torque YAMAHA WOLVERINE 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2016Pages: 192, PDF Size: 4.38 MB

Page 56 of 192

4-17

4

4. Install the bolts, and then tighten the boltsto the specified torque.

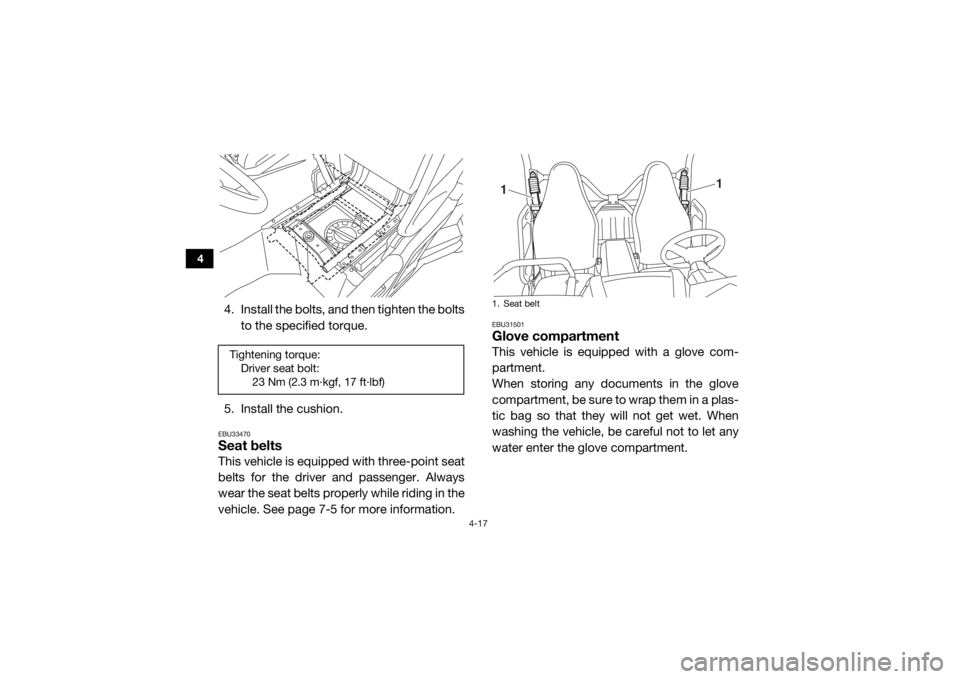

5. Install the cushion.EBU33470Seat beltsThis vehicle is equipped with three-point seat

belts for the driver and passenger. Always

wear the seat belts properly while riding in the

vehicle. See page 7-5 for more information.

EBU31501Glove compartmentThis vehicle is equipped with a glove com-

partment.

When storing any documents in the glove

compartment, be sure to wrap them in a plas-

tic bag so that they will not get wet. When

washing the vehicle, be careful not to let any

water enter the glove compartment.

Tightening torque: Driver seat bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

1. Seat belt1

1

UBN57AE0.book Page 17 Tuesday, November 24, 2015 1:42 PM

Page 64 of 192

4-25

4

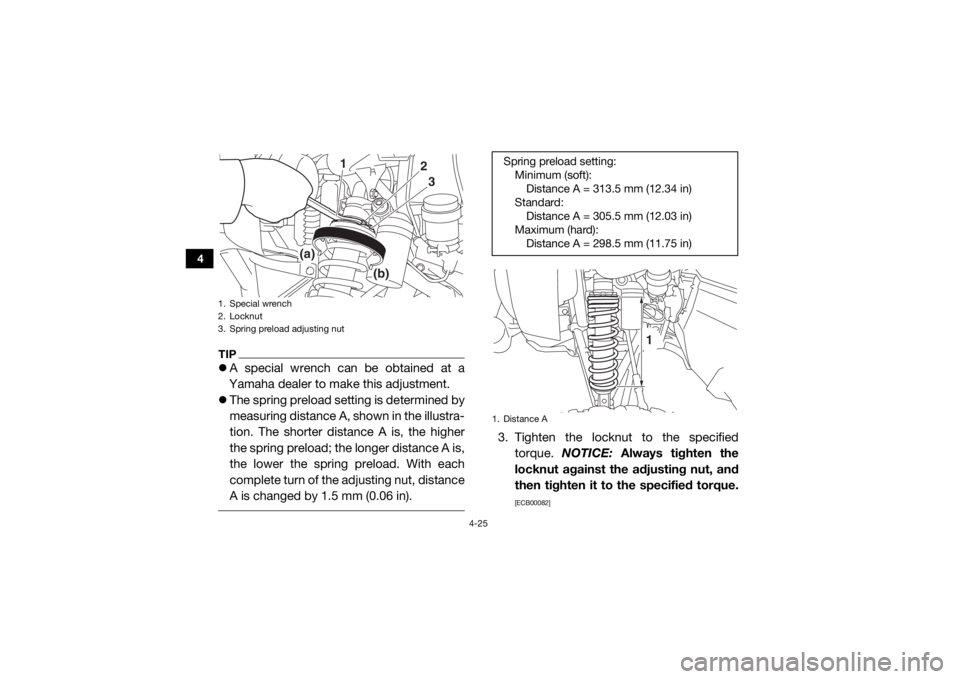

TIPA special wrench can be obtained at a

Yamaha dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustra-

tion. The shorter distance A is, the higher

the spring preload; the longer distance A is,

the lower the spring preload. With each

complete turn of the adjusting nut, distance

A is changed by 1.5 mm (0.06 in).

3. Tighten the locknut to the specified

torque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

1. Special wrench

2. Locknut

3. Spring preload adjusting nut

2

1

3

(a)

(b)

Spring preload setting: Minimum (soft):Distance A = 313.5 mm (12.34 in)

Standard: Distance A = 305.5 mm (12.03 in)

Maximum (hard): Distance A = 298.5 mm (11.75 in)1. Distance A

1

UBN57AE0.book Page 25 Tuesday, November 24, 2015 1:42 PM

Page 65 of 192

4-26

4

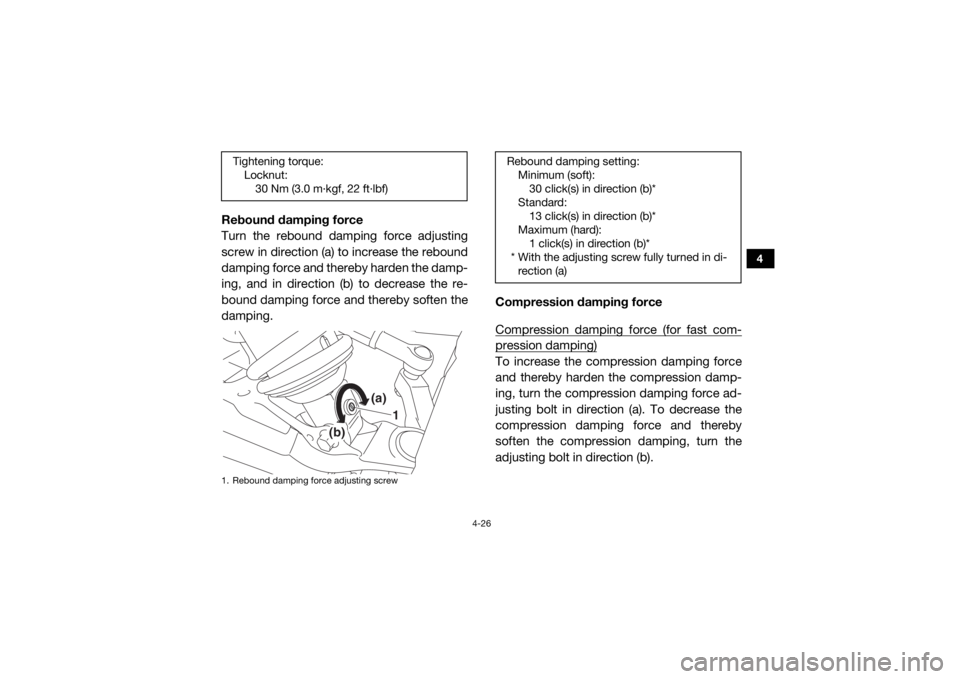

Rebound damping force

Turn the rebound damping force adjusting

screw in direction (a) to increase the rebound

damping force and thereby harden the damp-

ing, and in direction (b) to decrease the re-

bound damping force and thereby soften the

damping.Compression damping force

Compression damping force (for fast com-

pression damping)To increase the compression damping force

and thereby harden the compression damp-

ing, turn the compression damping force ad-

justing bolt in direction (a). To decrease the

compression damping force and thereby

soften the compression damping, turn the

adjusting bolt in direction (b).

Tightening torque:

Locknut:30 Nm (3.0 m·kgf, 22 ft·lbf)1. Rebound damping force adjusting screw

1

(a)

(b)

Rebound damping setting: Minimum (soft):30 click(s) in direction (b)*

Standard: 13 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in di- rection (a)

UBN57AE0.book Page 26 Tuesday, November 24, 2015 1:42 PM

Page 69 of 192

4-30

4

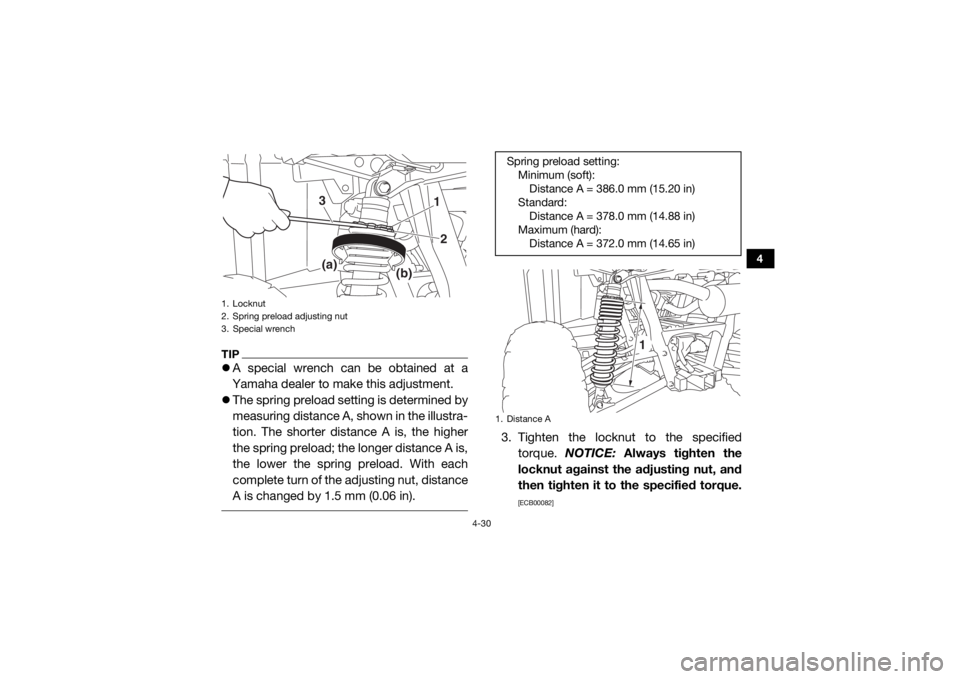

TIPA special wrench can be obtained at a

Yamaha dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustra-

tion. The shorter distance A is, the higher

the spring preload; the longer distance A is,

the lower the spring preload. With each

complete turn of the adjusting nut, distance

A is changed by 1.5 mm (0.06 in).

3. Tighten the locknut to the specified

torque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

1. Locknut

2. Spring preload adjusting nut

3. Special wrench

1

3

2

(a)

(b)

Spring preload setting: Minimum (soft):Distance A = 386.0 mm (15.20 in)

Standard: Distance A = 378.0 mm (14.88 in)

Maximum (hard): Distance A = 372.0 mm (14.65 in)1. Distance A

1

UBN57AE0.book Page 30 Tuesday, November 24, 2015 1:42 PM

Page 70 of 192

4-31

4

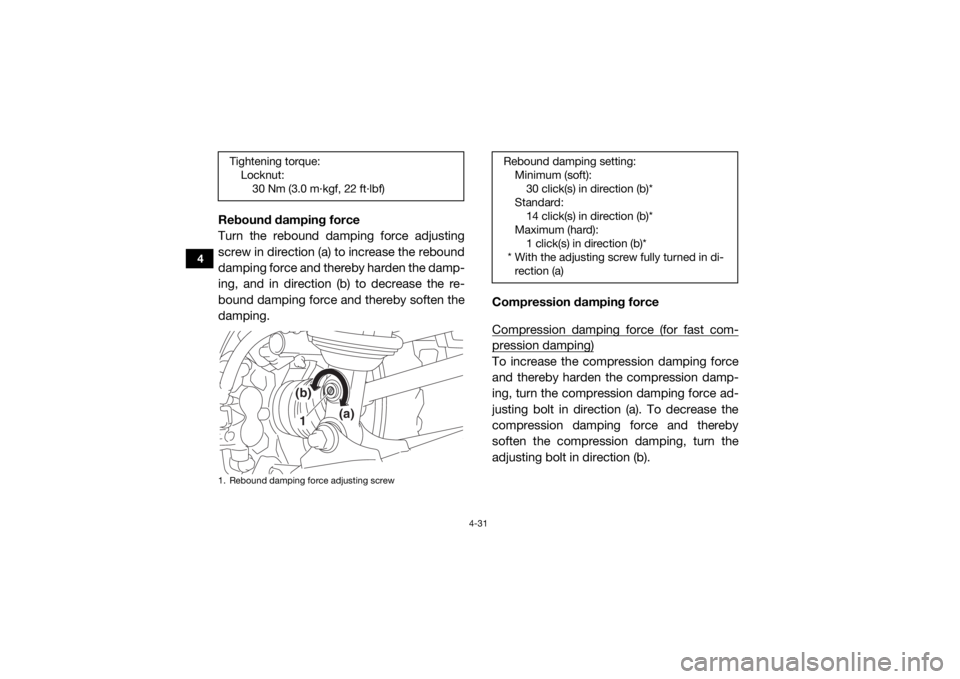

Rebound damping force

Turn the rebound damping force adjusting

screw in direction (a) to increase the rebound

damping force and thereby harden the damp-

ing, and in direction (b) to decrease the re-

bound damping force and thereby soften the

damping.Compression damping force

Compression damping force (for fast com-

pression damping)To increase the compression damping force

and thereby harden the compression damp-

ing, turn the compression damping force ad-

justing bolt in direction (a). To decrease the

compression damping force and thereby

soften the compression damping, turn the

adjusting bolt in direction (b).

Tightening torque:

Locknut:30 Nm (3.0 m·kgf, 22 ft·lbf)1. Rebound damping force adjusting screw

1

(a)

(b)

Rebound damping setting:Minimum (soft):30 click(s) in direction (b)*

Standard: 14 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in di- rection (a)

UBN57AE0.book Page 31 Tuesday, November 24, 2015 1:42 PM

Page 82 of 192

5-8

5

EBU35700Fittings and fastenersAlways check the tightness of chassis and

wheel fittings and fasteners before starting

off. Take the vehicle to a Yamaha dealer or re-

fer to the Service Manual for correct tighten-

ing torque.EBU31840Instruments, lights and switchesCheck that all instruments, lights and switch-

es are working properly. Correct if necessary.EBU31851Control cablesWhen driving in cold weather, always make

sure all control cables work smoothly before

starting off. WARNING! Control cables can

freeze in cold weather and you could be

unable to control the vehicle.

[EWB03280] EBU33480

TiresCheck tire pressure regularly to make sure it

is at the recommended specifications. Also

check for wear and damage.

Tire pressure

Use the tire pressure gauge to check and ad-

just tire pressures when the tires are cold. Tire

pressures must be equal on both sides.

WARNING! Operation of this vehicle with improper tire pressure may cause severe

injury or death from loss of control or roll-

over. Tire pressure below the minimum

specified could also cause the tire to dis-

lodge from the rim under severe riding

conditions.

[EWB02542]

Set tire pressures to the following specifica-

tions:

UBN57AE0.book Page 8 Tuesday, November 24, 2015 1:42 PM

Page 117 of 192

8-2

8

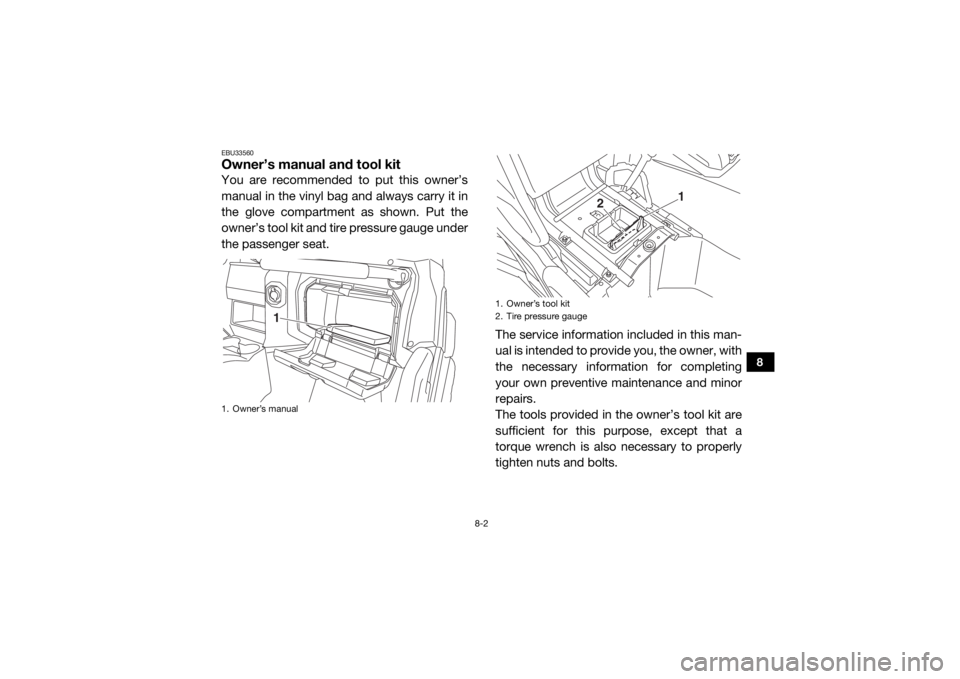

EBU33560Owner’s manual and tool kitYou are recommended to put this owner’s

manual in the vinyl bag and always carry it in

the glove compartment as shown. Put the

owner’s tool kit and tire pressure gauge under

the passenger seat.The service information included in this man-

ual is intended to provide you, the owner, with

the necessary information for completing

your own preventive maintenance and minor

repairs.

The tools provided in the owner’s tool kit are

sufficient for this purpose, except that a

torque wrench is also necessary to properly

tighten nuts and bolts.1. Owner’s manual

1

1. Owner’s tool kit

2. Tire pressure gauge

1

2

UBN57AE0.book Page 2 Tuesday, November 24, 2015 1:42 PM

Page 118 of 192

8-3

8

If you do not have a torque wrench available

during a service operation requiring one, take

your vehicle to a Yamaha dealer to check the

torque settings and adjust them as neces-

sary.UBN57AE0.book Page 3 Tuesday, November 24, 2015 1:42 PM

Page 133 of 192

8-18

8

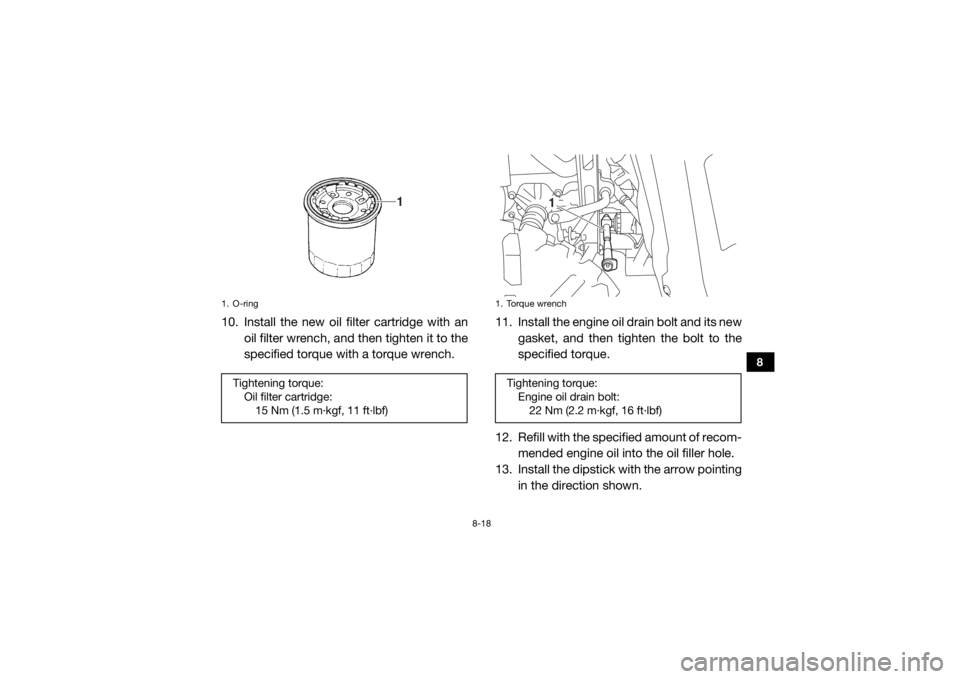

10. Install the new oil filter cartridge with anoil filter wrench, and then tighten it to the

specified torque with a torque wrench. 11. Install the engine oil drain bolt and its new

gasket, and then tighten the bolt to the

specified torque.

12. Refill with the specified amount of recom- mended engine oil into the oil filler hole.

13. Install the dipstick with the arrow pointing in the direction shown.1. O-ringTightening torque:Oil filter cartridge:15 Nm (1.5 m·kgf, 11 ft·lbf)

1

1. Torque wrenchTightening torque: Engine oil drain bolt:22 Nm (2.2 m·kgf, 16 ft·lbf)

1

UBN57AE0.book Page 18 Tuesday, November 24, 2015 1:42 PM

Page 135 of 192

8-20

8

15. Turn the engine off, wait at least 10 minu-tes, and then check the oil level and cor-

rect it if necessary.

16. Install the rubber cover.

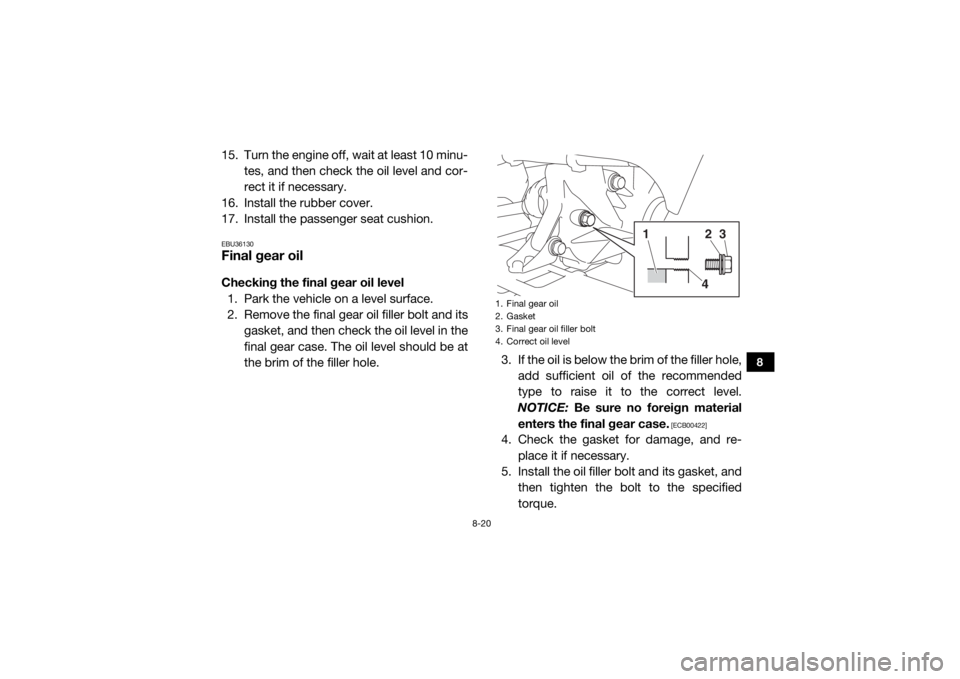

17. Install the passenger seat cushion.EBU36130Final gear oilChecking the final gear oil level 1. Park the vehicle on a level surface.

2. Remove the final gear oil filler bolt and its gasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole. 3. If the oil is below the brim of the filler hole,

add sufficient oil of the recommended

type to raise it to the correct level.

NOTICE: Be sure no foreign material

enters the final gear case.

[ECB00422]

4. Check the gasket for damage, and re- place it if necessary.

5. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque.1. Final gear oil

2. Gasket

3. Final gear oil filler bolt

4. Correct oil level

24

3

1

UBN57AE0.book Page 20 Tuesday, November 24, 2015 1:42 PM