YAMAHA WOLVERINE 2017 Owners Manual

Manufacturer: YAMAHA, Model Year: 2017, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2017Pages: 186, PDF Size: 4.22 MB

Page 141 of 186

8-29

8

18. When coolant begins to flow out of thebolt hole, tighten the cylinder head air

bleed bolt to the specified torque.

19. Start the engine and let it idle for ten mi- nutes.

20. Rev the engine five times.

21. Pour additional coolant into the radiator until it is full. 22. Stop the engine and allow it to cool. If the

coolant level has dropped after the en-

gine has cooled, add sufficient coolant

until it reaches the top of the radiator, and

then install the radiator cap.

23. Check the coolant level in the reservoir. If necessary, remove the coolant reservoir

cap, add coolant to the maximum level

mark, and then install the cap.

24. Start the engine, and then check for cool- ant leakage.

TIPIf any leakage is found, have a Yamaha dealer

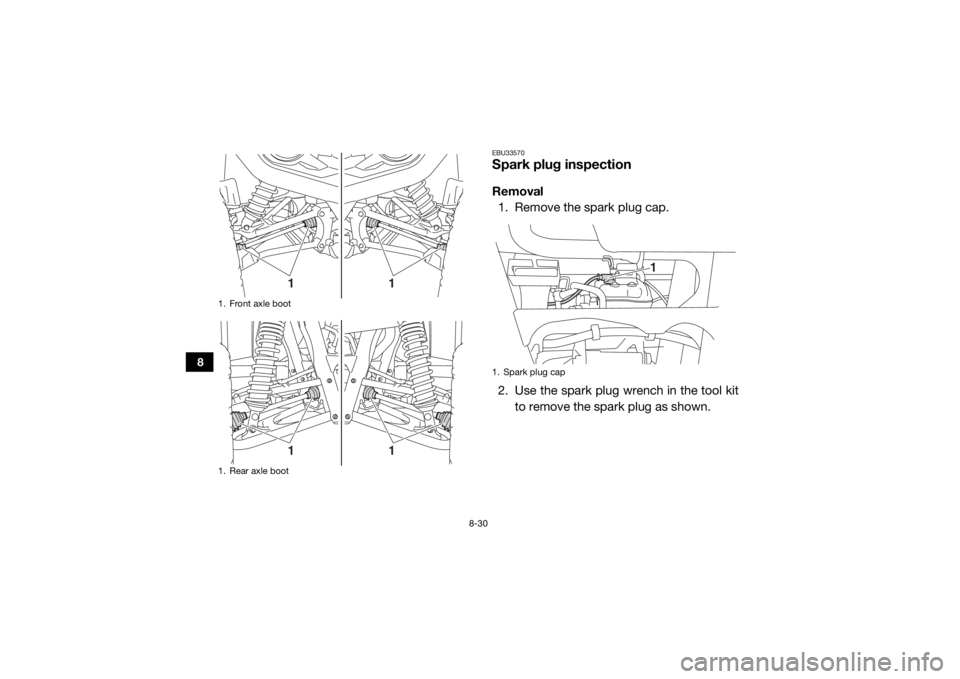

check the cooling system. 25. Install the panels and the hood.EBU32400Axle bootsCheck the axle boots for holes or tears.

If any damage is found, have them replaced

by a Yamaha dealer.

1. Cylinder head air bleed boltTightening torque:Cylinder head air bleed bolt:10 N·m (1.0 kgf·m, 7.2 lb·ft)

1

U2MB7BE0.book Page 29 Thursday, March 3, 2016 11:46 AM

Page 142 of 186

8-30

8

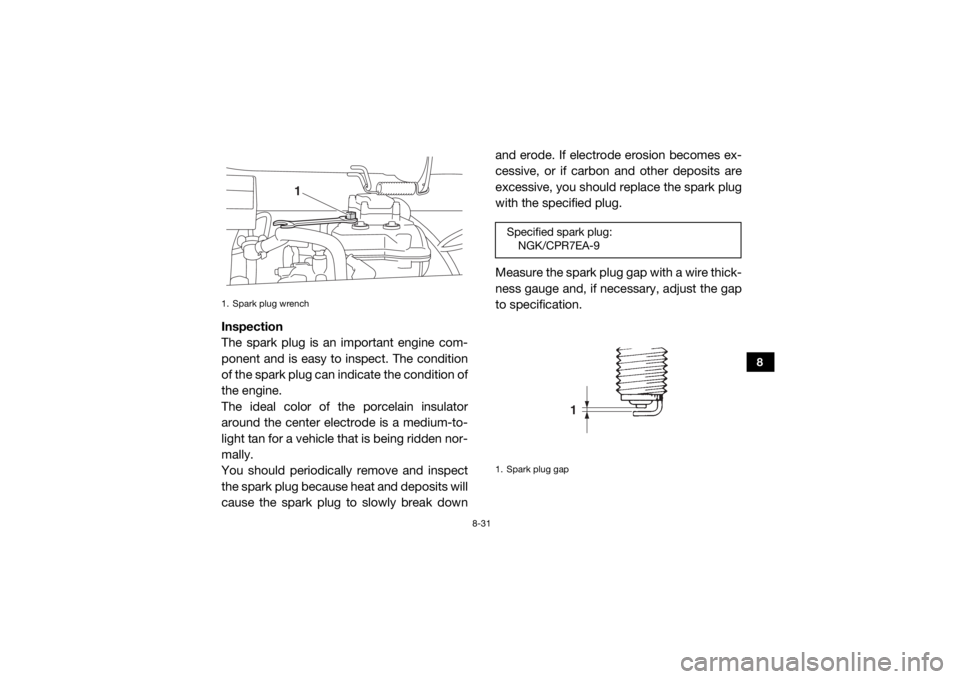

EBU33570Spark plug inspectionRemoval1. Remove the spark plug cap.

2. Use the spark plug wrench in the tool kit to remove the spark plug as shown.

1. Front axle boot

1. Rear axle boot

1

1

1

1

1. Spark plug cap

1

U2MB7BE0.book Page 30 Thursday, March 3, 2016 11:46 AM

Page 143 of 186

8-31

8

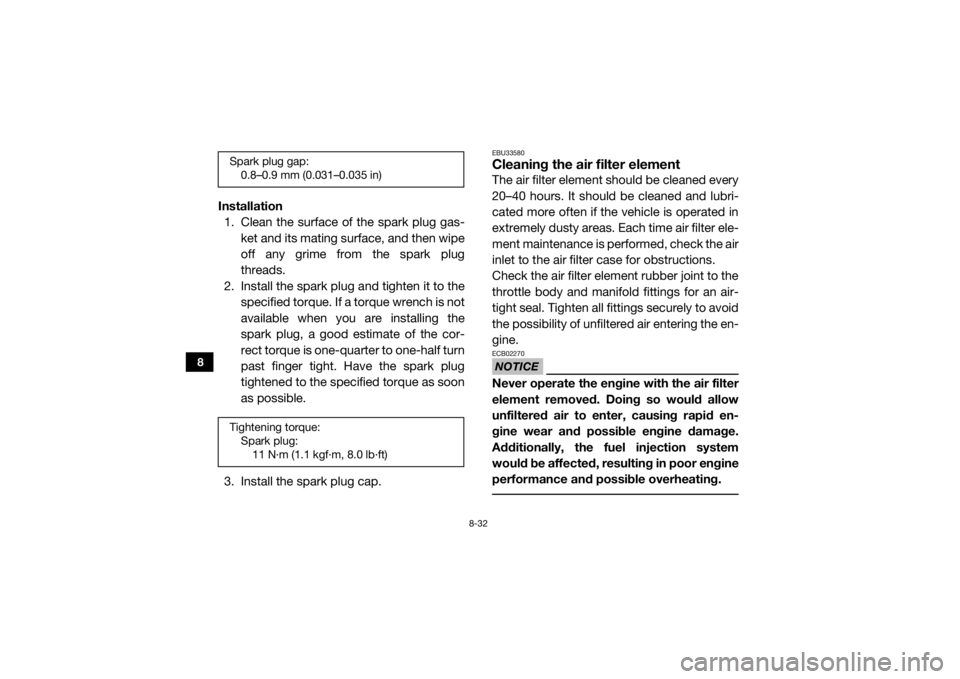

Inspection

The spark plug is an important engine com-

ponent and is easy to inspect. The condition

of the spark plug can indicate the condition of

the engine.

The ideal color of the porcelain insulator

around the center electrode is a medium-to-

light tan for a vehicle that is being ridden nor-

mally.

You should periodically remove and inspect

the spark plug because heat and deposits will

cause the spark plug to slowly break downand erode. If electrode erosion becomes ex-

cessive, or if carbon and other deposits are

excessive, you should replace the spark plug

with the specified plug.

Measure the spark plug gap with a wire thick-

ness gauge and, if necessary, adjust the gap

to specification.1. Spark plug wrench

1

Specified spark plug:

NGK/CPR7EA-91. Spark plug gap

1

U2MB7BE0.book Page 31 Thursday, March 3, 2016 11:46 AM

Page 144 of 186

8-32

8

Installation1. Clean the surface of the spark plug gas-

ket and its mating surface, and then wipe

off any grime from the spark plug

threads.

2. Install the spark plug and tighten it to the specified torque. If a torque wrench is not

available when you are installing the

spark plug, a good estimate of the cor-

rect torque is one-quarter to one-half turn

past finger tight. Have the spark plug

tightened to the specified torque as soon

as possible.

3. Install the spark plug cap.

EBU33580Cleaning the air filter elementThe air filter element should be cleaned every

20–40 hours. It should be cleaned and lubri-

cated more often if the vehicle is operated in

extremely dusty areas. Each time air filter ele-

ment maintenance is performed, check the air

inlet to the air filter case for obstructions.

Check the air filter element rubber joint to the

throttle body and manifold fittings for an air-

tight seal. Tighten all fittings securely to avoid

the possibility of unfiltered air entering the en-

gine.NOTICEECB02270Never operate the engine with the air filter

element removed. Doing so would allow

unfiltered air to enter, causing rapid en-

gine wear and possible engine damage.

Additionally, the fuel injection system

would be affected, resulting in poor engine

performance and possible overheating.

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)

Tightening torque: Spark plug:11 N·m (1.1 kgf·m, 8.0 lb·ft)

U2MB7BE0.book Page 32 Thursday, March 3, 2016 11:46 AM

Page 145 of 186

8-33

8

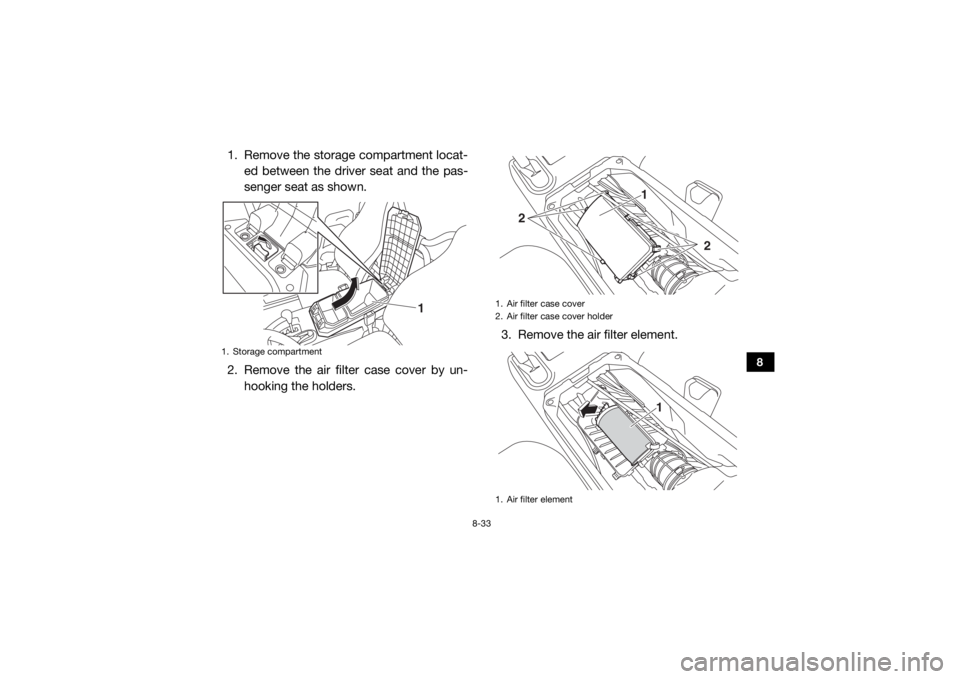

1. Remove the storage compartment locat-ed between the driver seat and the pas-

senger seat as shown.

2. Remove the air filter case cover by un- hooking the holders. 3. Remove the air filter element.1. Storage compartment

1

1. Air filter case cover

2. Air filter case cover holder

1. Air filter element

1

2

2

1

U2MB7BE0.book Page 33 Thursday, March 3, 2016 11:46 AM

Page 146 of 186

8-34

8

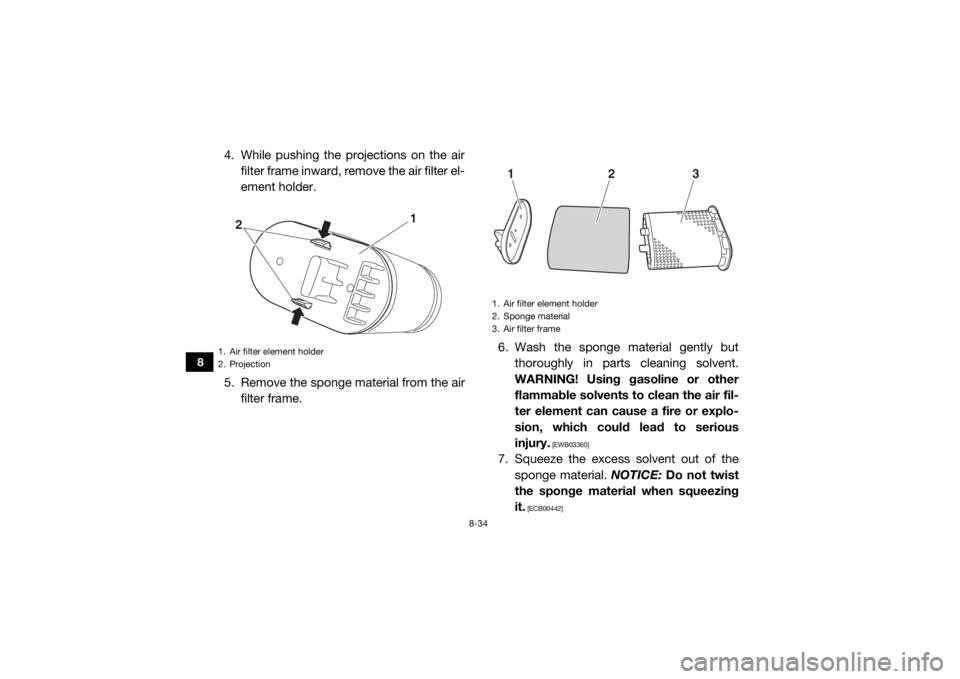

4. While pushing the projections on the airfilter frame inward, remove the air filter el-

ement holder.

5. Remove the sponge material from the air filter frame. 6. Wash the sponge material gently but

thoroughly in parts cleaning solvent.

WARNING! Using gasoline or other

flammable solvents to clean the air fil-

ter element can cause a fire or explo-

sion, which could lead to serious

injury.

[EWB03360]

7. Squeeze the excess solvent out of thesponge material. NOTICE: Do not twist

the sponge material when squeezing

it.

[ECB00442]

1. Air filter element holder

2. Projection

1

2

1. Air filter element holder

2. Sponge material

3. Air filter frame

3

2

1

U2MB7BE0.book Page 34 Thursday, March 3, 2016 11:46 AM

Page 147 of 186

8-35

8

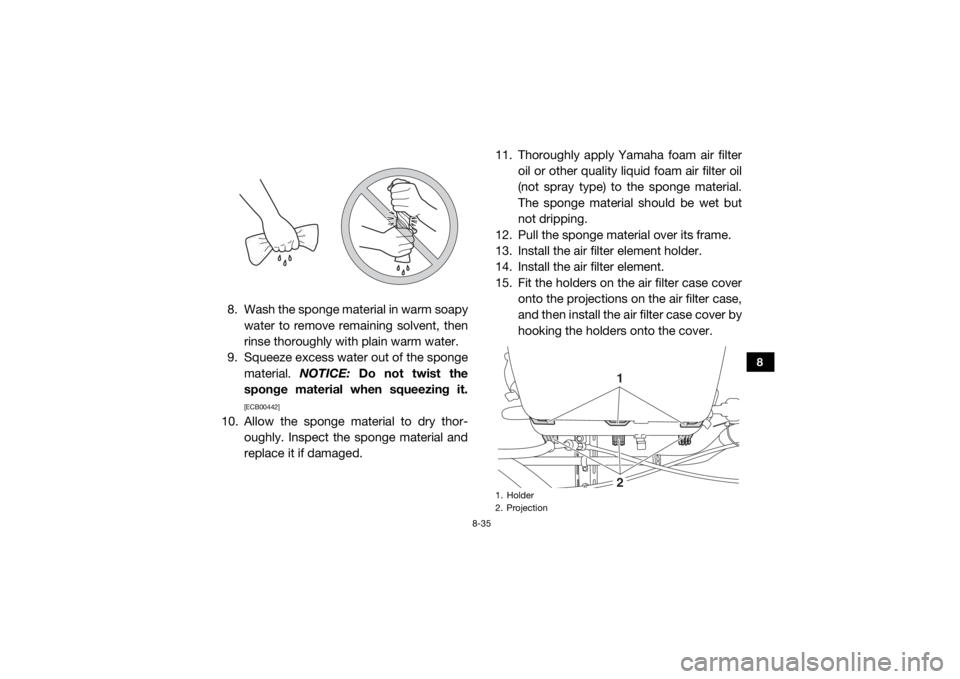

8. Wash the sponge material in warm soapywater to remove remaining solvent, then

rinse thoroughly with plain warm water.

9. Squeeze excess water out of the sponge

material. NOTICE: Do not twist the

sponge material when squeezing it.

[ECB00442]

10. Allow the sponge material to dry thor- oughly. Inspect the sponge material and

replace it if damaged. 11. Thoroughly apply Yamaha foam air filter

oil or other quality liquid foam air filter oil

(not spray type) to the sponge material.

The sponge material should be wet but

not dripping.

12. Pull the sponge material over its frame.

13. Install the air filter element holder.

14. Install the air filter element.

15. Fit the holders on the air filter case cover onto the projections on the air filter case,

and then install the air filter case cover by

hooking the holders onto the cover.

1. Holder

2. Projection

1

2

U2MB7BE0.book Page 35 Thursday, March 3, 2016 11:46 AM

Page 148 of 186

8-36

8

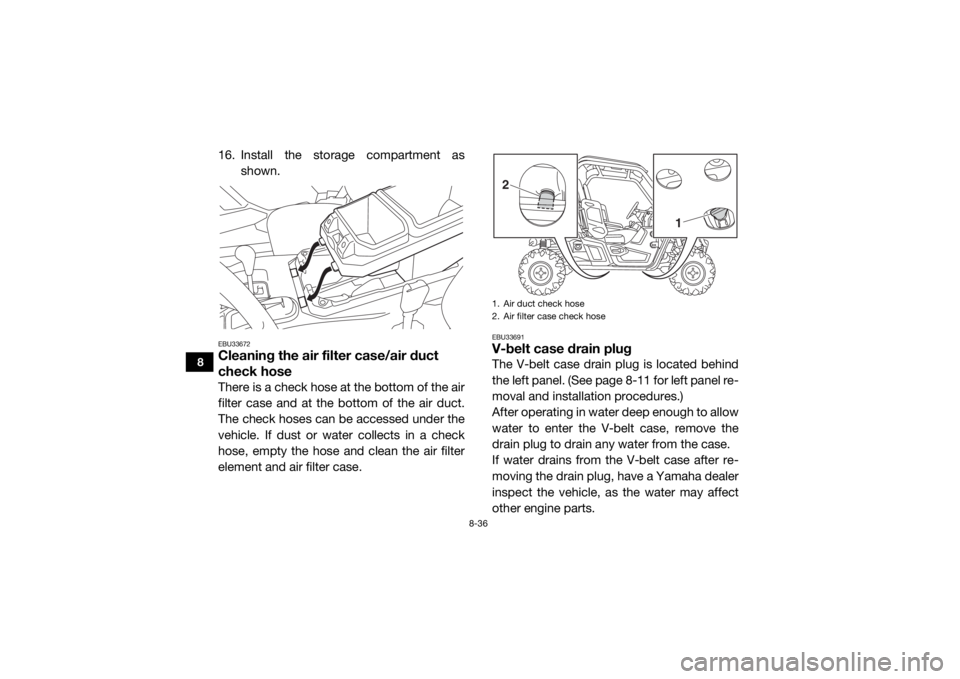

16. Install the storage compartment asshown.EBU33672Cleaning the air filter case/air duct

check hoseThere is a check hose at the bottom of the air

filter case and at the bottom of the air duct.

The check hoses can be accessed under the

vehicle. If dust or water collects in a check

hose, empty the hose and clean the air filter

element and air filter case.

EBU33691V-belt case drain plugThe V-belt case drain plug is located behind

the left panel. (See page 8-11 for left panel re-

moval and installation procedures.)

After operating in water deep enough to allow

water to enter the V-belt case, remove the

drain plug to drain any water from the case.

If water drains from the V-belt case after re-

moving the drai n plug, have a Yamaha dealer

inspect the vehicle, as the water may affect

other engine parts.1. Air duct check hose

2. Air filter case check hose2

1

U2MB7BE0.book Page 36 Thursday, March 3, 2016 11:46 AM

Page 149 of 186

8-37

8

EBU32450Cleaning the spark arrester

WARNING

EWB03370Hot exhaust system may cause burns. To

avoid burns or fires, make sure that the en-

gine is stopped and the exhaust system is

cool before cleaning the spark arrester. Do

not start the engine while cleaning the ex-

haust system. 1. Remove the tailpipe bolts.2. Remove the tailpipe by pulling it out of

the muffler, and then remove the gasket.

3. Tap the tailpipe lightly, and then use a

wire brush to remove any carbon depos-

its from the spark arrester portion of the

tailpipe and inside of the tailpipe housing.1. V-belt case drain plug

1

1. Tailpipe bolt

1

1

U2MB7BE0.book Page 37 Thursday, March 3, 2016 11:46 AM

Page 150 of 186

8-38

8

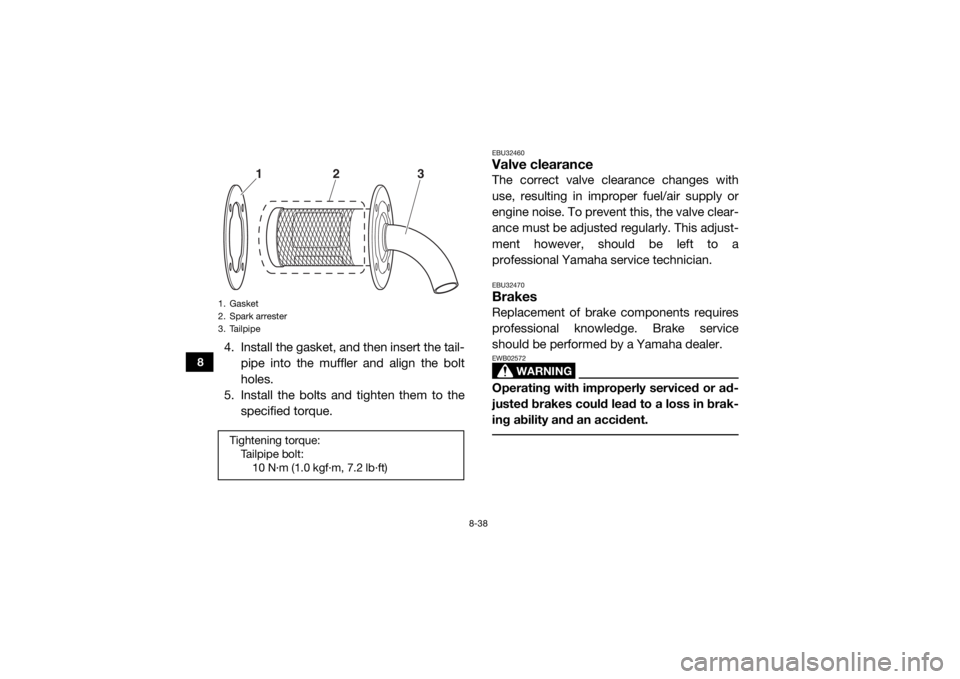

4. Install the gasket, and then insert the tail-pipe into the muffler and align the bolt

holes.

5. Install the bolts and tighten them to the

specified torque.

EBU32460Valve clearanceThe correct valve clearance changes with

use, resulting in improper fuel/air supply or

engine noise. To prevent this, the valve clear-

ance must be adjusted regularly. This adjust-

ment however, should be left to a

professional Yamaha service technician.EBU32470BrakesReplacement of brake components requires

professional knowledge. Brake service

should be performed by a Yamaha dealer.

WARNING

EWB02572Operating with improperly serviced or ad-

justed brakes could lead to a loss in brak-

ing ability and an accident.

1. Gasket

2. Spark arrester

3. TailpipeTightening torque:Tailpipe bolt:10 N·m (1.0 kgf·m, 7.2 lb·ft)

3

2

1

U2MB7BE0.book Page 38 Thursday, March 3, 2016 11:46 AM