clutch YAMAHA WR 250F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: WR 250F, Model: YAMAHA WR 250F 2014Pages: 230, PDF Size: 13.01 MB

Page 10 of 230

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-4

CONSUMER

INFORMATION................. 1-5

INCLUDED PARTS .......... 1-5

IMPORTANT

INFORMATION................. 1-5

CHECKING OF

CONNECTION .................. 1-6

SPECIAL TOOLS ............. 1-7

CONTROL

FUNCTIONS ................... 1-12

MULTI-FUNCTION

DISPLAY ........................ 1-13

STARTING AND

BREAK-IN ...................... 1-18

TORQUE-CHECK

POINTS........................... 1-20

CLEANING AND

STORAGE ...................... 1-21

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-12

LUBRICATION

DIAGRAMS .................... 2-19

CABLE ROUTING

DIAGRAM ....................... 2-21

CHAPTER 3

REGULAR INSPEC-

TION AND AD-

JUSTMENTS

MAINTENANCE INTER-

VALS FOR COMPETITION

USE ................................... 3-1

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-5

ENGINE ............................ 3-6

CHASSIS ........................ 3-17

ELECTRICAL ................. 3-27

CHAPTER 4

TUNING

ENGINE ............................ 4-1

CHASSIS .......................... 4-5

CHAPTER 5

ENGINE

RADIATOR ....................... 5-1

CARBURETOR................. 5-4

AIR INDICTOIN

SYSTEM ......................... 5-12

CAMSHAFTS.................. 5-14

CYLINDER HEAD........... 5-19

VALVES AND VALVE

SPRINGS ........................ 5-21

CYLINDER AND

PISTON ........................... 5-25

CLUTCH ......................... 5-29

OIL FILTER ELEMENT

AND WATER PUMP ....... 5-34

BALANCER .................... 5-39

OIL PUMP ....................... 5-41

KICK SHAFT AND

SHIFT SHAFT ................. 5-44

AC MAGNETO AND

STARTER CLUTCH ....... 5-49ENGINE REMOVAL........5-54

CRANKCASE AND

CRANKSHAFT ...............5-58

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK ...................5-64

CHAPTER 6

CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................6-1

FRONT BRAKE AND

REAR BRAKE ..................6-6

FRONT FORK .................6-16

HANDLEBAR..................6-23

STEERING ......................6-27

SWINGARM ....................6-31

REAR SHOCK

ABSORBER ....................6-36

CHAPTER 7

ELECTRICAL

ELECTRICAL COMPO-

NENTS AND WIRING

DIAGRAM .........................7-1

IGNITION SYSTEM...........7-3

ELECTRIC STARTING

SYSTEM............................7-5

CHARGING SYSTEM .....7-13

THROTTLE POSITION

SENSOR SYSTEM .........7-15

LIGHTING SYSTEM .......7-18

SIGNALING SYSTEM.....7-20

Page 14 of 230

1-4

DESCRIPTION

DESCRIPTION

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

1. Clutch lever

2. Hot starter lever

3. Engine stop switch

4. Multi-function display

5. Main switch

6. Start switch

7. Front brake lever

8. Throttle grip

9. Radiator cap

10. Fuel tank cap

11. Taillight

12. Kickstarter lever

13. Fuel tank14. Headlight

15. Radiator

16. Coolant drain bolt

17. Rear brake pedal

18. Valve joint

19. Fuel cock

20. Cold starter knob

21. Air cleaner

22. Catch tank

23. Drive chain

24. Oil level check window

25. Shift pedal

26. Front fork

Page 19 of 230

1-9

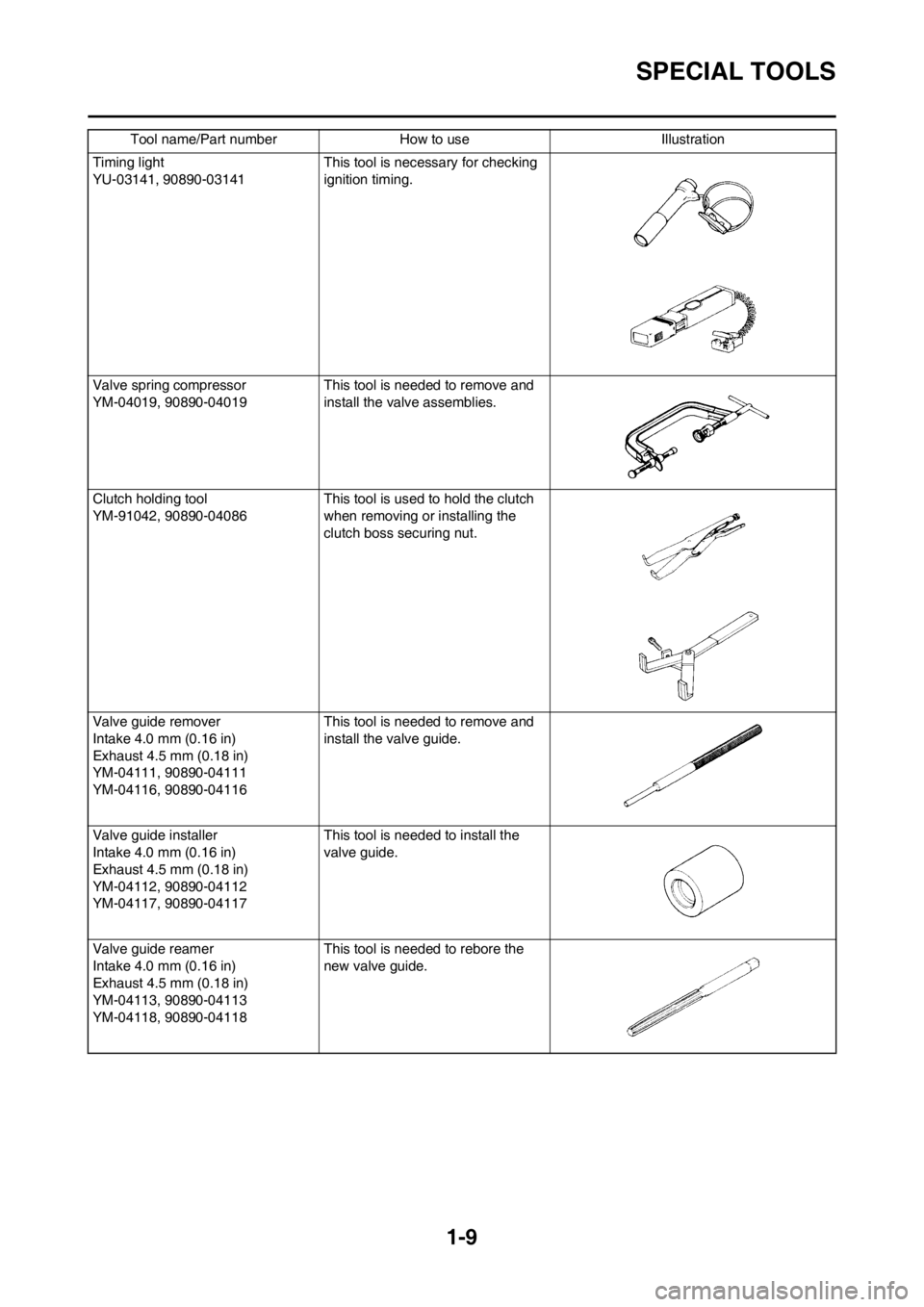

SPECIAL TOOLS

Timing light

YU-03141, 90890-03141 This tool is necessary for checking

ignition timing.

Valve spring compressor

YM-04019, 90890-04019 This tool is needed to remove and

install the valve assemblies.

Clutch holding tool

YM-91042, 90890-04086This tool is used to hold the clutch

when removing or installing the

clutch boss securing nut.

Valve guide remover

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

YM-04111, 90890-04111

YM-04116, 90890-04116This tool is needed to remove and

install the valve guide.

Valve guide installer

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

YM-04112, 90890-04112

YM-04117, 90890-04117This tool is needed to install the

valve guide.

Valve guide reamer

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

YM-04113, 90890-04113

YM-04118, 90890-04118This tool is needed to rebore the

new valve guide. Tool name/Part number How to use Illustration

Page 22 of 230

1-12

CONTROL FUNCTIONS

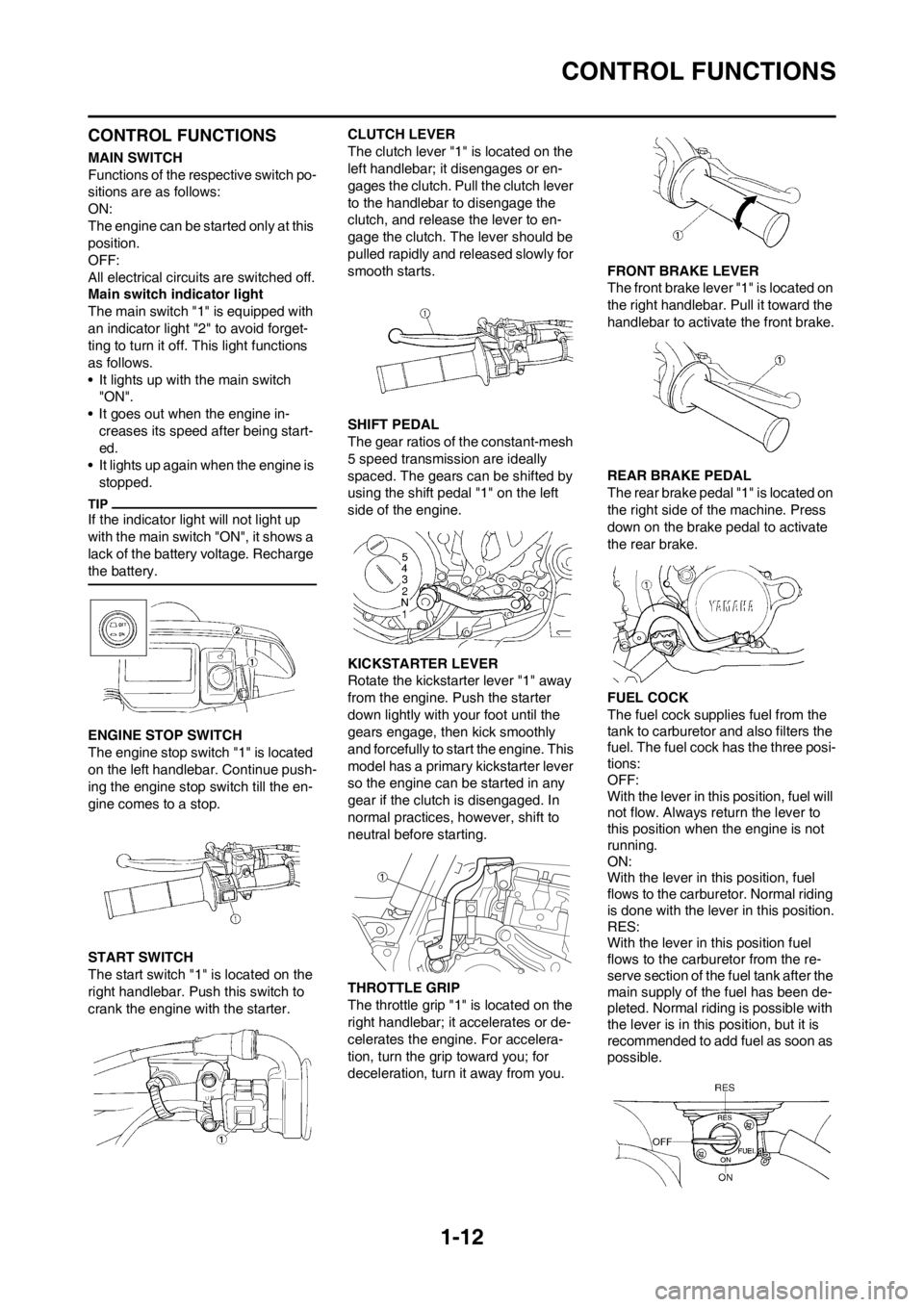

CONTROL FUNCTIONS

MAIN SWITCH

Functions of the respective switch po-

sitions are as follows:

ON:

The engine can be started only at this

position.

OFF:

All electrical circuits are switched off.

Main switch indicator light

The main switch "1" is equipped with

an indicator light "2" to avoid forget-

ting to turn it off. This light functions

as follows.

• It lights up with the main switch

"ON".

• It goes out when the engine in-

creases its speed after being start-

ed.

• It lights up again when the engine is

stopped.

If the indicator light will not light up

with the main switch "ON", it shows a

lack of the battery voltage. Recharge

the battery.

ENGINE STOP SWITCH

The engine stop switch "1" is located

on the left handlebar. Continue push-

ing the engine stop switch till the en-

gine comes to a stop.

START SWITCH

The start switch "1" is located on the

right handlebar. Push this switch to

crank the engine with the starter.CLUTCH LEVER

The clutch lever "1" is located on the

left handlebar; it disengages or en-

gages the clutch. Pull the clutch lever

to the handlebar to disengage the

clutch, and release the lever to en-

gage the clutch. The lever should be

pulled rapidly and released slowly for

smooth starts.

SHIFT PEDAL

The gear ratios of the constant-mesh

5 speed transmission are ideally

spaced. The gears can be shifted by

using the shift pedal "1" on the left

side of the engine.

KICKSTARTER LEVER

Rotate the kickstarter lever "1" away

from the engine. Push the starter

down lightly with your foot until the

gears engage, then kick smoothly

and forcefully to start the engine. This

model has a primary kickstarter lever

so the engine can be started in any

gear if the clutch is disengaged. In

normal practices, however, shift to

neutral before starting.

THROTTLE GRIP

The throttle grip "1" is located on the

right handlebar; it accelerates or de-

celerates the engine. For accelera-

tion, turn the grip toward you; for

deceleration, turn it away from you.FRONT BRAKE LEVER

The front brake lever "1" is located on

the right handlebar. Pull it toward the

handlebar to activate the front brake.

REAR BRAKE PEDAL

The rear brake pedal "1" is located on

the right side of the machine. Press

down on the brake pedal to activate

the rear brake.

FUEL COCK

The fuel cock supplies fuel from the

tank to carburetor and also filters the

fuel. The fuel cock has the three posi-

tions:

OFF:

With the lever in this position, fuel will

not flow. Always return the lever to

this position when the engine is not

running.

ON:

With the lever in this position, fuel

flows to the carburetor. Normal riding

is done with the lever in this position.

RES:

With the lever in this position fuel

flows to the carburetor from the re-

serve section of the fuel tank after the

main supply of the fuel has been de-

pleted. Normal riding is possible with

the lever is in this position, but it is

recommended to add fuel as soon as

possible.

Page 28 of 230

1-18

STARTING AND BREAK-IN

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline.

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine inter-

nal parts such as valves, piston

rings, and exhaust system, etc.

If knocking or pinging occurs, use a

different brand of gasoline or higher

octane grade.

• For refueling, be sure to stop the

engine and use enough care not

to spill any fuel. Also be sure to

avoid refueling close to a fire.

• Refuel after the engine, exhaust

pipe, etc. have cooled off.

HANDLING NOTE

Never start or run the engine in a

closed area. The exhaust fumes

are poisonous; they can cause

loss of consciousness and death

in a very short time. Always oper-

ate the machine in a well-ventilated

area.

• The carburetor on this machine

has a built-in accelerator pump.

Therefore, when starting the en-

gine, do not operate the throttle

or the spark plug will foul.

• Unlike a two-stroke engine, this

engine cannot be kick started

when the throttle is open be-

cause the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, per-

form the checks in the pre-opera-

tion check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may ad-

versely affect engine starting.)

STARTING A COLD ENGINE

This model is equipped with an igni-

tion circuit cut-off system. The engine

can be started under the following

conditions.

• When the transmission is in neutral.

• When the clutch is disengaged with

the transmission in any position.

However, it is recommended to shift

into neutral before starting the en-

gine.

1. Inspect the coolant level.

2. Turn the fuel cock to "ON".

3. Push on the main switch to "ON".

4. Shift the transmission into neutral.

5. Fully open the cold starter knob

"1".

6. Start the engine by pushing the

start switch or by kicking the kick-

starter lever.

If the engine fails to start by pushing

the start switch, release the switch,

wait a few seconds, and then try

again. Each starting attempt should

be as short as possible to preserve

the battery. Do not crank the engine

more than 10 seconds on any one at-

tempt. If the engine does not start

with the starter motor, try using the

kickstarter lever.

• If the starter motor will not turn

when pushing the start switch,

stop pushing it immediately and

kick start the engine in order to

avoid the load on the motor.

• Do not open the throttle while

kicking the kickstarter lever. Oth-

erwise, the kickstarter lever may

kick back.

7. Return the cold starter knob to its

original position and run the en-

gine at 3,000–5,000 r/min for 1 or

2 minutes.

Since this model is equipped with an

accelerator pump, if the engine is

raced (the throttle opened and

closed), the air/fuel mixture will be too

rich and the engine may stall. Also

unlike a two-stroke engine, this model

can idle.

Do not warm up the engine for ex-

tended periods of time.

STARTING A WARM ENGINE

Do not operate the cold starter knob

and throttle. Pull the hot starter lever

"1" and start the engine by pushing

the start switch or by kicking the kick-

starter lever forcefully with a firm

stroke. As soon as the engine starts,

Release the hot starter lever to close

the air passage.

Restarting an engine after a fall

Pull the hot starter lever and start the

engine. As soon as the engine starts,

Release the hot starter lever to close

the air passage.

The engine fails to start

Pull the hot starter lever all the way

out and while holding the lever, kick

the kickstarter lever 10 to 20 times to

clear the engine. Then, restart the en-

gine. Refer to "Restarting an engine

after a fall". Recommended fuel:

Premium unleaded

gasoline only with a re-

search octane number

of 95 or higher.

Page 33 of 230

2-2

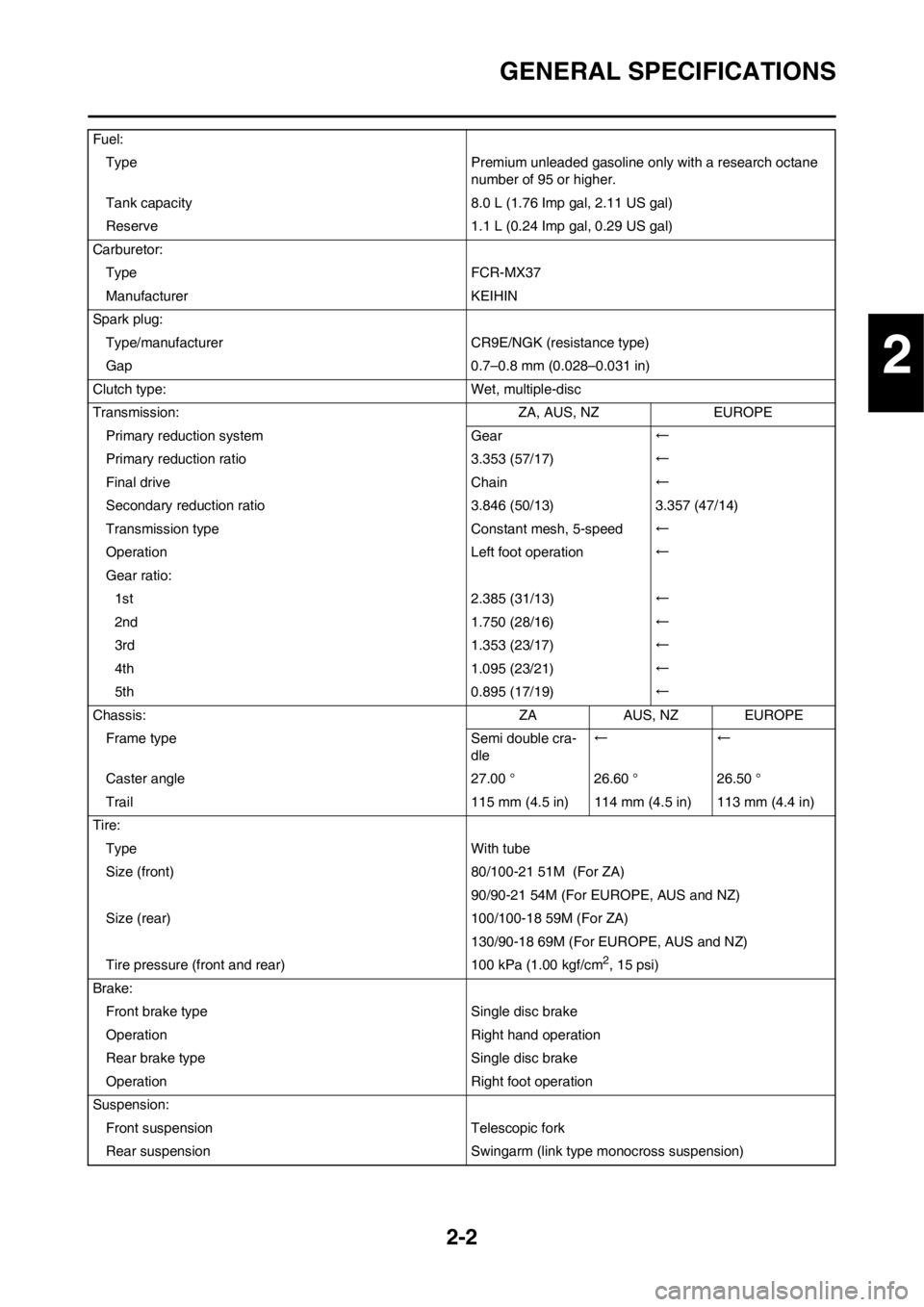

GENERAL SPECIFICATIONS

Fuel:

Type Premium unleaded gasoline only with a research octane

number of 95 or higher.

Tank capacity 8.0 L (1.76 Imp gal, 2.11 US gal)

Reserve 1.1 L (0.24 Imp gal, 0.29 US gal)

Carburetor:

Type FCR-MX37

Manufacturer KEIHIN

Spark plug:

Type/manufacturer CR9E/NGK (resistance type)

Gap 0.7–0.8 mm (0.028–0.031 in)

Clutch type: Wet, multiple-disc

Transmission: ZA, AUS, NZ EUROPE

Primary reduction system Gear←

Primary reduction ratio 3.353 (57/17)←

Final drive Chain←

Secondary reduction ratio 3.846 (50/13) 3.357 (47/14)

Transmission type Constant mesh, 5-speed←

Operation Left foot operation←

Gear ratio:

1st 2.385 (31/13)←

2nd 1.750 (28/16)←

3rd 1.353 (23/17)←

4th 1.095 (23/21)←

5th 0.895 (17/19)←

Chassis: ZA AUS, NZ EUROPE

Frame type Semi double cra-

dle←←

Caster angle 27.00 ° 26.60 ° 26.50 °

Trail 115 mm (4.5 in) 114 mm (4.5 in) 113 mm (4.4 in)

Tire:

Type With tube

Size (front) 80/100-21 51M (For ZA)

90/90-21 54M (For EUROPE, AUS and NZ)

Size (rear) 100/100-18 59M (For ZA)

130/90-18 69M (For EUROPE, AUS and NZ)

Tire pressure (front and rear) 100 kPa (1.00 kgf/cm

2, 15 psi)

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

2

Page 38 of 230

2-7

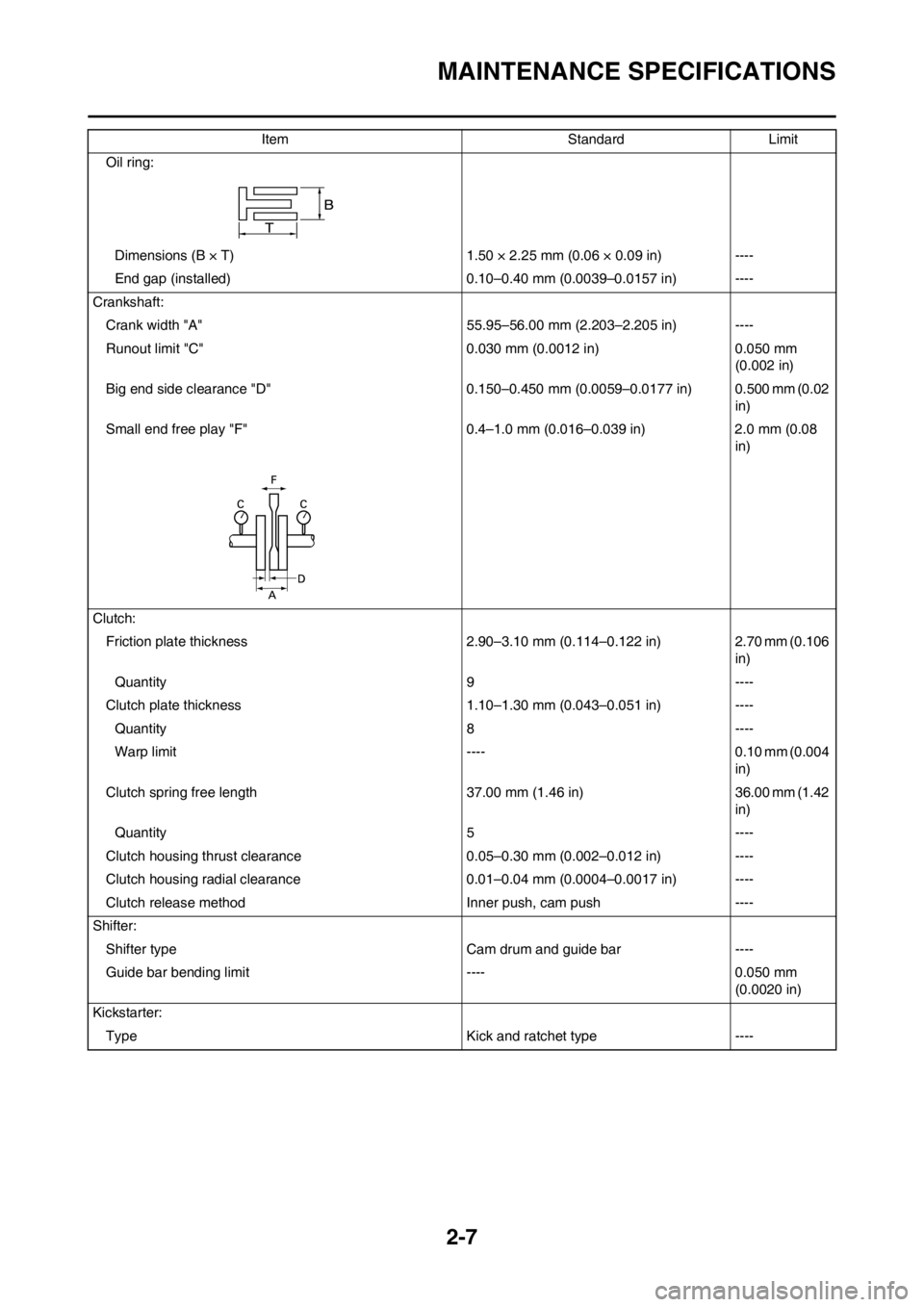

MAINTENANCE SPECIFICATIONS

Oil ring:

Dimensions (B × T) 1.50 × 2.25 mm (0.06 × 0.09 in) ----

End gap (installed) 0.10–0.40 mm (0.0039–0.0157 in) ----

Crankshaft:

Crank width "A" 55.95–56.00 mm (2.203–2.205 in) ----

Runout limit "C" 0.030 mm (0.0012 in) 0.050 mm

(0.002 in)

Big end side clearance "D" 0.150–0.450 mm (0.0059–0.0177 in) 0.500 mm (0.02

in)

Small end free play "F" 0.4–1.0 mm (0.016–0.039 in) 2.0 mm (0.08

in)

Clutch:

Friction plate thickness 2.90–3.10 mm (0.114–0.122 in) 2.70 mm (0.106

in)

Quantity 9 ----

Clutch plate thickness 1.10–1.30 mm (0.043–0.051 in) ----

Quantity 8 ----

Warp limit ---- 0.10 mm (0.004

in)

Clutch spring free length 37.00 mm (1.46 in) 36.00 mm (1.42

in)

Quantity 5 ----

Clutch housing thrust clearance 0.05–0.30 mm (0.002–0.012 in) ----

Clutch housing radial clearance 0.01–0.04 mm (0.0004–0.0017 in) ----

Clutch release method Inner push, cam push ----

Shifter:

Shifter type Cam drum and guide bar ----

Guide bar bending limit ---- 0.050 mm

(0.0020 in)

Kickstarter:

Type Kick and ratchet type ----Item Standard Limit

Page 41 of 230

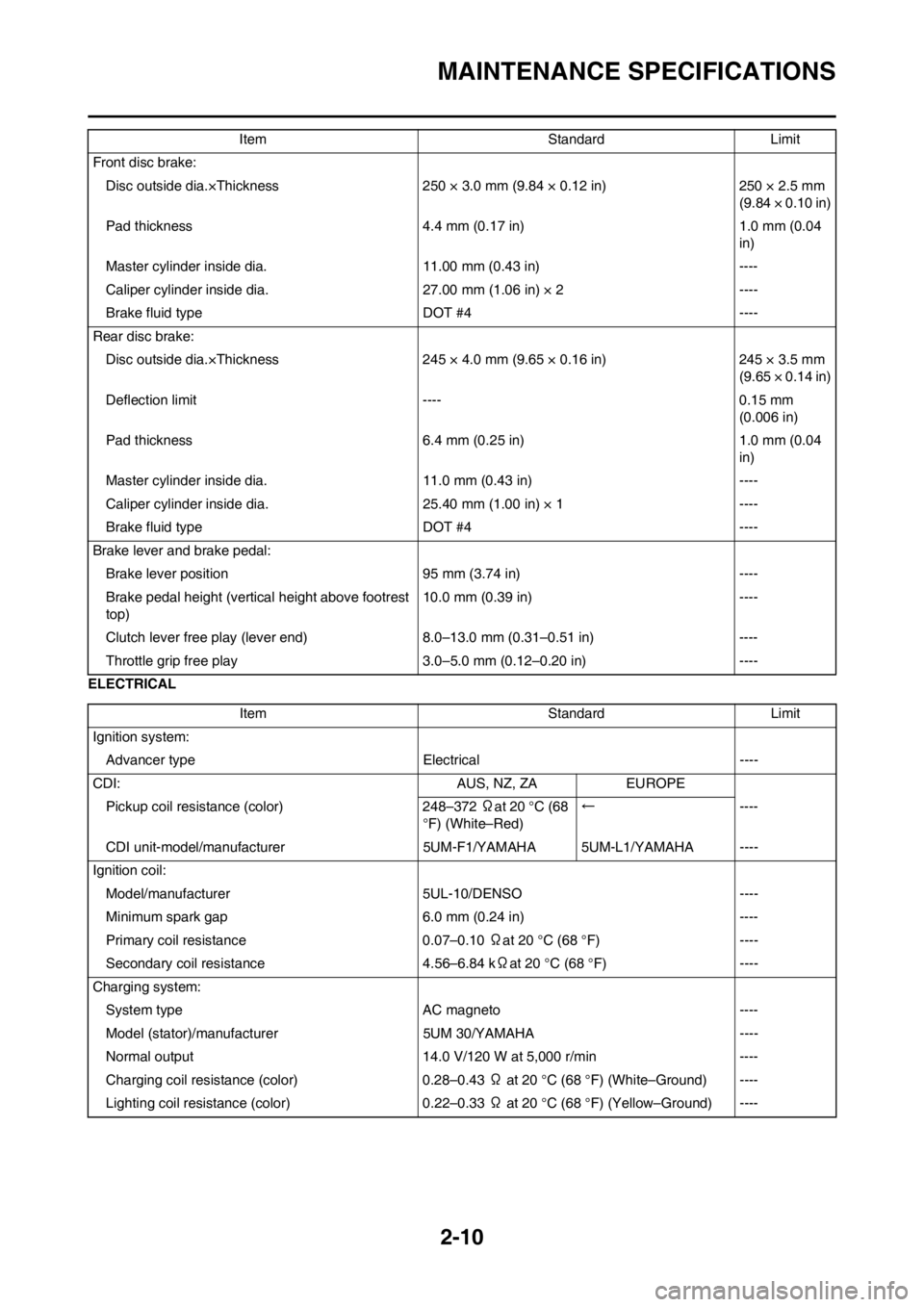

2-10

MAINTENANCE SPECIFICATIONS

ELECTRICALFront disc brake:

Disc outside dia.×Thickness 250 × 3.0 mm (9.84 × 0.12 in) 250 × 2.5 mm

(9.84 × 0.10 in)

Pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 11.00 mm (0.43 in) ----

Caliper cylinder inside dia.27.00 mm (1.06 in) × 2 ----

Brake fluid type DOT #4 ----

Rear disc brake:

Disc outside dia.×Thickness 245 × 4.0 mm (9.65 × 0.16 in) 245 × 3.5 mm

(9.65 × 0.14 in)

Deflection limit ---- 0.15 mm

(0.006 in)

Pad thickness 6.4 mm (0.25 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 11.0 mm (0.43 in) ----

Caliper cylinder inside dia.25.40 mm (1.00 in) × 1 ----

Brake fluid type DOT #4 ----

Brake lever and brake pedal:

Brake lever position 95 mm (3.74 in) ----

Brake pedal height (vertical height above footrest

top)10.0 mm (0.39 in) ----

Clutch lever free play (lever end) 8.0–13.0 mm (0.31–0.51 in) ----

Throttle grip free play 3.0–5.0 mm (0.12–0.20 in) ---- Item Standard Limit

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI: AUS, NZ, ZA EUROPE

Pickup coil resistance (color) 248–372 Ωat 20 °C (68

°F) (White–Red)←----

CDI unit-model/manufacturer5UM-F1/YAMAHA 5UM-L1/YAMAHA ----

Ignition coil:

Model/manufacturer 5UL-10/DENSO ----

Minimum spark gap 6.0 mm (0.24 in) ----

Primary coil resistance 0.07–0.10 Ωat 20 °C (68 °F) ----

Secondary coil resistance 4.56–6.84 kΩat 20 °C (68 °F) ----

Charging system:

System type AC magneto ----

Model (stator)/manufacturer 5UM 30/YAMAHA ----

Normal output 14.0 V/120 W at 5,000 r/min ----

Charging coil resistance (color) 0.28–0.43 Ω at 20 °C (68 °F) (White–Ground) ----

Lighting coil resistance (color) 0.22–0.33 Ω at 20 °C (68 °F) (Yellow–Ground) ----

Page 44 of 230

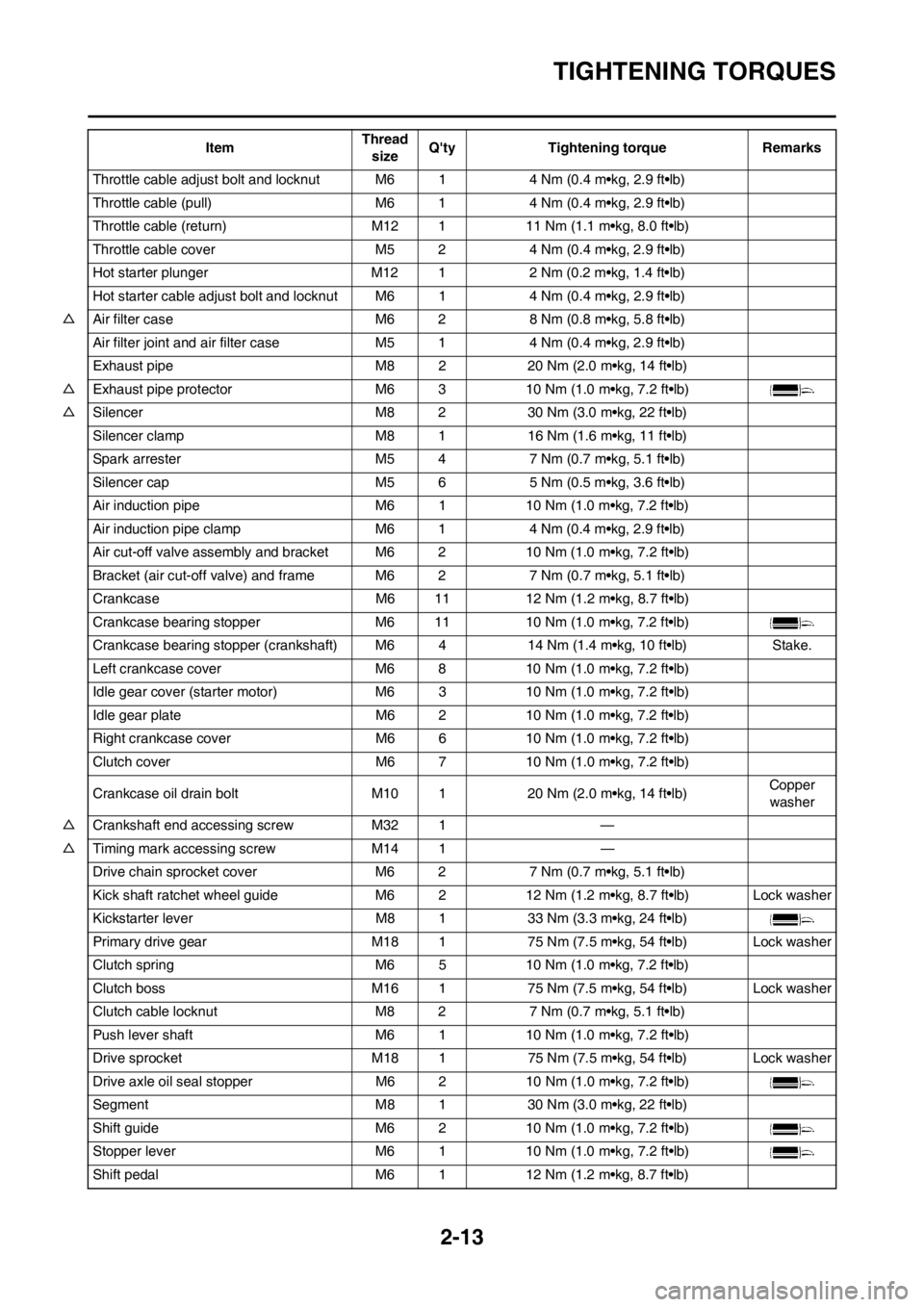

2-13

TIGHTENING TORQUES

Throttle cable adjust bolt and locknut M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Throttle cable (pull) M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Throttle cable (return) M12 1 11 Nm (1.1 m•kg, 8.0 ft•lb)

Throttle cable cover M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Hot starter plunger M12 1 2 Nm (0.2 m•kg, 1.4 ft•lb)

Hot starter cable adjust bolt and locknut M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

△Air filter case M6 2 8 Nm (0.8 m•kg, 5.8 ft•lb)

Air filter joint and air filter case M5 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Exhaust pipe M8 2 20 Nm (2.0 m•kg, 14 ft•lb)

△Exhaust pipe protector M6 3 10 Nm (1.0 m•kg, 7.2 ft•lb)

△Silencer M8 2 30 Nm (3.0 m•kg, 22 ft•lb)

Silencer clamp M8 1 16 Nm (1.6 m•kg, 11 ft•lb)

Spark arrester M5 4 7 Nm (0.7 m•kg, 5.1 ft•lb)

Silencer cap M5 6 5 Nm (0.5 m•kg, 3.6 ft•lb)

Air induction pipe M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Air induction pipe clamp M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Air cut-off valve assembly and bracket M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Bracket (air cut-off valve) and frame M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Crankcase M6 11 12 Nm (1.2 m•kg, 8.7 ft•lb)

Crankcase bearing stopper M6 11 10 Nm (1.0 m•kg, 7.2 ft•lb)

Crankcase bearing stopper (crankshaft) M6 4 14 Nm (1.4 m•kg, 10 ft•lb) Stake.

Left crankcase cover M6 8 10 Nm (1.0 m•kg, 7.2 ft•lb)

Idle gear cover (starter motor)M6 3 10 Nm (1.0 m•kg, 7.2 ft•lb)

Idle gear plate M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Right crankcase cover M6 6 10 Nm (1.0 m•kg, 7.2 ft•lb)

Clutch cover M6 7 10 Nm (1.0 m•kg, 7.2 ft•lb)

Crankcase oil drain bolt M10 1 20 Nm (2.0 m•kg, 14 ft•lb)Copper

washer

△Crankshaft end accessing screw M32 1 —

△Timing mark accessing screw M14 1 —

Drive chain sprocket cover M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Kick shaft ratchet wheel guide M6 2 12 Nm (1.2 m•kg, 8.7 ft•lb) Lock washer

Kickstarter lever M8 1 33 Nm (3.3 m•kg, 24 ft•lb)

Primary drive gear M18 1 75 Nm (7.5 m•kg, 54 ft•lb) Lock washer

Clutch spring M6 5 10 Nm (1.0 m•kg, 7.2 ft•lb)

Clutch boss M16 1 75 Nm (7.5 m•kg, 54 ft•lb) Lock washer

Clutch cable locknut M8 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Push lever shaft M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Drive sprocket M18 1 75 Nm (7.5 m•kg, 54 ft•lb) Lock washer

Drive axle oil seal stopper M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Segment M8 1 30 Nm (3.0 m•kg, 22 ft•lb)

Shift guide M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Stopper lever M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Shift pedal M6 1 12 Nm (1.2 m•kg, 8.7 ft•lb)ItemThread

sizeQ'ty Tightening torque Remarks

Page 45 of 230

2-14

TIGHTENING TORQUES

CHASSIS

△- marked portion shall be checked for torque tightening after break-in or before each race.

ItemThread

sizeQ'ty Tightening torque Remarks

△Upper bracket and outer tube M84 21 Nm (2.1 m•kg, 15 ft•lb)

△Lower bracket and outer tube M8 4 21 Nm (2.1 m•kg, 15 ft•lb)

△Upper bracket and steering stem M24 1 145 Nm (14.5 m•kg, 105 ft•lb)

△Handlebar upper holder and handlebar

lower holderM8 4 28 Nm (2.8 m•kg, 20 ft•lb)

△Handlebar lower holder and upper brack-

etM10 2 34 Nm (3.4 m•kg, 24 ft•lb)

△Steering stem and steering ring nut M28 1 Refer to TIP.

Front fork and front fork cap bolt M51 2 30 Nm (3.0 m•kg, 22 ft•lb)

Front fork and base valve M30 2 55 Nm (5.5 m•kg, 40 ft•lb)Copper

washer

Front fork cap bolt and damper rod M12 2 29 Nm (2.9 m•kg, 21 ft•lb)

Front fork bleed screw and front fork cap

boltM5 2 1 Nm (0.1 m•kg, 0.7 ft•lb)

△Front fork and front fork protector M6 6 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Front fork protector and brake hose hold-

erM6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Throttle grip cap M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Start switch M3 1 0.5 Nm (0.05 m•kg, 0.36 ft•lb)

Engine stop switch M3 1 0.5 Nm (0.05 m•kg, 0.36 ft•lb)

△Front brake master cylinder M6 29 Nm (0.9 m•kg, 6.5 ft•lb)

Brake lever mounting bolt M6 1 6 Nm (0.6 m•kg, 4.3 ft•lb)

Brake lever mounting nut M6 1 6 Nm (0.6 m•kg, 4.3 ft•lb)

Brake lever position locknut M6 1 5 Nm (0.5 m•kg, 3.6 ft•lb)

△Front brake hose guide and front brake

hose guide bracketM5 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

△Front brake hose guide and lower bracket M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Clutch lever holder M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Clutch lever mounting nut M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Hot starter lever holder M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Hot starter lever mounting nut M5 1 2 Nm (0.2 m•kg, 1.4 ft•lb)

Front brake master cylinder cap M4 2 2 Nm (0.2 m•kg, 1.4 ft•lb)

△

Front brake hose union bolt M10 2 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△Front brake caliper M8 2 23 Nm (2.3 m•kg, 17 ft•lb)

△Front brake caliper and brake hose holder M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)

Pad pin plug M10 2 3 Nm (0.3 m•kg, 2.2 ft•lb)

△Front brake caliper and pad pin M10 1 18 Nm (1.8 m•kg, 13 ft•lb)

△Rear brake caliper and pad pin M10 1 18 Nm (1.8 m•kg, 13 ft•lb)

△Brake caliper and bleed screw M8 2 6 Nm (0.6 m•kg, 4.3 ft•lb)

△Front wheel axle and axle nut M16 1 90 Nm (9.0 m•kg, 65 ft•lb)

△Front wheel axle holder M8 4 21 Nm (2.1 m•kg, 15 ft•lb)