sensor YAMAHA VX110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 44 of 347

2-23

ESPECCABLE AND HOSE ROUTING

13

90A

C B

88

4567

2

E

D

F

È

É

Í

Ê

Ë

Ì A-A

AA

Î

1Oil separator breather hose (to air intake duct)

2Wiring harness

3Ignition coil lead #1

4Ignition coil lead #2

5Ignition coil lead #3

6Ignition coil lead #4

7Cam position sensor

8Ignition coil

9ECM

0Rectifier/regulator

AOil pressure switch couplerBThermoswitch (exhaust) coupler

CGround lead plate

DWiring harness

EThermoswitch (exhaust) lead

FOil pressure switch lead

ÈFasten the oil separator breather hose (to air

intake duct) at the paint mark with a holder.

É15–25 mm (0.59–0.98 in)

ÊTo fuse box

ËTo multifunction meter

ProCarManuals.com

Page 46 of 347

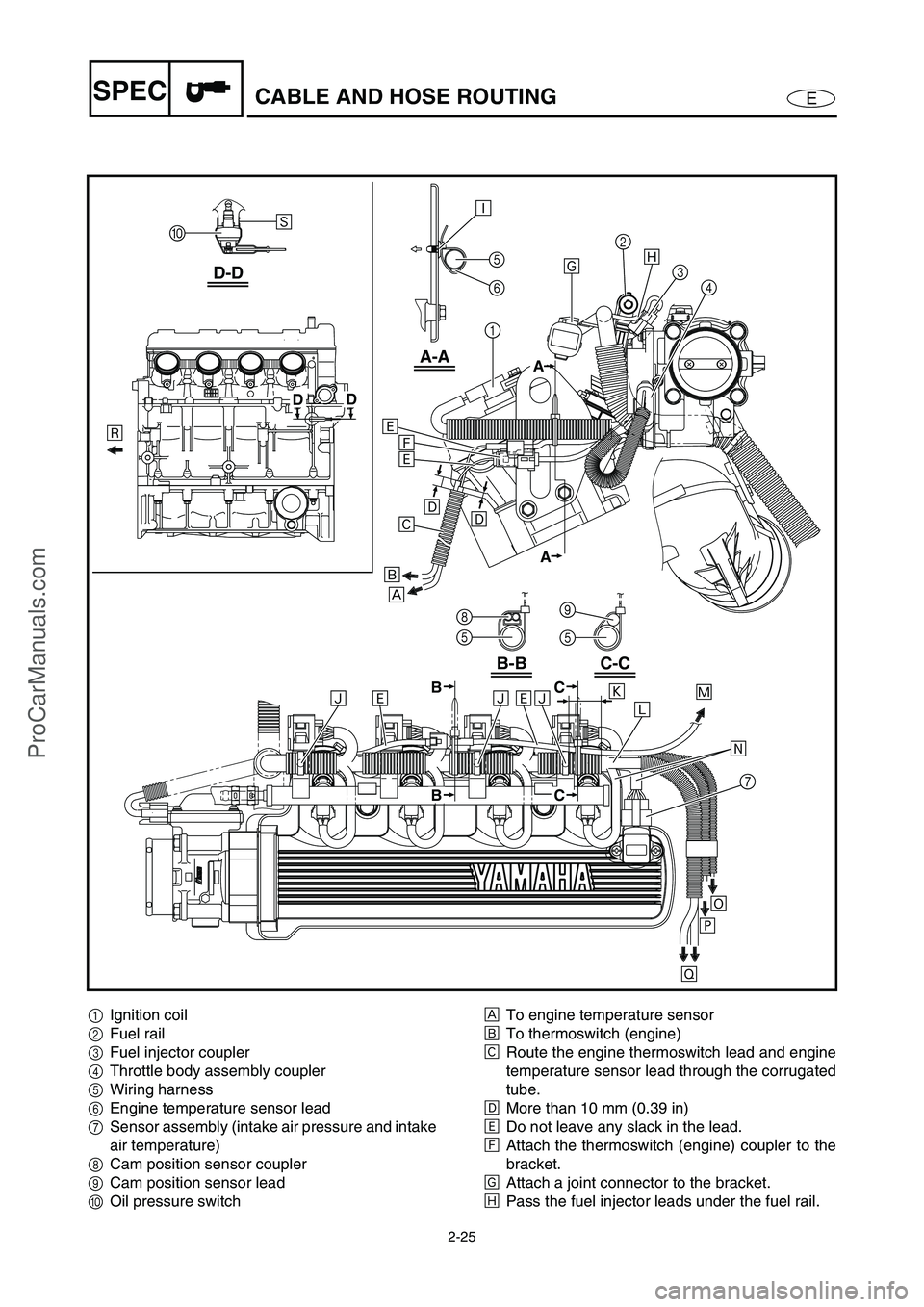

2-25

ESPECCABLE AND HOSE ROUTING

D-D

A-A

B-B

0

8

5

C-C

9

5 Ú

Ù

É

È

Ð

DD

5

6

A

A

1

2

7

34

Î

Ó ÒÌÑÑÌÑ

Ì

Ì

Ë Ë

Ê

Ø×Ö Ô

Õ

Í

Ï

C

CB

B

1Ignition coil

2Fuel rail

3Fuel injector coupler

4Throttle body assembly coupler

5Wiring harness

6Engine temperature sensor lead

7Sensor assembly (intake air pressure and intake

air temperature)

8Cam position sensor coupler

9Cam position sensor lead

0Oil pressure switchÈTo engine temperature sensor

ÉTo thermoswitch (engine)

ÊRoute the engine thermoswitch lead and engine

temperature sensor lead through the corrugated

tube.

ËMore than 10 mm (0.39 in)

ÌDo not leave any slack in the lead.

ÍAttach the thermoswitch (engine) coupler to the

bracket.

ÎAttach a joint connector to the bracket.

ÏPass the fuel injector leads under the fuel rail.

ProCarManuals.com

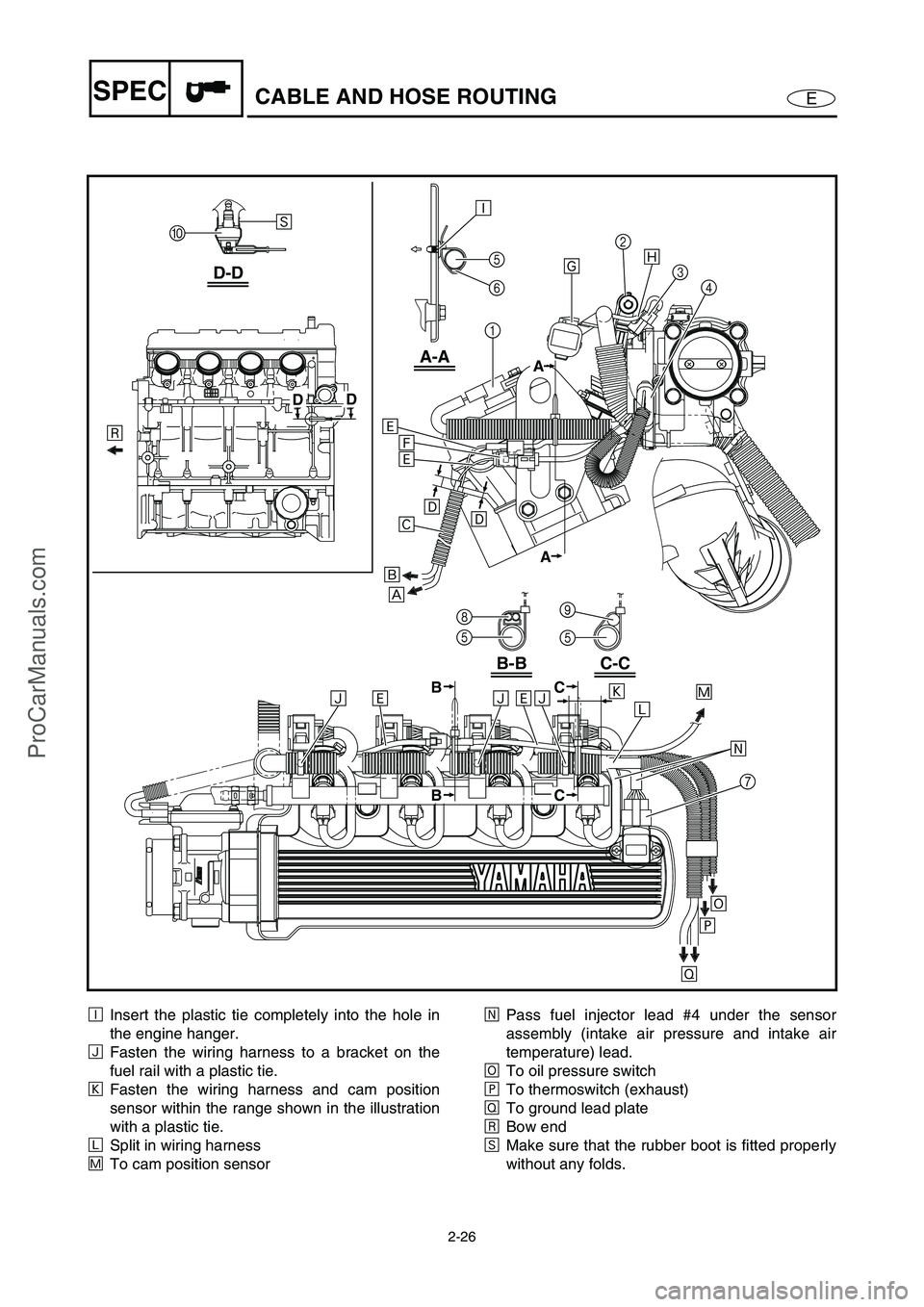

Page 47 of 347

2-26

ESPECCABLE AND HOSE ROUTING

D-D

A-A

B-B

0

8

5

C-C

9

5 Ú

Ù

É

È

Ð

DD

5

6

A

A

1

2

7

34

Î

Ó ÒÌÑÑÌÑ

Ì

Ì

Ë Ë

Ê

Ø×Ö Ô

Õ

Í

Ï

C

CB

B

ÐInsert the plastic tie completely into the hole in

the engine hanger.

ÑFasten the wiring harness to a bracket on the

fuel rail with a plastic tie.

ÒFasten the wiring harness and cam position

sensor within the range shown in the illustration

with a plastic tie.

ÓSplit in wiring harness

ÔTo cam position sensorÕPass fuel injector lead #4 under the sensor

assembly (intake air pressure and intake air

temperature) lead.

ÖTo oil pressure switch

×To thermoswitch (exhaust)

ØTo ground lead plate

ÙBow end

ÚMake sure that the rubber boot is fitted properly

without any folds.

ProCarManuals.com

Page 52 of 347

3-3

E

INSP

ADJ

CONTROL SYSTEM

2. Adjust:

Steering cable joint

(steering column end)

NOTE:

Adjust the cable joint at the jet pump end.

Refer to “REMOTE CONTROL CABLES AND

SPEED SENSOR LEAD” in Chapter 8. Adjustment steps:

Set the control grip to the neutral posi-

tion.

Loosen the locknut 1

.

Disconnect the cable joint 2

from the ball

joint 3

.

Turn the cable joint 2

in or out to adjust

the steering cable length c

.

Steering cable length

c:

218.8 mm (8.61 in)

NOTE:

Check that the sum of lengths c

and d

is

581.8 ±

1 mm (22.91 ±

0.04 in).

If the sum of lengths c

and d

is out of

specification, adjust length d

, and then

check the jet thrust nozzle distances

again.

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

Connect the cable joint and tighten the

locknut.

T R..

Locknut:

6.8 N m (0.68 kgf m, 4.9 ft lb)

c

d

ProCarManuals.com

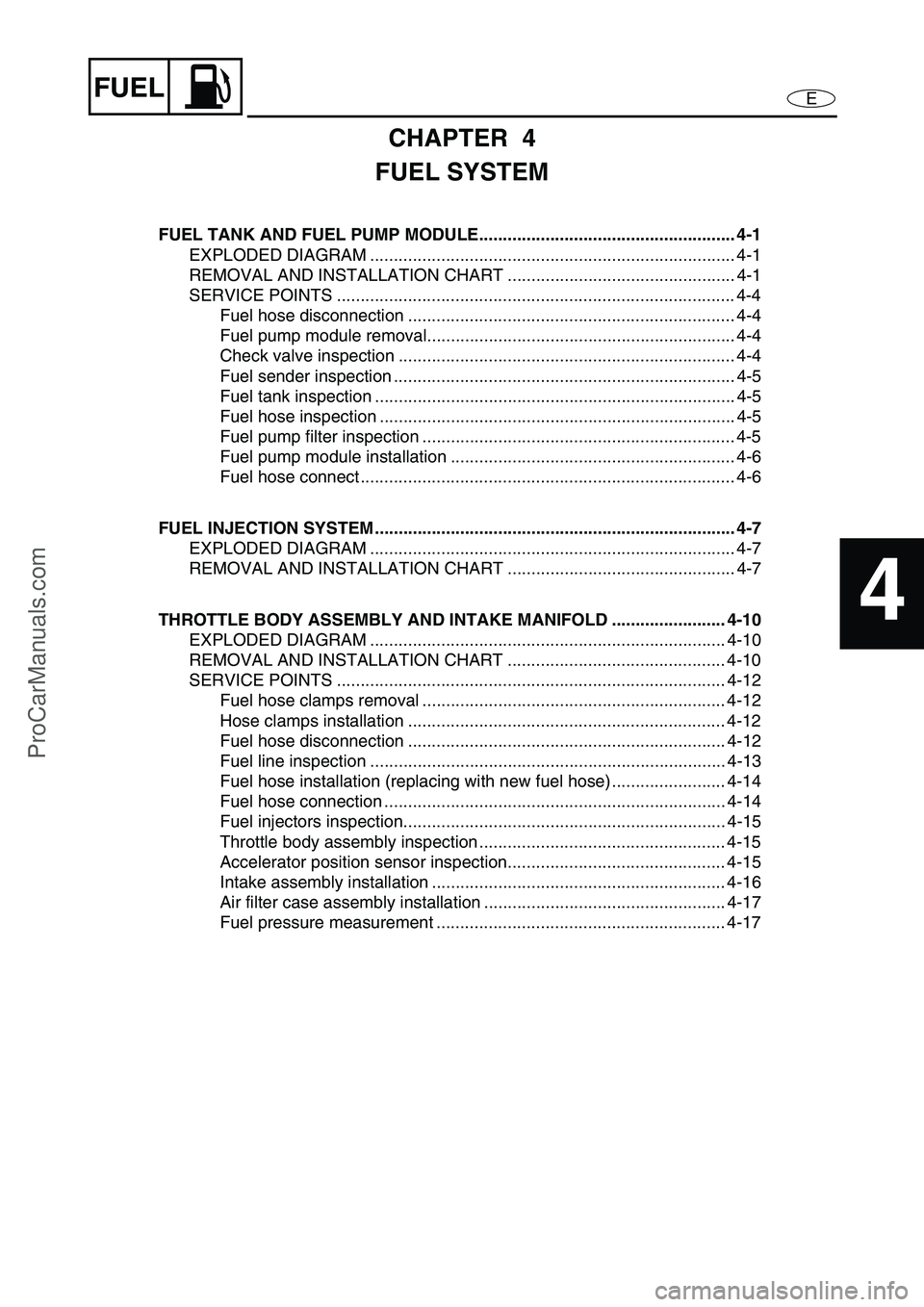

Page 77 of 347

EFUEL

1

2

3

4

5

6

7

8

9

CHAPTER 4

FUEL SYSTEM

FUEL TANK AND FUEL PUMP MODULE...................................................... 4-1

EXPLODED DIAGRAM ............................................................................. 4-1

REMOVAL AND INSTALLATION CHART ................................................ 4-1

SERVICE POINTS .................................................................................... 4-4

Fuel hose disconnection ..................................................................... 4-4

Fuel pump module removal................................................................. 4-4

Check valve inspection ....................................................................... 4-4

Fuel sender inspection ........................................................................ 4-5

Fuel tank inspection ............................................................................ 4-5

Fuel hose inspection ........................................................................... 4-5

Fuel pump filter inspection .................................................................. 4-5

Fuel pump module installation ............................................................ 4-6

Fuel hose connect ............................................................................... 4-6

FUEL INJECTION SYSTEM ............................................................................ 4-7

EXPLODED DIAGRAM ............................................................................. 4-7

REMOVAL AND INSTALLATION CHART ................................................ 4-7

THROTTLE BODY ASSEMBLY AND INTAKE MANIFOLD ........................ 4-10

EXPLODED DIAGRAM ........................................................................... 4-10

REMOVAL AND INSTALLATION CHART .............................................. 4-10

SERVICE POINTS .................................................................................. 4-12

Fuel hose clamps removal ................................................................ 4-12

Hose clamps installation ................................................................... 4-12

Fuel hose disconnection ................................................................... 4-12

Fuel line inspection ........................................................................... 4-13

Fuel hose installation (replacing with new fuel hose) ........................ 4-14

Fuel hose connection ........................................................................ 4-14

Fuel injectors inspection.................................................................... 4-15

Throttle body assembly inspection .................................................... 4-15

Accelerator position sensor inspection.............................................. 4-15

Intake assembly installation .............................................................. 4-16

Air filter case assembly installation ................................................... 4-17

Fuel pressure measurement ............................................................. 4-17

ProCarManuals.com

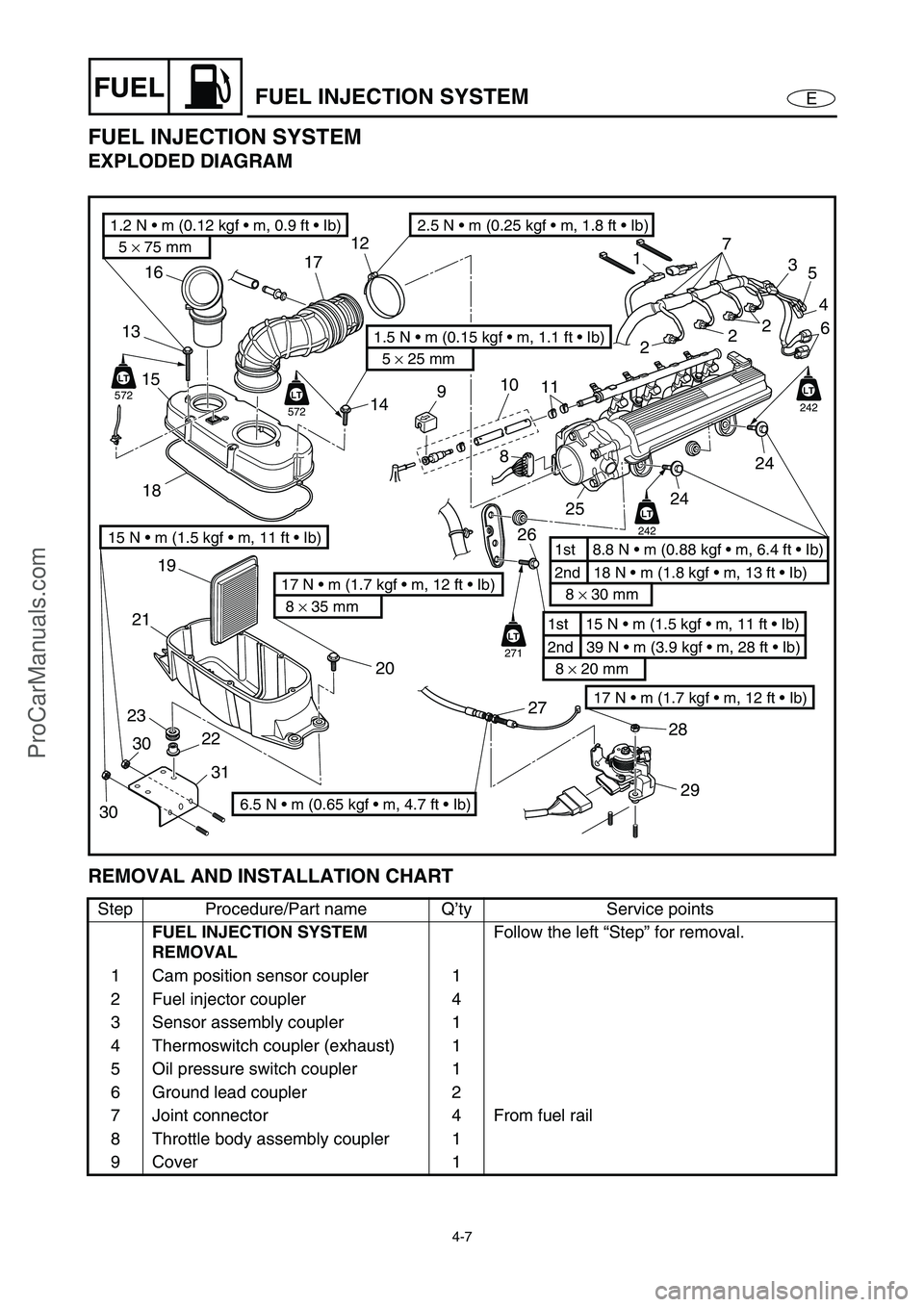

Page 84 of 347

4-7

EFUELFUEL INJECTION SYSTEM

FUEL INJECTION SYSTEM

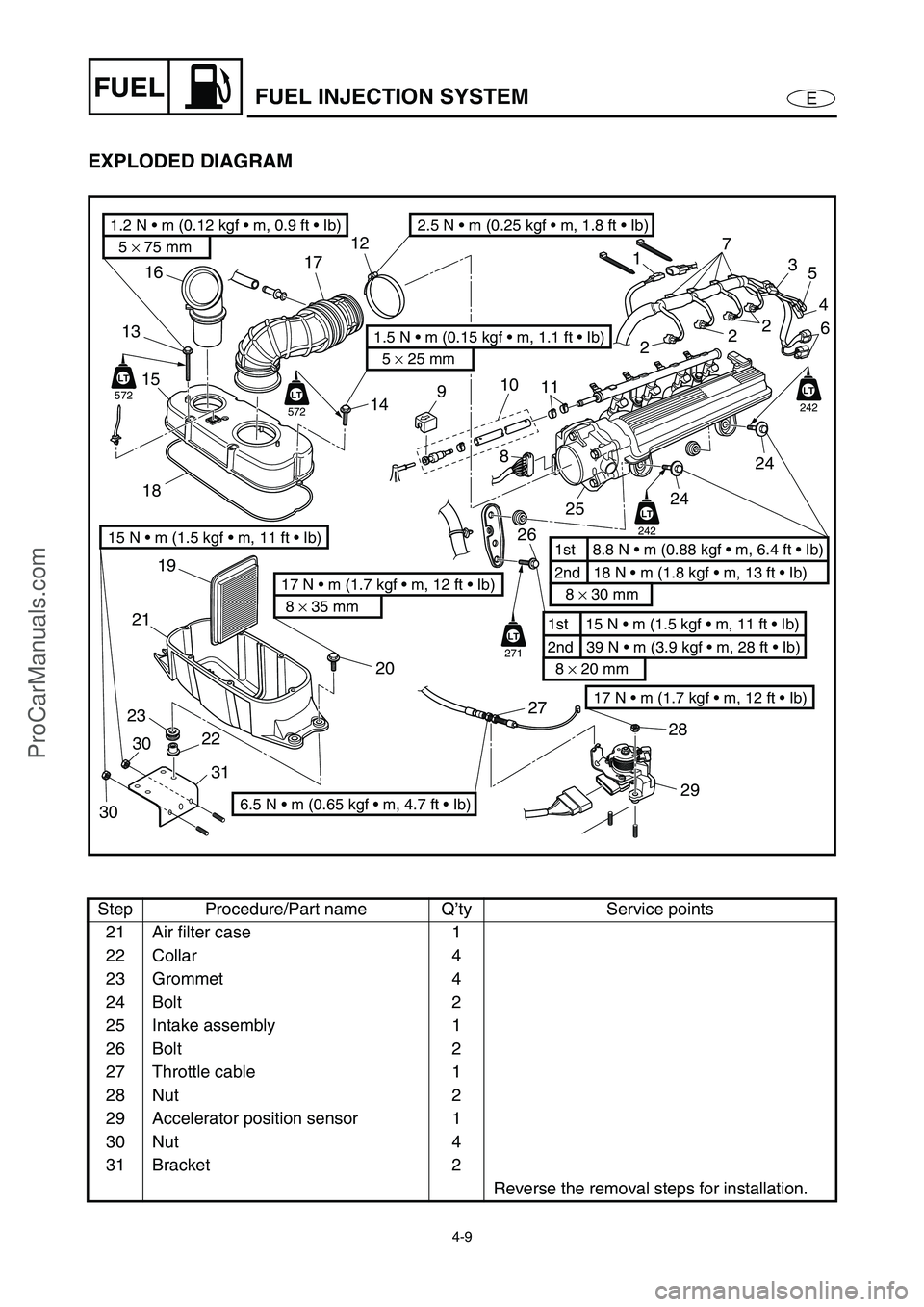

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL INJECTION SYSTEM

REMOVALFollow the left “Step” for removal.

1 Cam position sensor coupler 1

2 Fuel injector coupler 4

3 Sensor assembly coupler 1

4 Thermoswitch coupler (exhaust) 1

5 Oil pressure switch coupler 1

6 Ground lead coupler 2

7 Joint connector 4 From fuel rail

8 Throttle body assembly coupler 1

9 Cover 1

17 N m (1.7 kgf m, 12 ft Ib)

5 × 75 mm

1.2 N m (0.12 kgf m, 0.9 ft Ib)

5 × 25 mm

1.5 N m (0.15 kgf m, 1.1 ft Ib)

8 × 35 mm

17 N m (1.7 kgf m, 12 ft Ib)2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 30 mm

2nd 39 N m (3.9 kgf m, 28 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 20 mm

LT

242

LT

242

LT

271

LT

572

LT

LT

572

LT

22 2320 19

2118 15 1316

14 1712

17

3

2

2

25

4

6

24

24

25 8

26

27

28

29

11 10

9

2.5 N m (0.25 kgf m, 1.8 ft Ib)

6.5 N m (0.65 kgf m, 4.7 ft Ib)

15 N m (1.5 kgf m, 11 ft Ib)

3031

30

ProCarManuals.com

Page 86 of 347

4-9

EFUELFUEL INJECTION SYSTEM

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

21 Air filter case 1

22 Collar 4

23 Grommet 4

24 Bolt 2

25 Intake assembly 1

26 Bolt 2

27 Throttle cable 1

28 Nut 2

29 Accelerator position sensor 1

30 Nut 4

31 Bracket 2

Reverse the removal steps for installation.

17 N m (1.7 kgf m, 12 ft Ib)

5 × 75 mm

1.2 N m (0.12 kgf m, 0.9 ft Ib)

5 × 25 mm

1.5 N m (0.15 kgf m, 1.1 ft Ib)

8 × 35 mm

17 N m (1.7 kgf m, 12 ft Ib)2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 30 mm

2nd 39 N m (3.9 kgf m, 28 ft Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

8 × 20 mm

LT

242

LT

242

LT

271

LT

572

LT

LT

572

LT

22 2320 19

2118 15 1316

14 1712

17

3

2

2

25

4

6

24

24

25 8

26

27

28

29

11 10

9

2.5 N m (0.25 kgf m, 1.8 ft Ib)

6.5 N m (0.65 kgf m, 4.7 ft Ib)

15 N m (1.5 kgf m, 11 ft Ib)

3031

30

ProCarManuals.com

Page 88 of 347

4-11

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

8Gasket 4

9 Fuel injector 4

10 O-ring 4

11 Screw 2

12 Sensor assembly 1

13 O-ring 1

14 Clamp 4

15 Clamp 4

16 Intake manifold joint 4

Reverse the disassembly steps for

assembly.

8 × 17 mm

13 N m (1.3 kgf m, 9.4 ft Ib)5 × 15 mm

3.5 N m (0.35 kgf m, 2.5 ft Ib)

8 × 65 mm

13 N m (1.3 kgf m, 9.4 ft Ib)123 4 14151689 107661111

12

13

5

Not reusable

Not reusable

Not reusable

ProCarManuals.com

Page 92 of 347

4-15

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

Fuel injectors inspection

NOTE:

Do not remove the throttle body assembly.

1. Check:

Fuel injectors

Dirt/residue →

Clean.

Damage →

Replace.

2. Measure:

Fuel injectors resistance

Out of specification →

Replace.

3. Check the operation of the fuel injector

using the “Stationary Test” of the Yamaha

Diagnostic System.

Digital multimeter:

YU-34899-A

Digital circuit tester:

90890-03174

Fuel injector resistance:

(reference data)

11.5–12.5

Ω at 20 °C (68 °F)

Throttle body assembly inspection

CAUTION:

The throttle body assembly should not be

disassembled.

1. Check:

Throttle body assembly

Cracks/damage →

Replace the throttle

body assembly.

Accelerator position sensor inspection

1. Inspect:

Accelerator position sensor

Damage/cracks →

Replace the acceler-

ator position sensor.

ProCarManuals.com

Page 140 of 347

5-41

EPOWRCAMSHAFTS

CAMSHAFTS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CYLINDER HEAD COVER

REMOVALFollow the left “Step” for removal.

1Bolt 4

2 Ignition coil 4

3 Spark plug 4

4 Clamp/breather hose 1/1È

To oil tank

Paint mark a

5Bolt 1

6 Cam position sensor 1

7 Clamp/cooling water hose 1/1É

To transom plate

8 Rubber seal 1

E

4

65

7 8

10

11

12

13 9

LT

572

LT

14

16

15

3

13 N

m (1.3 kgf m, 9.4 ft Ib)

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 16 mm 6 × 16 mm

2nd 7.6 N m (0.76 kgf

m, 5.5 ft

Ib) 1st 3.7 N m (0.37 kgf

m, 2.7 ft

Ib)

12 N

m (1.2 kgf m, 8.7 ft Ib)

6 × 22 mm

aÈ

É

1

2

7.6 N

m (0.76 kgf m, 5.5 ft Ib)

6 × 16 mm

LT

572

LTAA

1280B

1280B

ProCarManuals.com