electrical YAMAHA VX110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 72 of 347

3-23

E

INSP

ADJ

ELECTRICAL

1. Remove:

Bands

Battery negative lead 1

Battery positive lead 2

Battery

Battery breather hose 3

WARNING

When removing the battery, disconnect

the negative lead first.

Remove the battery to prevent acid loss

during turning the watercraft on its side

for the impeller, etc.

2. Inspect:

Electrolyte level

Low →

Add distilled water.

The electrolyte level should be between

the maximum a

and minimum b

level

marks.

CAUTION:

Use only distilled water. Other types of

water contain minerals which are harmful

to batteries.Filling steps:

Remove each filler cap.

Add distilled water to the maximum level

mark.

When the electrolyte level reaches the

maximum level mark, allow the cell to

stand for 20 minutes. If the electrolyte

level drops, add more distilled water so

the level reaches the maximum level

mark.

ProCarManuals.com

Page 73 of 347

3-24

E

INSP

ADJ

ELECTRICAL

3. Inspect:

Specific gravity

Out of specification →

Charge.

4. Install:

Filler caps

CAUTION:

Before installation, rinse off any fluid from

the battery box and battery and make sure

that the battery is dry before installing it.

Specific gravity at 20 °C (68 °F):

1.28

Charging current:

1.9 A

× 10 h

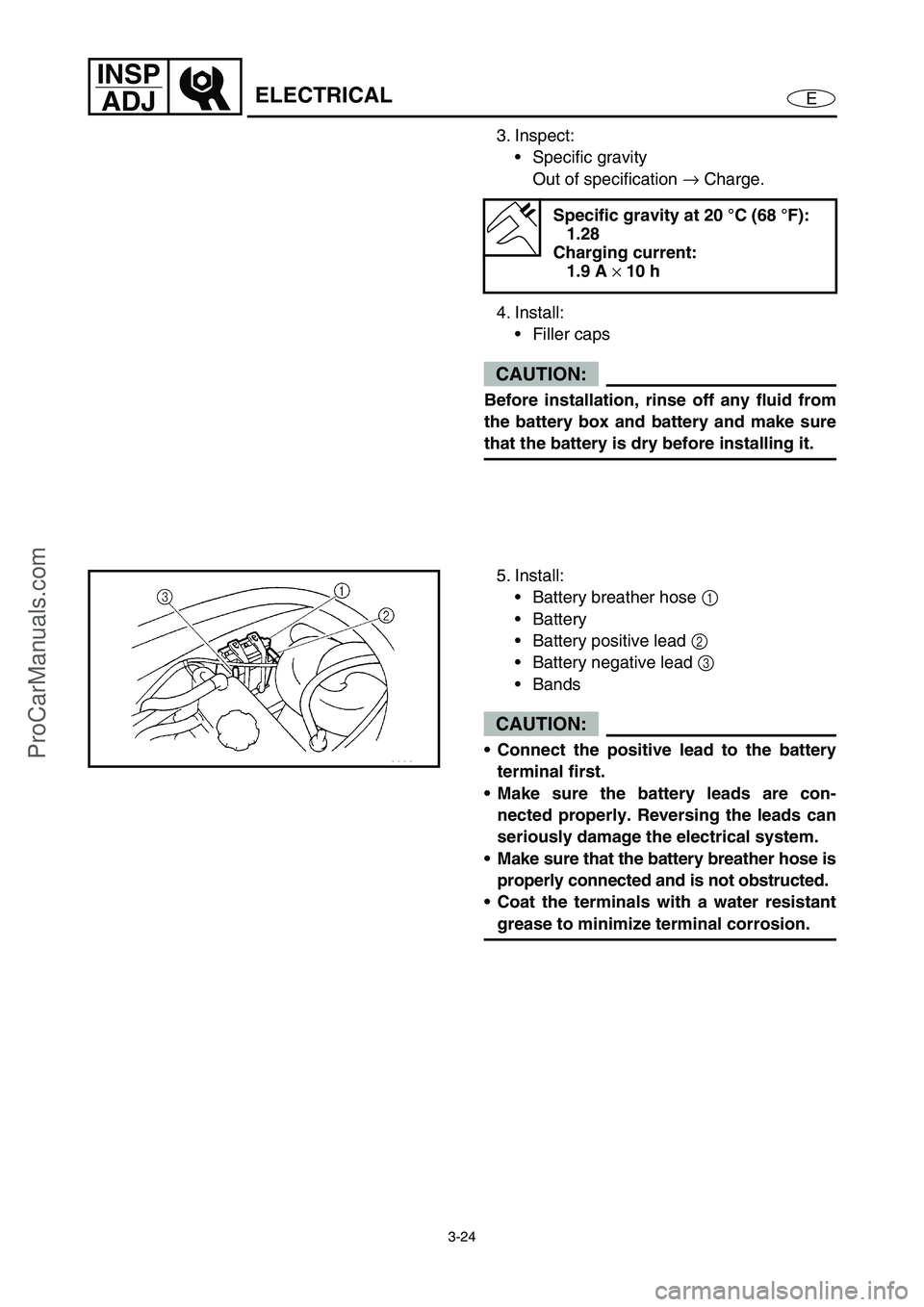

5. Install:

Battery breather hose 1

Battery

Battery positive lead 2

Battery negative lead 3

Bands

CAUTION:

Connect the positive lead to the battery

terminal first.

Make sure the battery leads are con-

nected properly. Reversing the leads can

seriously damage the electrical system.

Make sure that the battery breather hose is

properly connected and is not obstructed.

Coat the terminals with a water resistant

grease to minimize terminal corrosion.

ProCarManuals.com

Page 89 of 347

4-12

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

SERVICE POINTS

Fuel hose clamps removal

1. Remove:

Fuel hose clamps

CAUTION:

If the fuel hose clamps are removed with-

out cutting the joint first, the fuel hose will

be damaged.

Hose clamps installation

1. Install:

Fuel hose clamps

WARNING

Do not reuse the fuel hose clamps, always

replace them with new ones.

NOTE:

Crimp the fuel hose clamps properly to

securely fasten them.

Fuel hose disconnection

WARNING

Before disconnecting the hose, remove the

fuel tank filler cap to reduce any pressure

inside the fuel tank, and then disconnect

the battery negative lead to cut off the elec-

tric current to the electrical systems.

1. Wrap the quick connector with a cloth, and

then rotate the quick connector tab 1

to

the stopper position a

.

WARNING

If the quick connector is removed sud-

denly, pressurized fuel could spray out. To

gradually release the fuel pressure, be sure

to remove the quick connector slowly.

1

a

ProCarManuals.com

Page 225 of 347

E

–+ELEC

1

2

3

4

5

6

7

8

9

CHAPTER 7

ELECTRICAL SYSTEM

ELECTRICAL COMPONENTS........................................................................ 7-1

FUSE BOX ....................................................................................................... 7-2

EXPLODED DIAGRAM ............................................................................. 7-2

REMOVAL AND INSTALLATION CHART ................................................ 7-2

ECM AND RECTIFIER/REGULATOR............................................................. 7-7

EXPLODED DIAGRAM ............................................................................. 7-7

REMOVAL AND INSTALLATION CHART ................................................ 7-7

ELECTRICAL ANALYSIS ............................................................................... 7-9

INSPECTION............................................................................................. 7-9

Digital tester ........................................................................................ 7-9

Low resistance measurement ........................................................... 7-10

Peak voltage measurement .............................................................. 7-10

Peak voltage adapter ........................................................................ 7-11

Test harness .................................................................................... 7-11

IGNITION SYSTEM ....................................................................................... 7-12

WIRING DIAGRAM ................................................................................. 7-12

IGNITION SPARK ................................................................................... 7-14

IGNITION SYSTEM PEAK VOLTAGE .................................................... 7-15

BATTERY ................................................................................................ 7-17

FUSE ....................................................................................................... 7-17

SPARK PLUGS ....................................................................................... 7-17

IGNITION COIL ....................................................................................... 7-18

ENGINE STOP SWITCH ......................................................................... 7-18

ENGINE TEMPERATURE SENSOR ...................................................... 7-19

SENSOR ASSEMBLY ............................................................................. 7-19

THERMOSWITCH (ENGINE).................................................................. 7-20

THERMOSWITCH (EXHAUST) .............................................................. 7-21

MAIN AND FUEL PUMP RELAY............................................................. 7-22

ELECTRONIC CONTROL THROTTLE VALVE RELAY ......................... 7-23

THROTTLE POSITION SENSOR ........................................................... 7-24

ACCELERATOR POSITION SENSOR ................................................... 7-26

CAM POSITION SENSOR ...................................................................... 7-29

SLANT DETECTION SWITCH ................................................................ 7-30

ProCarManuals.com

Page 228 of 347

7-1

E

–+ELECELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

0

91

2

3

4

5

6

7

8

1Thermoswitch (engine)

2Fuse box

3Slant detection switch

4Starter motor

5Engine temperature sensor

6Spark plugs and ignition coils

7Cam position sensor

8Battery

9Speed sensor

0Sensor assembly (intake air

pressure and intake air tem-

perature)AOil pressure switch

BFuel injectors

CThermoswitch (exhaust)

DRectifier/regulator

EECM

FThrottle body assembly

GLighting coil and pickup coil

HEngine stop switch, engine

shut-off switch, and start

switch

ISteering sensor

JBuzzerKAccelerator position sensor

LElectric fuel pump

MFuel sender

NMultifunction meter

ORemote control unit (Deluxe

model only)

ProCarManuals.com

Page 236 of 347

7-9

E

–+ELECELECTRICAL ANALYSIS

ELECTRICAL ANALYSIS

INSPECTION

CAUTION:

All measuring instruments should be han-

dled with special care. Damaged or mis-

handled instruments will not measure

properly.

On an instrument powered by dry batter-

ies, check the battery’s voltage periodi-

cally and replace the batteries if

necessary.

Digital tester

NOTE:

Throughout this chapter the part numbers of

the specified digital testers have been omitted.

Refer to the following part numbers.

NOTE:

“” indicates a continuity of electricity;

i.e., a closed circuit at the respective switch

position.

Digital multimeter:

YU-34899-A

Digital circuit tester:

90890-03174

ProCarManuals.com

Page 237 of 347

7-10

E

–+ELECELECTRICAL ANALYSIS

Low resistance measurement

NOTE:

When measuring a resistance of 10 Ω

or less

using a digital tester, the correct measure-

ment cannot be obtained because of the

tester’s internal resistance.

To obtain the correct value, subtract the

internal resistance from the displayed mea-

surement.

The internal resistance of the tester can be

obtained by connecting both of its terminals.

Correct value =

Displayed measurement –

Internal resistance

Peak voltage measurement

NOTE:

When checking the condition of the ignition

system it is vital to know the peak voltage.

Cranking speed is dependant on many fac-

tors (e.g., fouled or weak spark plugs, a

weak battery). If one of these is defective,

the peak voltage will be lower than specifica-

tion.

If the peak voltage measurement is not

within specification the engine will not oper-

ate properly.

A low peak voltage will also cause compo-

nents to prematurely wear.

ProCarManuals.com

Page 238 of 347

7-11

E

–+ELECELECTRICAL ANALYSIS

Peak voltage adapter

NOTE:

Throughout this chapter the part numbers of

the specified peak voltage adapters have

been omitted. Refer to the following part

numbers.

The peak voltage adapter should be used

with a digital tester.

When measuring the peak voltage, connect

the peak voltage adapter to the digital circuit

tester and switch the selector to the DC volt-

age mode.

NOTE:

Make sure that the adapter leads are prop-

erly installed in the digital circuit tester.

Make sure that the positive pin (the “+” mark

facing up as shown) on the adapter is

installed into the positive terminal of the

tester.

The test harness is needed for the following

tests.

È Voltage measurement

É Peak voltage measurement

Test harness

NOTE:

If the lighting coil and pickup coil(s) are mea-

sured unloaded, disconnect the test harness

on the output side coupler.

Peak voltage adapter:

YU-39991

Peak voltage adapter B:

90890-03172

Checking steps:

Disconnect the coupler connections.

Connect the test harness between the

couplers.

Connect the tester terminals to the termi-

nals which are being checked.

Run the engine and observe the mea-

surement.È

É

ProCarManuals.com

Page 242 of 347

7-15

E

–+ELECIGNITION SYSTEM

IGNITION SYSTEM PEAK VOLTAGE

WARNING

When checking the electrical components,

do not touch any of the connections of the

digital tester lead wires.

NOTE:

If there is no spark, or the spark is weak,

continue with the ignition system test.

If a good spark is obtained, the problem is

not with the ignition system, but possibly with

the spark plug(s) or another component.

1. Measure:

ECM output peak voltage

Below specification →

Measure the

pickup coil output peak voltage.

NOTE:

When measuring the ECM output peak volt-

age while cranking the engine, disconnect

the ignition coil couplers for all cylinders

except for the cylinder being measured.

To crank the engine, connect the engine

shut-off cord (lanyard) to the engine shut-off

switch, and then press the start switch.

Test harness (2 pins):

New: YB-06867

Current: YB-06767

Test harness FWY-2 (2 pins):

New: 90890-06867

Current: 90890-06767

ECM output peak voltage:

Black/red (B/R) –

Red/yellow (R/Y)

Black/white (B/W) –

Red/yellow (R/Y)

Black/yellow (B/Y) –

Red/yellow (R/Y)

Black/green (B/G) –

Red/yellow (R/Y)

r/minLoaded

Cranking 2,000 3,500

V 90 130 140

ProCarManuals.com

Page 244 of 347

7-17

E

–+ELEC

NOTE:

To crank the engine, connect the engine shut-

off cord (lanyard) to the engine shut-off switch,

and then press the start switch and engine

stop switch simultaneously.

4. Measure:

Rectifier/regulator output voltage

Below specification →

Replace the recti-

fier/regulator.

NOTE:

Do not use the peak voltage adapter to mea-

sure the output voltage.

Disconnect the output lead of the tester har-

ness.

Test harness (6 pins):

YB-06848

Test harness FSW-6A (6 pins):

90890-06848

Rectifier/regulator output

voltage:

Red (R) – Black (B)

r/minUnloaded

3,500

V 13.0

BATTERY

Refer to “ELECTRICAL” in Chapter 3.

FUSE

Refer to “STARTING SYSTEM”.

SPARK PLUGS

Refer to “POWER UNIT” in Chapter 3.

IGNITION SYSTEM

ProCarManuals.com