electrical YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 2 of 347

E

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

A10001-0*

WaveRunner

VX110 Sport, VX110 Deluxe

SERVICE MANUAL

©2005 by Yamaha Motor Corporation, USA

1st Edition, January 2005

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, USA

is expressly prohibited.

Printed in USA

LIT-18616-02-91

ProCarManuals.com

Page 6 of 347

E

A50001-1-4

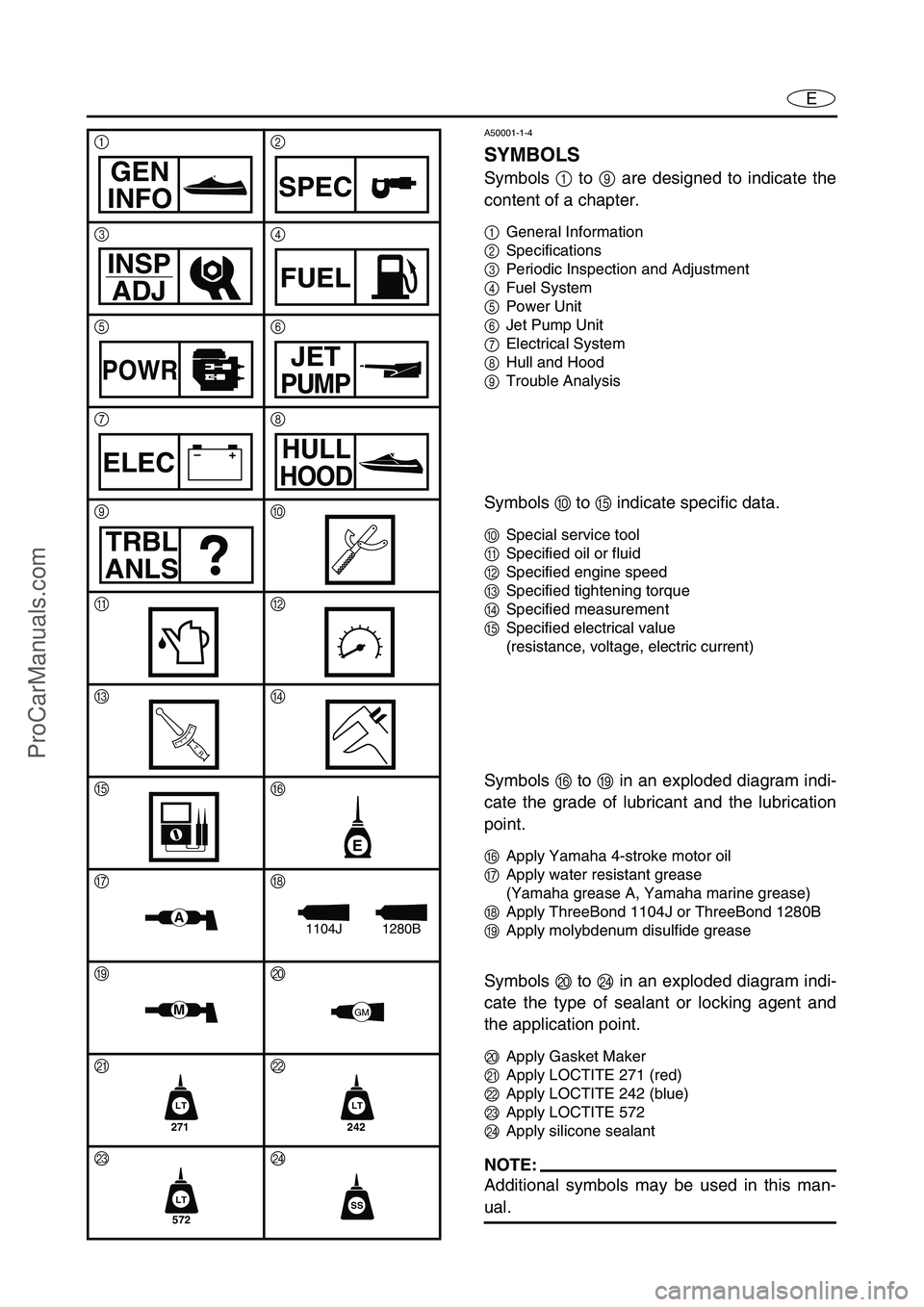

SYMBOLS

Symbols 1 to 9 are designed to indicate the

content of a chapter.

1General Information

2Specifications

3Periodic Inspection and Adjustment

4Fuel System

5Power Unit

6Jet Pump Unit

7Electrical System

8Hull and Hood

9Trouble Analysis

Symbols 0 to E indicate specific data.

0Special service tool

ASpecified oil or fluid

BSpecified engine speed

CSpecified tightening torque

DSpecified measurement

ESpecified electrical value

(resistance, voltage, electric current)

Symbols F to I in an exploded diagram indi-

cate the grade of lubricant and the lubrication

point.

FApply Yamaha 4-stroke motor oil

GApply water resistant grease

(Yamaha grease A, Yamaha marine grease)

HApply ThreeBond 1104J or ThreeBond 1280B

IApply molybdenum disulfide grease

Symbols J to N in an exploded diagram indi-

cate the type of sealant or locking agent and

the application point.

JApply Gasket Maker

KApply LOCTITE 271 (red)

LApply LOCTITE 242 (blue)

MApply LOCTITE 572

NApply silicone sealant

NOTE:

Additional symbols may be used in this man-

ual.

12

34

56

78

90

AB

CD

EF

GH

IJ

KL

MN

GEN

INFOSPEC

INSP

ADJFUEL

POWRJET

PUMP

–+ELECHULL

HOOD

TRBL

ANLS

T R..

E

A1280B1104J

MGM

271

LT

242

LT

572

LTSS

ProCarManuals.com

Page 7 of 347

E

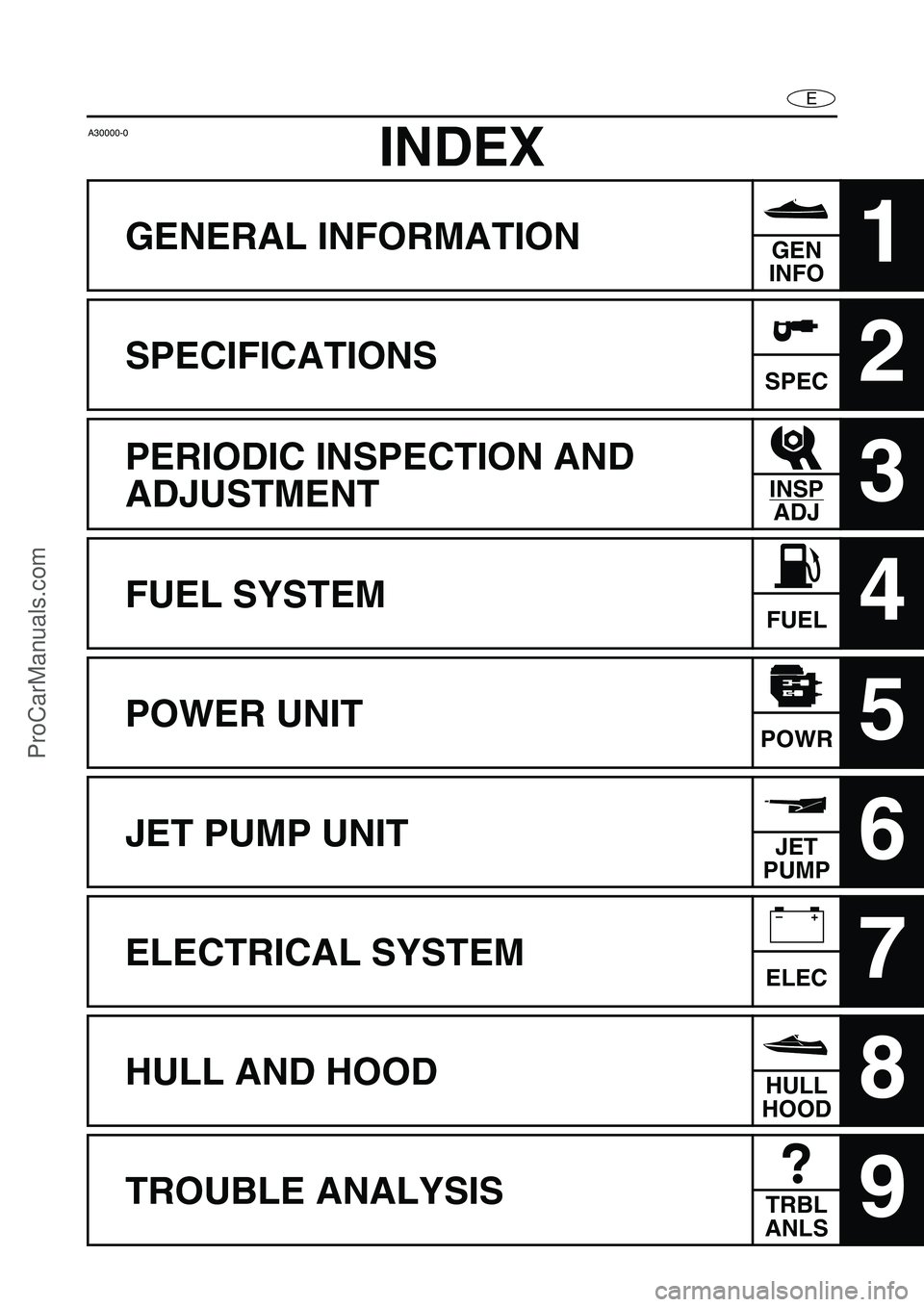

INDEX

GENERAL INFORMATION1GEN

INFO

SPECIFICATIONS2SPEC

PERIODIC INSPECTION AND

ADJUSTMENT

3INSP

ADJ

FUEL SYSTEM4FUEL

POWER UNIT5POWR

JET PUMP UNIT6JET

PUMP

ELECTRICAL SYSTEM7ELEC

HULL AND HOOD8HULL

HOOD

TROUBLE ANALYSIS9TRBL

ANLS

–+

A30000-0

ProCarManuals.com

Page 21 of 347

ESPEC

1

2

3

4

5

6

7

8

9

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS ....................................................................... 2-1

MAINTENANCE SPECIFICATIONS ............................................................... 2-3

ENGINE .................................................................................................... 2-3

JET PUMP UNIT ...................................................................................... 2-6

HULL AND HOOD .................................................................................... 2-6

ELECTRICAL ............................................................................................ 2-7

TIGHTENING TORQUES .............................................................................. 2-10

SPECIFIED TORQUES ........................................................................... 2-10

GENERAL TORQUE ............................................................................... 2-15

CABLE AND HOSE ROUTING ..................................................................... 2-16

ProCarManuals.com

Page 27 of 347

2-6

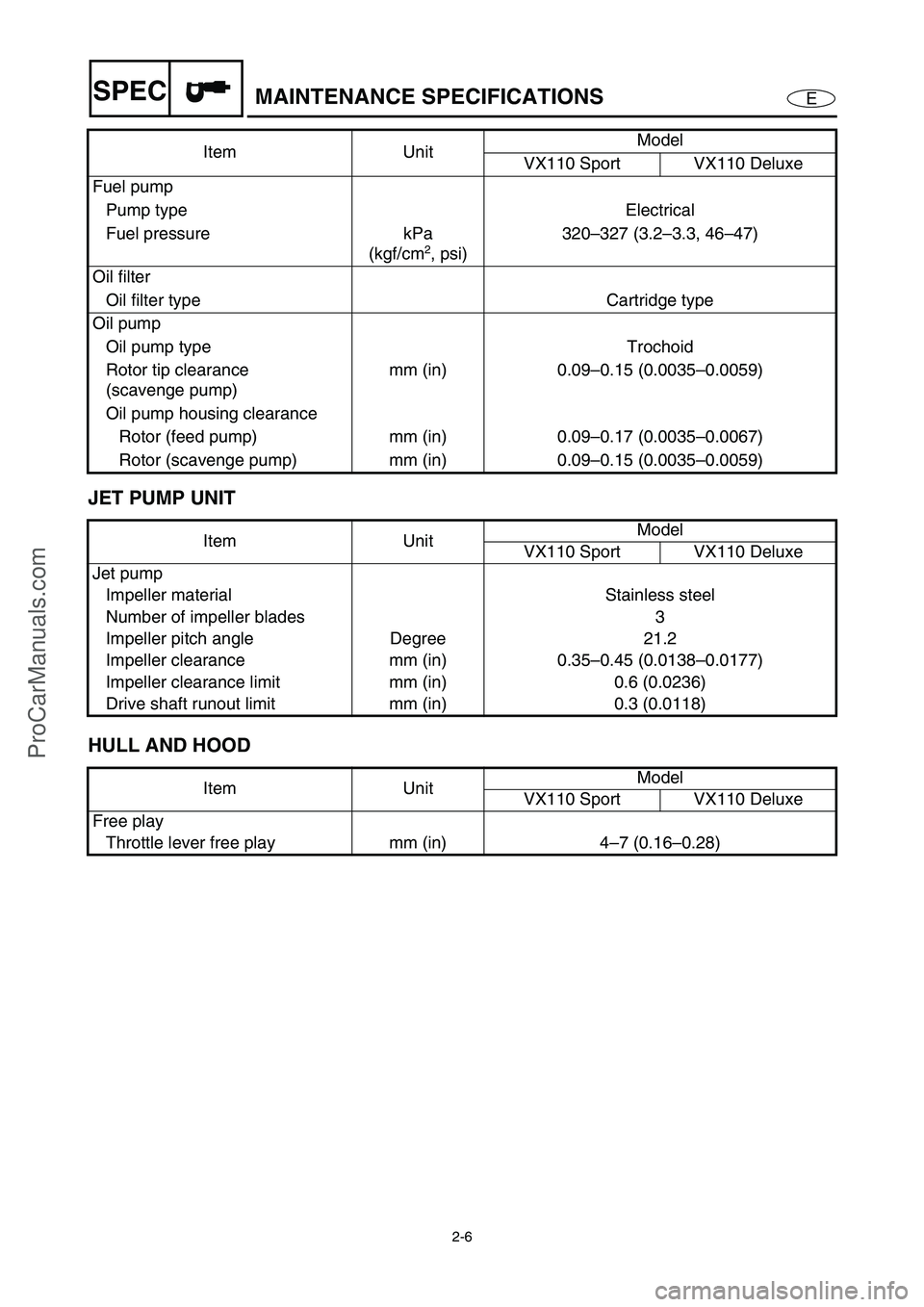

ESPECMAINTENANCE SPECIFICATIONS

JET PUMP UNIT

HULL AND HOOD

Fuel pump

Pump type Electrical

Fuel pressure kPa

(kgf/cm

2, psi)320–327 (3.2–3.3, 46–47)

Oil filter

Oil filter type Cartridge type

Oil pump

Oil pump type Trochoid

Rotor tip clearance

(scavenge pump)mm (in) 0.09–0.15 (0.0035–0.0059)

Oil pump housing clearance

Rotor (feed pump) mm (in) 0.09–0.17 (0.0035–0.0067)

Rotor (scavenge pump) mm (in) 0.09–0.15 (0.0035–0.0059)

Item UnitModel

VX110 Sport VX110 Deluxe

Jet pump

Impeller material Stainless steel

Number of impeller blades 3

Impeller pitch angle Degree 21.2

Impeller clearance mm (in) 0.35–0.45 (0.0138–0.0177)

Impeller clearance limit mm (in) 0.6 (0.0236)

Drive shaft runout limit mm (in) 0.3 (0.0118)

Item UnitModel

VX110 Sport VX110 Deluxe

Free play

Throttle lever free play mm (in) 4–7 (0.16–0.28) Item UnitModel

VX110 Sport VX110 Deluxe

ProCarManuals.com

Page 28 of 347

2-7

ESPECMAINTENANCE SPECIFICATIONS

ELECTRICAL

Item UnitModel

VX110 Sport VX110 Deluxe

Battery

Type Fluid

Capacity V/Ah 12/19

Specific gravity 1.28

ECM unit

(B/R – R/Y, B/W – R/Y,

B/Y – R/Y, B/G – R/Y)

Output peak voltage lower limit

@cranking (loaded) V 90

@2,000 r/min (loaded) V 130

@3,500 r/min (loaded) V 140

Stator

Pickup coil (W/B – B/O)

Output peak voltage

@cranking (unloaded) V 8.0

@cranking (loaded) V 6.9

@2,000 r/min (loaded) V 19.4

@3,500 r/min (loaded) V 25.1

Lighting coil (G – G)

Output peak voltage

@cranking (unloaded) V 7.8

@2,000 r/min (unloaded) V 24.5

@3,500 r/min (unloaded) V 41.6

Pickup coil resistance

(W/B – B/O)Ω

(color) 459–561

Lighting coil resistance (G – G)Ω

(color) 0.23–0.29

Minimum charging current A @ r/min 14 @ 6,000

Ignition coil

Primary coil resistance

@20 °C (68 °F)Ω

1.19–1.61

Secondary coil resistance

@20 °C (68 °F) kΩ

8.5–11.5

Rectifier/regulator (R – B)

Output peak voltage

@3,500 r/min (unloaded) V 13.0

ProCarManuals.com

Page 36 of 347

2-15

ESPECTIGHTENING TORQUES

Electrical

Fuse box Nut—2 17 1.7 12 7-2

Fuse box bracket Nut—4 15 1.5 11 7-2

ECM Bolt M6 4 4.0 0.4 2.9

572LT7-7

Bracket1st

Bolt M8 28.80.886.4

572LT7-7

2nd 18 1.8 13

Slant detection switchTapping

screwø6 2 3.90.392.8 7-2

Rectifier/regulator Bolt M8 2 4.0 0.4 2.9

572LT7-7

Brush assembly/spacer Nut—1 8.8 0.88 6.4 7-39

Starter motor rear cover Bolt M5 2 6.4 0.64 4.6 7-39

Remote control transmitter

coverTapping

screwø2 6 0.1 0.01 0.1 7-64 Part to tightenedPart

nameThread

sizeQ’tyTightening torque

RemarksRefer to

page

Nmkgfmftlb

GENERAL TORQUE

This chart specifies tightening torques for stan-

dard fasteners with a standard ISO thread

pitch. Tightening torque specifications for spe-

cial components or assemblies are provided in

applicable sections of this manual. To avoid

warpage, tighten multi-fastener assemblies in

a crisscross fashion and progressive stages

until the specified tightening torque is reached.

Unless otherwise specified, tightening torque

specifications require clean, dry threads.

Components should be at room temperature.Nut A

Bolt B

General torque

specifications

Nmkgfmftlb

8 mm M5 5.0 0.5 3.6

10 mm M6 8.0 0.8 5.8

12 mm M8 18 1.8 13

14 mm M10 36 3.6 26

17 mm M12 43 4.3 31

ProCarManuals.com

Page 49 of 347

E

INSP

ADJ

1

2

3

4

5

6

7

8

9

CHAPTER 3

PERIODIC INSPECTION AND ADJUSTMENT

MAINTENANCE INTERVAL CHART .............................................................. 3-1

PERIODIC SERVICE ....................................................................................... 3-2

CONTROL SYSTEM ................................................................................. 3-2

Steering column inspection ................................................................. 3-2

Steering cable inspection and adjustment .......................................... 3-2

Throttle cable inspection and adjustment............................................ 3-4

Shift cable inspection and adjustment (Deluxe model only)................ 3-5

Trolling speed inspection .................................................................... 3-6

FUEL SYSTEM.......................................................................................... 3-7

Fuel line inspection ............................................................................. 3-7

Water separator inspection ................................................................. 3-8

POWER UNIT............................................................................................ 3-8

Valve clearance adjustment ................................................................ 3-8

Engine oil level check........................................................................ 3-14

Engine oil change — using oil changer ............................................. 3-16

Air filter element clean....................................................................... 3-18

Spark plug inspection ........................................................................ 3-20

ELECTRICAL .......................................................................................... 3-22

Battery inspection.............................................................................. 3-22

JET PUMP UNIT ..................................................................................... 3-25

Impeller inspection ............................................................................ 3-25

Water inlet strainer inspection ........................................................... 3-25

BILGE PUMP........................................................................................... 3-26

Bilge strainer inspection .................................................................... 3-26

GENERAL ............................................................................................... 3-26

Drain plug inspection......................................................................... 3-26

Lubrication points .............................................................................. 3-26

ProCarManuals.com

Page 69 of 347

3-20

E

INSP

ADJ

POWER UNIT

Spark plug inspection

1. Remove:

Ignition coils

CAUTION:

Be careful not to get any foreign sub-

stances or water in spark plug hole.

2. Inspect:

Electrodes 1

Damage/wear →

Replace.

Insulator color 2

Distinctly different color →

Check the

engine condition.

Color guide:

Medium to light tan color:

Normal

Whitish color:

Lean fuel mixture

Air leak

Incorrect settings

Blackish color:

Overly rich mixture

Electrical malfunction

Defective spark plug

3. Clean:

Spark plug

(with a spark plug cleaner or wire brush)

4. Measure:

Spark plug gap a

Out of specification →

Regap.

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

ProCarManuals.com

Page 71 of 347

3-22

E

INSP

ADJ

ELECTRICAL

ELECTRICAL

Battery inspection

WARNING

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Electro-

lyte contains sulfuric acid. Avoid contact

with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg or vegetable oil. Call physician immedi-

ately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., well away. If

using or charging the battery in an

enclosed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHILDREN.

CAUTION:

Be careful not to place the battery on its

side.

Make sure to remove the battery from the

battery compartment when adding battery

electrolyte or charging the battery.

When checking the battery, make sure the

breather hose is connected to the battery

and not obstructed.

ProCarManuals.com