YAMAHA WR 250F 2013 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2013, Model line: WR 250F, Model: YAMAHA WR 250F 2013Pages: 232, PDF Size: 13.36 MB

Page 51 of 232

2-20

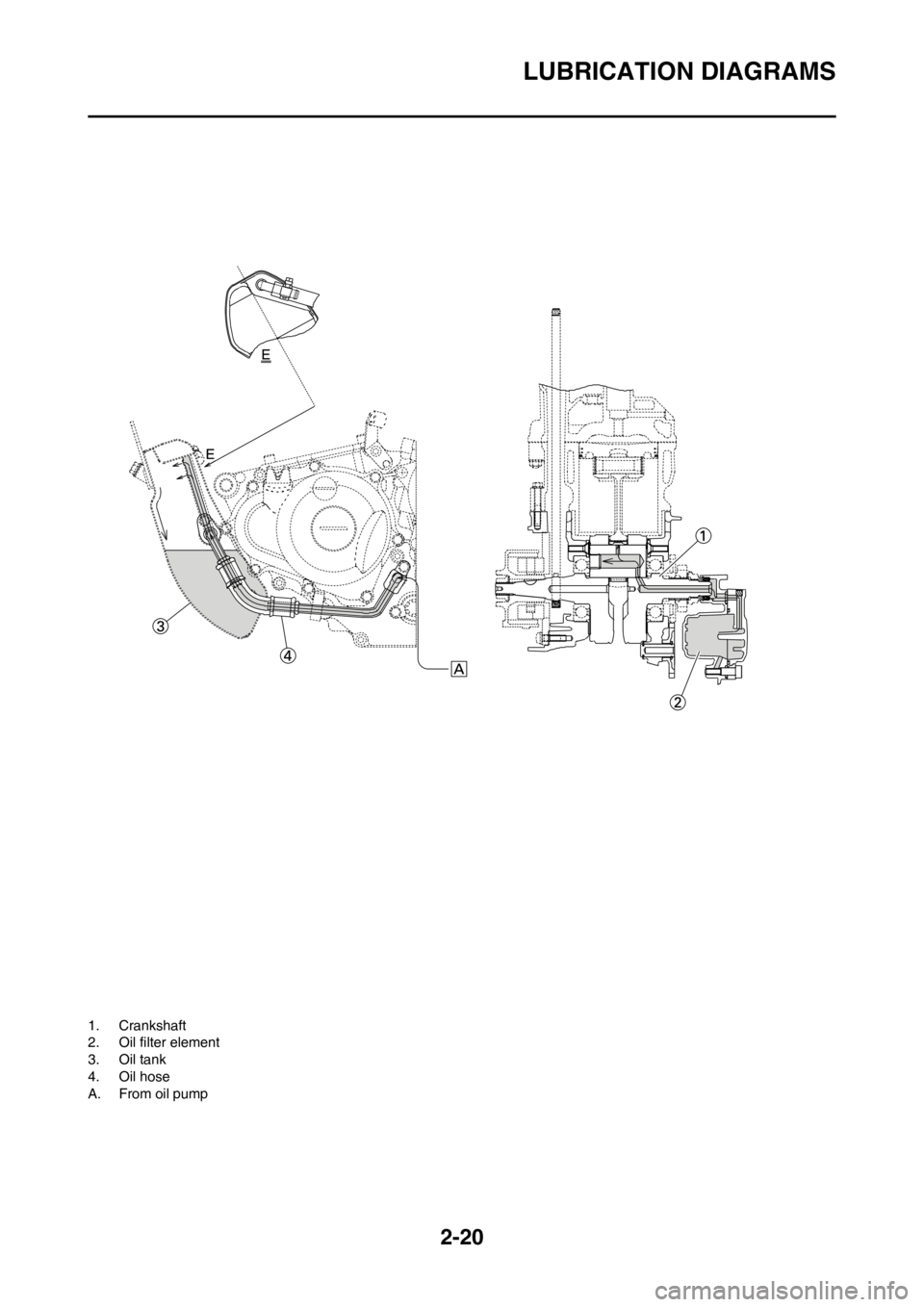

LUBRICATION DIAGRAMS

1. Crankshaft

2. Oil filter element

3. Oil tank

4. Oil hose

A. From oil pump

Page 52 of 232

2-21

CABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1. Fuel tank breather hose

2. Clamp

3. Diode

4. Hot starter cable

5. Wire harness

6. Hump (frame)

7. Cylinder head breather hose

8. Throttle position sensor lead

9. Neutral switch lead10. Oil hose

11. Clutch cable

12. Starter motor lead

13. Cable guide

14. Negative battery lead

15. AC magneto lead

16. Brake hose

17. Rectifier/regulator lead

18. Carburetor breather hose19. Carburetor overflow hose

20. Catch tank breather hose

21. Hot starter cable protector

22. Rubber cap

Page 53 of 232

2-22

CABLE ROUTING DIAGRAM

A. Insert the end of the fuel tank

breather hose into the hole in

the steering stem.

B. Fasten the throttle cable, hot

starter cable and rectifier/regula-

tor lead onto the frame. Locate

the clamp under the throttle ca-

ble on the right side of the frame,

and face its ends, as well as the

tie ends, downward.

C. Fasten the diode (at the mark-

ing), throttle cable and hot start-

er cable onto the frame. Locate

the clamp end facing toward the

lower right of the frame and with

the tie end facing downward.

D. Fasten the wire harness, throttle

position sensor lead, starter mo-

tor lead and negative battery

lead onto the frame. Pass the

clamp through the hole in the

stay (air cut-off valve). Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

E. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose

between the connecting rod and

cross tube (frame).

F. Fasten the neutral switch lead

and oil hose together with the

plastic locking ties and cut off

the tie ends.

G. Fasten the neutral switch lead

and AC magneto lead onto the

frame. Locate the clamp end

facing toward the outside of the

frame and tie end facing toward

the rear of the frame.

H. Pass the clutch cable through

the cable guide.

I. Fasten the starter motor lead,

AC magneto lead and neutral

switch lead onto the frame. Lo-

cate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

J. Fasten the clutch cable, starter

motor lead, negative battery

lead, AC magneto lead and neu-

tral switch lead onto the frame.

Locate the clamp end facing to-

ward the rear of the frame and

cut off the tie end.

K. Pass the neutral switch lead and

AC magneto lead on the inside

of the wire harness.

L. Fasten the clutch cable, AC

magneto lead and neutral switch

lead onto the frame. Locate the

clamp end near the clutch cable

and cut off the tie end.M. Pass the clutch cable and wire

harness through the cable

guide.

N. Locate the couplers in the frame

recess.

O. Pass the carburetor breather

hoses, carburetor overflow hose

and catch tank breather hose so

that the hoses do not contact the

rear shock absorber.

P. Secure the coupler by pushing it

into the hole in the headlight

unit.

Q. Fasten the throttle position sen-

sor lead and the hot starter ca-

ble.

R. Locate the clamp between the

hot starter cable protector and

rubber cap.

Page 54 of 232

2-23

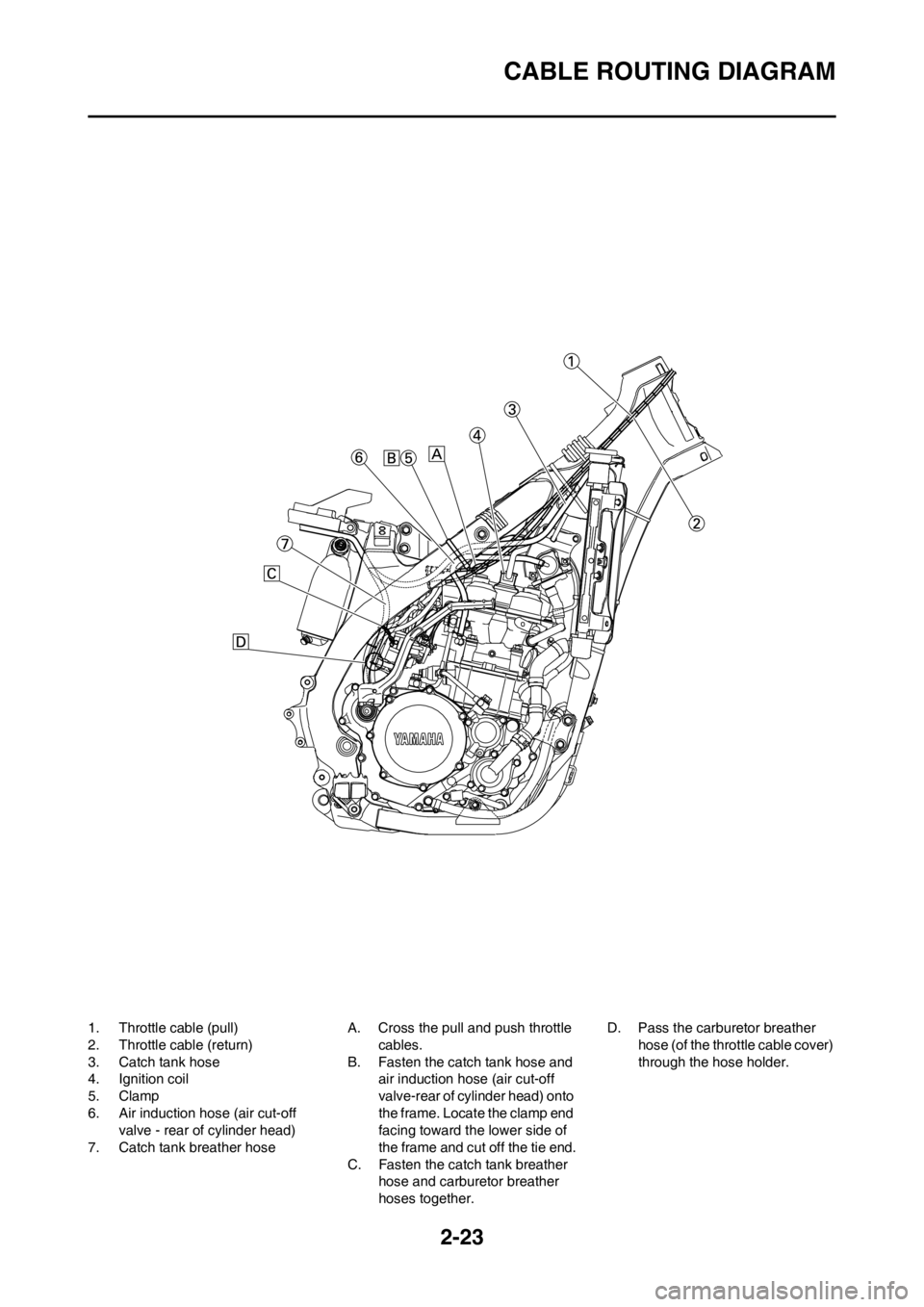

CABLE ROUTING DIAGRAM

1. Throttle cable (pull)

2. Throttle cable (return)

3. Catch tank hose

4. Ignition coil

5. Clamp

6. Air induction hose (air cut-off

valve - rear of cylinder head)

7. Catch tank breather hoseA. Cross the pull and push throttle

cables.

B. Fasten the catch tank hose and

air induction hose (air cut-off

valve-rear of cylinder head) onto

the frame. Locate the clamp end

facing toward the lower side of

the frame and cut off the tie end.

C. Fasten the catch tank breather

hose and carburetor breather

hoses together.D. Pass the carburetor breather

hose (of the throttle cable cover)

through the hose holder.

Page 55 of 232

2-24

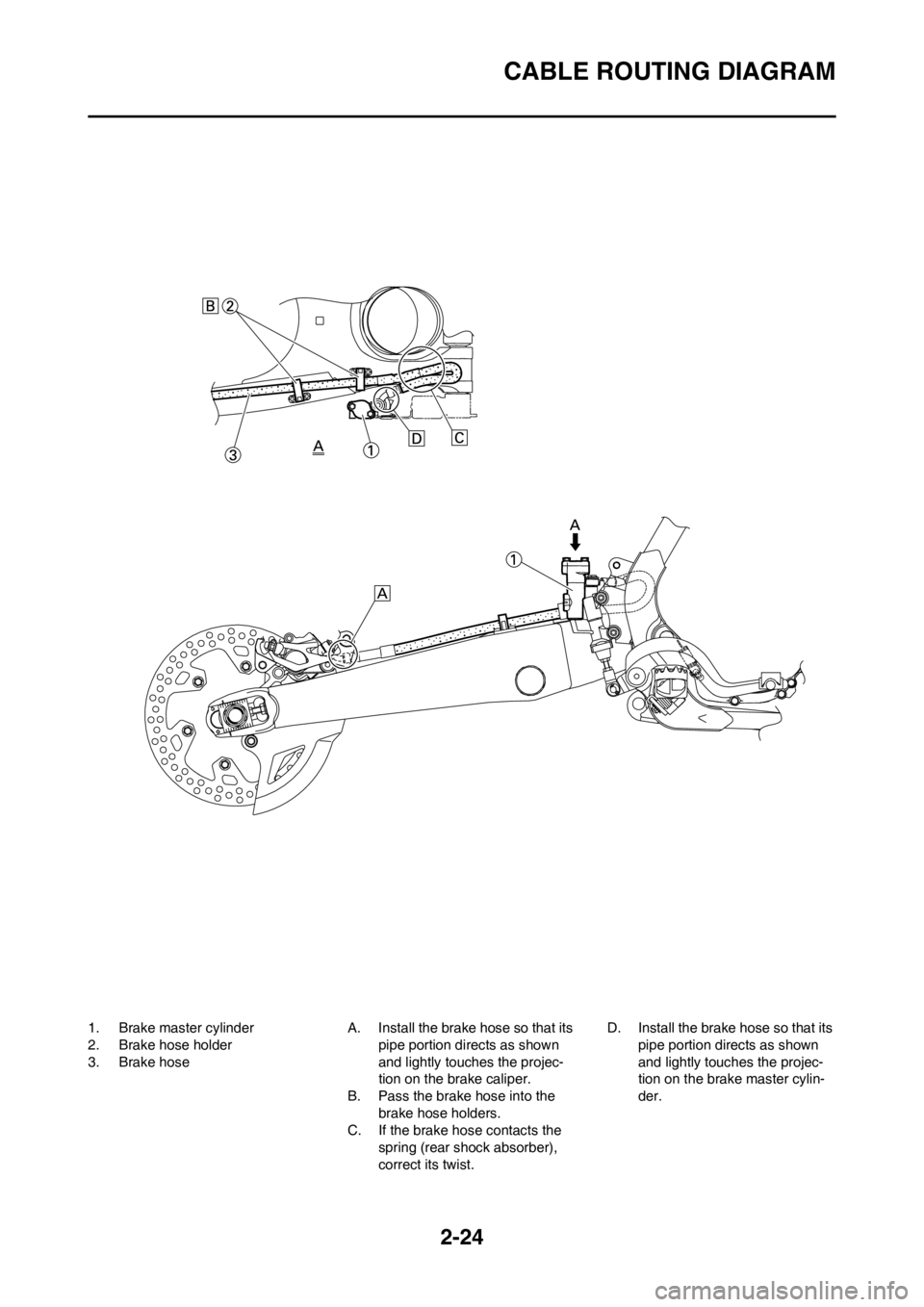

CABLE ROUTING DIAGRAM

1. Brake master cylinder

2. Brake hose holder

3. Brake hoseA. Install the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the brake caliper.

B. Pass the brake hose into the

brake hose holders.

C. If the brake hose contacts the

spring (rear shock absorber),

correct its twist.D. Install the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the brake master cylin-

der.

Page 56 of 232

2-25

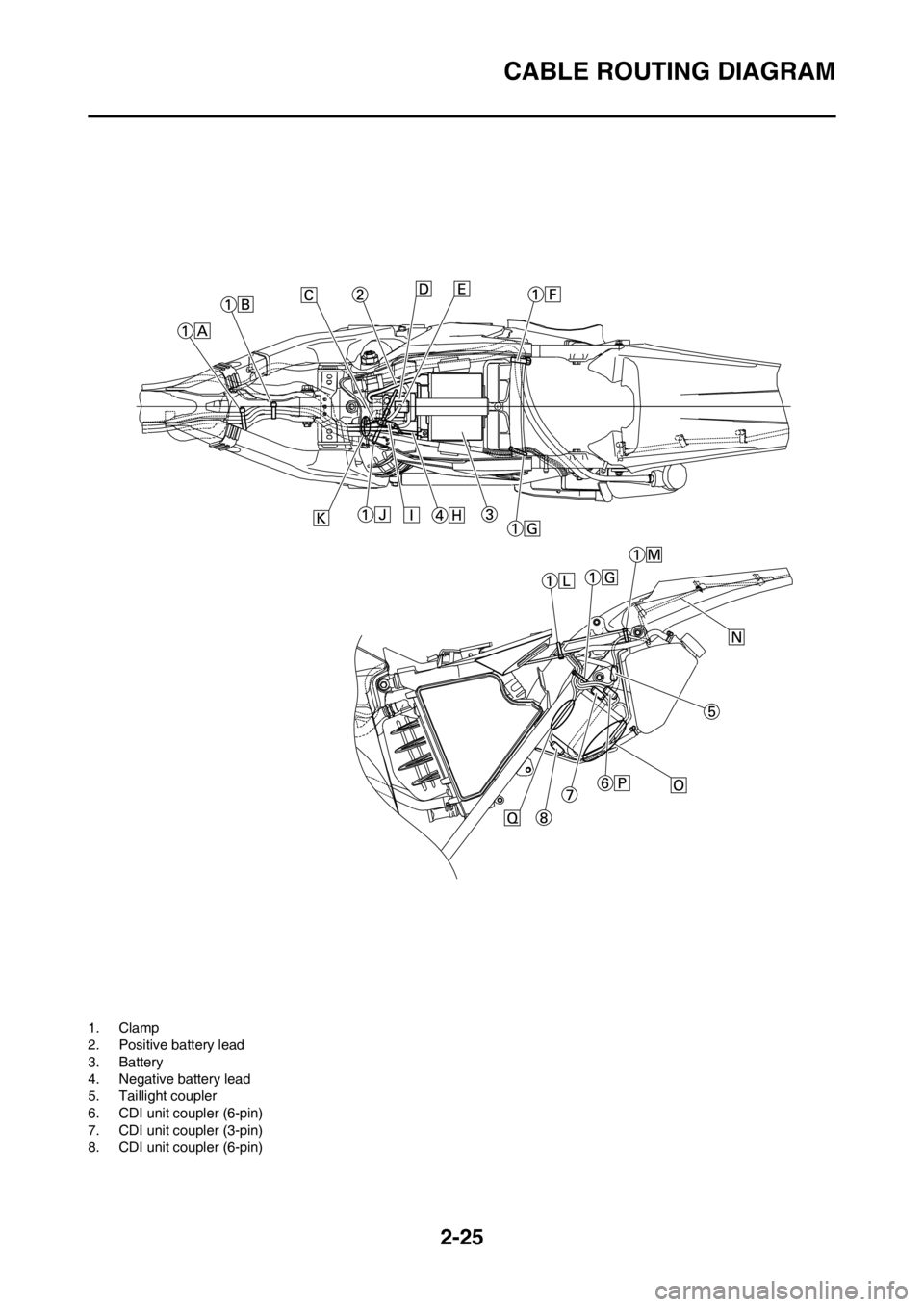

CABLE ROUTING DIAGRAM

1. Clamp

2. Positive battery lead

3. Battery

4. Negative battery lead

5. Taillight coupler

6. CDI unit coupler (6-pin)

7. CDI unit coupler (3-pin)

8. CDI unit coupler (6-pin)

Page 57 of 232

2-26

CABLE ROUTING DIAGRAM

A. Fasten the wire harness, nega-

tive battery lead and starter mo-

tor lead to the upper engine

bracket (left side). Locate the

clamp end facing toward the up-

per side of the frame with the tie

end cut off on the inside of the

frame.

B. Fasten the wire harness, nega-

tive battery lead and starter mo-

tor lead to the upper engine

bracket (left side). Locate the

clamp end facing toward the up-

per side of the frame with the tie

end cut off on the inside of the

frame. Clamp the wire harness

and negative lead at the mark-

ing.

C. Pass the starter motor lead

through the hole in the relay

holder.

D. Fit the cover securely.

E. Connect the wire harness to the

starter relay.

F. Fasten the catch tank breather

hose and catch tank hose to the

rear frame. Clamp them close to

where they are joined to the

frame. Fasten the pipe tightly

enough not to crush it. Locate

the clamp end facing toward the

rear of the frame with the tie end

facing downward.

G. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the upper side of

the frame and cut off the tie end.

H. Connect the negative battery

lead to the battery negative ter-

minal.

I. Connect the negative battery

lead to the wire harness.

J. Fasten the wire harness to the

rear frame. Locate the clamp

end facing toward the upper side

of the frame and the tie end to-

ward the inside of the frame.

Clamp the wire harness at the

marking.

K. Pass the wire harness, starter

relay lead, starting circuit cut-off

relay lead and negative battery

lead through the hole in the relay

holder.

L. Fasten the (three) CDI unit leads

and taillight lead to the rear

frame. Locate the clamp end

facing toward the lower side of

the frame and cut off the tie end.M. Fasten the taillight lead to the

rear frame. Locate the clamp

end facing toward the upper side

of the frame and cut off the tie

end.

N. Do not allow the taillight lead to

slacken.

O. Locate the CDI unit lead be-

tween the CDI unit and rear

fender.

P. Locate the CDI unit coupler in

the clearance between the up-

per side of the CDI unit and low-

er side of the catch tank stay.

Q. Locate the CDI unit lead be-

tween the CDI unit and rear

frame.

Page 58 of 232

2-27

CABLE ROUTING DIAGRAM

1. Throttle cable

2. Clamp

3. Brake hose

4. Clutch cable

5. Hose guide

6. Main switch coupler

7. Wire harness

8. Headlight coupler

9. Hot starter cable

10. Multi-function display bracket

11. Main switch12. Upper bracket

13. Clutch switch coupler

14. Engine stop switch coupler

15. Multi-function display coupler

16. Start switch coupler

17. Speed sensor coupler

18. Speed sensor lead

Page 59 of 232

2-28

CABLE ROUTING DIAGRAM

A. Fasten the start switch lead to

the handlebar with the plastic

bands.

B. Fasten the engine stop switch

lead and clutch switch lead to

the handlebar with the plastic

bands.

C. Pass the brake hose through

the hose guides.

D. Secure the coupler by inserting

it into the multi-function display

bracket.

E. Pass the throttle cables, clutch

cable and hot starter cable be-

tween the upper bracket and

multi-function display bracket.

F. Fasten the multi-function display

leads to the bracket. Cut off the

tie end.

G. Secure the coupler by pushing it

into the hole in the multi-function

display bracket.

H. Secure the wire harness clip by

pushing it into the hole in the

multi-function display bracket on

the inside.

I. Fasten the wire harness to the

multi-function display bracket.

Cut off the tie end.

J. Fasten the main switch lead

(wire harness side) to the multi-

function display bracket. Locate

the clamp end facing toward the

lower side of the frame and cut

off the tie end.

K. Pass the speed sensor lead

through the guide on the outside

of the front fork.

Page 60 of 232

3-1

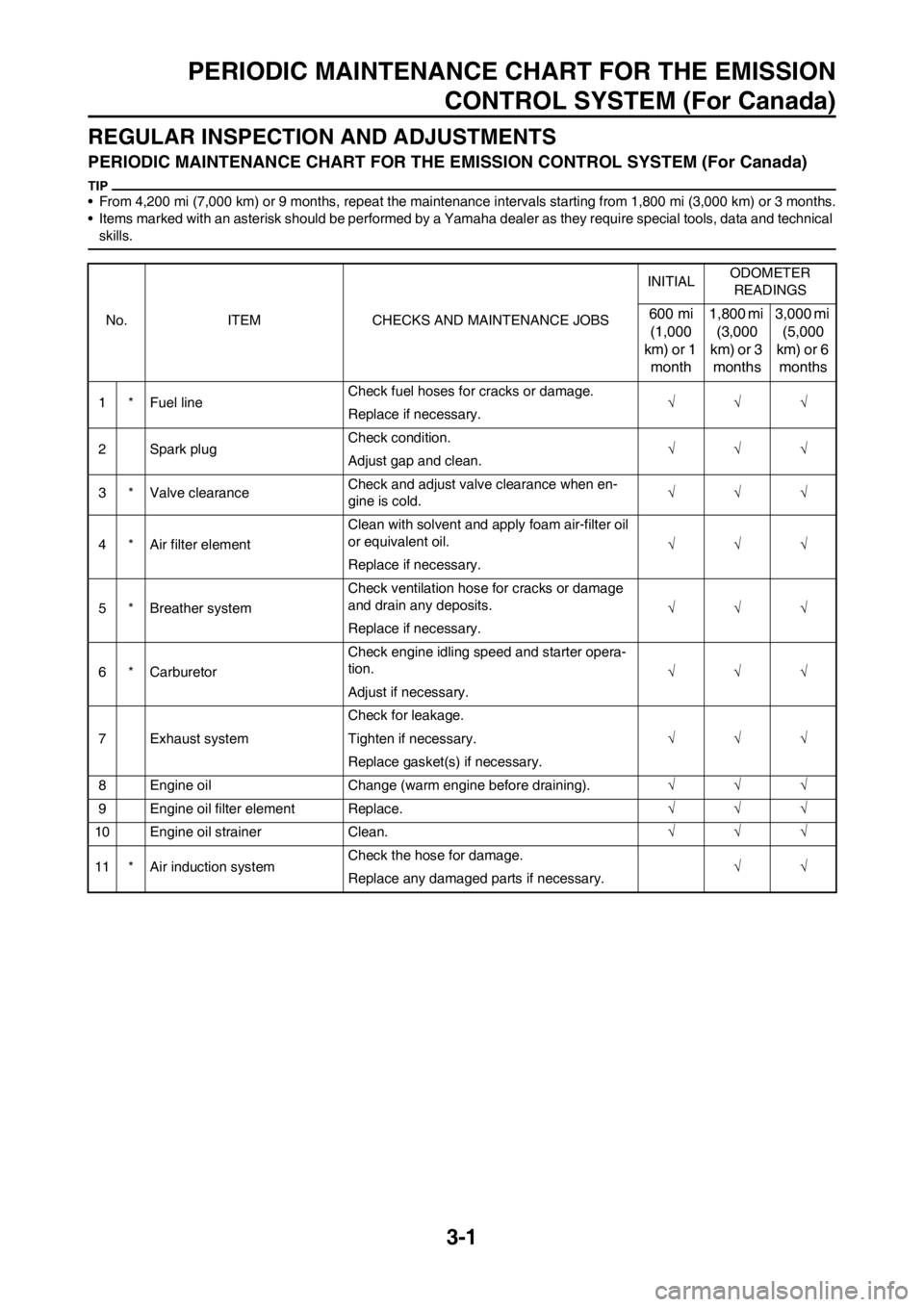

PERIODIC MAINTENANCE CHART FOR THE EMISSION

CONTROL SYSTEM (For Canada)

REGULAR INSPECTION AND ADJUSTMENTS

PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL SYSTEM (For Canada)

• From 4,200 mi (7,000 km) or 9 months, repeat the maintenance intervals starting from 1,800 mi (3,000 km) or 3 months.

• Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical

skills.

No. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER

READINGS600 mi

(1,000

km) or 1

month1,800 mi

(3,000

km) or 3

months3,000 mi

(5,000

km) or 6

months

1 * Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.

2 Spark plugCheck condition.

Adjust gap and clean.

3 * Valve clearanceCheck and adjust valve clearance when en-

gine is cold.

4 * Air filter elementClean with solvent and apply foam air-filter oil

or equivalent oil.

Replace if necessary.

5 * Breather systemCheck ventilation hose for cracks or damage

and drain any deposits.

Replace if necessary.

6 * CarburetorCheck engine idling speed and starter opera-

tion.

Adjust if necessary.

7 Exhaust systemCheck for leakage.

Tighten if necessary.

Replace gasket(s) if necessary.

8 Engine oil Change (warm engine before draining).

9 Engine oil filter element Replace.

10 Engine oil strainer Clean.

11 * Air induction systemCheck the hose for damage.

Replace any damaged parts if necessary.