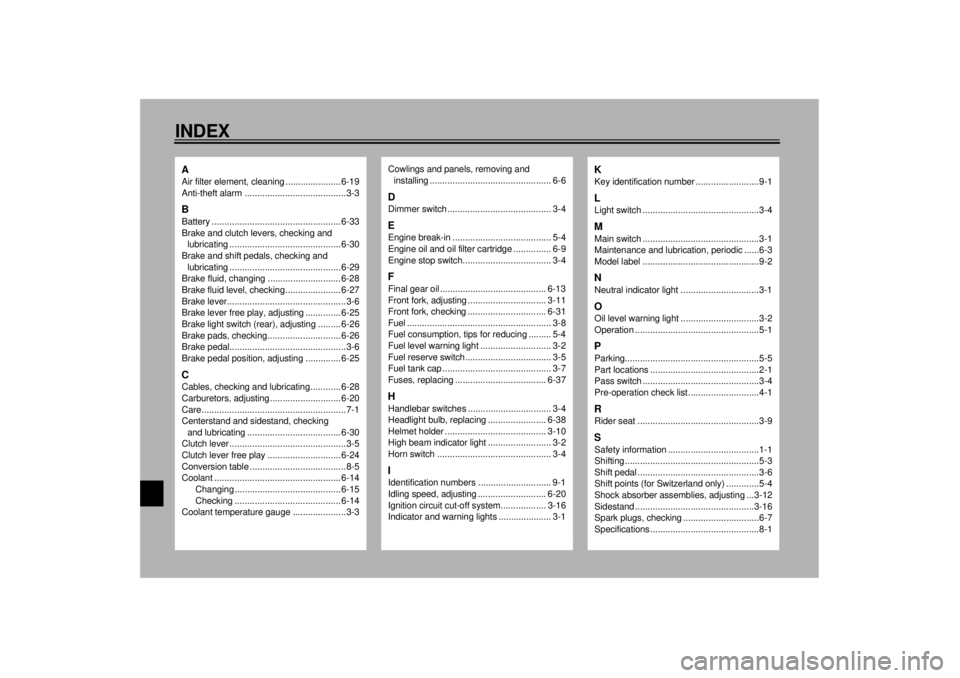

10-INDEXAAir filter element, cleaning ...................... 6-19

Anti-theft alarm ........................................3-3BBattery ................................................... 6-33

Brake and clutch levers, checking and

lubricating ............................................ 6-30

Brake and shift pedals, checking and

lubricating ............................................ 6-29

Brake fluid, changing ............................. 6-28

Brake fluid level, checking...................... 6-27

Brake lever...............................................3-6

Brake lever free play, adjusting .............. 6-25

Brake light switch (rear), adjusting ......... 6-26

Brake pads, checking............................. 6-26

Brake pedal..............................................3-6

Brake pedal position, adjusting .............. 6-25CCables, checking and lubricating............ 6-28

Carburetors, adjusting............................ 6-20

Care.........................................................7-1

Centerstand and sidestand, checking

and lubricating ..................................... 6-30

Clutch lever ..............................................3-5

Clutch lever free play ............................. 6-24

Conversion table ......................................8-5

Coolant .................................................. 6-14

Changing .......................................... 6-15

Checking .......................................... 6-14

Coolant temperature gauge .....................3-3

Cowlings and panels, removing and

installing................................................ 6-6DDimmer switch ......................................... 3-4EEngine break-in ....................................... 5-4

Engine oil and oil filter cartridge ............... 6-9

Engine stop switch................................... 3-4FFinal gear oil .......................................... 6-13

Front fork, adjusting ............................... 3-11

Front fork, checking ............................... 6-31

Fuel ......................................................... 3-8

Fuel consumption, tips for reducing ......... 5-4

Fuel level warning light ............................ 3-2

Fuel reserve switch.................................. 3-5

Fuel tank cap ........................................... 3-7

Fuses, replacing .................................... 6-37HHandlebar switches ................................. 3-4

Headlight bulb, replacing ....................... 6-38

Helmet holder ........................................ 3-10

High beam indicator light ......................... 3-2

Horn switch ............................................. 3-4IIdentification numbers ............................. 9-1

Idling speed, adjusting ........................... 6-20

Ignition circuit cut-off system.................. 3-16

Indicator and warning lights ..................... 3-1

KKey identification number .........................9-1LLight switch ..............................................3-4MMain switch ..............................................3-1

Maintenance and lubrication, periodic ......6-3

Model label ..............................................9-2NNeutral indicator light ...............................3-1OOil level warning light ...............................3-2

Operation .................................................5-1PParking.....................................................5-5

Part locations ...........................................2-1

Pass switch ..............................................3-4

Pre-operation check list ............................4-1RRider seat ................................................3-9SSafety information ....................................1-1

Shifting .....................................................5-3

Shift pedal ................................................3-6

Shift points (for Switzerland only) .............5-4

Shock absorber assemblies, adjusting ...3-12

Sidestand ...............................................3-16

Spark plugs, checking ..............................6-7

Specifications ...........................................8-1

E_3lr.book Page 1 Wednesday, November 22, 2000 4:10 PM

Page 107 of 110

INDEX

Speedometer unit .................................... 3-2

Starter (choke) lever ................................ 3-8

Starting a cold engine .............................. 5-1

Starting a warm engine ............................ 5-3

Start switch .............................................. 3-5

Steering, checking ................................. 6-32

Steering lock............................................ 3-9

Storage.................................................... 7-4

Suspension (rear), lubricating ................ 6-31

Suspension settings, matching

front and rear....................................... 3-15TTachometer ............................................. 3-3

Throttle cable free play, adjusting .......... 6-21

Throttle grip and cable, checking and

lubricating............................................ 6-29

Tires ...................................................... 6-21

Tool kit..................................................... 6-1

Troubleshooting..................................... 6-44

Troubleshooting charts .......................... 6-45

Turn signal indicator light ......................... 3-1

Turn signal light or tail/brake light bulb,

replacing ............................................. 6-39

Turn signal switch .................................... 3-4VValve clearance, adjusting ..................... 6-21

Vehicle identification number ................... 9-1

W Wheel bearings, checking ..................... 6-33

Wheel (front) ......................................... 6-40

Installing .......................................... 6-40

Removing ........................................ 6-40

Wheel (rear) .......................................... 6-41

Installing .......................................... 6-43

Removing ........................................ 6-41

Wheels .................................................. 6-24

E_3lr.book Page 2 Wednesday, November 22, 2000 4:10 PM