wheel YAMAHA WR 250F 2008 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 250F, Model: YAMAHA WR 250F 2008Pages: 224, PDF Size: 13.66 MB

Page 173 of 224

6-12

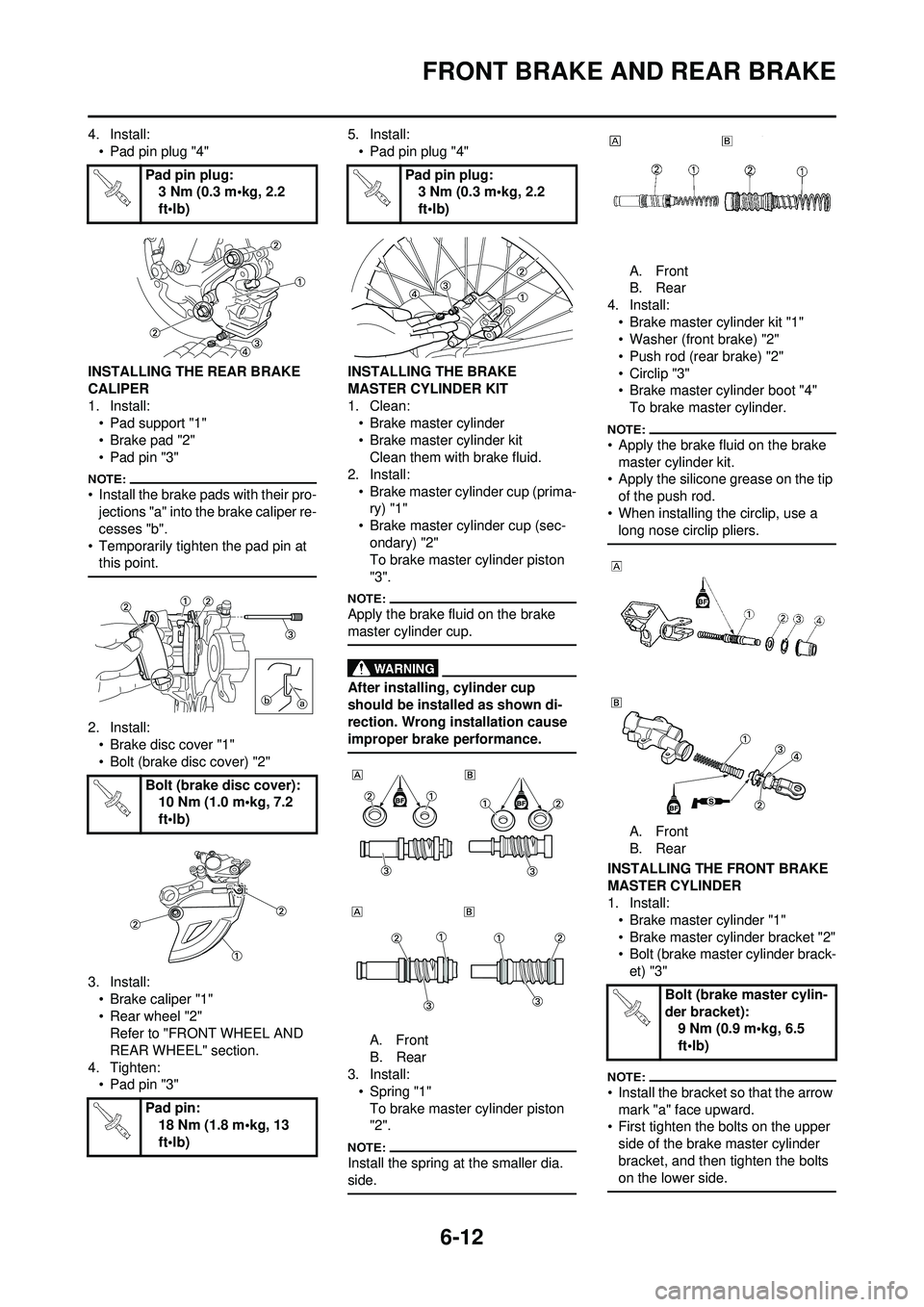

FRONT BRAKE AND REAR BRAKE

4. Install:• Pad pin plug "4"

INSTALLING THE REAR BRAKE

CALIPER

1. Install: • Pad support "1"

• Brake pad "2"

• Pad pin "3"

• Install the brake pads with their pro-jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at this point.

2. Install:• Brake disc cover "1"

• Bolt (brake disc cover) "2"

3. Install: • Brake caliper "1"

• Rear wheel "2"Refer to "FRONT WHEEL AND

REAR WHEEL" section.

4. Tighten: • Pad pin "3" 5. Install:

• Pad pin plug "4"

INSTALLING THE BRAKE

MASTER CYLINDER KIT

1. Clean: • Brake master cylinder

• Brake master cylinder kitClean them with brake fluid.

2. Install:

• Brake master cylinder cup (prima-ry) "1"

• Brake master cylinder cup (sec-

ondary) "2"

To brake master cylinder piston

"3".

Apply the brake fluid on the brake

master cylinder cup.

After installing, cylinder cup

should be installed as shown di-

rection. Wrong installation cause

improper brake performance.

A. Front

B. Rear

3. Install:

• Spring "1"To brake master cylinder piston

"2".

Install the spring at the smaller dia.

side.

A. Front

B. Rear

4. Install: • Brake master cylinder kit "1"

• Washer (front brake) "2"

• Push rod (rear brake) "2"

• Circlip "3"

• Brake master cylinder boot "4"

To brake master cylinder.

• Apply the brake fluid on the brake master cylinder kit.

• Apply the silicone grease on the tip

of the push rod.

• When installing the circlip, use a long nose circlip pliers.

A. Front

B. Rear

INSTALLING THE FRONT BRAKE

MASTER CYLINDER

1. Install: • Brake master cylinder "1"

• Brake master cylinder bracket "2"

• Bolt (brake master cylinder brack-et) "3"

• Install the bracket so that the arrow mark "a" face upward.

• First tighten the bolts on the upper

side of the brake master cylinder

bracket, and then tighten the bolts

on the lower side.

Pad pin plug: 3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (brake disc cover): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Pad pin: 18 Nm (1.8 m•kg, 13

ft•lb)Pad pin plug:3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (brake master cylin-

der bracket): 9 Nm (0.9 m•kg, 6.5

ft•lb)

Page 177 of 224

6-16

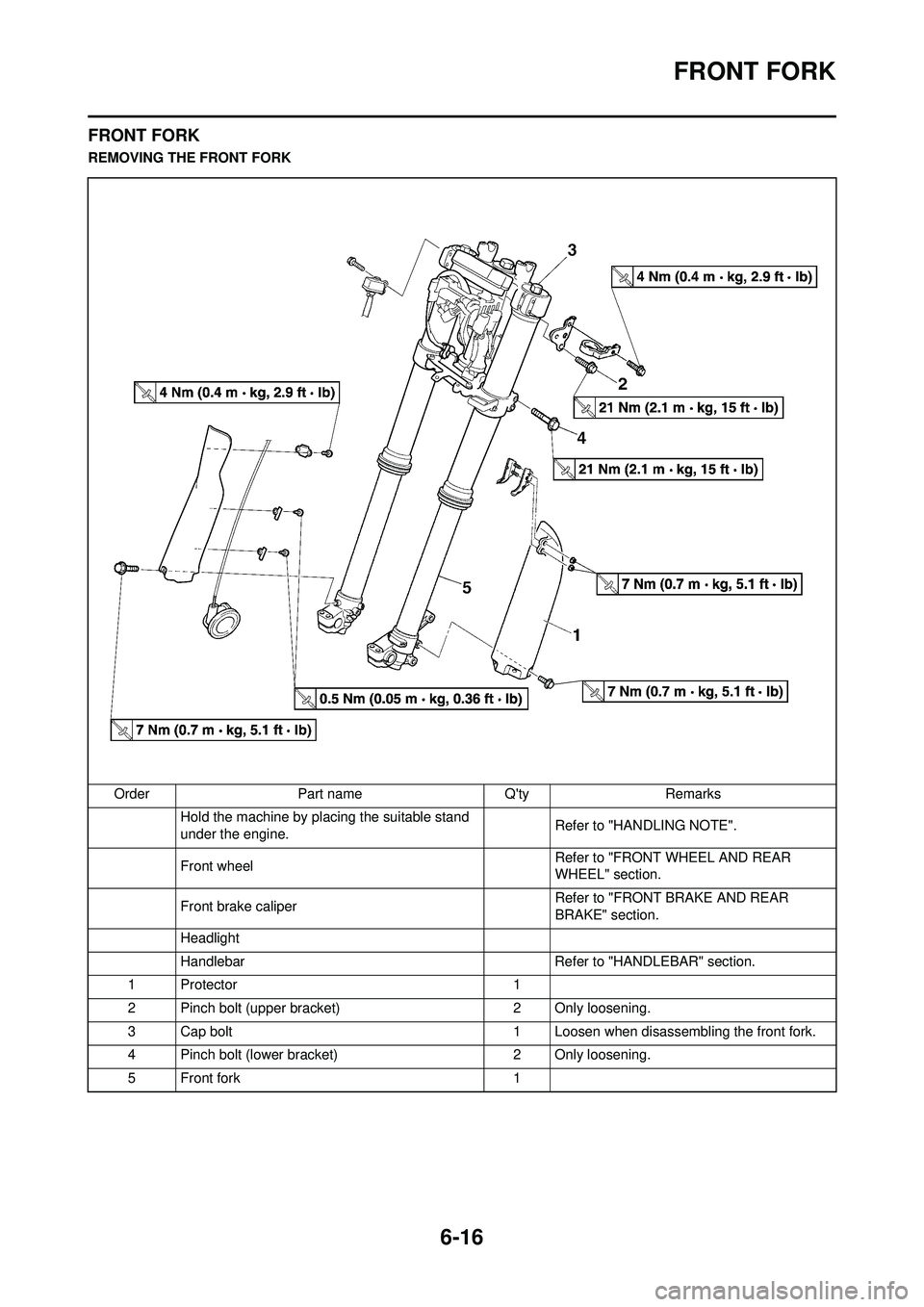

FRONT FORK

FRONT FORK

REMOVING THE FRONT FORKOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Front wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Front brake caliper Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Headlight

Handlebar Refer to "HANDLEBAR" section.

1 Protector 1

2 Pinch bolt (upper bracket) 2 Only loosening.

3 Cap bolt 1 Loosen when disassembling the front fork.

4 Pinch bolt (lower bracket) 2 Only loosening.

5 Front fork 1

Page 222 of 224

7-21

SIGNALING SYSTEM

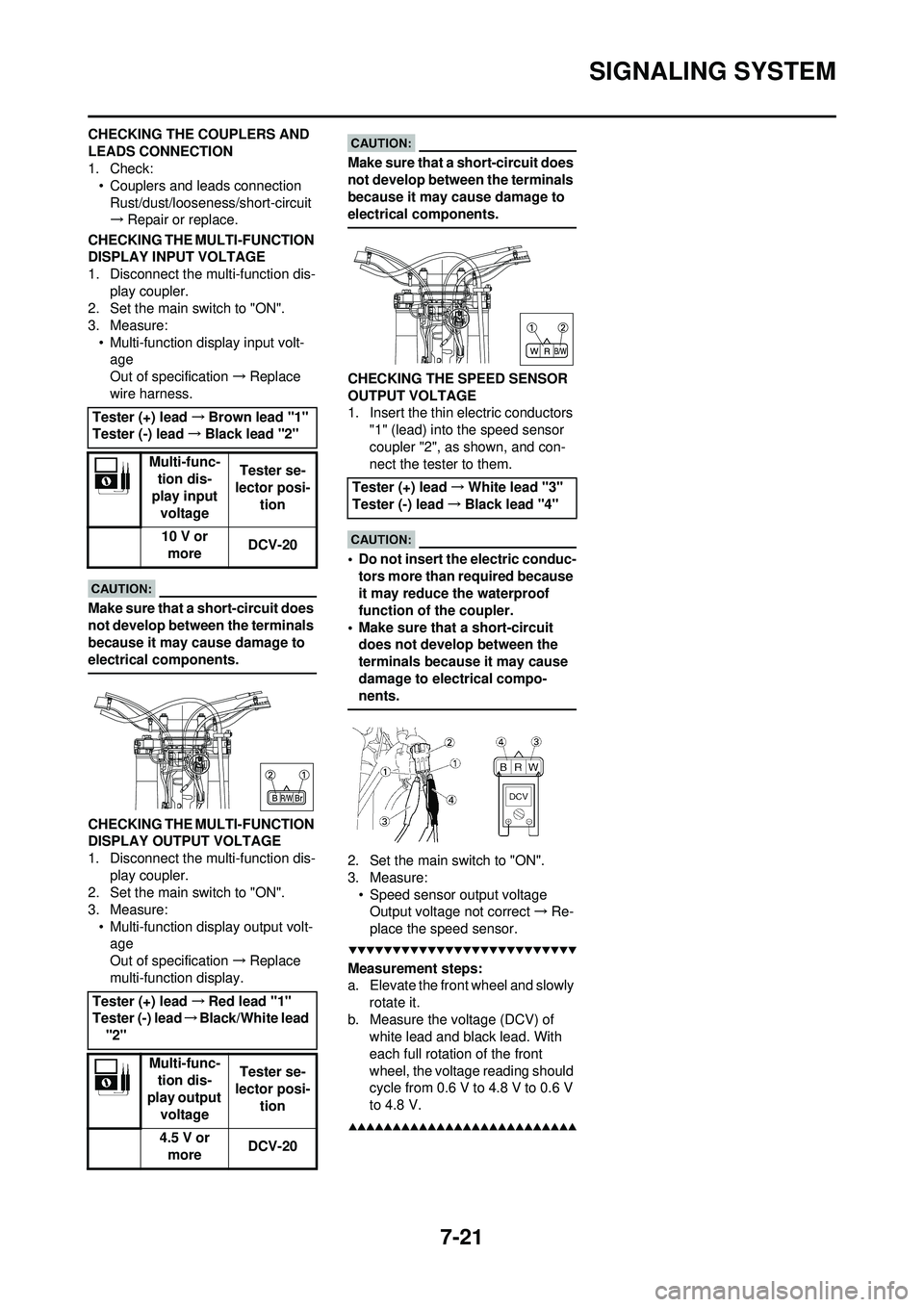

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:• Couplers and leads connection

Rust/dust/looseness/short-circuit

→ Repair or replace.

CHECKING THE MULTI-FUNCTION

DISPLAY INPUT VOLTAGE

1. Disconnect the multi-function dis- play coupler.

2. Set the main switch to "ON".

3. Measure:

• Multi-function display input volt-age

Out of specification →Replace

wire harness.

Make sure that a short-circuit does

not develop between the terminals

because it may cause damage to

electrical components.

CHECKING THE MULTI-FUNCTION

DISPLAY OUTPUT VOLTAGE

1. Disconnect the multi-function dis- play coupler.

2. Set the main switch to "ON".

3. Measure: • Multi-function display output volt-age

Out of specification →Replace

multi-function display.

Make sure that a short-circuit does

not develop between the terminals

because it may cause damage to

electrical components.

CHECKING THE SPEED SENSOR

OUTPUT VOLTAGE

1. Insert the thin electric conductors

"1" (lead) into the speed sensor

coupler "2", as shown, and con-

nect the tester to them.

• Do not insert the electric conduc-tors more than required because

it may reduce the waterproof

function of the coupler.

• Make sure that a short-circuit does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

2. Set the main switch to "ON".

3. Measure:

• Speed sensor output voltageOutput voltage not correct →Re-

place the speed sensor.

Measurement steps:

a. Elevate the front wheel and slowly

rotate it.

b. Measure the voltage (DCV) of white lead and black lead. With

each full rotation of the front

wheel, the voltage reading should

cycle from 0.6 V to 4.8 V to 0.6 V

to 4.8 V.

Tester (+) lead →Brown lead "1"

Tester (-) lead →Black lead "2"

Multi-func- tion dis-

play input voltage Tester se-

lector posi- tion

10 V or more DCV-20

Tester (+) lead →Red lead "1"

Tester (-) lead →Black/White lead

"2"

Multi-func-tion dis-

play output

voltage Tester se-

lector posi- tion

4.5 V or more DCV-20

Tester (+) lead

→White lead "3"

Tester (-) lead →Black lead "4"