light YAMAHA WR 250F 2007 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 250F, Model: YAMAHA WR 250F 2007Pages: 912, PDF Size: 23.95 MB

Page 109 of 912

MAINTENANCE SPECIFICATIONS

2 - 16

SPEC

NOTE:

- marked portion shall be checked for torque tightening after break-in. Speed sensor lead holder and lower bracket M6 × 1.0 1 13 1.3 9.4

Headlight body and headlight unit—210.10.7

Headlight (left and right) M6 × 1.0 2 7 0.7 5.1

Taillight—310.10.7

Taillight lead clamp and rear fender—3 0.5 0.05 0.36

Catch tank (upper) M6 × 1.0 1 16 1.6 11

Catch tank (lower) M6 × 1.0 1 7 0.7 5.1

Footrest bracket and frame M10 × 1.25 4 55 5.5 40

Sidestand M10 × 1.25 1 25 2.5 18 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Page 110 of 912

MAINTENANCE SPECIFICATIONS

2 - 17

SPEC

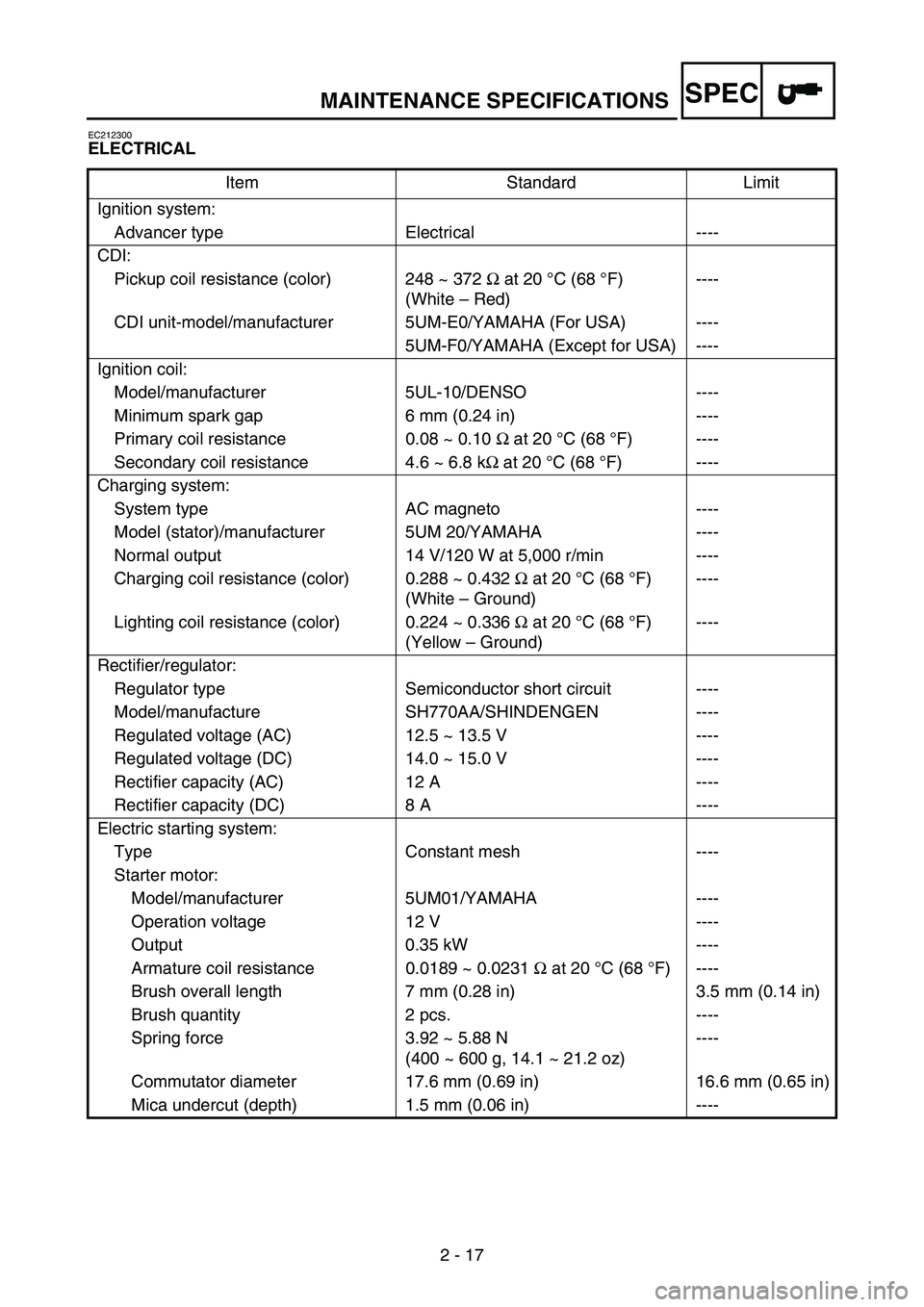

EC212300

ELECTRICAL

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI:

Pickup coil resistance (color) 248 ~ 372 Ω at 20°C (68 °F)

(White – Red)----

CDI unit-model/manufacturer 5UM-E0/YAMAHA (For USA) ----

5UM-F0/YAMAHA (Except for USA) ----

Ignition coil:

Model/manufacturer 5UL-10/DENSO ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.08 ~ 0.10 Ω at 20 °C (68 °F) ----

Secondary coil resistance 4.6 ~ 6.8 kΩ at 20 °C (68 °F) ----

Charging system:

System type AC magneto ----

Model (stator)/manufacturer 5UM 20/YAMAHA ----

Normal output 14 V/120 W at 5,000 r/min ----

Charging coil resistance (color) 0.288 ~ 0.432 Ω at 20 °C (68 °F)

(White – Ground)----

Lighting coil resistance (color) 0.224 ~ 0.336 Ω at 20 °C (68 °F)

(Yellow – Ground)----

Rectifier/regulator:

Regulator type Semiconductor short circuit ----

Model/manufacture SH770AA/SHINDENGEN ----

Regulated voltage (AC) 12.5 ~ 13.5 V ----

Regulated voltage (DC) 14.0 ~ 15.0 V ----

Rectifier capacity (AC) 12 A ----

Rectifier capacity (DC) 8 A ----

Electric starting system:

Type Constant mesh ----

Starter motor:

Model/manufacturer 5UM01/YAMAHA ----

Operation voltage 12 V ----

Output 0.35 kW ----

Armature coil resistance 0.0189 ~ 0.0231 Ω at 20 °C (68 °F) ----

Brush overall length 7 mm (0.28 in) 3.5 mm (0.14 in)

Brush quantity 2 pcs. ----

Spring force 3.92 ~ 5.88 N

(400 ~ 600 g, 14.1 ~ 21.2 oz)----

Commutator diameter 17.6 mm (0.69 in) 16.6 mm (0.65 in)

Mica undercut (depth) 1.5 mm (0.06 in) ----

Page 198 of 912

2 - 105

SPECCABLE ROUTING DIAGRAM

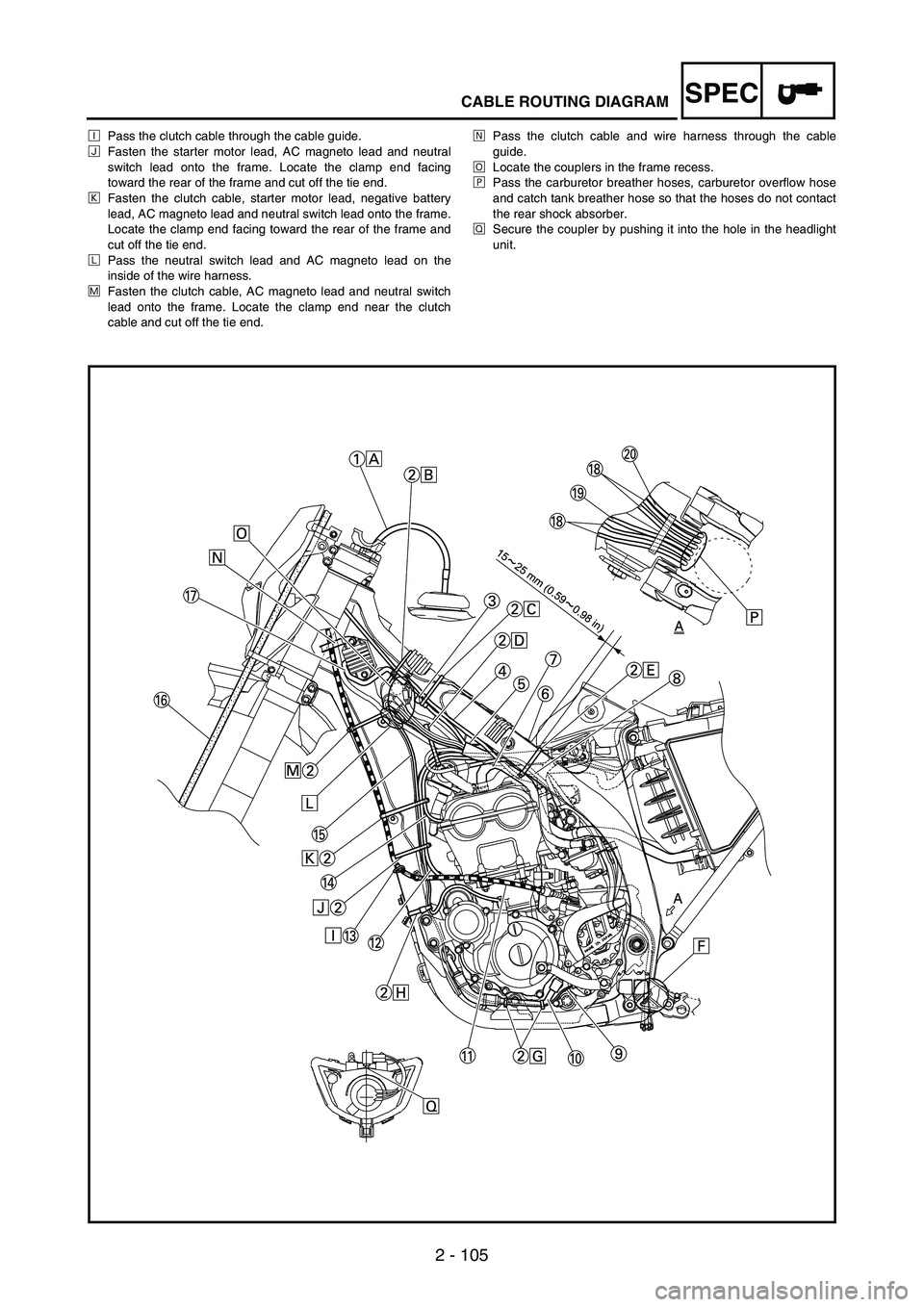

ÐPass the clutch cable through the cable guide.

ÑFasten the starter motor lead, AC magneto lead and neutral

switch lead onto the frame. Locate the clamp end facing

toward the rear of the frame and cut off the tie end.

ÒFasten the clutch cable, starter motor lead, negative battery

lead, AC magneto lead and neutral switch lead onto the frame.

Locate the clamp end facing toward the rear of the frame and

cut off the tie end.

ÓPass the neutral switch lead and AC magneto lead on the

inside of the wire harness.

ÔFasten the clutch cable, AC magneto lead and neutral switch

lead onto the frame. Locate the clamp end near the clutch

cable and cut off the tie end.ÕPass the clutch cable and wire harness through the cable

guide.

ÖLocate the couplers in the frame recess.

×Pass the carburetor breather hoses, carburetor overflow hose

and catch tank breather hose so that the hoses do not contact

the rear shock absorber.

ØSecure the coupler by pushing it into the hole in the headlight

unit.

Page 202 of 912

SPEC

2 - 109

CABLE ROUTING DIAGRAM

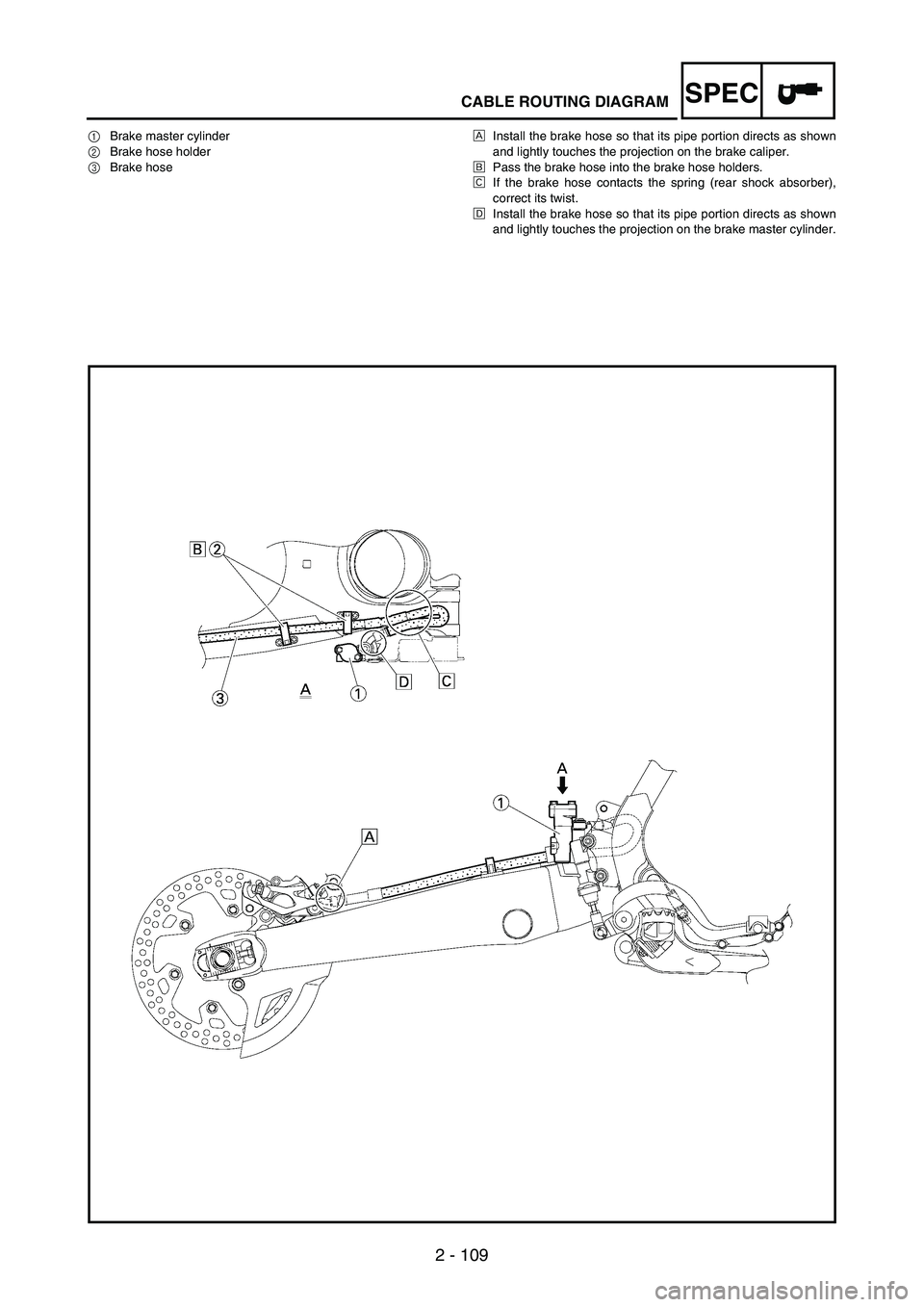

1Brake master cylinder

2Brake hose holder

3Brake hoseÈInstall the brake hose so that its pipe portion directs as shown

and lightly touches the projection on the brake caliper.

ÉPass the brake hose into the brake hose holders.

ÊIf the brake hose contacts the spring (rear shock absorber),

correct its twist.

ËInstall the brake hose so that its pipe portion directs as shown

and lightly touches the projection on the brake master cylinder.

Page 204 of 912

SPEC

2 - 111

CABLE ROUTING DIAGRAM

1Clamp

2Positive battery lead

3Battery

4Negative battery lead

5Taillight coupler

6CDI unit coupler (6-pin)

7CDI unit coupler (3-pin)

8CDI unit coupler (6-pin)ÈFasten the wire harness, negative battery lead and starter

motor lead to the upper engine bracket (left side). Locate the

clamp end facing toward the upper side of the frame with the

tie end cut off on the inside of the frame.

ÉFasten the wire harness, negative battery lead and starter

motor lead to the upper engine bracket (left side). Locate the

clamp end facing toward the upper side of the frame with the

tie end cut off on the inside of the frame. Clamp the wire har-

ness and negative lead at the marking.

ÊPass the starter motor lead through the hole in the relay

holder.

ËFit the cover securely.

ÌConnect the wire harness to the starter relay.

Page 206 of 912

SPEC

2 - 113

CABLE ROUTING DIAGRAM

ÍFasten the catch tank breather hose

and catch tank hose to the rear frame.

Clamp them close to where they are

joined to the frame. Fasten the pipe

tightly enough not to crush it. Locate the

clamp end facing toward the rear of the

frame with the tie end facing downward.

ÎFasten the (three) CDI unit leads and

taillight lead to the rear frame. Locate

the clamp end facing toward the upper

side of the frame and cut off the tie end.

ÏConnect the negative battery lead to

the battery negative terminal.

ÐConnect the negative battery lead to

the wire harness.ÑFasten the wire harness to the rear

frame. Locate the clamp end facing

toward the upper side of the frame and

the tie end toward the inside of the

frame. Clamp the wire harness at the

marking.

ÒPass the wire harness, starter relay

lead, starting circuit cut-off relay lead

and negative battery lead through the

hole in the relay holder.

ÓFasten the (three) CDI unit leads and

taillight lead to the rear frame. Locate

the clamp end facing toward the lower

side of the frame and cut off the tie end.ÔFasten the taillight lead to the rear

frame. Locate the clamp end facing

toward the upper side of the frame and

cut off the time end.

ÕDo not allow the taillight lead to

slacken.

ÖLocate the CDI unit lead between the

CDI unit and rear fender.

×Locate the CDI unit coupler in the clear-

ance between the upper side of the CDI

unit and lower side of the catch tank

stay.

ØLocate the CDI unit lead between the

CDI unit and rear frame.

Page 208 of 912

2 - 115

SPECCABLE ROUTING DIAGRAM

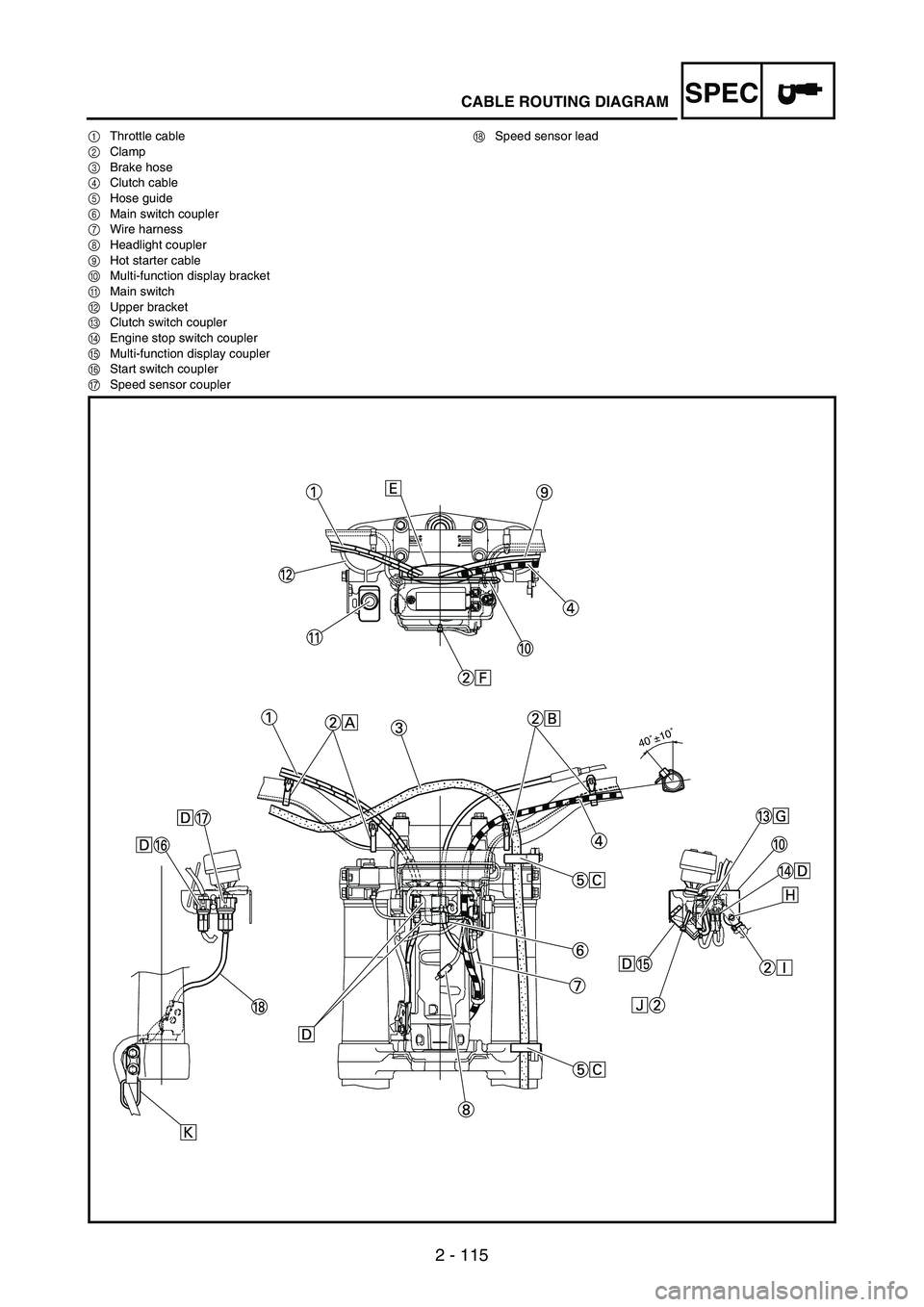

1Throttle cable

2Clamp

3Brake hose

4Clutch cable

5Hose guide

6Main switch coupler

7Wire harness

8Headlight coupler

9Hot starter cable

0Multi-function display bracket

AMain switch

BUpper bracket

CClutch switch coupler

DEngine stop switch coupler

EMulti-function display coupler

FStart switch coupler

GSpeed sensor couplerHSpeed sensor lead

40˚±10˚

Page 232 of 912

INSP

ADJ

3 - 21

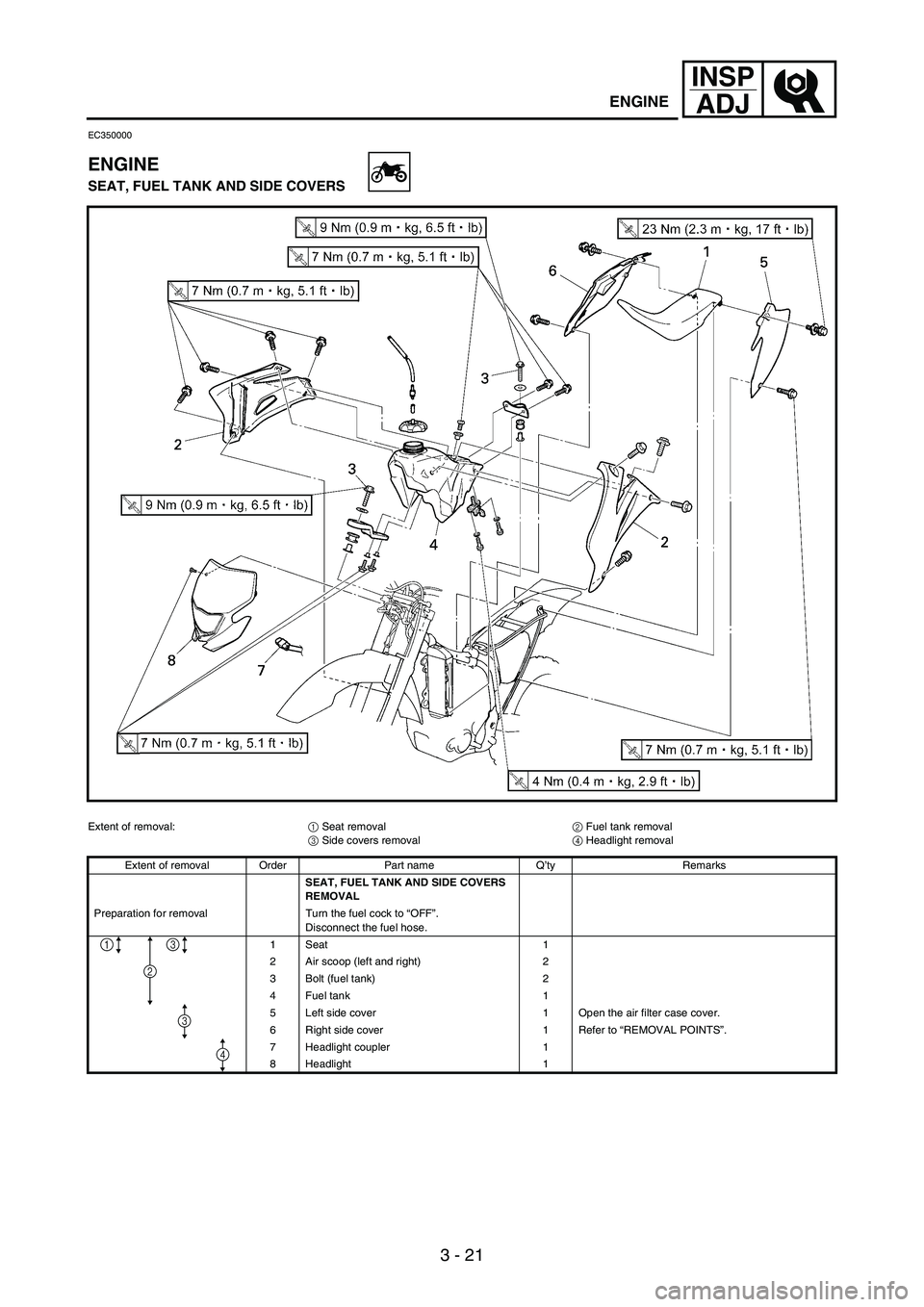

EC350000

ENGINE

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1 Seat removal

2 Fuel tank removal

3 Side covers removal

4 Headlight removal

Extent of removal Order Part name Q’ty Remarks

SEAT, FUEL TANK AND SIDE COVERS

REMOVAL

Preparation for removal Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1Seat 1

2 Air scoop (left and right) 2

3 Bolt (fuel tank) 2

4 Fuel tank 1

5 Left side cover 1 Open the air filter case cover.

6 Right side cover 1 Refer to “REMOVAL POINTS”.

7 Headlight coupler 1

8 Headlight 1

2

13

4

3

ENGINE

Page 270 of 912

3 - 59

INSP

ADJ

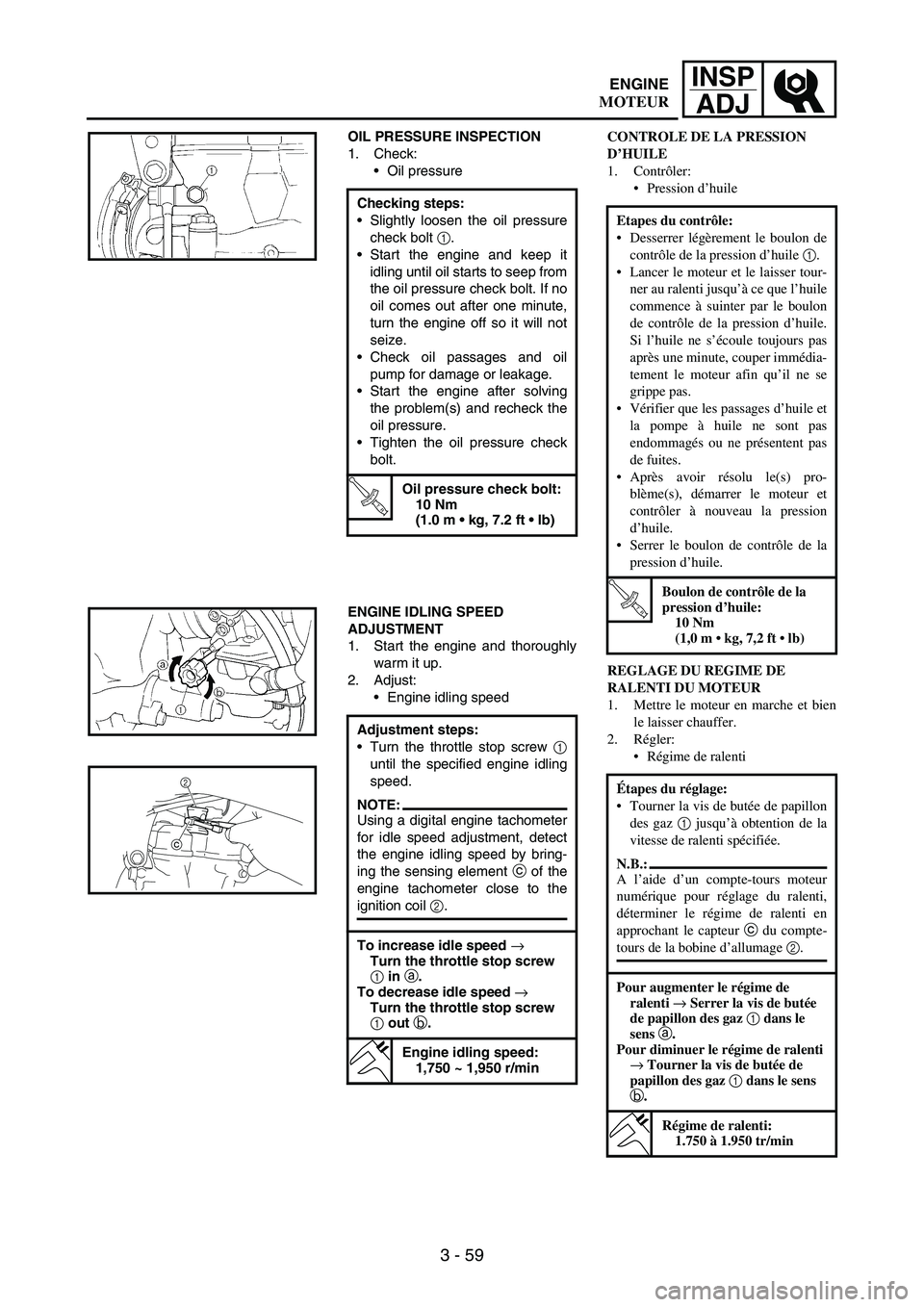

OIL PRESSURE INSPECTION

1. Check:

Oil pressure

Checking steps:

Slightly loosen the oil pressure

check bolt

1.

Start the engine and keep it

idling until oil starts to seep from

the oil pressure check bolt. If no

oil comes out after one minute,

turn the engine off so it will not

seize.

Check oil passages and oil

pump for damage or leakage.

Start the engine after solving

the problem(s) and recheck the

oil pressure.

Tighten the oil pressure check

bolt.

T R..

Oil pressure check bolt:

10 Nm

(1.0 m kg, 7.2 ft lb)

ENGINE IDLING SPEED

ADJUSTMENT

1. Start the engine and thoroughly

warm it up.

2. Adjust:

Engine idling speed

Adjustment steps:

Turn the throttle stop screw

1

until the specified engine idling

speed.

NOTE:Using a digital engine tachometer

for idle speed adjustment, detect

the engine idling speed by bring-

ing the sensing element

c of the

engine tachometer close to the

ignition coil

2.

To increase idle speed →

Turn the throttle stop screw

1 in a.

To decrease idle speed →

Turn the throttle stop screw

1 out b.

Engine idling speed:

1,750 ~ 1,950 r/min

c2

CONTROLE DE LA PRESSION

D’HUILE

1. Contrôler:

Pression d’huile

REGLAGE DU REGIME DE

RALENTI DU MOTEUR

1. Mettre le moteur en marche et bien

le laisser chauffer.

2. Régler:

Régime de ralenti Etapes du contrôle:

Desserrer légèrement le boulon de

contrôle de la pression d’huile 1.

Lancer le moteur et le laisser tour-

ner au ralenti jusqu’à ce que l’huile

commence à suinter par le boulon

de contrôle de la pression d’huile.

Si l’huile ne s’écoule toujours pas

après une minute, couper immédia-

tement le moteur afin qu’il ne se

grippe pas.

Vérifier que les passages d’huile et

la pompe à huile ne sont pas

endommagés ou ne présentent pas

de fuites.

Après avoir résolu le(s) pro-

blème(s), démarrer le moteur et

contrôler à nouveau la pression

d’huile.

Serrer le boulon de contrôle de la

pression d’huile.

T R..

Boulon de contrôle de la

pression d’huile:

10 Nm

(1,0 m kg, 7,2 ft lb)

Étapes du réglage:

Tourner la vis de butée de papillon

des gaz 1 jusqu’à obtention de la

vitesse de ralenti spécifiée.

N.B.:

A l’aide d’un compte-tours moteur

numérique pour réglage du ralenti,

déterminer le régime de ralenti en

approchant le capteur c du compte-

tours de la bobine d’allumage 2.

Pour augmenter le régime de

ralenti → Serrer la vis de butée

de papillon des gaz 1 dans le

sens a.

Pour diminuer le régime de ralenti

→ Tourner la vis de butée de

papillon des gaz 1 dans le sens

b.

Régime de ralenti:

1.750 à 1.950 tr/min

ENGINE

MOTEUR

Page 286 of 912

3 - 75

INSP

ADJ

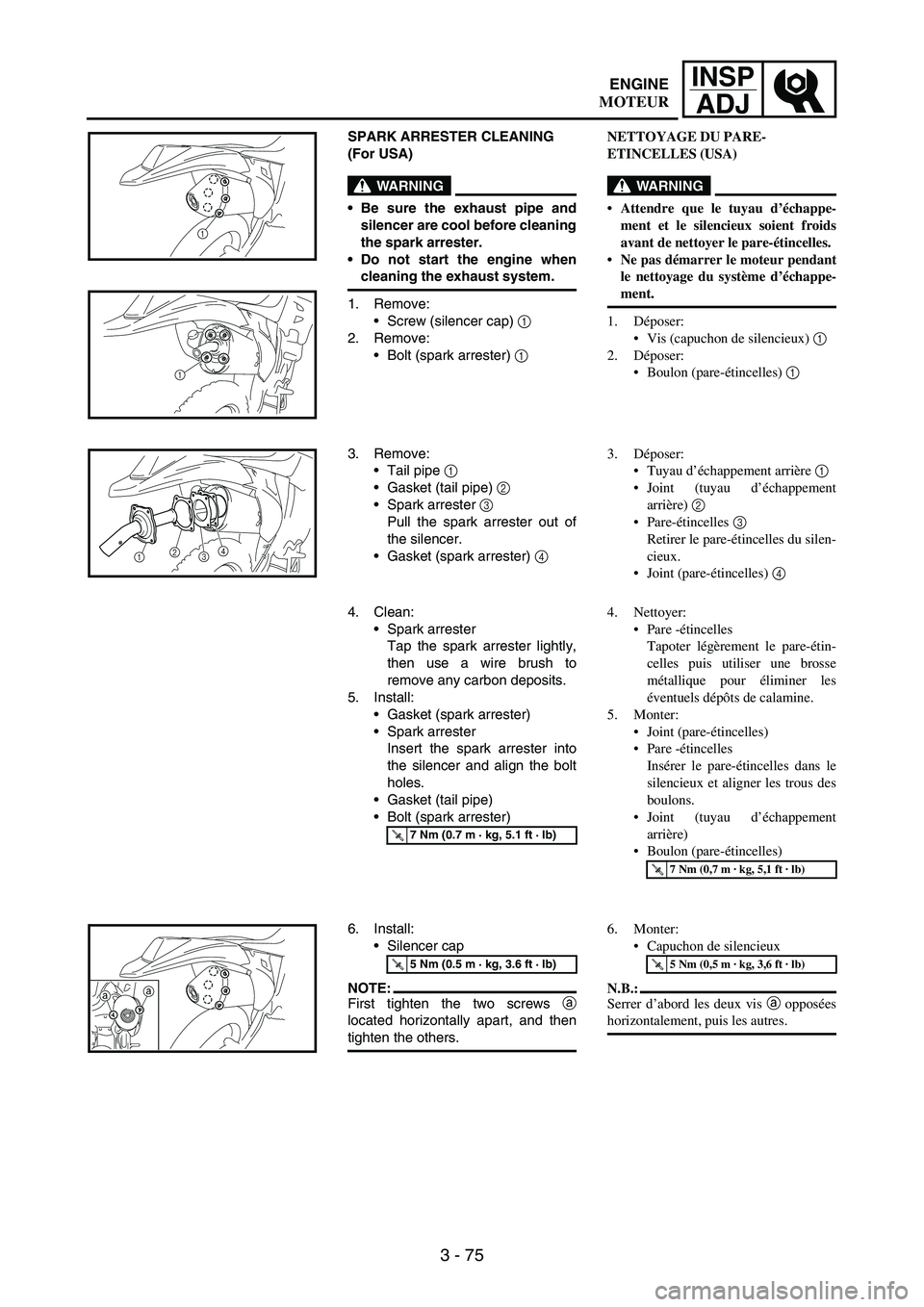

SPARK ARRESTER CLEANING

(For USA)

WARNING

Be sure the exhaust pipe and

silencer are cool before cleaning

the spark arrester.

Do not start the engine when

cleaning the exhaust system.

1. Remove:

Screw (silencer cap)

1

2. Remove:

Bolt (spark arrester)

1

1

1

3. Remove:

Tail pipe

1

Gasket (tail pipe)

2

Spark arrester 3

Pull the spark arrester out of

the silencer.

Gasket (spark arrester) 4

12

34

4. Clean:

Spark arrester

Tap the spark arrester lightly,

then use a wire brush to

remove any carbon deposits.

5. Install:

Gasket (spark arrester)

Spark arrester

Insert the spark arrester into

the silencer and align the bolt

holes.

Gasket (tail pipe)

Bolt (spark arrester)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

6. Install:

Silencer cap

NOTE:First tighten the two screws a

located horizontally apart, and then

tighten the others.

T R..5 Nm (0.5 m · kg, 3.6 ft · lb)

aa

NETTOYAGE DU PARE-

ETINCELLES (USA)

WARNING

Attendre que le tuyau d’échappe-

ment et le silencieux soient froids

avant de nettoyer le pare-étincelles.

Ne pas démarrer le moteur pendant

le nettoyage du système d’échappe-

ment.

1. Déposer:

Vis (capuchon de silencieux) 1

2. Déposer:

Boulon (pare-étincelles) 1

3. Déposer:

Tuyau d’échappement arrière 1

Joint (tuyau d’échappement

arrière) 2

Pare-étincelles 3

Retirer le pare-étincelles du silen-

cieux.

Joint (pare-étincelles) 4

4. Nettoyer:

Pare -étincelles

Tapoter légèrement le pare-étin-

celles puis utiliser une brosse

métallique pour éliminer les

éventuels dépôts de calamine.

5. Monter:

Joint (pare-étincelles)

Pare -étincelles

Insérer le pare-étincelles dans le

silencieux et aligner les trous des

boulons.

Joint (tuyau d’échappement

arrière)

Boulon (pare-étincelles)

T R..7 Nm (0,7 m · kg, 5,1 ft · lb)

6. Monter:

Capuchon de silencieux

N.B.:

Serrer d’abord les deux vis a opposées

horizontalement, puis les autres.

T R..5 Nm (0,5 m · kg, 3,6 ft · lb)

ENGINE

MOTEUR