ignition YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 15 of 347

1-6

E

GEN

INFO

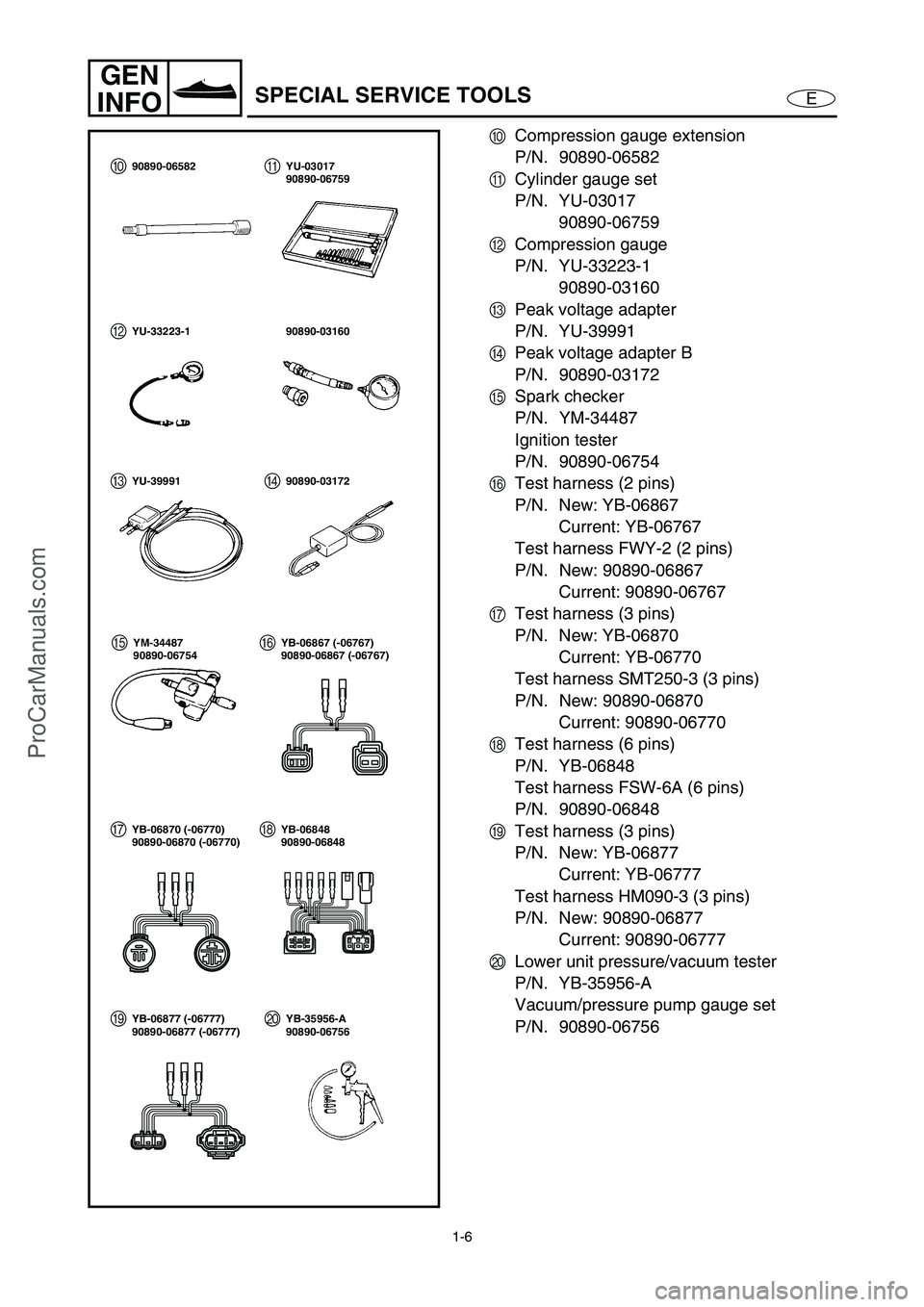

SPECIAL SERVICE TOOLS

0

Compression gauge extension

P/N. 90890-06582

A

Cylinder gauge set

P/N. YU-03017

90890-06759

B

Compression gauge

P/N. YU-33223-1

90890-03160

C

Peak voltage adapter

P/N. YU-39991

D

Peak voltage adapter B

P/N. 90890-03172

E

Spark checker

P/N. YM-34487

Ignition tester

P/N. 90890-06754

F

Test harness (2 pins)

P/N. New: YB-06867

Current: YB-06767

Test harness FWY-2 (2 pins)

P/N. New: 90890-06867

Current: 90890-06767

G

Test harness (3 pins)

P/N. New: YB-06870

Current: YB-06770

Test harness SMT250-3 (3 pins)

P/N. New: 90890-06870

Current: 90890-06770

H

Test harness (6 pins)

P/N. YB-06848

Test harness FSW-6A (6 pins)

P/N. 90890-06848

I

Test harness (3 pins)

P/N. New: YB-06877

Current: YB-06777

Test harness HM090-3 (3 pins)

P/N. New: 90890-06877

Current: 90890-06777

J

Lower unit pressure/vacuum tester

P/N. YB-35956-A

Vacuum/pressure pump gauge set

P/N. 90890-06756

0A

B

C

EF

GH90890-06582 YU-03017

90890-06759

YU-33223-1 90890-03160

YU-39991 90890-03172

YM-34487

90890-06754YB-06867 (-06767)

90890-06867 (-06767)

YB-06870 (-06770)

90890-06870 (-06770)YB-06848

90890-06848

D

IJYB-06877 (-06777)

90890-06877 (-06777)YB-35956-A

90890-06756

ProCarManuals.com

Page 22 of 347

2-1

ESPECGENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

Item UnitModel

VX110 Sport VX110 Deluxe

Model code

Hull F1K

Engine/jet 6D3

Dimensions

Length mm (in) 3,220 (126.8)

Width mm (in) 1,170 (46.1)

Height mm (in) 1,150 (45.3)

Dry weight kg (lb) 325 (716)

Maximum capacity Person/kg (lb) 3/240 (530)

Performance

Maximum output kW (PS) @ r/min 81.0 (110) @ 8,000

Maximum fuel consumption l/h (US gal/h,

lmp gal/h)28.0 (7.4, 6.2)

Cruising range h 2.1

Engine

Engine type 4-stroke, L4, DOHC

Displacement cm

3 (cu. in) 1,052 (64.2)

Bore ×

stroke mm (in) 76.0 ×

58.0 (2.99 ×

2.28)

Compression ratio 11.4:1

Exhaust system Wet exhaust

Lubrication system Dry sump

Cooling system Water cooled

Starting system Electric starter

Ignition system TCI

Ignition timing Degree BTDC 5–BTDC 35

Spark plug model

(manufacturer)CR9EB (NGK)

Spark plug gap mm (in) 0.7–0.8 (0.028–0.031)

Battery capacity V/Ah 12/19

Generator output A @ r/min 12–21 @ 6,000

Drive unit

Propulsion system Jet pump

Jet pump type Axial flow, single stage

Impeller rotation Counterclockwise (viewed from rear)

Transmission Constant mesh 1-speed

Jet thrust nozzle horizontal

angleDegree 24 + 24

Jet thrust nozzle trim angle Degree 3

Reverse system—Reverse gate

ProCarManuals.com

Page 28 of 347

2-7

ESPECMAINTENANCE SPECIFICATIONS

ELECTRICAL

Item UnitModel

VX110 Sport VX110 Deluxe

Battery

Type Fluid

Capacity V/Ah 12/19

Specific gravity 1.28

ECM unit

(B/R – R/Y, B/W – R/Y,

B/Y – R/Y, B/G – R/Y)

Output peak voltage lower limit

@cranking (loaded) V 90

@2,000 r/min (loaded) V 130

@3,500 r/min (loaded) V 140

Stator

Pickup coil (W/B – B/O)

Output peak voltage

@cranking (unloaded) V 8.0

@cranking (loaded) V 6.9

@2,000 r/min (loaded) V 19.4

@3,500 r/min (loaded) V 25.1

Lighting coil (G – G)

Output peak voltage

@cranking (unloaded) V 7.8

@2,000 r/min (unloaded) V 24.5

@3,500 r/min (unloaded) V 41.6

Pickup coil resistance

(W/B – B/O)Ω

(color) 459–561

Lighting coil resistance (G – G)Ω

(color) 0.23–0.29

Minimum charging current A @ r/min 14 @ 6,000

Ignition coil

Primary coil resistance

@20 °C (68 °F)Ω

1.19–1.61

Secondary coil resistance

@20 °C (68 °F) kΩ

8.5–11.5

Rectifier/regulator (R – B)

Output peak voltage

@3,500 r/min (unloaded) V 13.0

ProCarManuals.com

Page 33 of 347

2-12

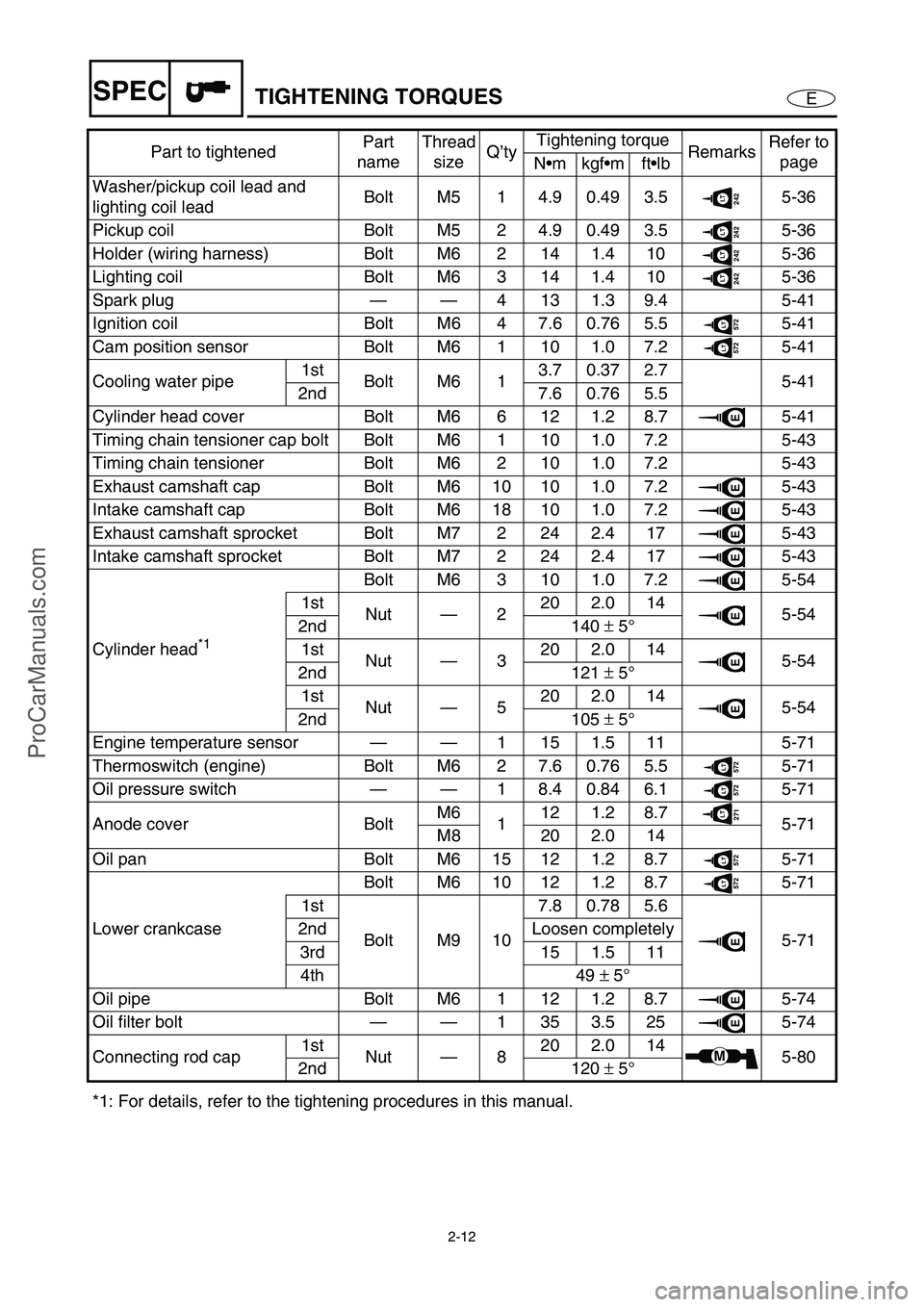

ESPECTIGHTENING TORQUES

Washer/pickup coil lead and

lighting coil leadBolt M5 1 4.9 0.49 3.5242LT5-36

Pickup coil Bolt M5 2 4.9 0.49 3.5

242LT5-36

Holder (wiring harness) Bolt M6 2 14 1.4 10

242LT5-36

Lighting coil Bolt M6 3 14 1.4 10

242LT5-36

Spark plug——4131.39.4 5-41

Ignition coil Bolt M6 4 7.6 0.76 5.5

572LT5-41

Cam position sensor Bolt M6 1 10 1.0 7.2

572LT5-41

Cooling water pipe1st

Bolt M6 13.70.372.7

5-41

2nd 7.6 0.76 5.5

Cylinder head cover Bolt M6 6 12 1.2 8.7

E5-41

Timing chain tensioner cap bolt Bolt M6 1 10 1.0 7.2 5-43

Timing chain tensioner Bolt M6 2 10 1.0 7.2 5-43

Exhaust camshaft cap Bolt M6 10 10 1.0 7.2

E5-43

Intake camshaft cap Bolt M6 18 10 1.0 7.2

E5-43

Exhaust camshaft sprocket Bolt M7 2 24 2.4 17

E5-43

Intake camshaft sprocket Bolt M7 2 24 2.4 17

E5-43

Cylinder head

*1 Bolt M6 3 10 1.0 7.2

E5-54

1st

Nut—220 2.0 14

E5-54

2nd 140 ±

5°

1st

Nut—320 2.0 14

E5-54

2nd 121 ±

5°

1st

Nut—520 2.0 14

E5-54

2nd 105 ±

5°

Engine temperature sensor——1 15 1.5 11 5-71

Thermoswitch (engine) Bolt M6 2 7.6 0.76 5.5

572LT5-71

Oil pressure switch——1 8.4 0.84 6.1

572LT5-71

Anode cover BoltM6

112 1.2 8.7

271LT5-71

M8 20 2.0 14

Oil pan Bolt M6 15 12 1.2 8.7

572LT5-71

Lower crankcaseBolt M6 10 12 1.2 8.7

572LT5-71

1st

Bolt M9 107.80.785.6

E5-71 2nd Loosen completely

3rd 15 1.5 11

4th 49 ±

5°

Oil pipe Bolt M6 1 12 1.2 8.7

E5-74

Oil filter bolt——1353.525

E5-74

Connecting rod cap1st

Nut—820 2.0 14

M5-80

2nd 120 ±

5°

*1: For details, refer to the tightening procedures in this manual.Part to tightenedPart

nameThread

sizeQ’tyTightening torque

RemarksRefer to

page

Nmkgfmftlb

ProCarManuals.com

Page 44 of 347

2-23

ESPECCABLE AND HOSE ROUTING

13

90A

C B

88

4567

2

E

D

F

È

É

Í

Ê

Ë

Ì A-A

AA

Î

1Oil separator breather hose (to air intake duct)

2Wiring harness

3Ignition coil lead #1

4Ignition coil lead #2

5Ignition coil lead #3

6Ignition coil lead #4

7Cam position sensor

8Ignition coil

9ECM

0Rectifier/regulator

AOil pressure switch couplerBThermoswitch (exhaust) coupler

CGround lead plate

DWiring harness

EThermoswitch (exhaust) lead

FOil pressure switch lead

ÈFasten the oil separator breather hose (to air

intake duct) at the paint mark with a holder.

É15–25 mm (0.59–0.98 in)

ÊTo fuse box

ËTo multifunction meter

ProCarManuals.com

Page 46 of 347

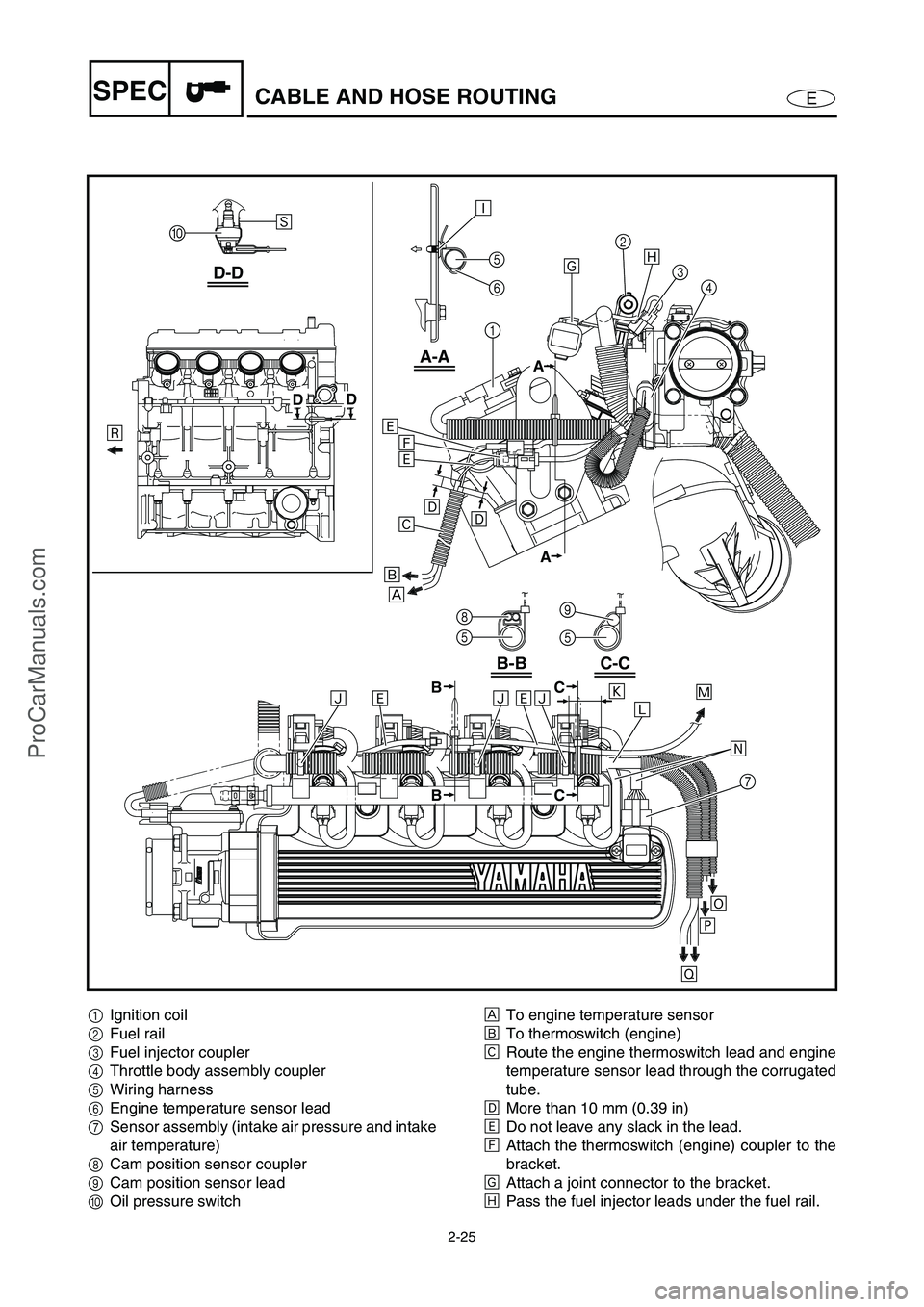

2-25

ESPECCABLE AND HOSE ROUTING

D-D

A-A

B-B

0

8

5

C-C

9

5 Ú

Ù

É

È

Ð

DD

5

6

A

A

1

2

7

34

Î

Ó ÒÌÑÑÌÑ

Ì

Ì

Ë Ë

Ê

Ø×Ö Ô

Õ

Í

Ï

C

CB

B

1Ignition coil

2Fuel rail

3Fuel injector coupler

4Throttle body assembly coupler

5Wiring harness

6Engine temperature sensor lead

7Sensor assembly (intake air pressure and intake

air temperature)

8Cam position sensor coupler

9Cam position sensor lead

0Oil pressure switchÈTo engine temperature sensor

ÉTo thermoswitch (engine)

ÊRoute the engine thermoswitch lead and engine

temperature sensor lead through the corrugated

tube.

ËMore than 10 mm (0.39 in)

ÌDo not leave any slack in the lead.

ÍAttach the thermoswitch (engine) coupler to the

bracket.

ÎAttach a joint connector to the bracket.

ÏPass the fuel injector leads under the fuel rail.

ProCarManuals.com

Page 57 of 347

3-8

E

INSP

ADJ

FUEL SYSTEM/POWER UNIT

Water separator inspection

1. Inspect:

Water separator 1

Water accumulation →

Drain.

NOTE:

To drain the water, remove the drain plug.

POWER UNIT

Valve clearance adjustment

The following procedure applies to all of the

valves.

NOTE:

Valve clearance adjustment should be made

on a cold engine, at room temperature.

When the valve clearance is to be measured

or adjusted, the piston must be at top dead

center (TDC) of the compression stroke.

1. Remove:

Ignition coils

Spark plugs

Cylinder head cover

Cylinder head cover gasket

Refer to “CAMSHAFTS” in Chapter 5.

2. Install:

Dial gauge needle

Dial gauge stand 1

(into spark plug hole #1)

Dial gauge 2

Dial gauge stand:

90890-06583

Dial gauge needle:

90890-06584

Dial gauge stand set:

YB-06585/90890-06585

Dial indicator gauge:

YU-03097

Dial gauge set:

90890-012522

1

ProCarManuals.com

Page 69 of 347

3-20

E

INSP

ADJ

POWER UNIT

Spark plug inspection

1. Remove:

Ignition coils

CAUTION:

Be careful not to get any foreign sub-

stances or water in spark plug hole.

2. Inspect:

Electrodes 1

Damage/wear →

Replace.

Insulator color 2

Distinctly different color →

Check the

engine condition.

Color guide:

Medium to light tan color:

Normal

Whitish color:

Lean fuel mixture

Air leak

Incorrect settings

Blackish color:

Overly rich mixture

Electrical malfunction

Defective spark plug

3. Clean:

Spark plug

(with a spark plug cleaner or wire brush)

4. Measure:

Spark plug gap a

Out of specification →

Regap.

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

ProCarManuals.com

Page 70 of 347

3-21

E

INSP

ADJ

POWER UNIT

5. Tighten:

Spark plug

NOTE:

Before installing the spark plug, clean the

gasket surface and spark plug surface. Also,

it is suggested to apply a thin film of anti-

seize compound to the spark plug threads to

prevent thread seizure.

If a torque wrench is not available, a good

estimate of the correct tightening torque for a

new spark plug is to finger tighten a

the

spark plug and then tighten it another 1/4 to

1/2 of a turnb

.

T R..

Spark plug:

13 N m (1.3 kgf m, 9.4 ft lb)

6. Install:

Ignition coils

T R..

Ignition coil bolt:

7.6 N m (0.76 kgf m, 5.5 ft lb)

LOCTITE 572

ProCarManuals.com

Page 103 of 347

5-4

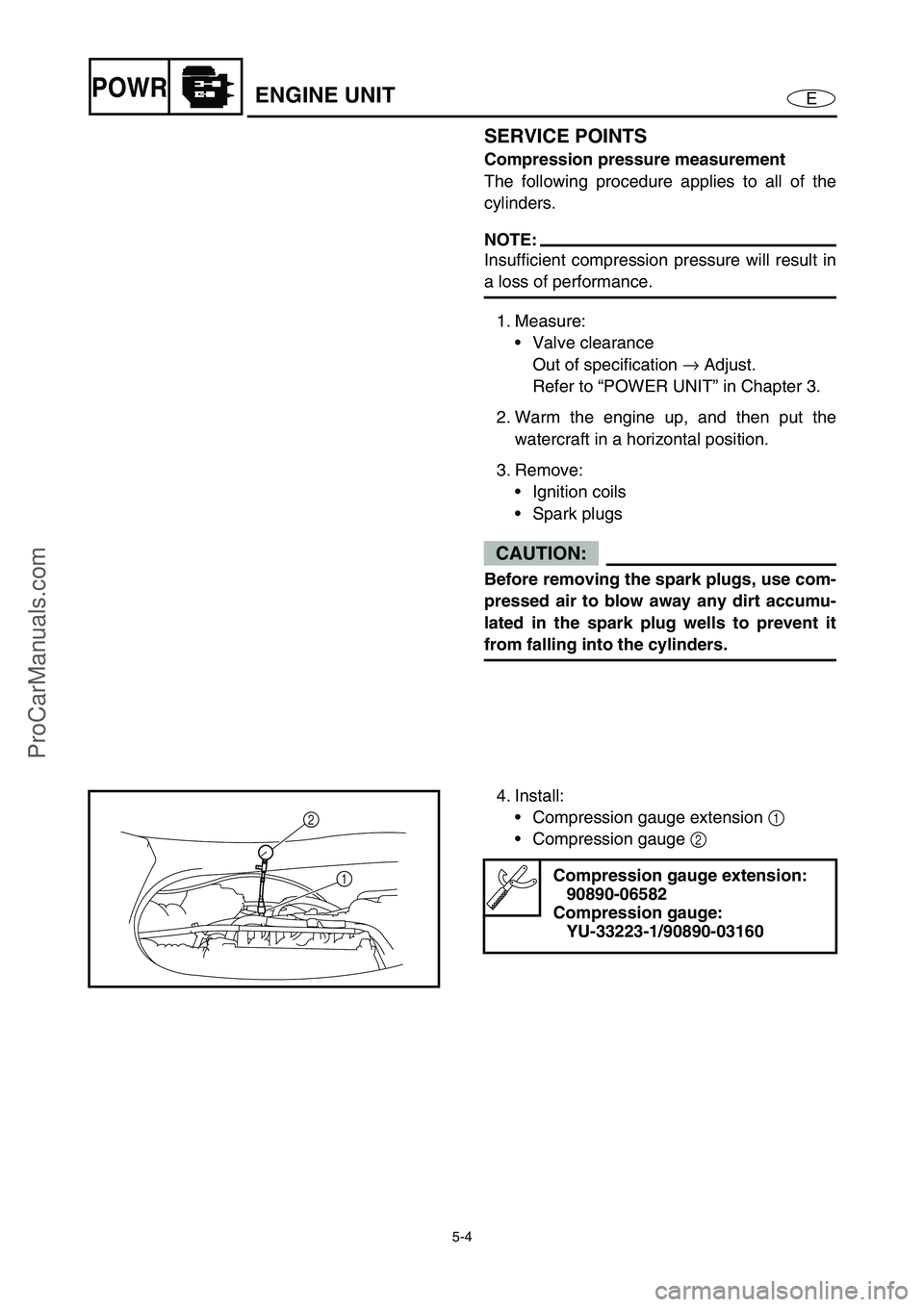

EPOWRENGINE UNIT

SERVICE POINTS

Compression pressure measurement

The following procedure applies to all of the

cylinders.

NOTE:

Insufficient compression pressure will result in

a loss of performance.

1. Measure:

Valve clearance

Out of specification →

Adjust.

Refer to “POWER UNIT” in Chapter 3.

2. Warm the engine up, and then put the

watercraft in a horizontal position.

3. Remove:

Ignition coils

Spark plugs

CAUTION:

Before removing the spark plugs, use com-

pressed air to blow away any dirt accumu-

lated in the spark plug wells to prevent it

from falling into the cylinders.

4. Install:

Compression gauge extension 1

Compression gauge 2

Compression gauge extension:

90890-06582

Compression gauge:

YU-33223-1/90890-03160

2

1

ProCarManuals.com