width YAMAHA WR 250F 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: WR 250F, Model: YAMAHA WR 250F 2014Pages: 230, PDF Size: 13.01 MB

Page 32 of 230

2-1

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name: WR250FE (AUS, NZ)

WR250F (EUROPE, ZA)

Model code number: 1HCD (EUROPE)

1HCE (AUS, NZ, ZA)

Dimensions: ZA AUS, NZ EUROPE

Overall length 2,165 mm (85.2

in)2,175 mm (85.6

in)2,185 mm (86.0

in)

Overall width 825 mm (32.5 in)←←

Overall height 1,300 mm (51.2

in)1,305 mm (51.4

in)←

Seat height 980 mm (38.6 in) 990 mm (39.0 in)←

Wheelbase 1,480 mm (58.3

in)←1,485 mm (58.5

in)

Minimum ground clearance 365 mm (14.37 in)←←

Weight: ZA EUROPE, AUS, NZ

Curb weight

116 kg (256 lb)117 kg (258 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder

Displacement 250 cm

3 (8.80 Imp oz, 8.45 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 12.5 : 1

Starting system Kick and electric starter

Lubrication system: Dry sump

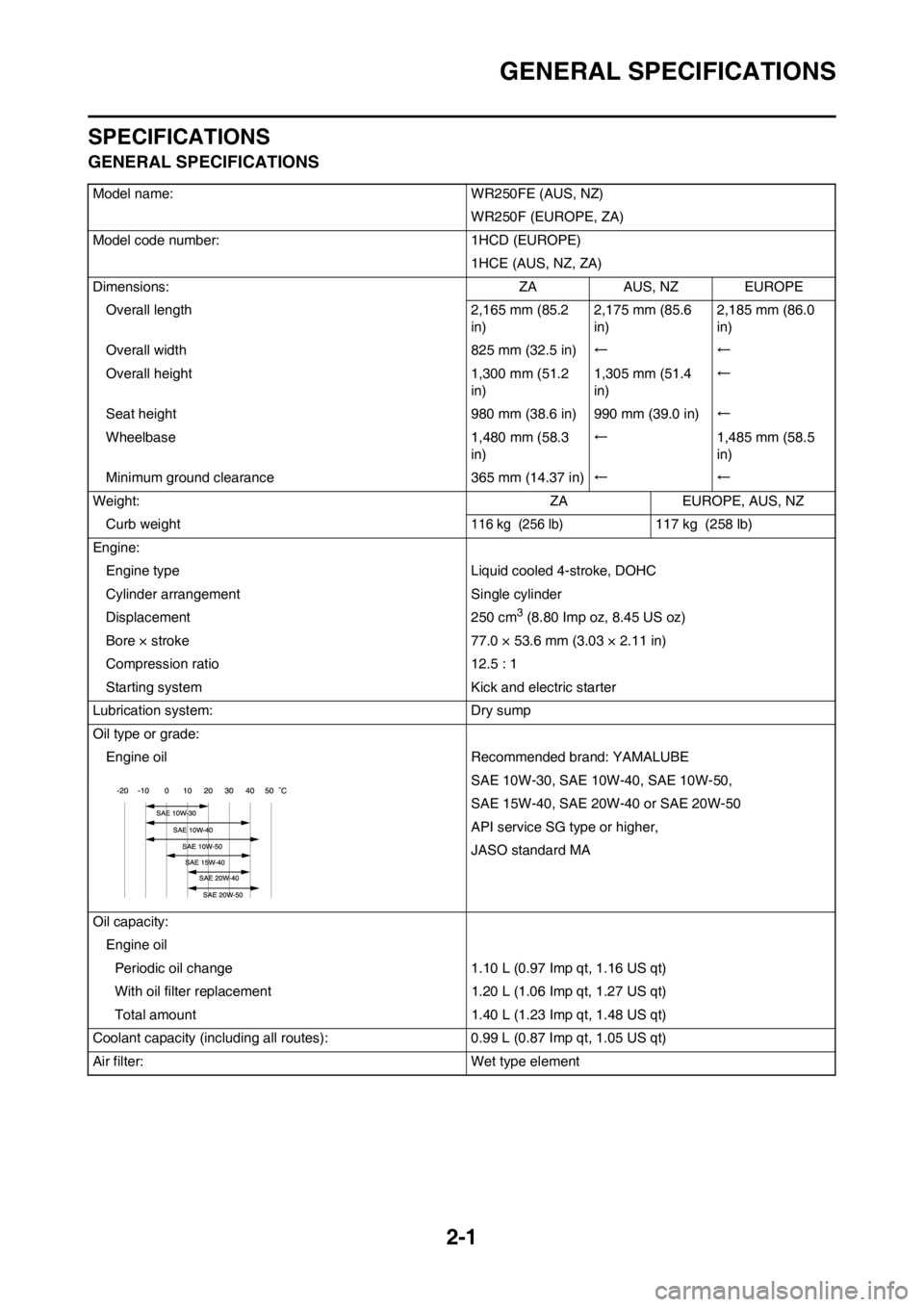

Oil type or grade:

Engine oil Recommended brand: YAMALUBE

SAE 10W-30, SAE 10W-40, SAE 10W-50,

SAE 15W-40, SAE 20W-40 or SAE 20W-50

API service SG type or higher,

JASO standard MA

Oil capacity:

Engine oil

Periodic oil change 1.10 L (0.97 Imp qt, 1.16 US qt)

With oil filter replacement 1.20 L (1.06 Imp qt, 1.27 US qt)

Total amount 1.40 L (1.23 Imp qt, 1.48 US qt)

Coolant capacity (including all routes): 0.99 L (0.87 Imp qt, 1.05 US qt)

Air filter: Wet type element

Page 35 of 230

2-4

MAINTENANCE SPECIFICATIONS

Intake "A" 29.650–29.750 mm (1.1673–1.1713 in) 29.550 mm

(1.1634 in)

Intake "B" 22.450–22.550 mm (0.8839–0.8878 in) 22.350 mm

(0.8799 in)

Exhaust "A" 30.399–30.499 mm (1.1968–1.2007 in) 30.299 mm

(1.1929 in)

Exhaust "B" 22.450–22.550 mm (0.8839–0.8878 in) 22.350 mm

(0.8799 in)

Camshaft runout limit ---- 0.015 mm

(0.0006 in)

Timing chain:

Timing chain type/No. of links 92RH2010-114M/114 ----

Timing chain adjustment method Automatic ----

Valve, valve seat, valve guide:

Valve clearance (cold)

IN 0.10–0.15 mm (0.0039–0.0059 in) ----

EX 0.17–0.22 mm (0.0067–0.0087 in) ----

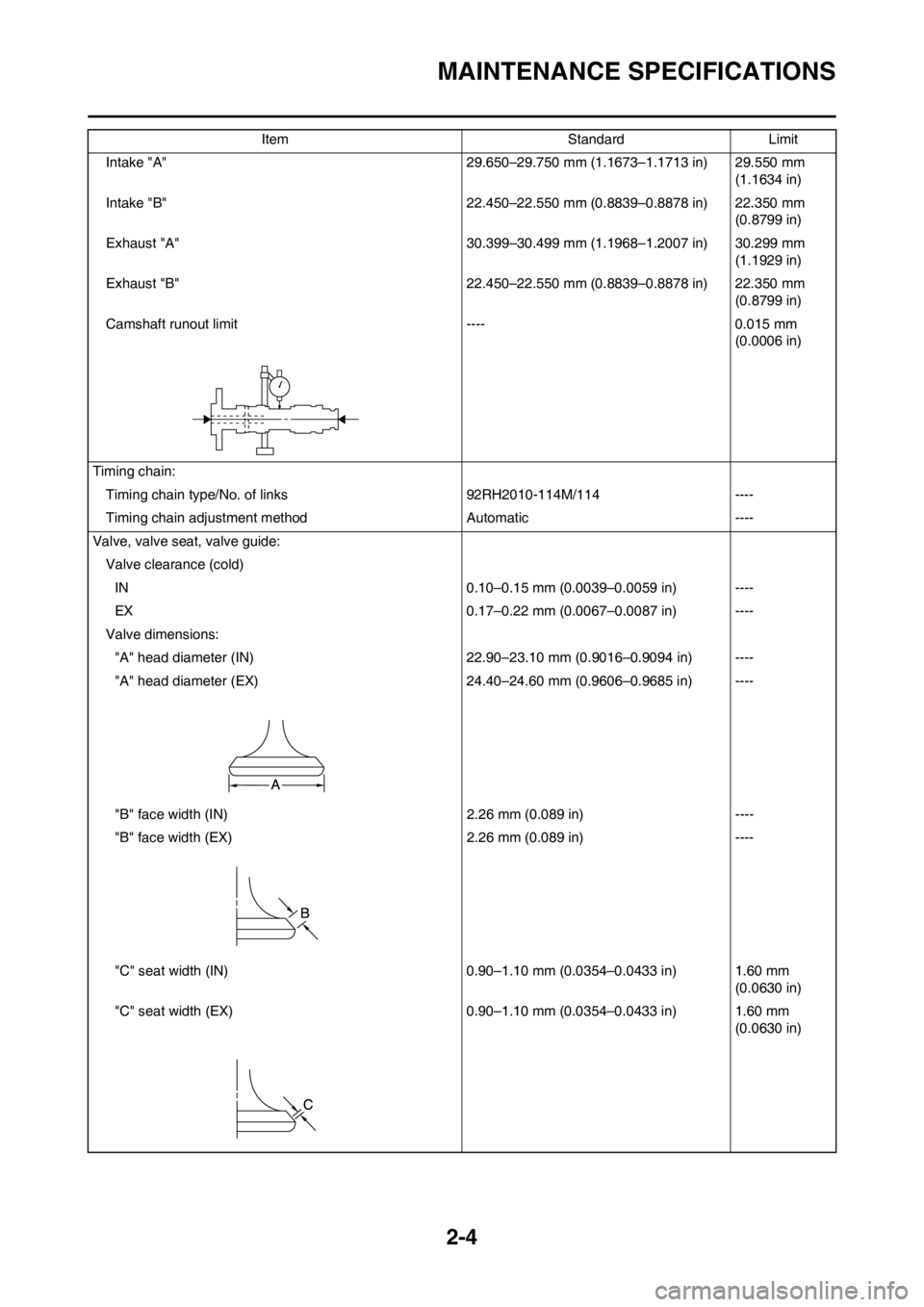

Valve dimensions:

"A" head diameter (IN) 22.90–23.10 mm (0.9016–0.9094 in) ----

"A" head diameter (EX) 24.40–24.60 mm (0.9606–0.9685 in) ----

"B" face width (IN) 2.26 mm (0.089 in) ----

"B" face width (EX) 2.26 mm (0.089 in) ----

"C" seat width (IN) 0.90–1.10 mm (0.0354–0.0433 in) 1.60 mm

(0.0630 in)

"C" seat width (EX) 0.90–1.10 mm (0.0354–0.0433 in) 1.60 mm

(0.0630 in) Item Standard Limit

Page 36 of 230

2-5

MAINTENANCE SPECIFICATIONS

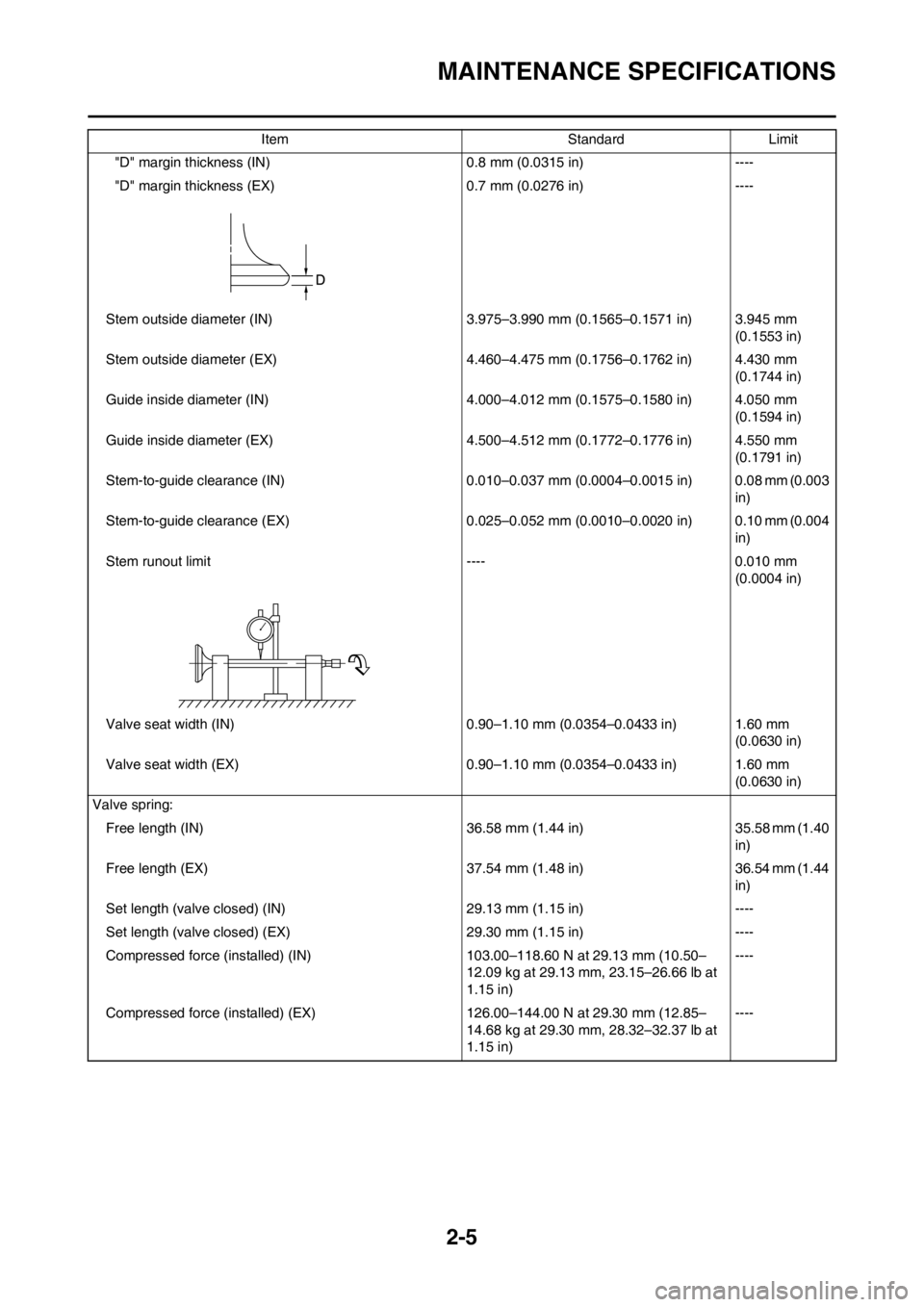

"D" margin thickness (IN) 0.8 mm (0.0315 in) ----

"D" margin thickness (EX) 0.7 mm (0.0276 in) ----

Stem outside diameter (IN) 3.975–3.990 mm (0.1565–0.1571 in) 3.945 mm

(0.1553 in)

Stem outside diameter (EX) 4.460–4.475 mm (0.1756–0.1762 in) 4.430 mm

(0.1744 in)

Guide inside diameter (IN) 4.000–4.012 mm (0.1575–0.1580 in) 4.050 mm

(0.1594 in)

Guide inside diameter (EX) 4.500–4.512 mm (0.1772–0.1776 in) 4.550 mm

(0.1791 in)

Stem-to-guide clearance (IN) 0.010–0.037 mm (0.0004–0.0015 in) 0.08 mm (0.003

in)

Stem-to-guide clearance (EX) 0.025–0.052 mm (0.0010–0.0020 in) 0.10 mm (0.004

in)

Stem runout limit ---- 0.010 mm

(0.0004 in)

Valve seat width (IN) 0.90–1.10 mm (0.0354–0.0433 in) 1.60 mm

(0.0630 in)

Valve seat width (EX) 0.90–1.10 mm (0.0354–0.0433 in) 1.60 mm

(0.0630 in)

Valve spring:

Free length (IN) 36.58 mm (1.44 in) 35.58 mm (1.40

in)

Free length (EX) 37.54 mm (1.48 in) 36.54 mm (1.44

in)

Set length (valve closed) (IN) 29.13 mm (1.15 in) ----

Set length (valve closed) (EX) 29.30 mm (1.15 in) ----

Compressed force (installed) (IN) 103.00–118.60 N at 29.13 mm (10.50–

12.09 kg at 29.13 mm, 23.15–26.66 lb at

1.15 in)----

Compressed force (installed) (EX) 126.00–144.00 N at 29.30 mm (12.85–

14.68 kg at 29.30 mm, 28.32–32.37 lb at

1.15 in)---- Item Standard Limit

Page 38 of 230

2-7

MAINTENANCE SPECIFICATIONS

Oil ring:

Dimensions (B × T) 1.50 × 2.25 mm (0.06 × 0.09 in) ----

End gap (installed) 0.10–0.40 mm (0.0039–0.0157 in) ----

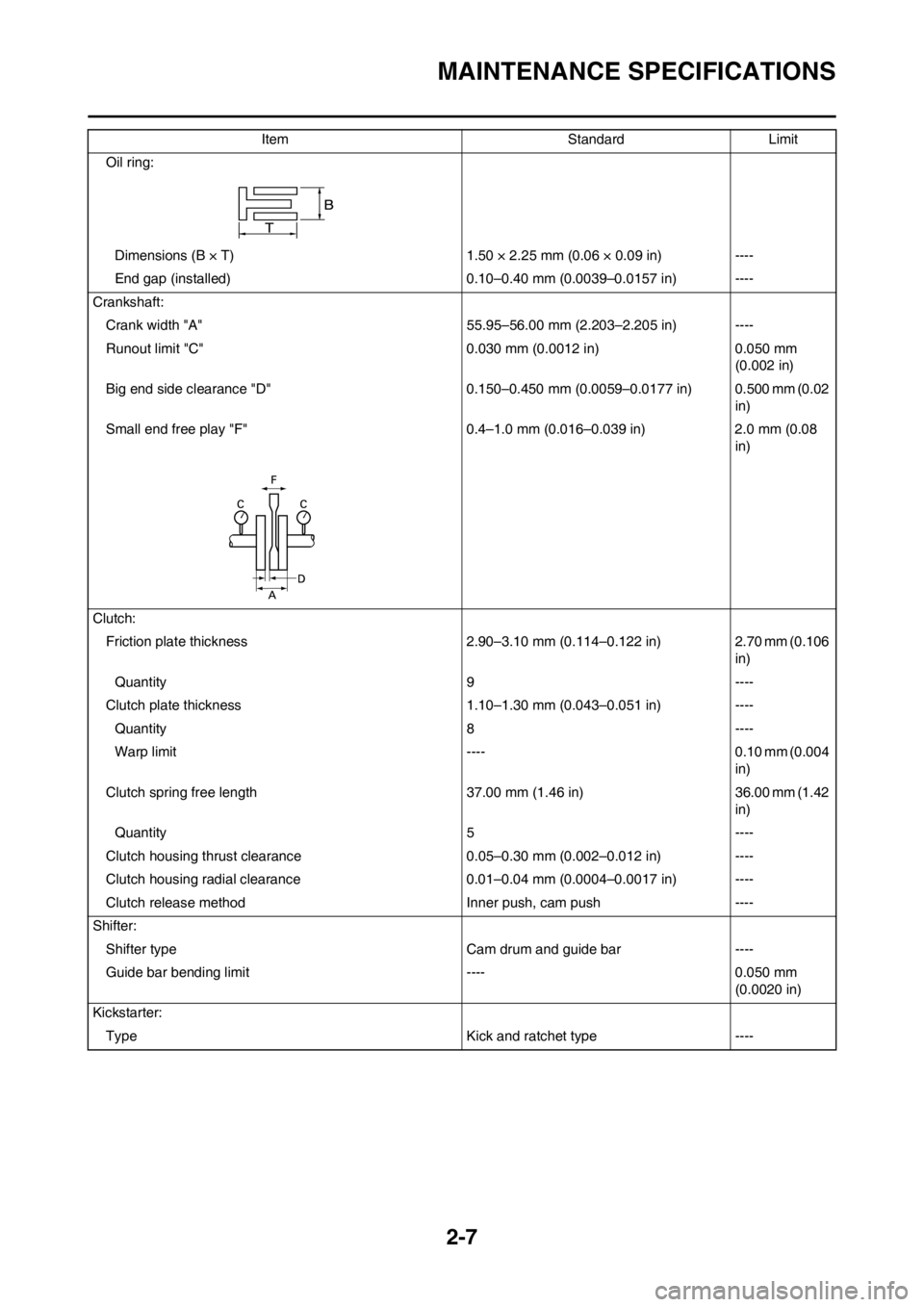

Crankshaft:

Crank width "A" 55.95–56.00 mm (2.203–2.205 in) ----

Runout limit "C" 0.030 mm (0.0012 in) 0.050 mm

(0.002 in)

Big end side clearance "D" 0.150–0.450 mm (0.0059–0.0177 in) 0.500 mm (0.02

in)

Small end free play "F" 0.4–1.0 mm (0.016–0.039 in) 2.0 mm (0.08

in)

Clutch:

Friction plate thickness 2.90–3.10 mm (0.114–0.122 in) 2.70 mm (0.106

in)

Quantity 9 ----

Clutch plate thickness 1.10–1.30 mm (0.043–0.051 in) ----

Quantity 8 ----

Warp limit ---- 0.10 mm (0.004

in)

Clutch spring free length 37.00 mm (1.46 in) 36.00 mm (1.42

in)

Quantity 5 ----

Clutch housing thrust clearance 0.05–0.30 mm (0.002–0.012 in) ----

Clutch housing radial clearance 0.01–0.04 mm (0.0004–0.0017 in) ----

Clutch release method Inner push, cam push ----

Shifter:

Shifter type Cam drum and guide bar ----

Guide bar bending limit ---- 0.050 mm

(0.0020 in)

Kickstarter:

Type Kick and ratchet type ----Item Standard Limit

Page 39 of 230

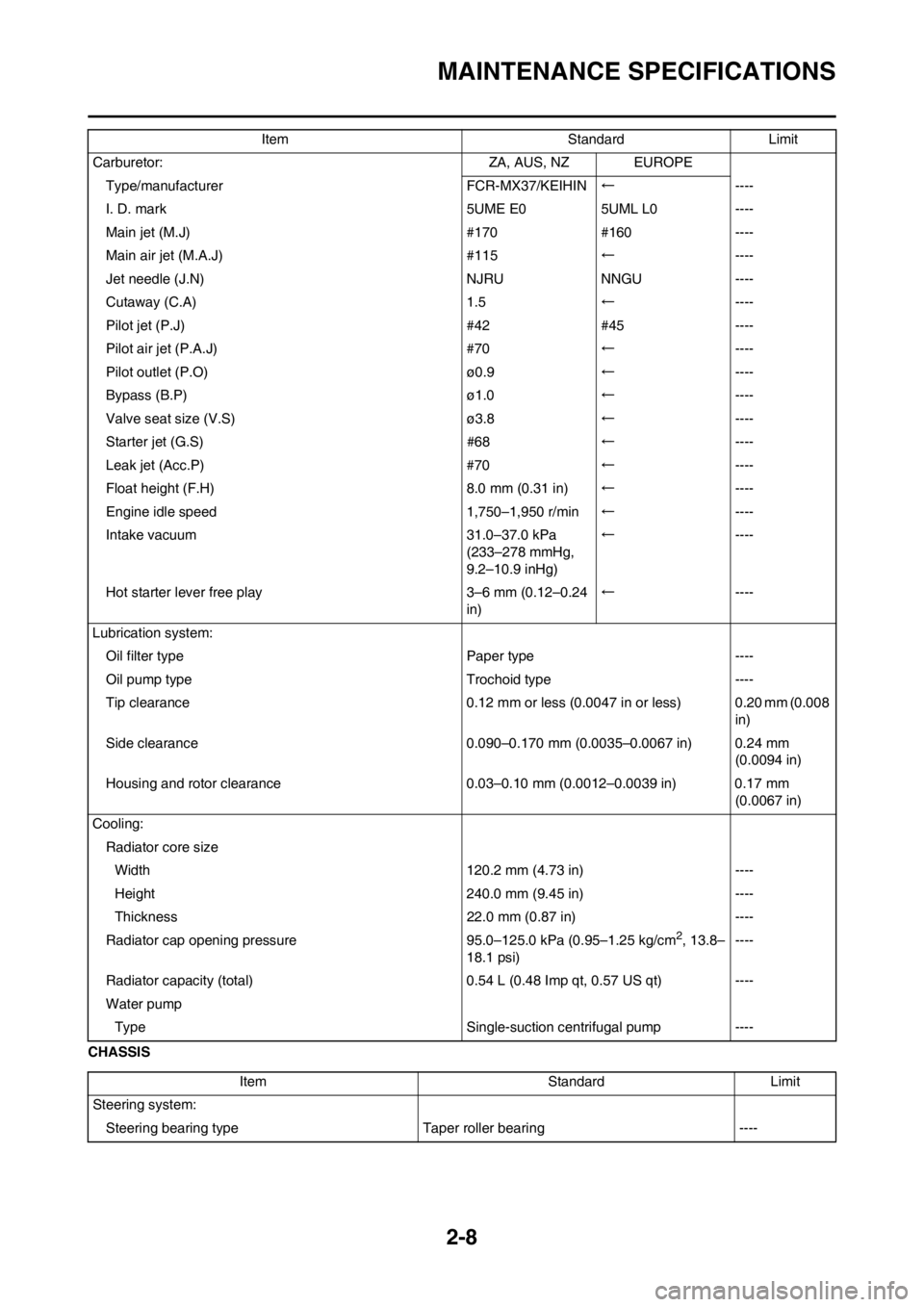

2-8

MAINTENANCE SPECIFICATIONS

CHASSISCarburetor: ZA, AUS, NZ EUROPE

Type/manufacturer FCR-MX37/KEIHIN←----

I. D. mark 5UME E0 5UML L0 ----

Main jet (M.J) #170 #160 ----

Main air jet (M.A.J) #115←----

Jet needle (J.N) NJRU NNGU ----

Cutaway (C.A) 1.5←----

Pilot jet (P.J) #42 #45 ----

Pilot air jet (P.A.J) #70←----

Pilot outlet (P.O) ø0.9←----

Bypass (B.P) ø1.0←----

Valve seat size (V.S) ø3.8←----

Starter jet (G.S) #68←----

Leak jet (Acc.P) #70←----

Float height (F.H) 8.0 mm (0.31 in)←----

Engine idle speed 1,750–1,950 r/min←----

Intake vacuum 31.0–37.0 kPa

(233–278 mmHg,

9.2–10.9 inHg)←----

Hot starter lever free play 3–6 mm (0.12–0.24

in)←----

Lubrication system:

Oil filter type Paper type ----

Oil pump type Trochoid type ----

Tip clearance 0.12 mm or less (0.0047 in or less) 0.20 mm (0.008

in)

Side clearance 0.090–0.170 mm (0.0035–0.0067 in) 0.24 mm

(0.0094 in)

Housing and rotor clearance 0.03–0.10 mm (0.0012–0.0039 in) 0.17 mm

(0.0067 in)

Cooling:

Radiator core size

Width 120.2 mm (4.73 in) ----

Height 240.0 mm (9.45 in) ----

Thickness 22.0 mm (0.87 in) ----

Radiator cap opening pressure 95.0–125.0 kPa (0.95–1.25 kg/cm

2, 13.8–

18.1 psi)----

Radiator capacity (total) 0.54 L (0.48 Imp qt, 0.57 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Page 118 of 230

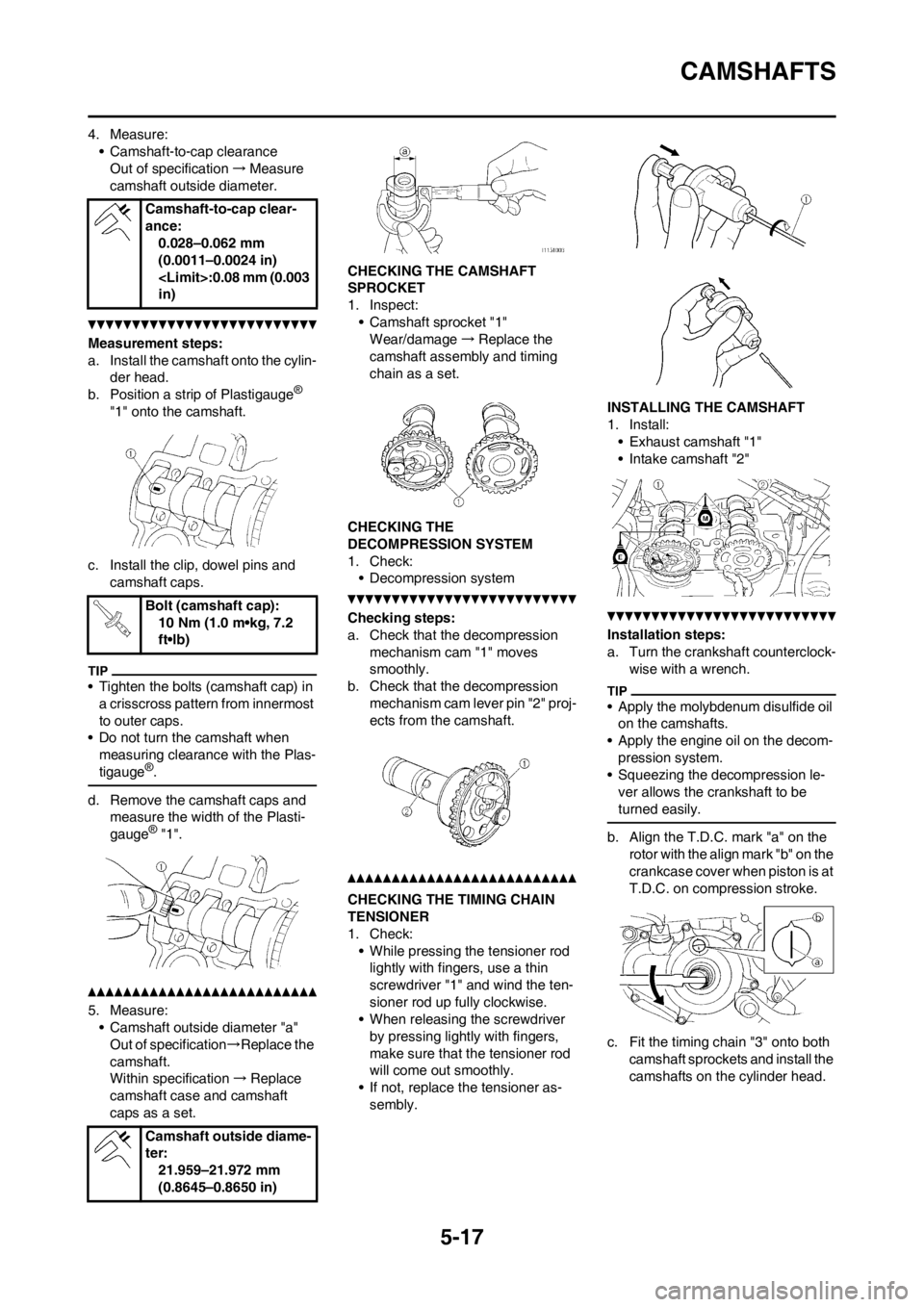

5-17

CAMSHAFTS

4. Measure:

• Camshaft-to-cap clearance

Out of specification→Measure

camshaft outside diameter.

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the Plas-

tigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification→Replace the

camshaft.

Within specification→Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2" proj-

ects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

• Squeezing the decompression le-

ver allows the crankshaft to be

turned easily.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head. Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 121 of 230

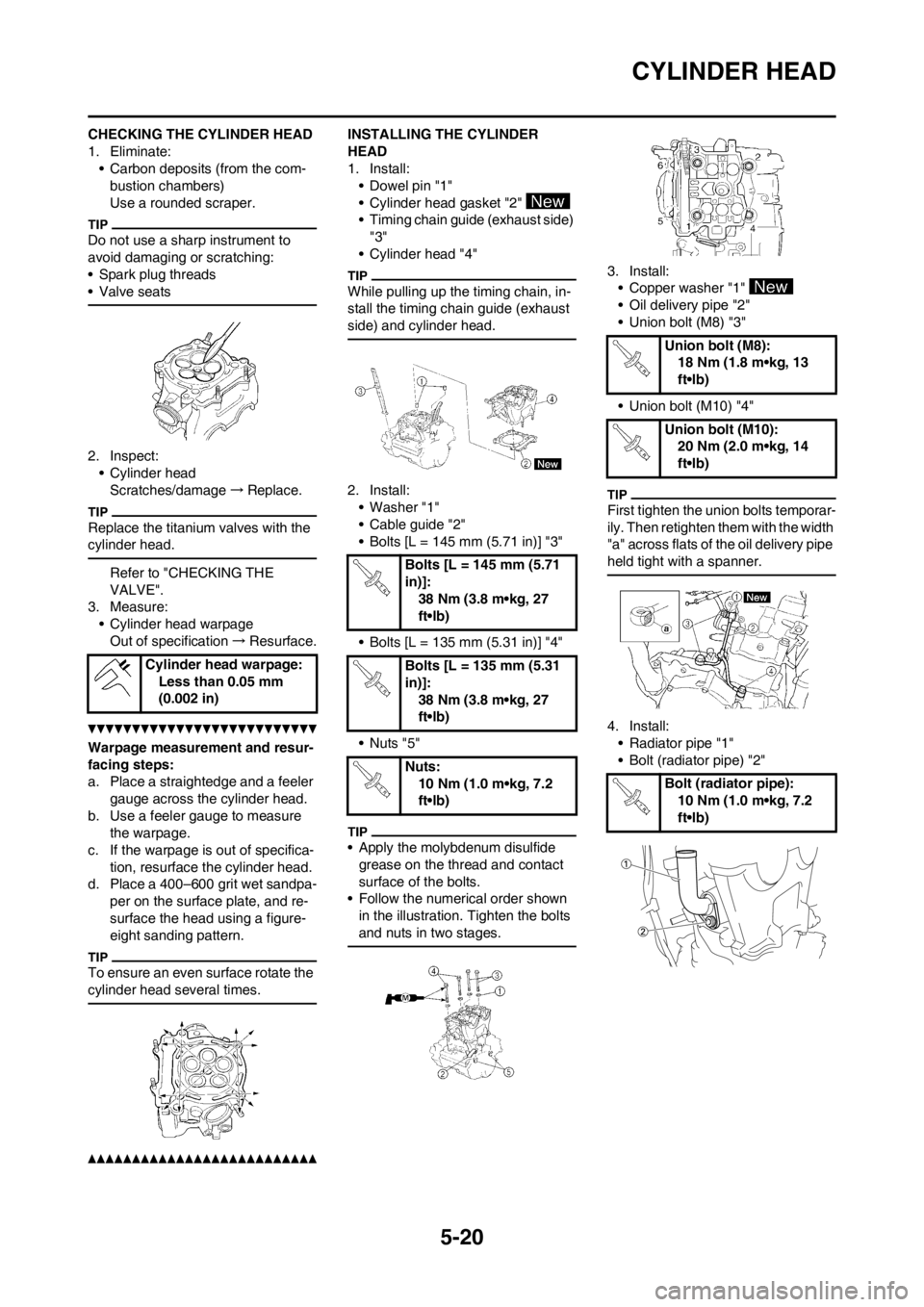

5-20

CYLINDER HEAD

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits (from the com-

bustion chambers)

Use a rounded scraper.

Do not use a sharp instrument to

avoid damaging or scratching:

• Spark plug threads

• Valve seats

2. Inspect:

• Cylinder head

Scratches/damage→Replace.

Replace the titanium valves with the

cylinder head.

Refer to "CHECKING THE

VALVE".

3. Measure:

• Cylinder head warpage

Out of specification→Resurface.

Warpage measurement and resur-

facing steps:

a. Place a straightedge and a feeler

gauge across the cylinder head.

b. Use a feeler gauge to measure

the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per on the surface plate, and re-

surface the head using a figure-

eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

INSTALLING THE CYLINDER

HEAD

1. Install:

• Dowel pin "1"

• Cylinder head gasket "2"

• Timing chain guide (exhaust side)

"3"

• Cylinder head "4"

While pulling up the timing chain, in-

stall the timing chain guide (exhaust

side) and cylinder head.

2. Install:

• Washer "1"

• Cable guide "2"

• Bolts [L = 145 mm (5.71 in)] "3"

• Bolts [L = 135 mm (5.31 in)] "4"

•Nuts "5"

• Apply the molybdenum disulfide

grease on the thread and contact

surface of the bolts.

• Follow the numerical order shown

in the illustration. Tighten the bolts

and nuts in two stages.

3. Install:

• Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4"

First tighten the union bolts temporar-

ily. Then retighten them with the width

"a" across flats of the oil delivery pipe

held tight with a spanner.

4. Install:

• Radiator pipe "1"

• Bolt (radiator pipe) "2" Cylinder head warpage:

Less than 0.05 mm

(0.002 in)

Bolts [L = 145 mm (5.71

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolts [L = 135 mm (5.31

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Nuts:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Union bolt (M8):

18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

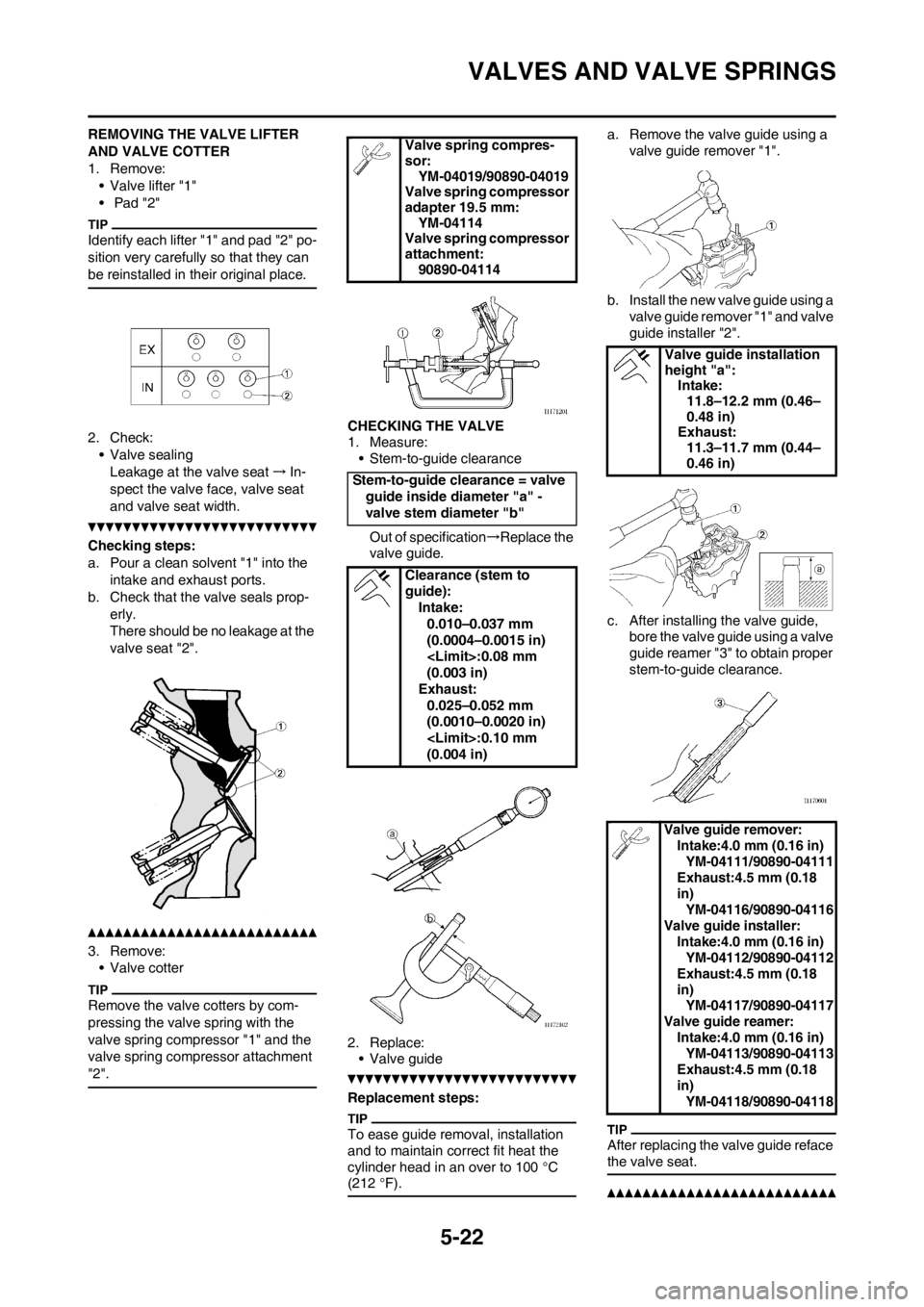

Page 123 of 230

5-22

VALVES AND VALVE SPRINGS

REMOVING THE VALVE LIFTER

AND VALVE COTTER

1. Remove:

• Valve lifter "1"

• Pad "2"

Identify each lifter "1" and pad "2" po-

sition very carefully so that they can

be reinstalled in their original place.

2. Check:

• Valve sealing

Leakage at the valve seat→In-

spect the valve face, valve seat

and valve seat width.

Checking steps:

a. Pour a clean solvent "1" into the

intake and exhaust ports.

b. Check that the valve seals prop-

erly.

There should be no leakage at the

valve seat "2".

3. Remove:

• Valve cotter

Remove the valve cotters by com-

pressing the valve spring with the

valve spring compressor "1" and the

valve spring compressor attachment

"2".

CHECKING THE VALVE

1. Measure:

• Stem-to-guide clearance

Out of specification→Replace the

valve guide.

2. Replace:

• Valve guide

Replacement steps:

To ease guide removal, installation

and to maintain correct fit heat the

cylinder head in an over to 100 °C

(212 °F).

a. Remove the valve guide using a

valve guide remover "1".

b. Install the new valve guide using a

valve guide remover "1" and valve

guide installer "2".

c. After installing the valve guide,

bore the valve guide using a valve

guide reamer "3" to obtain proper

stem-to-guide clearance.

After replacing the valve guide reface

the valve seat.

Valve spring compres-

sor:

YM-04019/90890-04019

Valve spring compressor

adapter 19.5 mm:

YM-04114

Valve spring compressor

attachment:

90890-04114

Stem-to-guide clearance = valve

guide inside diameter "a" -

valve stem diameter "b"

Clearance (stem to

guide):

Intake:

0.010–0.037 mm

(0.0004–0.0015 in)

(0.003 in)

Exhaust:

0.025–0.052 mm

(0.0010–0.0020 in)

(0.004 in)

Valve guide installation

height "a":

Intake:

11.8–12.2 mm (0.46–

0.48 in)

Exhaust:

11.3–11.7 mm (0.44–

0.46 in)

Valve guide remover:

Intake:4.0 mm (0.16 in)

YM-04111/90890-04111

Exhaust:4.5 mm (0.18

in)

YM-04116/90890-04116

Valve guide installer:

Intake:4.0 mm (0.16 in)

YM-04112/90890-04112

Exhaust:4.5 mm (0.18

in)

YM-04117/90890-04117

Valve guide reamer:

Intake:4.0 mm (0.16 in)

YM-04113/90890-04113

Exhaust:4.5 mm (0.18

in)

YM-04118/90890-04118

Page 124 of 230

5-23

VALVES AND VALVE SPRINGS

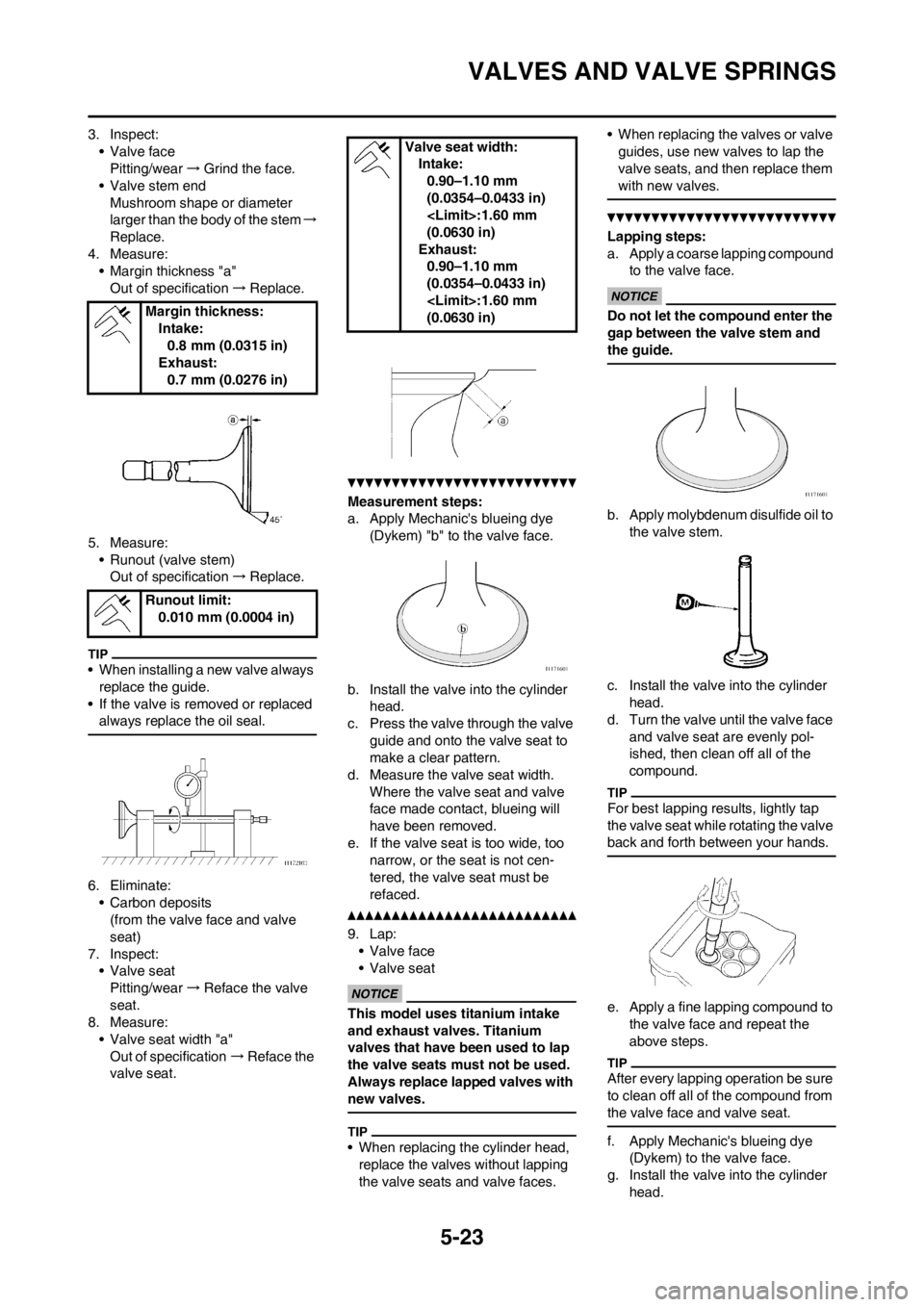

3. Inspect:

• Valve face

Pitting/wear→Grind the face.

• Valve stem end

Mushroom shape or diameter

larger than the body of the stem→

Replace.

4. Measure:

• Margin thickness "a"

Out of specification→Replace.

5. Measure:

• Runout (valve stem)

Out of specification→Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:

• Carbon deposits

(from the valve face and valve

seat)

7. Inspect:

• Valve seat

Pitting/wear→Reface the valve

seat.

8. Measure:

• Valve seat width "a"

Out of specification→Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye

(Dykem) "b" to the valve face.

b. Install the valve into the cylinder

head.

c. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width.

Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve seat must be

refaced.

9. Lap:

• Valve face

• Valve seat

This model uses titanium intake

and exhaust valves. Titanium

valves that have been used to lap

the valve seats must not be used.

Always replace lapped valves with

new valves.

• When replacing the cylinder head,

replace the valves without lapping

the valve seats and valve faces.• When replacing the valves or valve

guides, use new valves to lap the

valve seats, and then replace them

with new valves.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the compound enter the

gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to

the valve stem.

c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face

and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to

the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye

(Dykem) to the valve face.

g. Install the valve into the cylinder

head. Margin thickness:

Intake:

0.8 mm (0.0315 in)

Exhaust:

0.7 mm (0.0276 in)

Runout limit:

0.010 mm (0.0004 in)

Valve seat width:

Intake:

0.90–1.10 mm

(0.0354–0.0433 in)

(0.0630 in)

Exhaust:

0.90–1.10 mm

(0.0354–0.0433 in)

(0.0630 in)

Page 125 of 230

5-24

VALVES AND VALVE SPRINGS

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

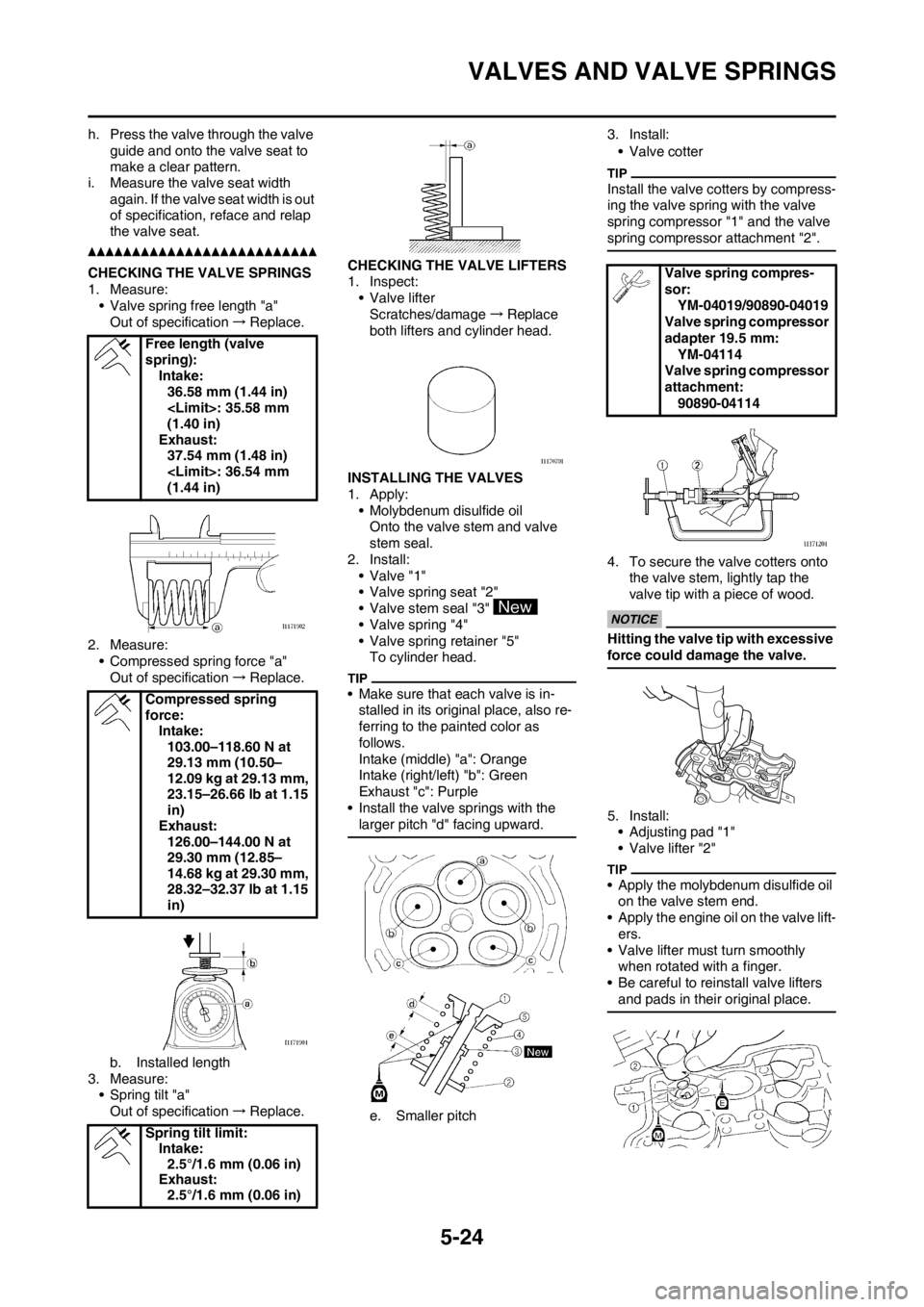

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification→Replace.

2. Measure:

• Compressed spring force "a"

Out of specification→Replace.

b. Installed length

3. Measure:

• Spring tilt "a"

Out of specification→Replace.CHECKING THE VALVE LIFTERS

1. Inspect:

• Valve lifter

Scratches/damage→Replace

both lifters and cylinder head.

INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

• Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"

To cylinder head.

• Make sure that each valve is in-

stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Orange

Intake (right/left) "b": Green

Exhaust "c": Purple

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch3. Install:

• Valve cotter

Install the valve cotters by compress-

ing the valve spring with the valve

spring compressor "1" and the valve

spring compressor attachment "2".

4. To secure the valve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:

• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

Free length (valve

spring):

Intake:

36.58 mm (1.44 in)

(1.40 in)

Exhaust:

37.54 mm (1.48 in)

(1.44 in)

Compressed spring

force:

Intake:

103.00–118.60 N at

29.13 mm (10.50–

12.09 kg at 29.13 mm,

23.15–26.66 lb at 1.15

in)

Exhaust:

126.00–144.00 N at

29.30 mm (12.85–

14.68 kg at 29.30 mm,

28.32–32.37 lb at 1.15

in)

Spring tilt limit:

Intake:

2.5°/1.6 mm (0.06 in)

Exhaust:

2.5°/1.6 mm (0.06 in)

Valve spring compres-

sor:

YM-04019/90890-04019

Valve spring compressor

adapter 19.5 mm:

YM-04114

Valve spring compressor

attachment:

90890-04114