check engine YAMAHA VX110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 104 of 347

5-5

EPOWRENGINE UNIT

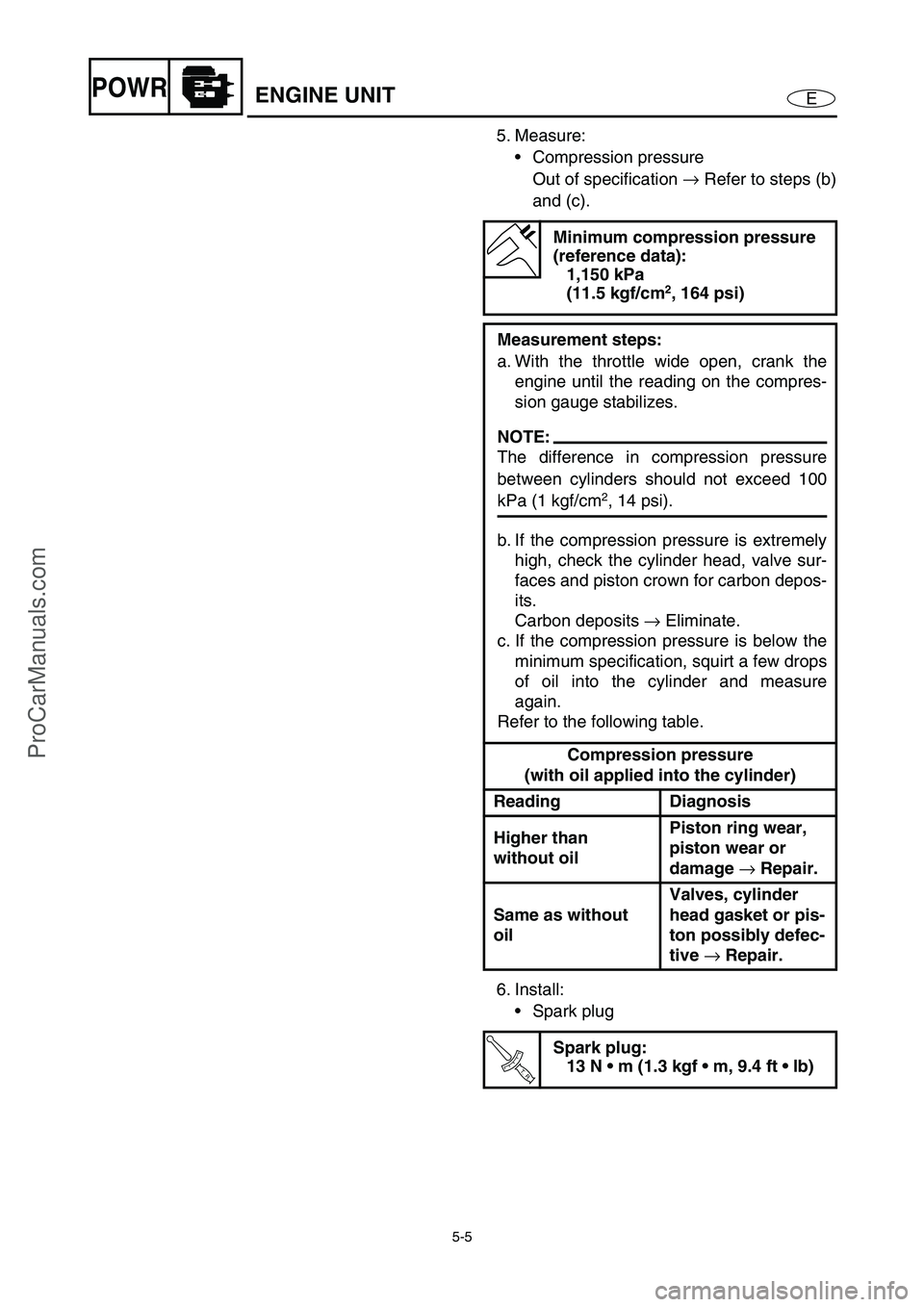

5. Measure:

Compression pressure

Out of specification →

Refer to steps (b)

and (c).

6. Install:

Spark plug

Minimum compression pressure

(reference data):

1,150 kPa

(11.5 kgf/cm

2, 164 psi)

Measurement steps:

a. With the throttle wide open, crank the

engine until the reading on the compres-

sion gauge stabilizes.

NOTE:

The difference in compression pressure

between cylinders should not exceed 100

kPa (1 kgf/cm2, 14 psi).

b. If the compression pressure is extremely

high, check the cylinder head, valve sur-

faces and piston crown for carbon depos-

its.

Carbon deposits →

Eliminate.

c. If the compression pressure is below the

minimum specification, squirt a few drops

of oil into the cylinder and measure

again.

Refer to the following table.

Compression pressure

(with oil applied into the cylinder)

Reading Diagnosis

Higher than

without oilPiston ring wear,

piston wear or

damage

→ Repair.

Same as without

oilValves, cylinder

head gasket or pis-

ton possibly defec-

tive

→ Repair.

T R..

Spark plug:

13 N m (1.3 kgf m, 9.4 ft lb)

ProCarManuals.com

Page 227 of 347

E

–+ELEC

INDICATION SYSTEM .................................................................................. 7-48

WIRING DIAGRAM ................................................................................. 7-48

FUSE ....................................................................................................... 7-50

BATTERY ................................................................................................ 7-50

MAIN AND FUEL PUMP RELAY............................................................. 7-50

ECM......................................................................................................... 7-50

ENGINE TEMPERATURE SENSOR ...................................................... 7-50

THERMOSWITCH (ENGINE).................................................................. 7-50

THERMOSWITCH (EXHAUST) .............................................................. 7-50

REMOTE CONTROL UNIT (DELUXE MODEL ONLY) ........................... 7-50

BUZZER .................................................................................................. 7-50

OIL PRESSURE SWITCH ....................................................................... 7-51

MULTIFUNCTION METER...................................................................... 7-51

Multifunction meter ............................................................................ 7-51

MULTIFUNCTION METER REMOVAL ................................................... 7-51

Display function (Sport model only) .................................................. 7-52

Display function (Deluxe model only) ................................................ 7-53

Speedometer display ........................................................................ 7-54

Tachometer display ........................................................................... 7-55

Hour meter display ............................................................................ 7-55

Voltage meter display........................................................................ 7-55

Low oil pressure warning indicator .................................................... 7-55

Fuel level meter display and fuel warning indicator .......................... 7-55

Overheat warning indicator ............................................................... 7-56

Check engine warning indicator ........................................................ 7-56

Diagnostic display ............................................................................. 7-57

REMOTE CONTROL SYSTEM (DELUXE MODEL ONLY) .......................... 7-58

WIRING DIAGRAM ................................................................................. 7-58

REMOTE CONTROL SYSTEM ............................................................... 7-59

Yamaha Security System indicator ................................................... 7-59

Low-rpm mode indicator.................................................................... 7-59

Checking the remote control transmitter ........................................... 7-60

Transmitter registration ..................................................................... 7-62

Replacing of the transmitter battery .................................................. 7-63

ProCarManuals.com

Page 237 of 347

7-10

E

–+ELECELECTRICAL ANALYSIS

Low resistance measurement

NOTE:

When measuring a resistance of 10 Ω

or less

using a digital tester, the correct measure-

ment cannot be obtained because of the

tester’s internal resistance.

To obtain the correct value, subtract the

internal resistance from the displayed mea-

surement.

The internal resistance of the tester can be

obtained by connecting both of its terminals.

Correct value =

Displayed measurement –

Internal resistance

Peak voltage measurement

NOTE:

When checking the condition of the ignition

system it is vital to know the peak voltage.

Cranking speed is dependant on many fac-

tors (e.g., fouled or weak spark plugs, a

weak battery). If one of these is defective,

the peak voltage will be lower than specifica-

tion.

If the peak voltage measurement is not

within specification the engine will not oper-

ate properly.

A low peak voltage will also cause compo-

nents to prematurely wear.

ProCarManuals.com

Page 238 of 347

7-11

E

–+ELECELECTRICAL ANALYSIS

Peak voltage adapter

NOTE:

Throughout this chapter the part numbers of

the specified peak voltage adapters have

been omitted. Refer to the following part

numbers.

The peak voltage adapter should be used

with a digital tester.

When measuring the peak voltage, connect

the peak voltage adapter to the digital circuit

tester and switch the selector to the DC volt-

age mode.

NOTE:

Make sure that the adapter leads are prop-

erly installed in the digital circuit tester.

Make sure that the positive pin (the “+” mark

facing up as shown) on the adapter is

installed into the positive terminal of the

tester.

The test harness is needed for the following

tests.

È Voltage measurement

É Peak voltage measurement

Test harness

NOTE:

If the lighting coil and pickup coil(s) are mea-

sured unloaded, disconnect the test harness

on the output side coupler.

Peak voltage adapter:

YU-39991

Peak voltage adapter B:

90890-03172

Checking steps:

Disconnect the coupler connections.

Connect the test harness between the

couplers.

Connect the tester terminals to the termi-

nals which are being checked.

Run the engine and observe the mea-

surement.È

É

ProCarManuals.com

Page 241 of 347

7-14

E

–+ELECIGNITION SYSTEM

IGNITION SPARK

WARNING

When checking the spark gap, do not

touch any of the connections of the spark

checker/ignition tester lead wires.

When performing the spark gap test, take

special care not to let sparks leak out of

the removed spark plug cap.

When performing the spark gap check,

keep flammable gas or liquids away,

since this test can produce sparks.

1. Check:

Ignition spark

Weak →

Check the ECM output peak

voltage.

Check the ignition coil for resistance.

Checking steps:

Connect the spark plug cap to the special

service tool.

Spark checker:

YM-34487

Ignition tester:

90890-06754

Crank the engine and observe the igni-

tion system spark through the discharge

window.

OK

ProCarManuals.com

Page 242 of 347

7-15

E

–+ELECIGNITION SYSTEM

IGNITION SYSTEM PEAK VOLTAGE

WARNING

When checking the electrical components,

do not touch any of the connections of the

digital tester lead wires.

NOTE:

If there is no spark, or the spark is weak,

continue with the ignition system test.

If a good spark is obtained, the problem is

not with the ignition system, but possibly with

the spark plug(s) or another component.

1. Measure:

ECM output peak voltage

Below specification →

Measure the

pickup coil output peak voltage.

NOTE:

When measuring the ECM output peak volt-

age while cranking the engine, disconnect

the ignition coil couplers for all cylinders

except for the cylinder being measured.

To crank the engine, connect the engine

shut-off cord (lanyard) to the engine shut-off

switch, and then press the start switch.

Test harness (2 pins):

New: YB-06867

Current: YB-06767

Test harness FWY-2 (2 pins):

New: 90890-06867

Current: 90890-06767

ECM output peak voltage:

Black/red (B/R) –

Red/yellow (R/Y)

Black/white (B/W) –

Red/yellow (R/Y)

Black/yellow (B/Y) –

Red/yellow (R/Y)

Black/green (B/G) –

Red/yellow (R/Y)

r/minLoaded

Cranking 2,000 3,500

V 90 130 140

ProCarManuals.com

Page 245 of 347

7-18

E

–+ELEC

IGNITION COIL

1. Measure:

Primary coil resistance

Out of specification →

Replace.

NOTE:

When measuring a resistance of 10 Ω

or less

using a digital tester, the correct measurement

cannot be obtained because of the tester’s

internal resistance.

Refer to “Low resistance measurement”.

Primary coil resistance:

1.19–1.61

Ω at 20 °C (68 °F)

2. Measure:

Secondary coil resistance

Out of specification →

Replace.

Secondary coil resistance:

8.5–11.5 k

Ω at 20 °C (68 °F)

ENGINE STOP SWITCH

1. Check:

Engine stop switch continuity

Out of specification →

Replace.

Engine stop switch continuity

(black coupler)

Clip PositionLead color

White Black

InstalledFree

Push

RemovedFree

Push

IGNITION SYSTEM

ProCarManuals.com

Page 246 of 347

7-19

E

–+ELECIGNITION SYSTEM

ENGINE TEMPERATURE SENSOR

1. Measure:

Engine temperature sensor resistance

(at the specified temperature)

Out of specification →

Replace.

Engine temperature sensor

resistance:

20 °C (68 °F): 54.2–69.0 k

Ω

100 °C (212 °F): 3.12–3.48 k

Ω

Measurement steps:

Suspend the engine temperature sensor

in a container filled with water.

Place a thermometer in the water.

Slowly heat the water.

Measure the resistance when the speci-

fied temperature is reached.

SENSOR ASSEMBLY

1. Check:

Intake air temperature sensor

Out of specification →

Replace the sen-

sor assembly.

Checking steps:

Measure the ambient temperature.

Connect a computer to the watercraft and

use the Yamaha Diagnostic System to

display the intake air temperature.

If the ambient temperature and the dis-

played intake air temperature differ by

more than ±

5 °C (±

9 °F), replace the

sensor assembly.

ProCarManuals.com

Page 247 of 347

7-20

E

–+ELECIGNITION SYSTEM

THERMOSWITCH (ENGINE)

1. Check:

Thermoswitch (engine) continuity

(at the specified temperature)

Out of specification →

Replace.

1 No continuity

È Temperature

2 Continuity

É Time

NOTE:

The thermoswitch (engine) connector is blue.

Thermoswitch (engine) continuity

temperature:

a 84–90 °C (183–194 °F)

b 70–84 °C (158–183 °F)

Checking steps:

Suspend the thermoswitch (engine) in a

container filled with water.

Place a thermometer in the water.

Slowly heat the water.

Measure the continuity when the speci-

fied temperature is reached.

ProCarManuals.com

Page 274 of 347

7-47

E

–+ELECOFF THROTTLE STEERING SYSTEM

STEERING SENSOR

1. Check:

Steering sensor

Malfunction → Replace the steering

sensor.

Checking steps:

Turn the handlebar all the way to the left

or right, and then release it.

Install a plastic tie 1 loosely around the

center of the handlebar grip as shown.

Hook a spring gauge 2 onto the plastic

tie.

Hold the spring gauge at a 90° angle

from the handlebar, and then pull the

spring gauge with a force of 10 kgf

(22 lb).

When handlebar

pulledWhen handlebar

not pulled

ON OFF

Check that the following is displayed in

the “Engine Monitor” window of the

Yamaha Diagnostic System.

Use the same procedure to check that

the steering sensor operates correctly

when the handlebar is turned to both the

left and right. Replace the steering sen-

sor if it is a malfunction.

1

2

ECM

Refer to “IGNITION SYSTEM”.

PICKUP COIL

Refer to “IGNITION SYSTEM”.

THROTTLE POSITION SENSOR

Refer to “IGNITION SYSTEM”.

ACCELERATOR POSITION SENSOR

Refer to “IGNITION SYSTEM”.

ProCarManuals.com