light YAMAHA WR 250F 2007 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: WR 250F, Model: YAMAHA WR 250F 2007Pages: 912, PDF Size: 23.95 MB

Page 718 of 912

6 - 55

CHASFRONT BRAKE AND REAR BRAKE

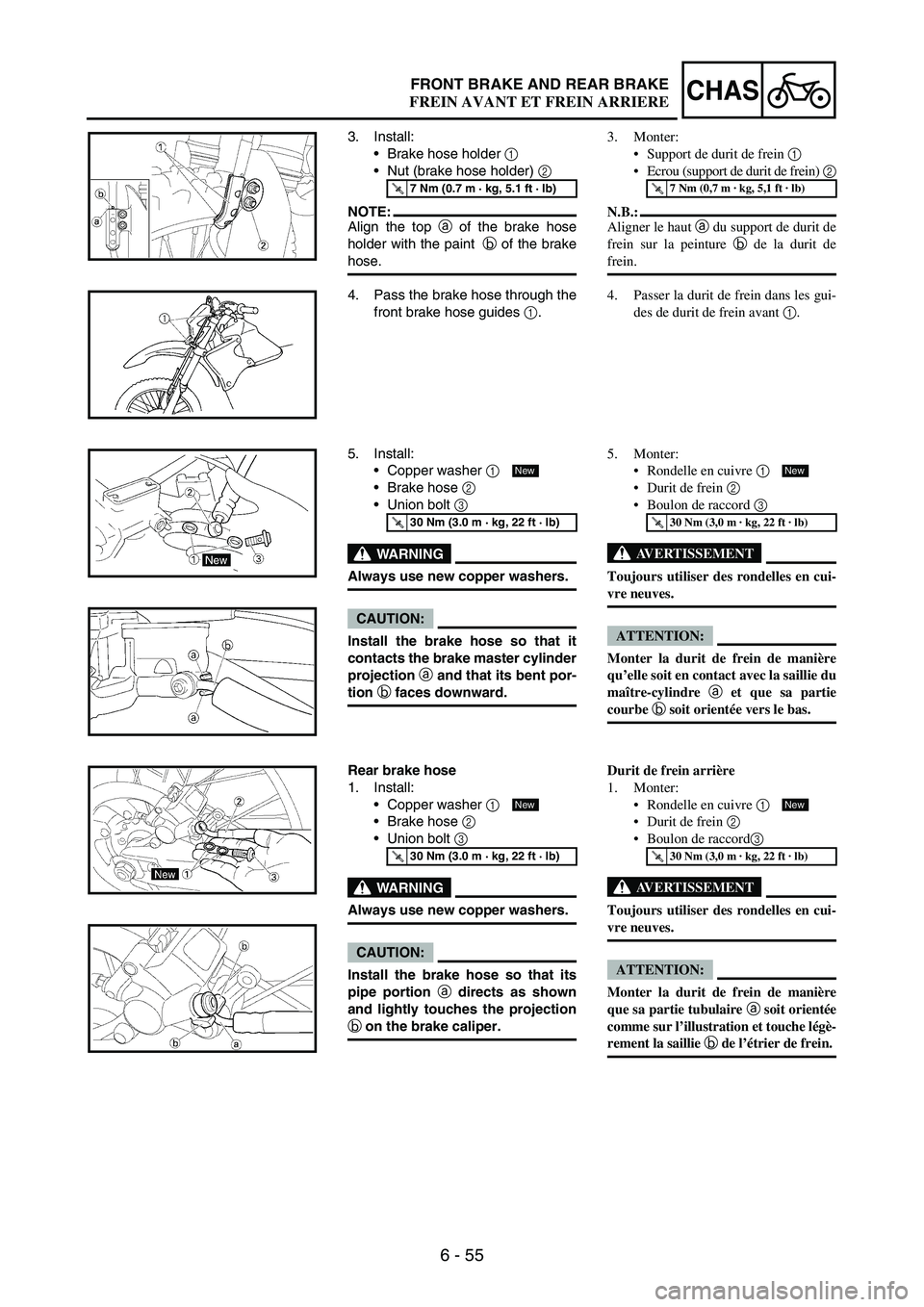

3. Install:

Brake hose holder

1

Nut (brake hose holder)

2

NOTE:Align the top

a of the brake hose

holder with the paint

b of the brake

hose.

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

4. Pass the brake hose through the

front brake hose guides

1.

5. Install:

Copper washer

1

Brake hose

2

Union bolt

3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that it

contacts the brake master cylinder

projection a

and that its bent por-

tion b

faces downward.

T R..30 Nm (3.0 m · kg, 22 ft · lb)

New

Rear brake hose

1. Install:

Copper washer

1

Brake hose

2

Union bolt

3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that its

pipe portion a

directs as shown

and lightly touches the projection

b

on the brake caliper.

T R..30 Nm (3.0 m · kg, 22 ft · lb)

New

3. Monter:

Support de durit de frein 1

Ecrou (support de durit de frein) 2

N.B.:

Aligner le haut a du support de durit de

frein sur la peinture b de la durit de

frein.

T R..7 Nm (0,7 m · kg, 5,1 ft · lb)

4. Passer la durit de frein dans les gui-

des de durit de frein avant 1.

5. Monter:

Rondelle en cuivre 1

Durit de frein 2

Boulon de raccord 3

AVERTISSEMENT

Toujours utiliser des rondelles en cui-

vre neuves.

ATTENTION:

Monter la durit de frein de manière

qu’elle soit en contact avec la saillie du

maître-cylindre a et que sa partie

courbe b soit orientée vers le bas.

T R..30 Nm (3,0 m · kg, 22 ft · lb)

New

Durit de frein arrière

1. Monter:

Rondelle en cuivre 1

Durit de frein 2

Boulon de raccord3

AVERTISSEMENT

Toujours utiliser des rondelles en cui-

vre neuves.

ATTENTION:

Monter la durit de frein de manière

que sa partie tubulaire a soit orientée

comme sur l’illustration et touche légè-

rement la saillie b de l’étrier de frein.

T R..30 Nm (3,0 m · kg, 22 ft · lb)

New

FREIN AVANT ET FREIN ARRIERE

Page 724 of 912

6 - 61

CHASFRONT FORK

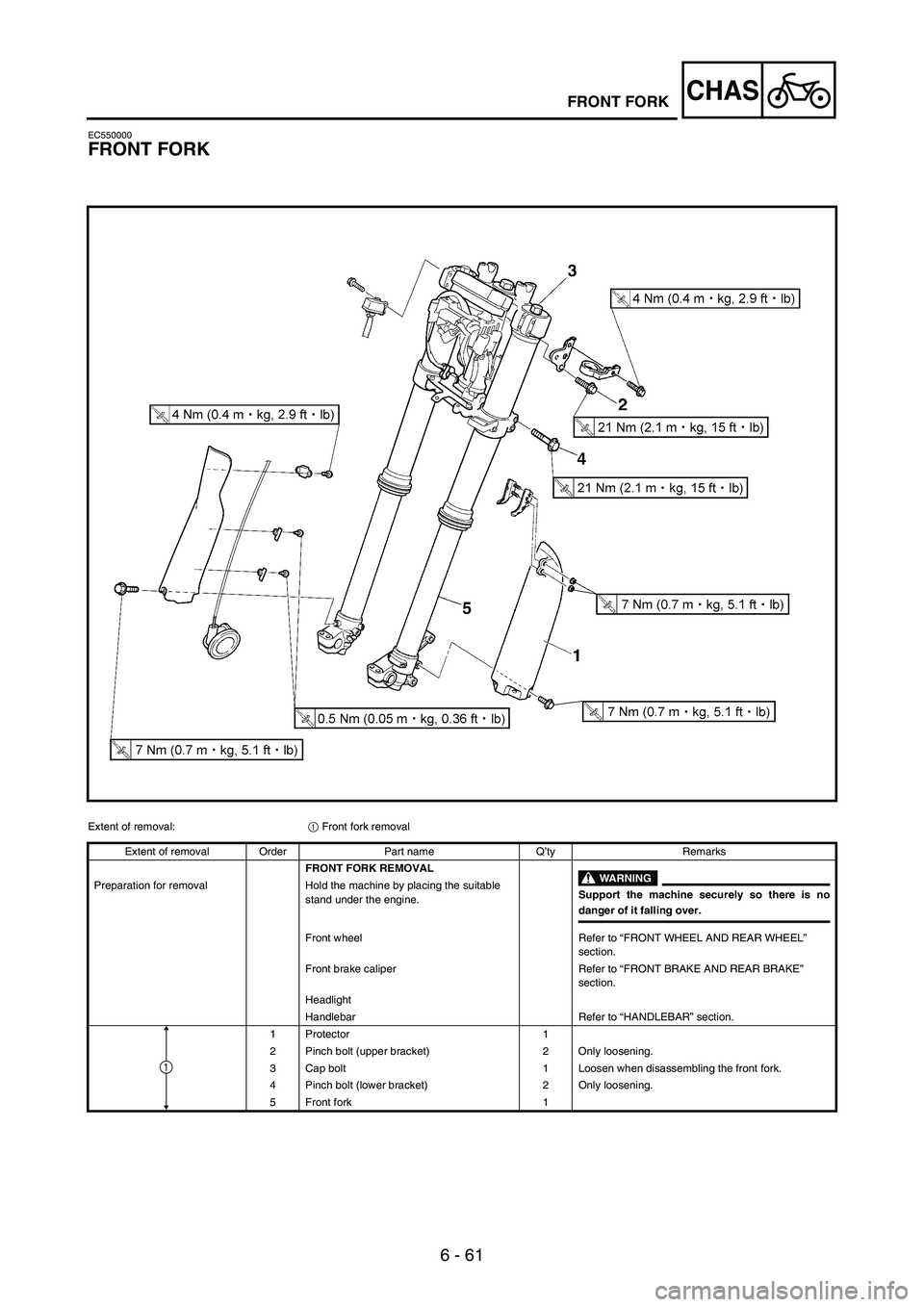

EC550000

FRONT FORK

Extent of removal:

1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

FRONT FORK REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR WHEEL”

section.

Front brake caliper Refer to “FRONT BRAKE AND REAR BRAKE”

section.

Headlight

Handlebar Refer to “HANDLEBAR” section.

1 Protector 1

2 Pinch bolt (upper bracket) 2 Only loosening.

3 Cap bolt 1 Loosen when disassembling the front fork.

4 Pinch bolt (lower bracket) 2 Only loosening.

5 Front fork 1

1

Page 754 of 912

6 - 91

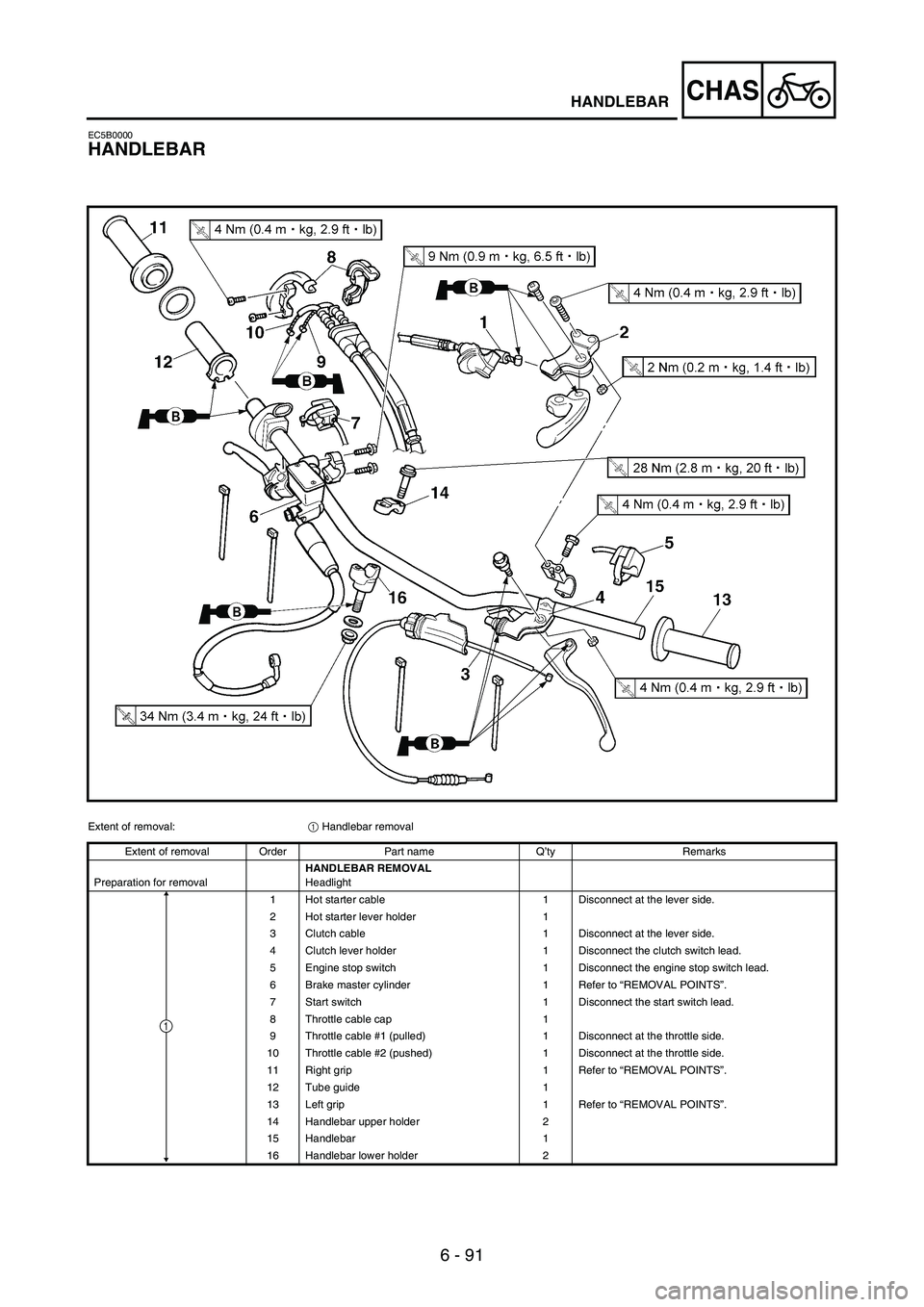

CHASHANDLEBAR

EC5B0000

HANDLEBAR

Extent of removal:

1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalHANDLEBAR REMOVAL

Headlight

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1 Disconnect the clutch switch lead.

5 Engine stop switch 1 Disconnect the engine stop switch lead.

6 Brake master cylinder 1 Refer to “REMOVAL POINTS”.

7 Start switch 1 Disconnect the start switch lead.

8 Throttle cable cap 1

9 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

10 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

11 Right grip 1 Refer to “REMOVAL POINTS”.

12 Tube guide 1

13 Left grip 1 Refer to “REMOVAL POINTS”.

14 Handlebar upper holder 2

15 Handlebar 1

16 Handlebar lower holder 2

1

Page 768 of 912

6 - 105

CHASSTEERING

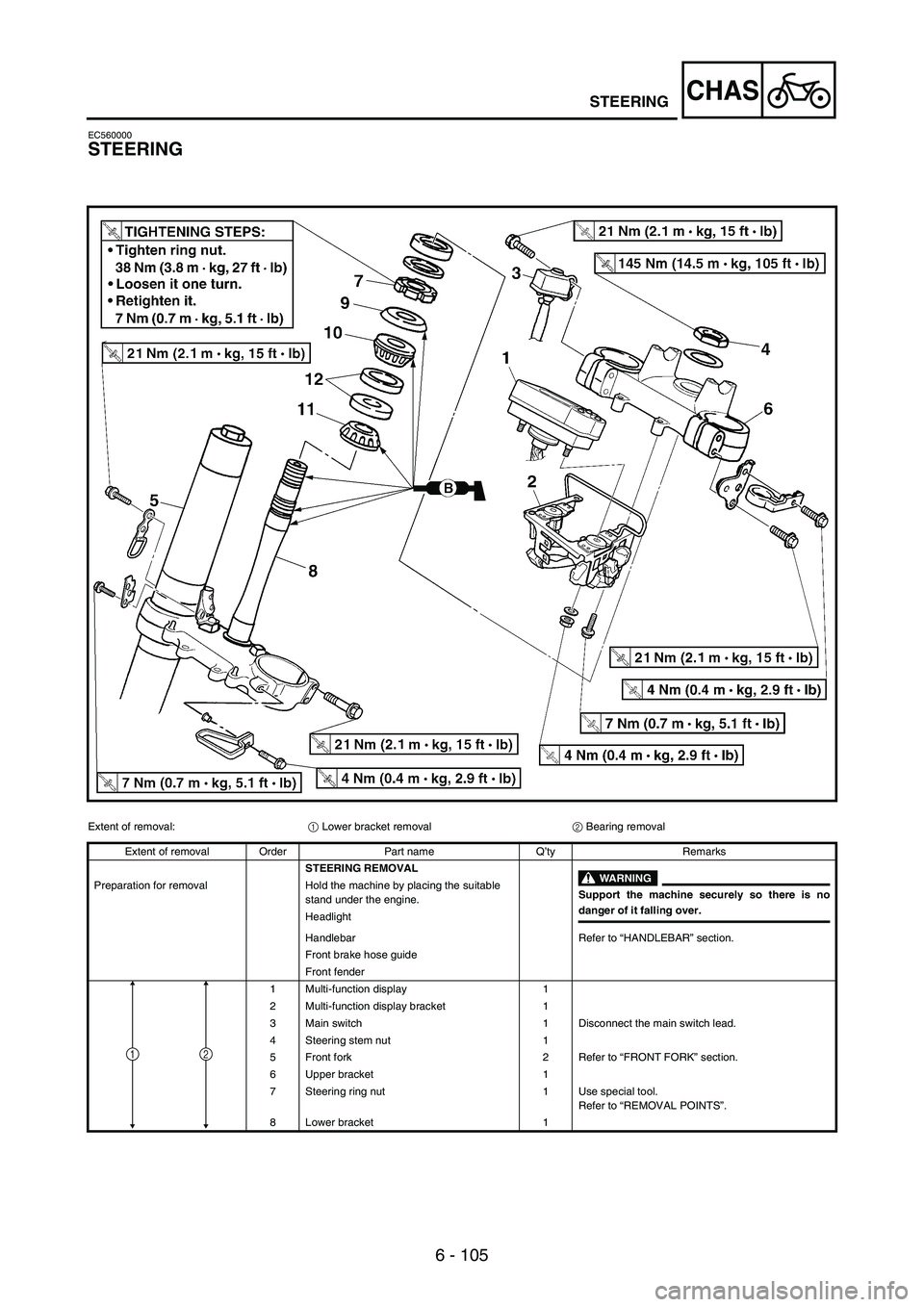

EC560000

STEERING

Extent of removal:

1 Lower bracket removal

2 Bearing removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

Headlight

Handlebar Refer to “HANDLEBAR” section.

Front brake hose guide

Front fender

1 Multi-function display 1

2 Multi-function display bracket 1

3 Main switch 1 Disconnect the main switch lead.

4 Steering stem nut 1

5 Front fork 2 Refer to “FRONT FORK” section.

6 Upper bracket 1

7 Steering ring nut 1 Use special tool.

Refer to “REMOVAL POINTS”.

8 Lower bracket 1

12

Page 808 of 912

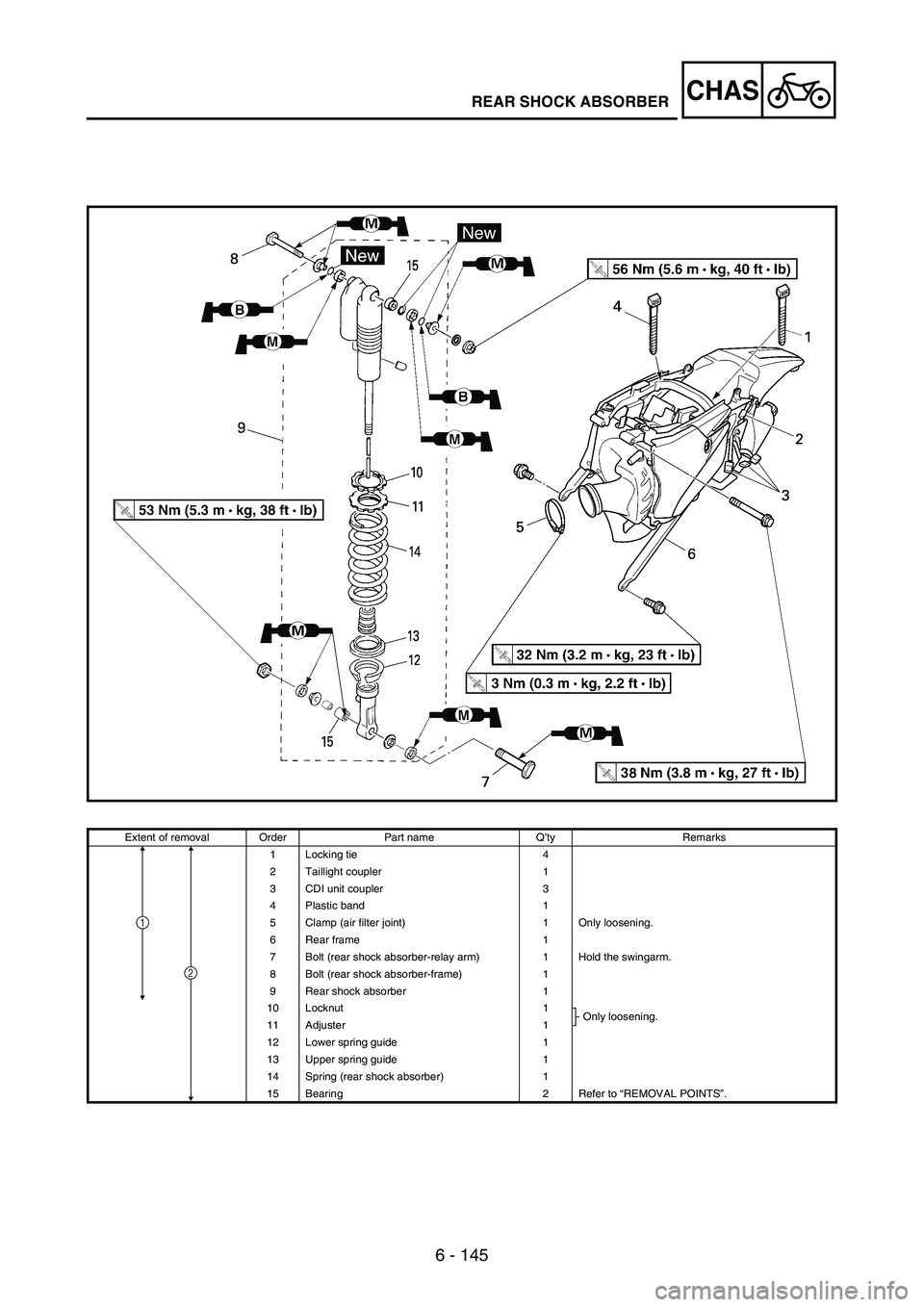

6 - 145

CHASREAR SHOCK ABSORBER

Extent of removal Order Part name Q’ty Remarks

1 Locking tie 4

2 Taillight coupler 1

3 CDI unit coupler 3

4 Plastic band 1

5 Clamp (air filter joint) 1 Only loosening.

6 Rear frame 1

7 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

8 Bolt (rear shock absorber-frame) 1

9 Rear shock absorber 1

10 Locknut 1

Only loosening.

11 Adjuster 1

12 Lower spring guide 1

13 Upper spring guide 1

14 Spring (rear shock absorber) 1

15 Bearing 2 Refer to “REMOVAL POINTS”.

1

2

Page 820 of 912

6 - 157

CHASREAR SHOCK ABSORBER

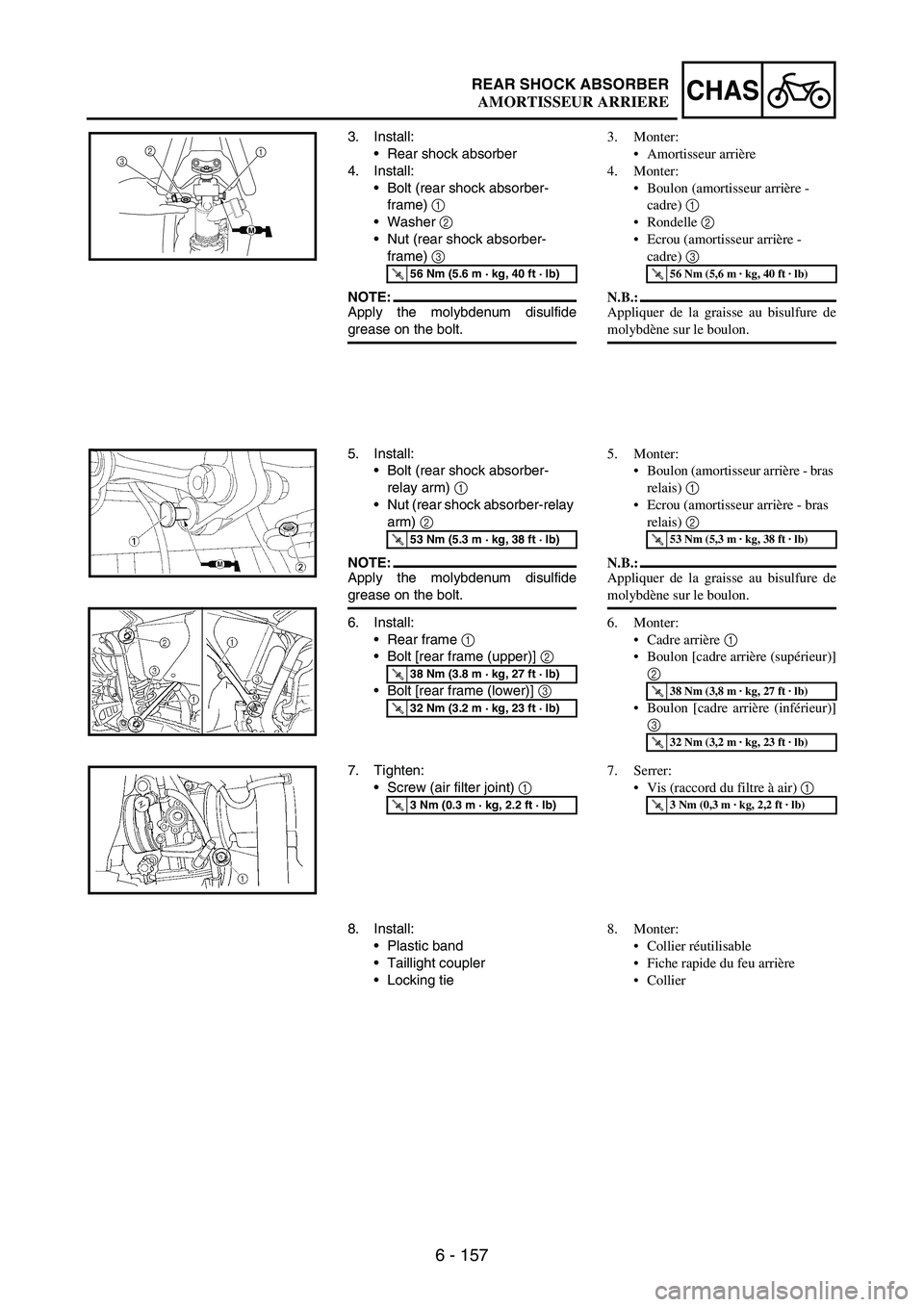

3. Install:

•Rear shock absorber

4. Install:

•Bolt (rear shock absorber-

frame)

1

•Washer

2

•Nut (rear shock absorber-

frame)

3

NOTE:Apply the molybdenum disulfide

grease on the bolt.

T R..56 Nm (5.6 m · kg, 40 ft · lb)

1 2

3

M

5. Install:

•Bolt (rear shock absorber-

relay arm)

1

•Nut (rear shock absorber-relay

arm)

2

NOTE:Apply the molybdenum disulfide

grease on the bolt.

6. Install:

•Rear frame

1

•Bolt [rear frame (upper)]

2

•Bolt [rear frame (lower)]

3

T R..53 Nm (5.3 m · kg, 38 ft · lb)

T R..38 Nm (3.8 m · kg, 27 ft · lb)

T R..32 Nm (3.2 m · kg, 23 ft · lb)

7. Tighten:

•Screw (air filter joint)

1

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

8. Install:

•Plastic band

•Taillight coupler

•Locking tie3. Monter:

Amortisseur arrière

4. Monter:

Boulon (amortisseur arrière -

cadre) 1

Rondelle 2

Ecrou (amortisseur arrière -

cadre) 3

N.B.:

Appliquer de la graisse au bisulfure de

molybdène sur le boulon.

T R..56 Nm (5,6 m · kg, 40 ft · lb)

5. Monter:

Boulon (amortisseur arrière - bras

relais) 1

Ecrou (amortisseur arrière - bras

relais) 2

N.B.:

Appliquer de la graisse au bisulfure de

molybdène sur le boulon.

6. Monter:

Cadre arrière 1

Boulon [cadre arrière (supérieur)]

2

Boulon [cadre arrière (inférieur)]

3

T R..53 Nm (5,3 m · kg, 38 ft · lb)

T R..38 Nm (3,8 m · kg, 27 ft · lb)

T R..32 Nm (3,2 m · kg, 23 ft · lb)

7. Serrer:

Vis (raccord du filtre à air) 1

T R..3 Nm (0,3 m · kg, 2,2 ft · lb)

8. Monter:

Collier réutilisable

Fiche rapide du feu arrière

Collier

AMORTISSEUR ARRIERE

Page 822 of 912

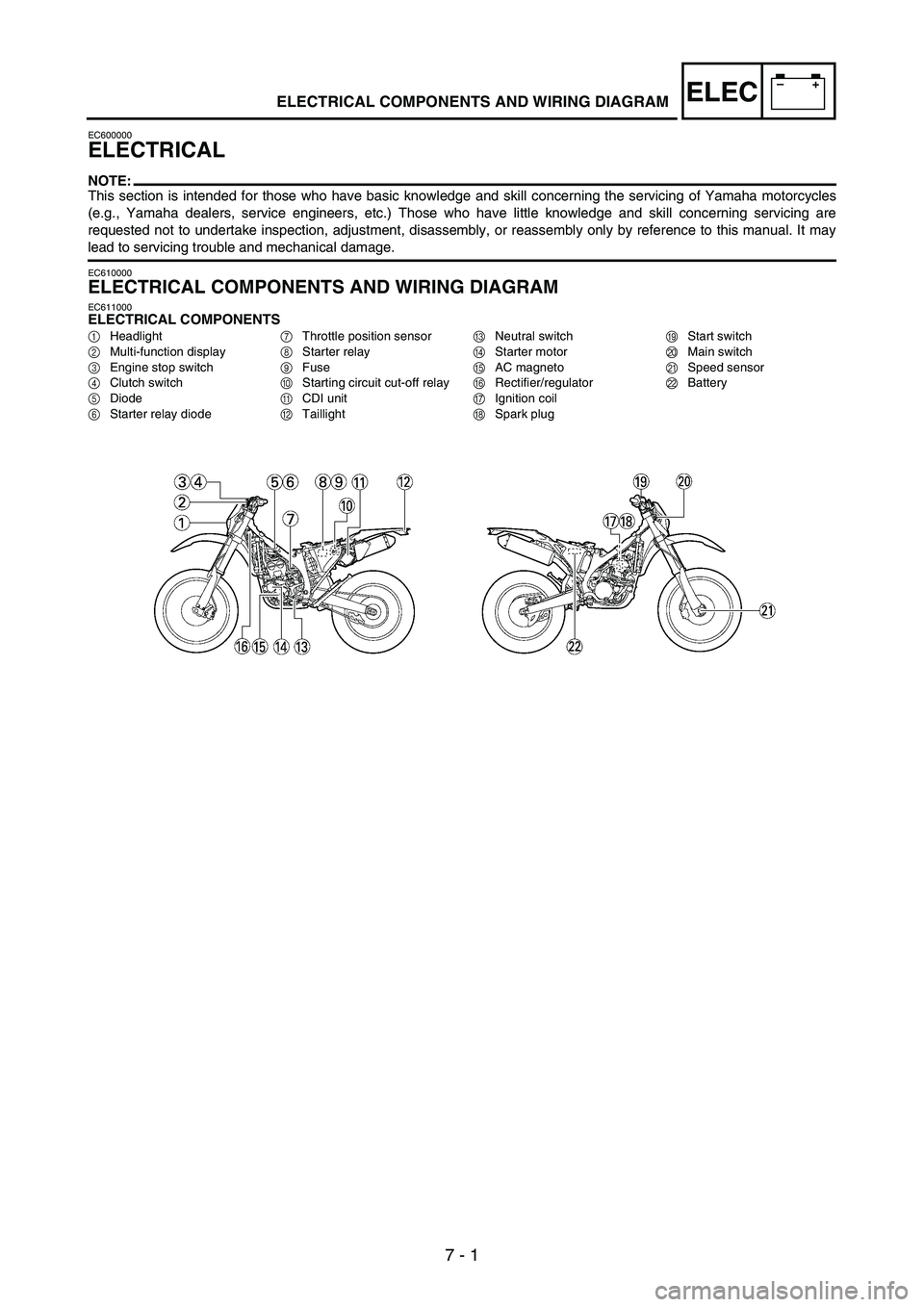

7 - 1

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

NOTE:This section is intended for those who have basic knowledge and skill concerning the servicing of Yamaha motorcycles

(e.g., Yamaha dealers, service engineers, etc.) Those who have little knowledge and skill concerning servicing are

requested not to undertake inspection, adjustment, disassembly, or reassembly only by reference to this manual. It may

lead to servicing trouble and mechanical damage.

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000ELECTRICAL COMPONENTS

1Headlight

2Multi-function display

3Engine stop switch

4Clutch switch

5Diode

6Starter relay diode7Throttle position sensor

8Starter relay

9Fuse

0Starting circuit cut-off relay

ACDI unit

BTaillightCNeutral switch

DStarter motor

EAC magneto

FRectifier/regulator

GIgnition coil

HSpark plugIStart switch

JMain switch

KSpeed sensor

LBattery

Page 824 of 912

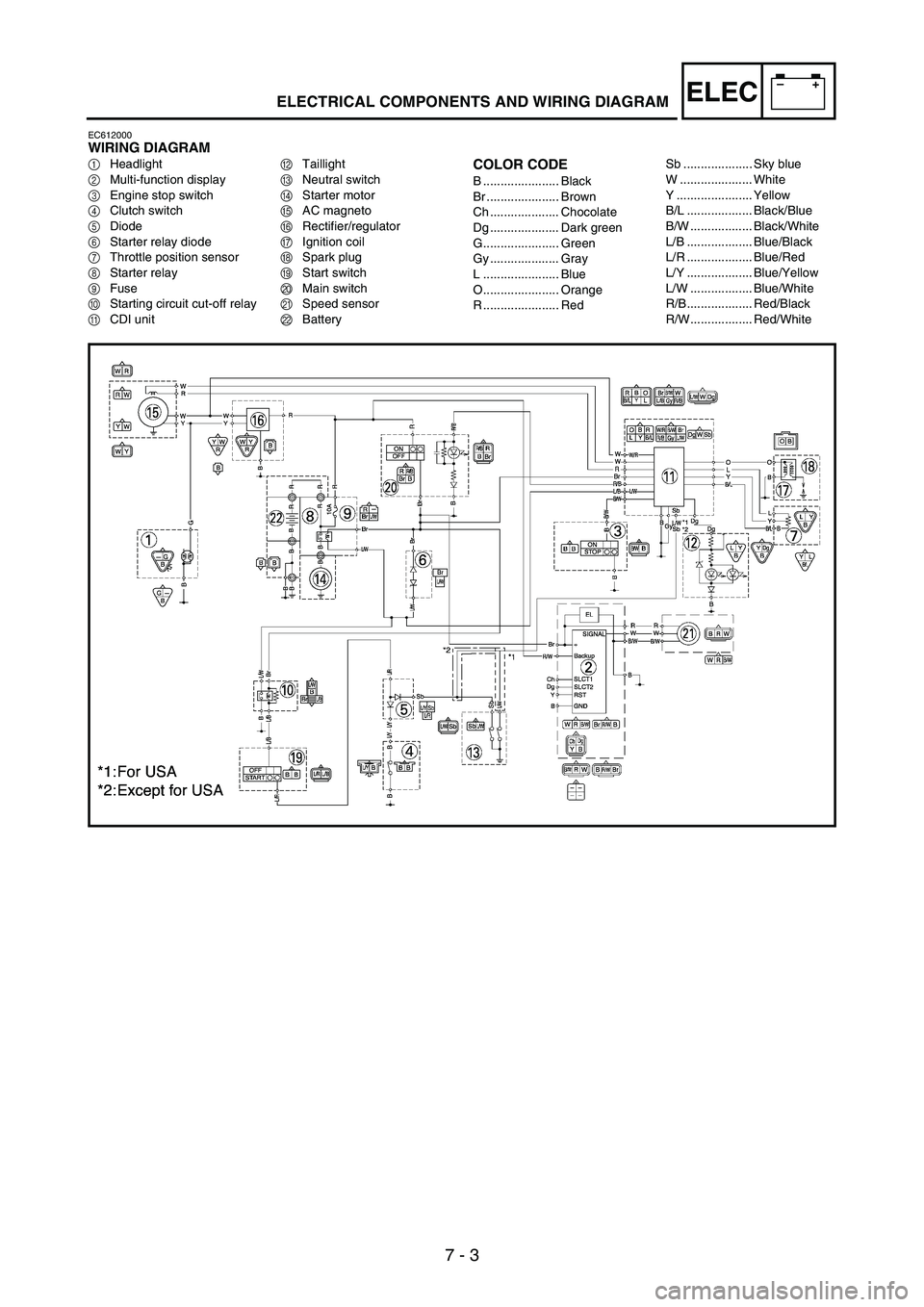

7 - 3

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC612000WIRING DIAGRAM

1Headlight

2Multi-function display

3Engine stop switch

4Clutch switch

5Diode

6Starter relay diode

7Throttle position sensor

8Starter relay

9Fuse

0Starting circuit cut-off relay

ACDI unitBTaillight

CNeutral switch

DStarter motor

EAC magneto

FRectifier/regulator

GIgnition coil

HSpark plug

IStart switch

JMain switch

KSpeed sensor

LBatteryCOLOR CODE

B ...................... Black

Br ..................... Brown

Ch .................... Chocolate

Dg .................... Dark green

G...................... Green

Gy .................... Gray

L ...................... Blue

O...................... Orange

R ...................... RedSb .................... Sky blue

W ..................... White

Y ...................... Yellow

B/L ................... Black/Blue

B/W .................. Black/White

L/B ................... Blue/Black

L/R ................... Blue/Red

L/Y ................... Blue/Yellow

L/W .................. Blue/White

R/B................... Red/Black

R/W.................. Red/White

Page 834 of 912

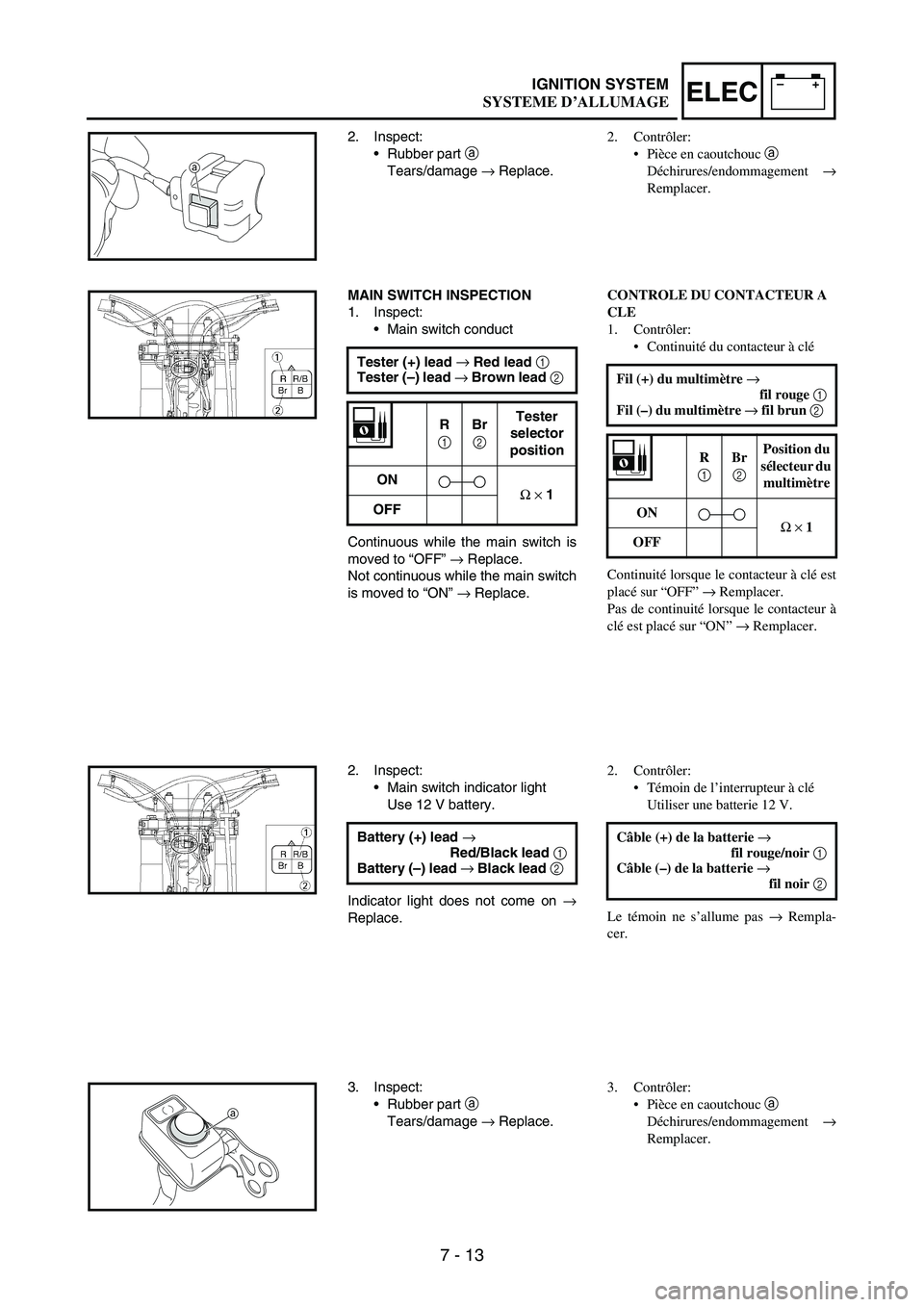

7 - 13

–+ELECIGNITION SYSTEM

2. Inspect:

•Rubber part

a

Tears/damage

→ Replace.

a

MAIN SWITCH INSPECTION

1. Inspect:

•Main switch conduct

Continuous while the main switch is

moved to “OFF”

→ Replace.

Not continuous while the main switch

is moved to “ON”

→ Replace. Tester (+) lead →

Red lead 1

Tester (–) lead →

Brown lead 2

R

1

Br

2

Tester

selector

position

ON

Ω

×

1

OFF

2. Inspect:

•Main switch indicator light

Use 12 V battery.

Indicator light does not come on

→

Replace.Battery (+) lead →

Red/Black lead 1

Battery (–) lead →

Black lead 2

3. Inspect:

•Rubber part

a

Tears/damage

→ Replace.

a

2. Contrôler:

Pièce en caoutchouc a

Déchirures/endommagement →

Remplacer.

CONTROLE DU CONTACTEUR A

CLE

1. Contrôler:

Continuité du contacteur à clé

Continuité lorsque le contacteur à clé est

placé sur “OFF” → Remplacer.

Pas de continuité lorsque le contacteur à

clé est placé sur “ON” → Remplacer. Fil (+) du multimètre →

fil rouge 1

Fil (–) du multimètre → fil brun 2

R

1 Br

2 Position du

sélecteur du

multimètre

ON

Ω × 1

OFF

2. Contrôler:

Témoin de l’interrupteur à clé

Utiliser une batterie 12 V.

Le témoin ne s’allume pas → Rempla-

cer.Câble (+) de la batterie →

fil rouge/noir 1

Câble (–) de la batterie →

fil noir 2

3. Contrôler:

Pièce en caoutchouc a

Déchirures/endommagement →

Remplacer.

SYSTEME D’ALLUMAGE

Page 888 of 912

7 - 67

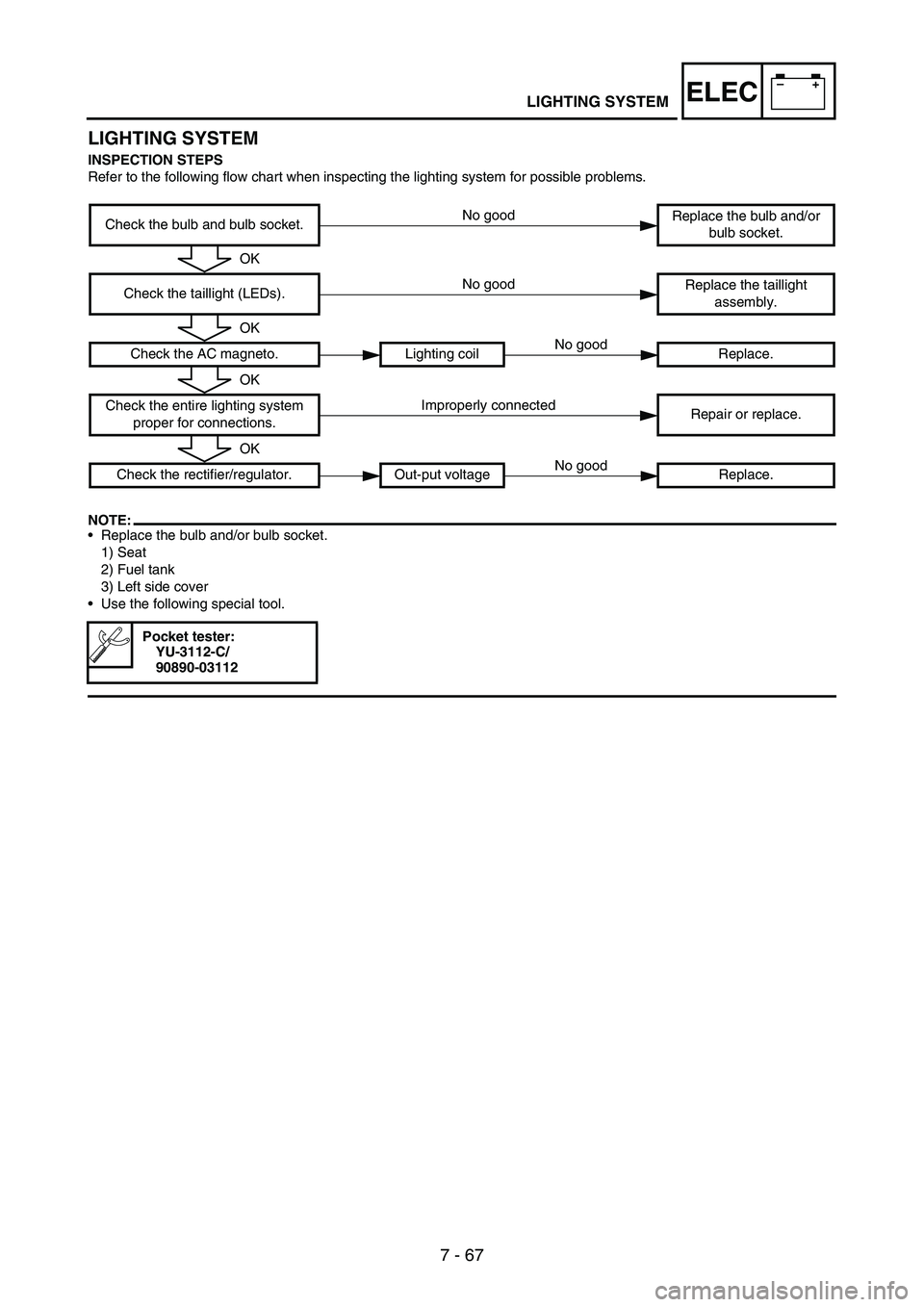

–+ELECLIGHTING SYSTEM

LIGHTING SYSTEM

INSPECTION STEPS

Refer to the following flow chart when inspecting the lighting system for possible problems.

NOTE:•Replace the bulb and/or bulb socket.

1) Seat

2) Fuel tank

3) Left side cover

•Use the following special tool.

Check the bulb and bulb socket.Replace the bulb and/or

bulb socket.

Check the taillight (LEDs).Replace the taillight

assembly.

Check the AC magneto. Lighting coil Replace.

Check the entire lighting system

proper for connections.Repair or replace.

Check the rectifier/regulator. Out-put voltage Replace.

Pocket tester:

YU-3112-C/

90890-03112

No good

OK

No good

OK

No good

OK

Improperly connected

OK

No good