YAMAHA WOLVERINE 2017 Owners Manual

Manufacturer: YAMAHA, Model Year: 2017, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2017Pages: 186, PDF Size: 4.22 MB

Page 131 of 186

8-19

8

TIPBe sure to wipe off spilled oil on any parts af-

ter the engine and exhaust system have

cooled down. NOTICEECB00301In order to prevent clutch slippage (since

the engine oil also lubricates the clutch),

do not mix any chemical additives. Do

not use oils with a diesel specification of

“CD” or oils of a higher quality than

specified. In addition, do not use oils la-

beled “ENERGY CONSERVING II” or

higher.

Make sure that no foreign material en-

ters the crankcase. 14. Start the engine, and then let it idle for

several minutes while checking it for oil

leakage. If oil is leaking, immediately turn

the engine off and check for the cause.

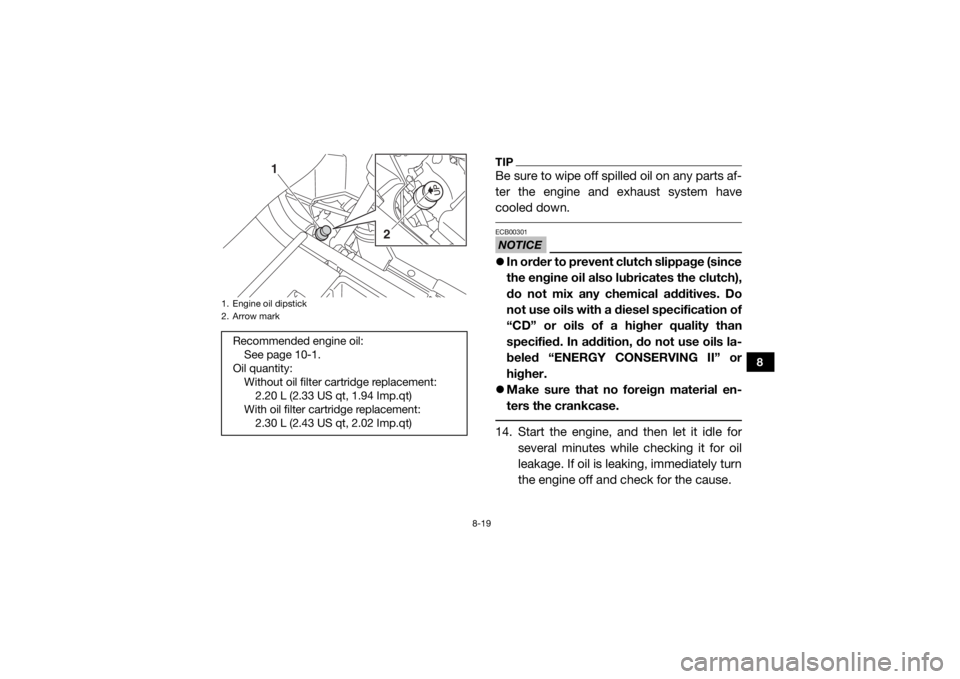

1. Engine oil dipstick

2. Arrow markRecommended engine oil:See page 10-1.

Oil quantity: Without oil filter cartridge replacement:2.20 L (2.33 US qt, 1.94 Imp.qt)

With oil filter cartridge replacement: 2.30 L (2.43 US qt, 2.02 Imp.qt)

1

2

U2MB7BE0.book Page 19 Thursday, March 3, 2016 11:46 AM

Page 132 of 186

8-20

8

15. Turn the engine off, wait at least 10 minu-tes, and then check the oil level and cor-

rect it if necessary.

16. Install the rubber cover.

17. Install the passenger seat cushion.EBU36050Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the general

maintenance and lubrication chart.

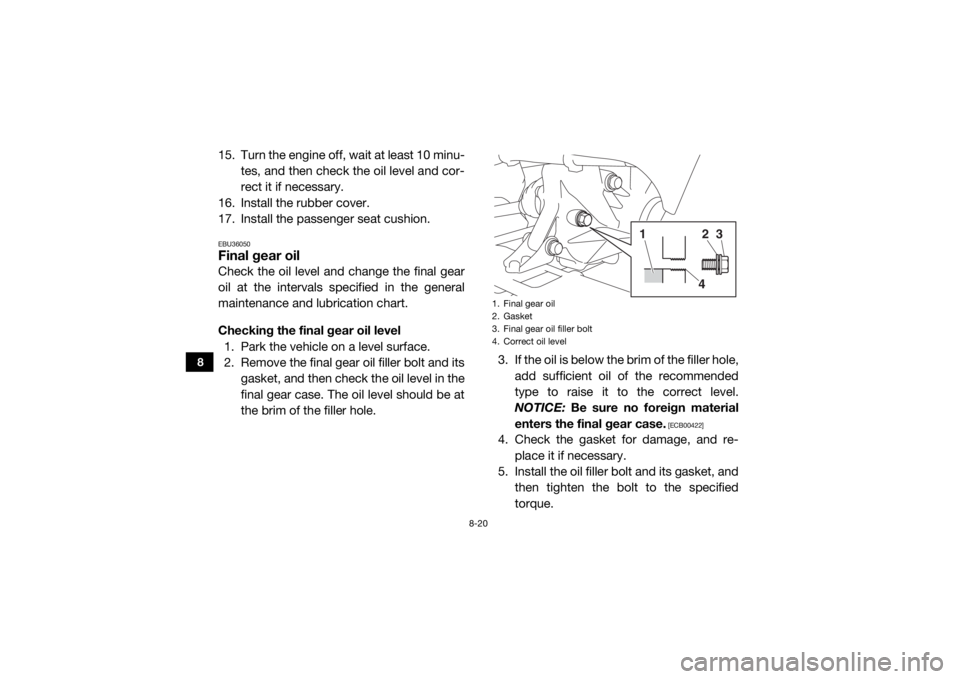

Checking the final gear oil level 1. Park the vehicle on a level surface.

2. Remove the final gear oil filler bolt and its gasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole. 3. If the oil is below the brim of the filler hole,

add sufficient oil of the recommended

type to raise it to the correct level.

NOTICE: Be sure no foreign material

enters the final gear case.

[ECB00422]

4. Check the gasket for damage, and re- place it if necessary.

5. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque.1. Final gear oil

2. Gasket

3. Final gear oil filler bolt

4. Correct oil level

24

3

1

U2MB7BE0.book Page 20 Thursday, March 3, 2016 11:46 AM

Page 133 of 186

8-21

8

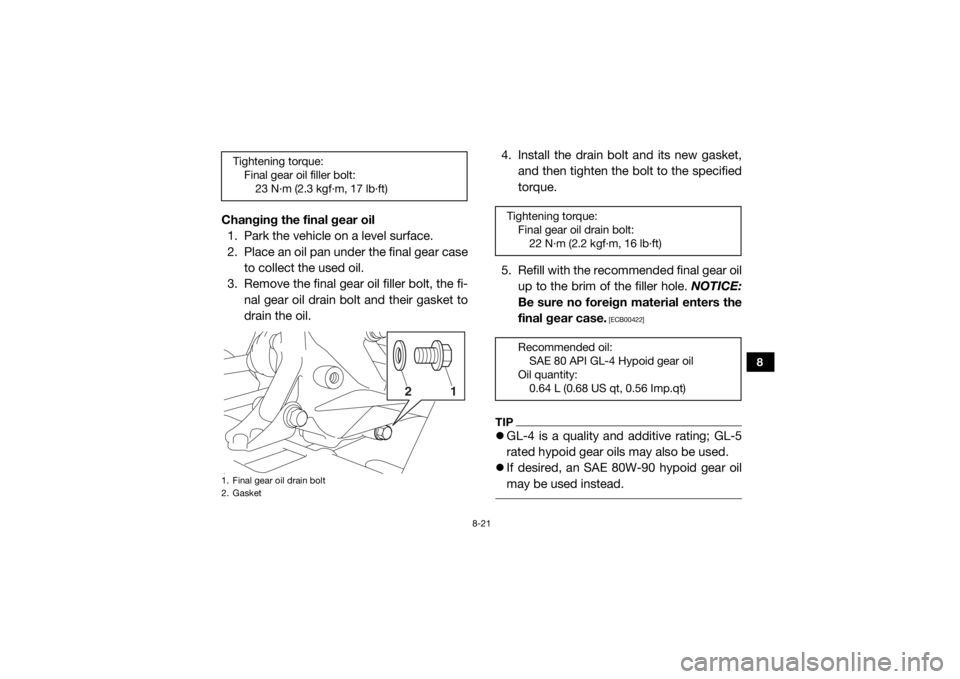

Changing the final gear oil1. Park the vehicle on a level surface.

2. Place an oil pan under the final gear case

to collect the used oil.

3. Remove the final gear oil filler bolt, the fi-

nal gear oil drain bolt and their gasket to

drain the oil. 4. Install the drain bolt and its new gasket,

and then tighten the bolt to the specified

torque.

5. Refill with the recommended final gear oil up to the brim of the filler hole. NOTICE:

Be sure no foreign material enters the

final gear case.

[ECB00422]

TIP GL-4 is a quality and additive rating; GL-5

rated hypoid gear oils may also be used.

If desired, an SAE 80W-90 hypoid gear oil

may be used instead.

Tightening torque:

Final gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)1. Final gear oil drain bolt

2. Gasket

21

Tightening torque: Final gear oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.64 L (0.68 US qt, 0.56 Imp.qt)

U2MB7BE0.book Page 21 Thursday, March 3, 2016 11:46 AM

Page 134 of 186

8-22

8

6. Check the oil filler bolt gasket for dam-age, and replace it if necessary.

7. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque.

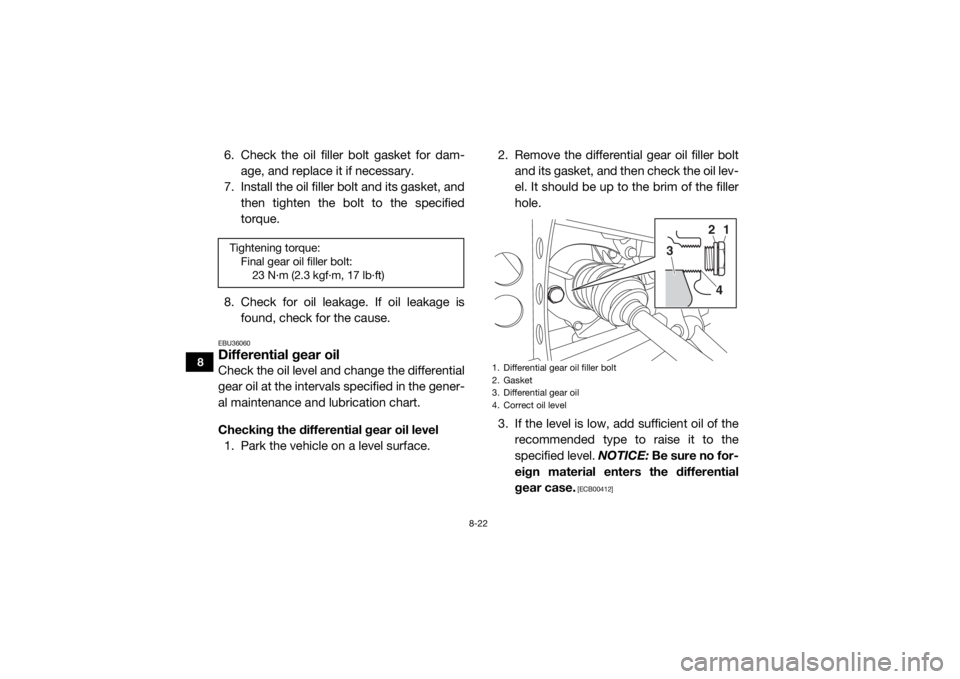

8. Check for oil leakage. If oil leakage is found, check for the cause.EBU36060Differential gear oilCheck the oil level and change the differential

gear oil at the intervals specified in the gener-

al maintenance and lubrication chart.

Checking the differential gear oil level

1. Park the vehicle on a level surface. 2. Remove the differential gear oil filler bolt

and its gasket, and then check the oil lev-

el. It should be up to the brim of the filler

hole.

3. If the level is low, add sufficient oil of the recommended type to raise it to the

specified level. NOTICE: Be sure no for-

eign material enters the differential

gear case.

[ECB00412]

Tightening torque: Final gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil level

1

2

3

4

U2MB7BE0.book Page 22 Thursday, March 3, 2016 11:46 AM

Page 135 of 186

8-23

8

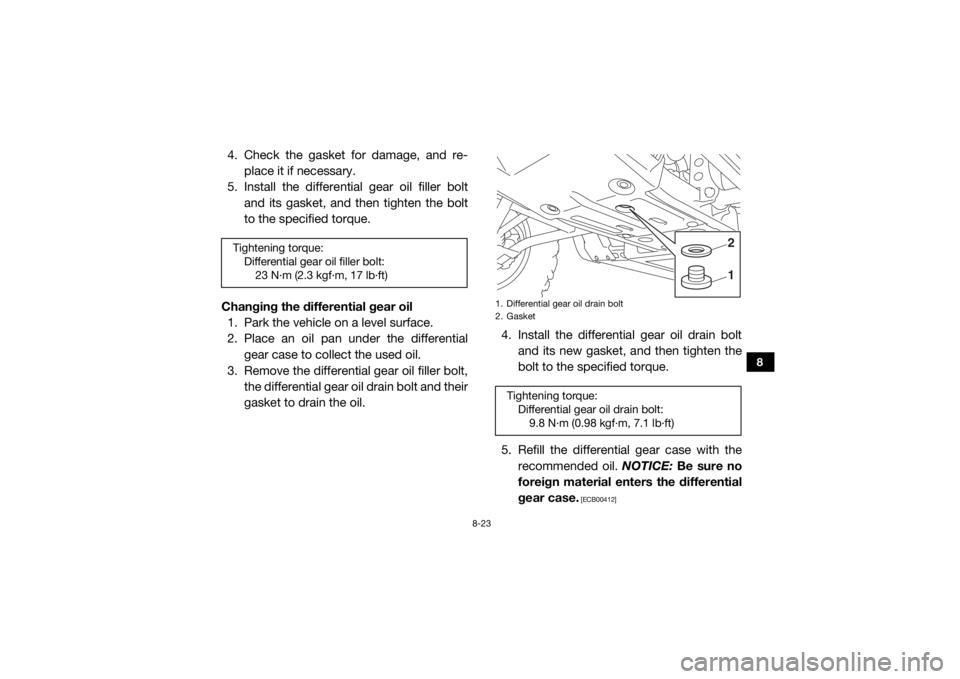

4. Check the gasket for damage, and re-place it if necessary.

5. Install the differential gear oil filler bolt and its gasket, and then tighten the bolt

to the specified torque.

Changing the differential gear oil 1. Park the vehicle on a level surface.

2. Place an oil pan under the differential gear case to collect the used oil.

3. Remove the differential gear oil filler bolt, the differential gear oil drain bolt and their

gasket to drain the oil. 4. Install the differential gear oil drain bolt

and its new gasket, and then tighten the

bolt to the specified torque.

5. Refill the differential gear case with the recommended oil. NOTICE: Be sure no

foreign material enters the differential

gear case.

[ECB00412]

Tightening torque: Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

1. Differential gear oil drain bolt

2. GasketTightening torque: Differential gear oil drain bolt:9.8 N·m (0.98 kgf·m, 7.1 lb·ft)

12

U2MB7BE0.book Page 23 Thursday, March 3, 2016 11:46 AM

Page 136 of 186

8-24

8

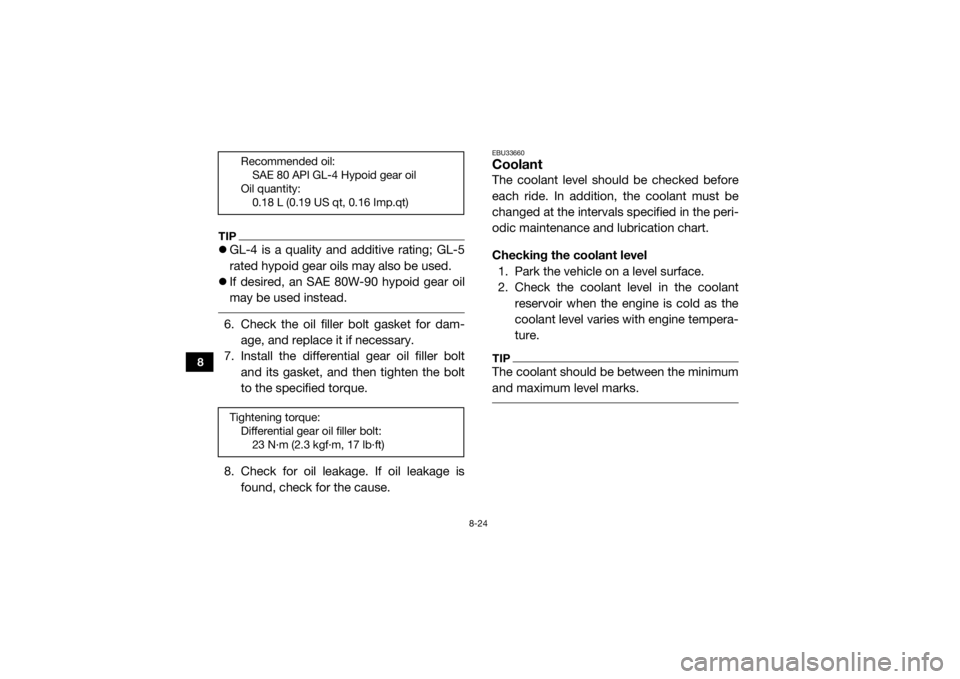

TIPGL-4 is a quality and additive rating; GL-5

rated hypoid gear oils may also be used.

If desired, an SAE 80W -90 hypoid gear oil

may be used instead. 6. Check the oil filler bolt gasket for dam-

age, and replace it if necessary.

7. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.

EBU33660CoolantThe coolant level should be checked before

each ride. In addition, the coolant must be

changed at the intervals specified in the peri-

odic maintenance and lubrication chart.

Checking the coolant level1. Park the vehicle on a level surface.

2. Check the coolant level in the coolant reservoir when the engine is cold as the

coolant level varies with engine tempera-

ture.TIPThe coolant should be between the minimum

and maximum level marks.

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

Tightening torque: Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

U2MB7BE0.book Page 24 Thursday, March 3, 2016 11:46 AM

Page 137 of 186

8-25

8

3. If the coolant is at or below the minimumlevel mark, remove the coolant reservoir

cap, add coolant to the maximum level

mark, and install the reservoir cap. Changing the coolant

WARNING

EWB01891Wait for the engine and radiator to cool be-

fore removing the radiator cap. You could

be burned by hot fluid and steam blown

out under pressure. Always place a thick

rag over the cap when opening. Allow any

remaining pressure to escape before com-

pletely removing the cap. 1. Park the vehicle on a level surface.

2. Remove the hood. (See page 8-10 for

hood removal and installation proce-

dures.)

3. Place a container under the engine to col- lect the used coolant.

4. Remove the radiator cap.

1. Coolant reservoir cap

2. Maximum level mark

3. Minimum level markCoolant reservoir capacity (up to the maxi-

mum level mark): 0.28 L (0.30 US qt, 0.25 Imp.qt)

123

U2MB7BE0.book Page 25 Thursday, March 3, 2016 11:46 AM

Page 138 of 186

8-26

8

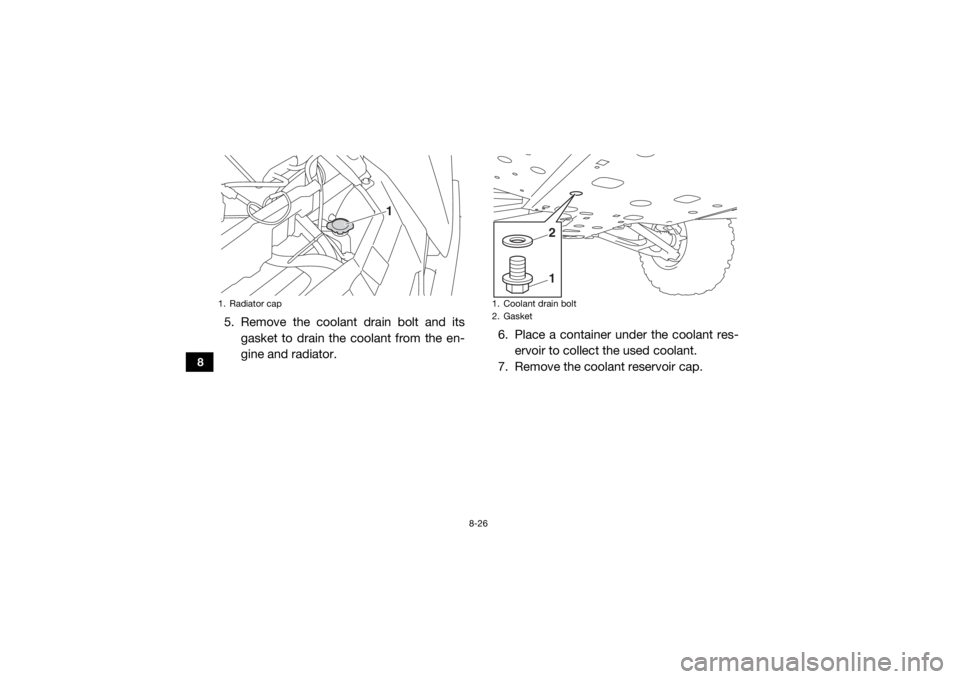

5. Remove the coolant drain bolt and itsgasket to drain the coolant from the en-

gine and radiator. 6. Place a container under the coolant res-

ervoir to collect the used coolant.

7. Remove the coolant reservoir cap.1. Radiator cap

1

1. Coolant drain bolt

2. Gasket

1 2

U2MB7BE0.book Page 26 Thursday, March 3, 2016 11:46 AM

Page 139 of 186

8-27

8

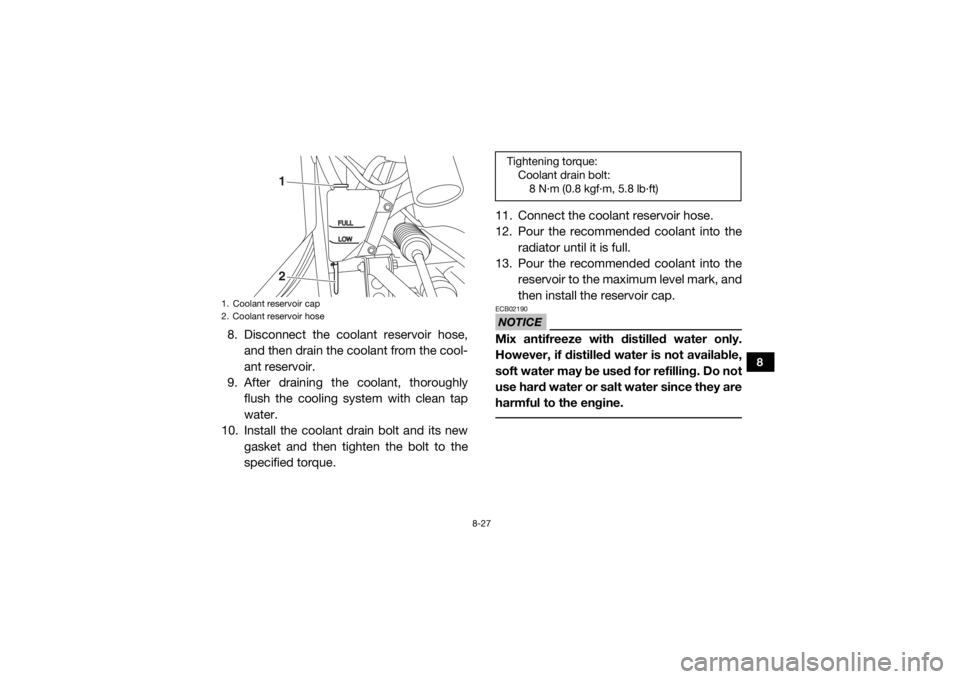

8. Disconnect the coolant reservoir hose,and then drain the coolant from the cool-

ant reservoir.

9. After draining the coolant, thoroughly flush the cooling system with clean tap

water.

10. Install the coolant drain bolt and its new gasket and then tighten the bolt to the

specified torque. 11. Connect the coolant reservoir hose.

12. Pour the recommended coolant into the

radiator until it is full.

13. Pour the recommended coolant into the

reservoir to the maximum level mark, and

then install the reservoir cap.

NOTICEECB02190Mix antifreeze with distilled water only.

However, if distilled water is not available,

soft water may be used for refilling. Do not

use hard water or salt water since they are

harmful to the engine.

1. Coolant reservoir cap

2. Coolant reservoir hose

12

Tightening torque:Coolant drain bolt:8 N·m (0.8 kgf·m, 5.8 lb·ft)

U2MB7BE0.book Page 27 Thursday, March 3, 2016 11:46 AM

Page 140 of 186

8-28

8

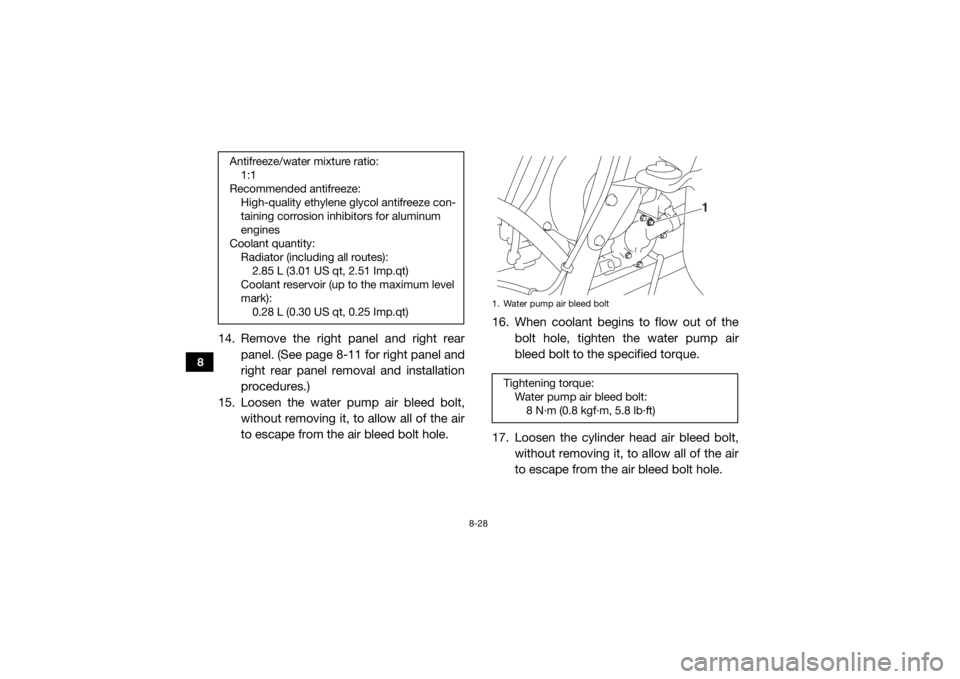

14. Remove the right panel and right rearpanel. (See page 8-11 for right panel and

right rear panel removal and installation

procedures.)

15. Loosen the water pump air bleed bolt, without removing it, to allow all of the air

to escape from the air bleed bolt hole. 16. When coolant begins to flow out of the

bolt hole, tighten the water pump air

bleed bolt to the specified torque.

17. Loosen the cylinder head air bleed bolt, without removing it, to allow all of the air

to escape from the air bleed bolt hole.Antifreeze/water mixture ratio:1:1

Recommended antifreeze: High-quality ethylene glycol antifreeze con-

taining corrosion inhibitors for aluminum

engines

Coolant quantity: Radiator (including all routes):2.85 L (3.01 US qt, 2.51 Imp.qt)

Coolant reservoir (up to the maximum level

mark): 0.28 L (0.30 US qt, 0.25 Imp.qt)

1. Water pump air bleed boltTightening torque:Water pump air bleed bolt:8 N·m (0.8 kgf·m, 5.8 lb·ft)

1

U2MB7BE0.book Page 28 Thursday, March 3, 2016 11:46 AM