coolant temperature YAMAHA WR 250F 2015 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 360 of 430

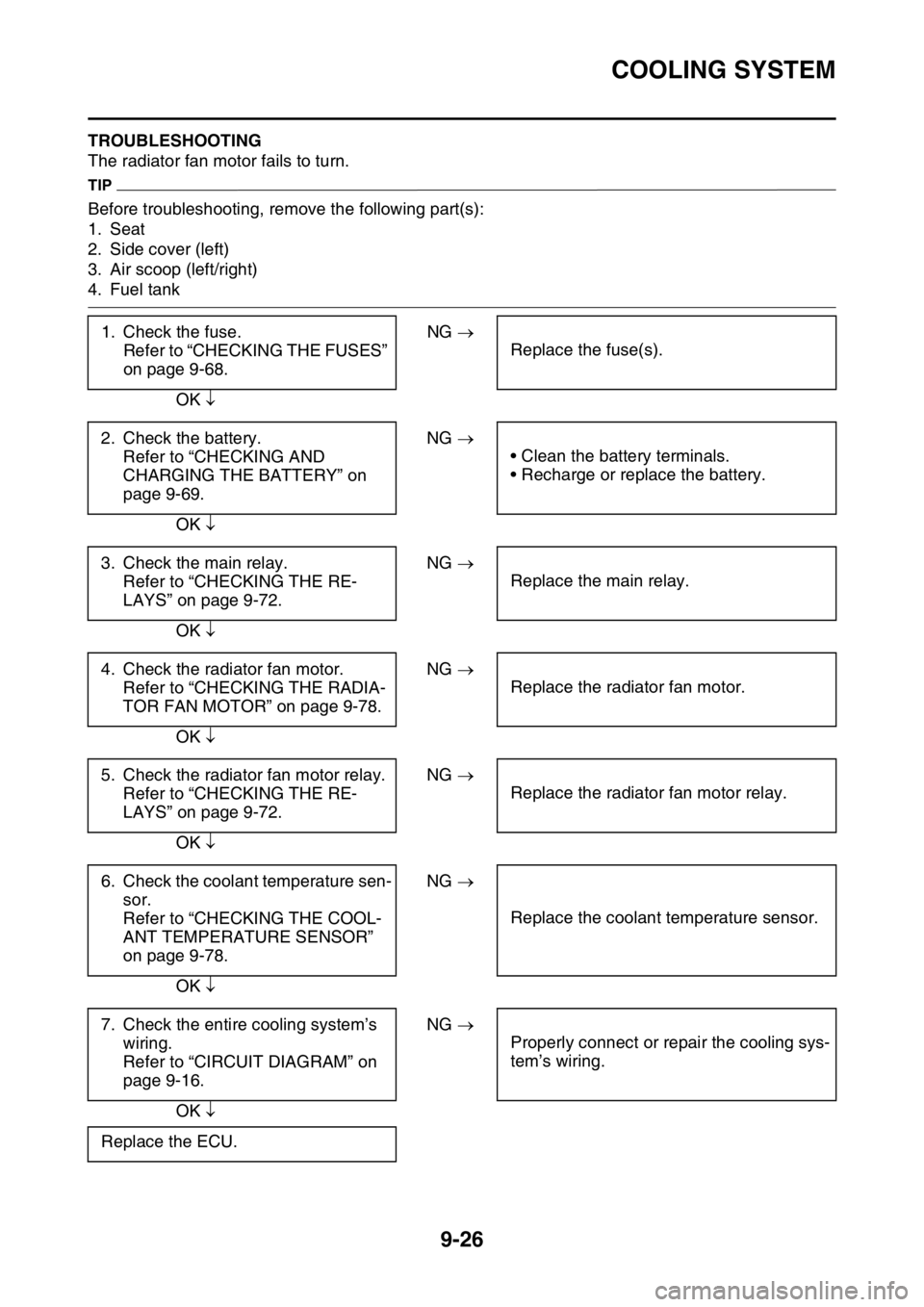

COOLING SYSTEM

9-26

EAS2GB2373TROUBLESHOOTING

The radiator fan motor fails to turn.

TIP

Before troubleshooting, remove the following part(s):

1. Seat

2. Side cover (left)

3. Air scoop (left/right)

4. Fuel tank

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the main relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the main relay.

OK

4. Check the radiator fan motor.

Refer to “CHECKING THE RADIA-

TOR FAN MOTOR” on page 9-78.NG

Replace the radiator fan motor.

OK

5. Check the radiator fan motor relay.

Refer to “CHECKING THE RE-

LAYS” on page 9-72.NG

Replace the radiator fan motor relay.

OK

6. Check the coolant temperature sen-

sor.

Refer to “CHECKING THE COOL-

ANT TEMPERATURE SENSOR”

on page 9-78.NG

Replace the coolant temperature sensor.

OK

7. Check the entire cooling system’s

wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-16.NG

Properly connect or repair the cooling sys-

tem’s wiring.

OK

Replace the ECU.

Page 363 of 430

FUEL INJECTION SYSTEM

9-29

1. Joint connector

2. Joint connector

3. Joint connector

4. AC magneto

7. Main relay

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

15.Indicator light

16.Engine trouble warning light

22.ECU (engine control unit)

25.Injector

30.Joint connector

31.Intake air temperature sensor

32.Coolant temperature sensor

33.Throttle position sensor

34.Intake air pressure sensor

35.Lean angle sensor

36.Engine stop switch

37.Neutral switch

38.Diode

39.Starting circuit cut-off relay

40.Clutch switch

42.Joint connector

48.Frame ground

Page 376 of 430

FUEL INJECTION SYSTEM

9-42

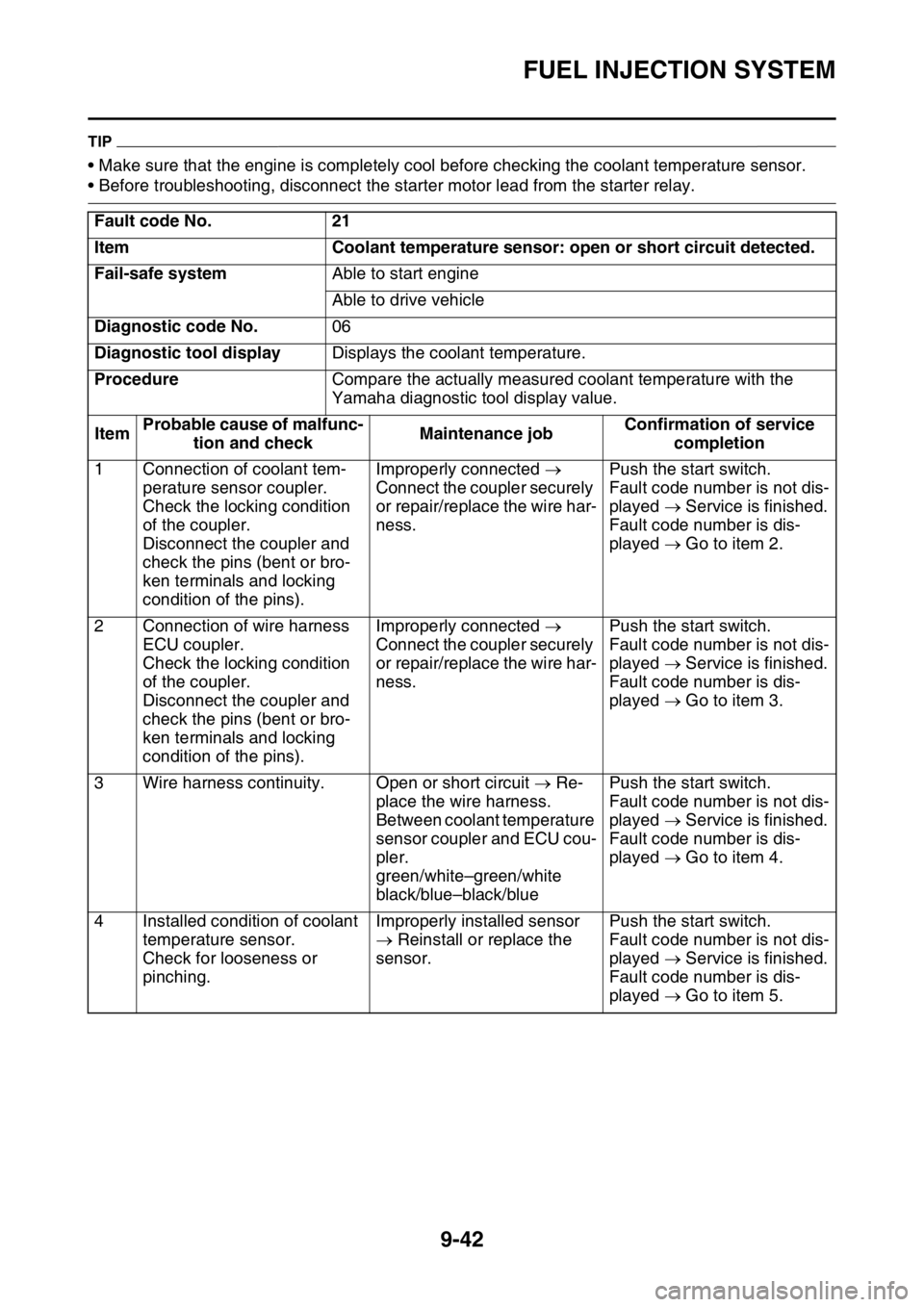

TIP

• Make sure that the engine is completely cool before checking the coolant temperature sensor.

• Before troubleshooting, disconnect the starter motor lead from the starter relay.

Fault code No. 21

Item Coolant temperature sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.06

Diagnostic tool displayDisplays the coolant temperature.

ProcedureCompare the actually measured coolant temperature with the

Yamaha diagnostic tool display value.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of coolant tem-

perature sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between coolant temperature

sensor coupler and ECU cou-

pler.

green/white–green/white

black/blue–black/bluePush the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Installed condition of coolant

temperature sensor.

Check for looseness or

pinching.Improperly installed sensor

Reinstall or replace the

sensor.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 5.

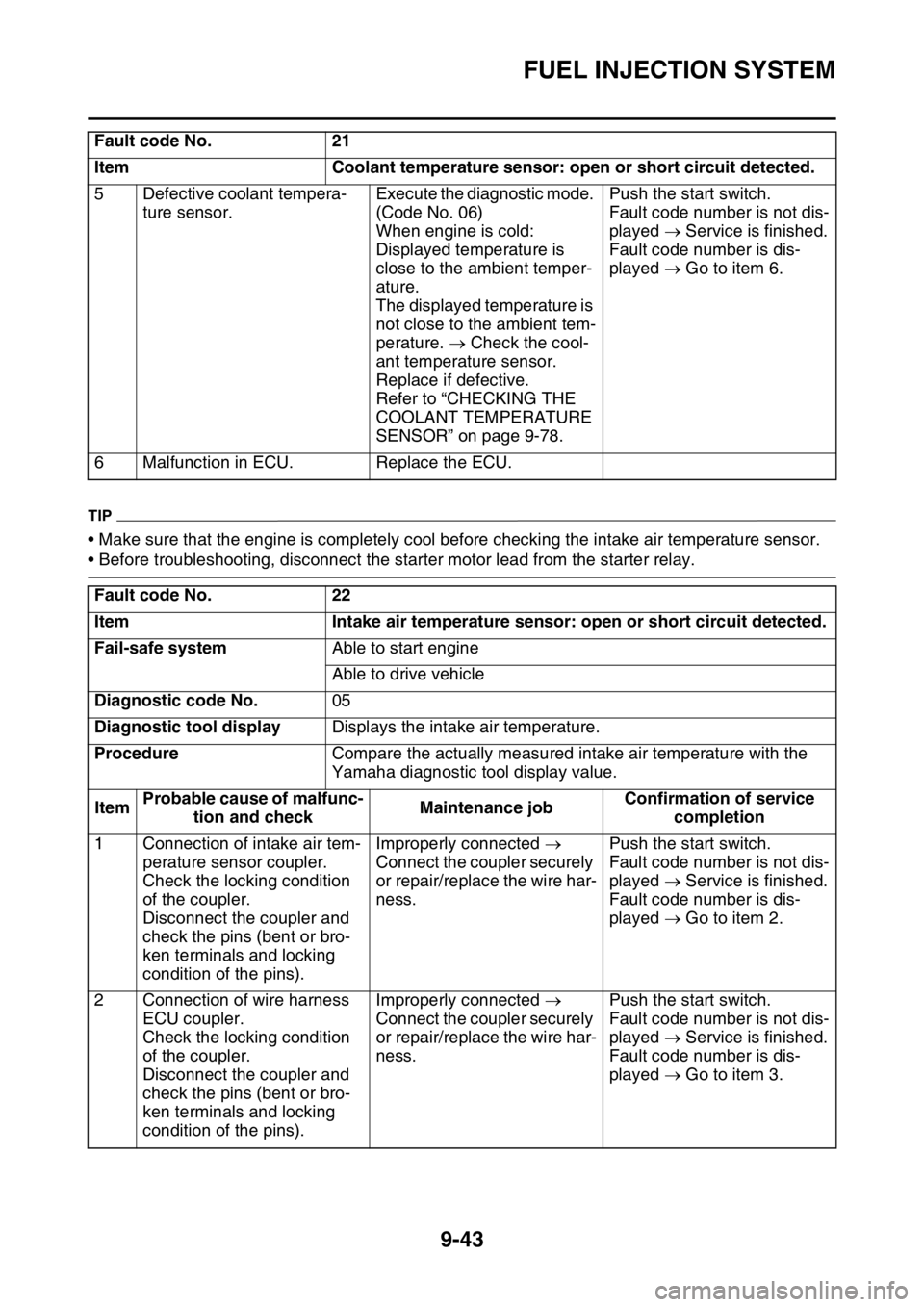

Page 377 of 430

FUEL INJECTION SYSTEM

9-43

TIP

• Make sure that the engine is completely cool before checking the intake air temperature sensor.

• Before troubleshooting, disconnect the starter motor lead from the starter relay. 5 Defective coolant tempera-

ture sensor.Execute the diagnostic mode.

(Code No. 06)

When engine is cold:

Displayed temperature is

close to the ambient temper-

ature.

The displayed temperature is

not close to the ambient tem-

perature. Check the cool-

ant temperature sensor.

Replace if defective.

Refer to “CHECKING THE

COOLANT TEMPERATURE

SENSOR” on page 9-78.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 6.

6 Malfunction in ECU. Replace the ECU.

Fault code No. 22

Item Intake air temperature sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.05

Diagnostic tool displayDisplays the intake air temperature.

ProcedureCompare the actually measured intake air temperature with the

Yamaha diagnostic tool display value.

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of intake air tem-

perature sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3. Fault code No. 21

Item Coolant temperature sensor: open or short circuit detected.

Page 397 of 430

ELECTRICAL COMPONENTS

9-63

1. Intake air temperature sensor

2. Intake air pressure sensor

3. Throttle position sensor

4. Starter relay

5. Main fuse

6. Headlight relay

7. Starting circuit cut-off relay

8. Lean angle sensor

9. Radiator fan motor fuse

10.Radiator fan motor relay

11.Main relay

12.Coolant temperature sensor

Page 409 of 430

ELECTRICAL COMPONENTS

9-75

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 100) to the

crankshaft position sensor coupler.

b. Measure the crankshaft position sensor re-

sistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

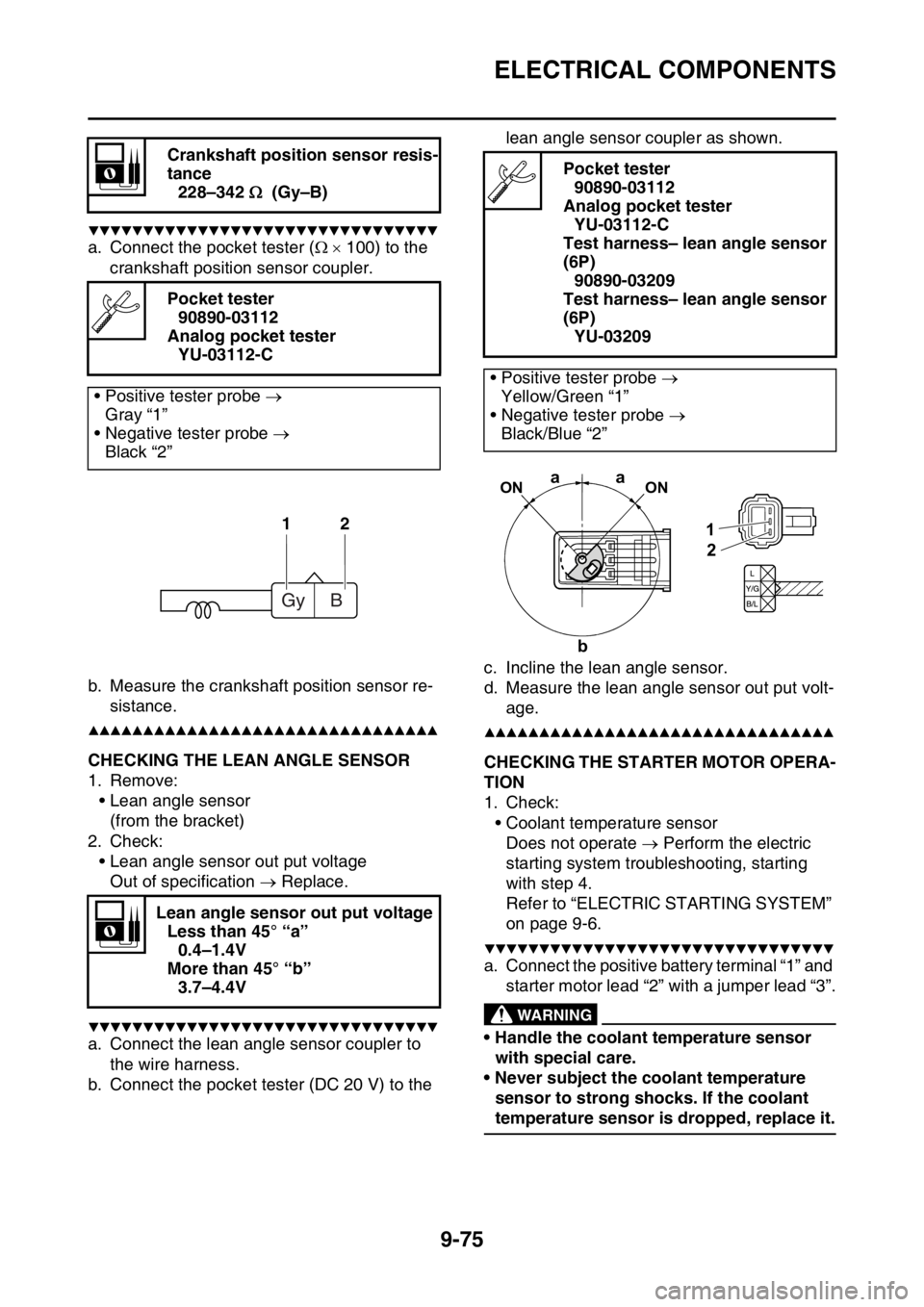

EAS2GB2394CHECKING THE LEAN ANGLE SENSOR

1. Remove:

• Lean angle sensor

(from the bracket)

2. Check:

• Lean angle sensor out put voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the lean angle sensor coupler to

the wire harness.

b. Connect the pocket tester (DC 20 V) to the lean angle sensor coupler as shown.

c. Incline the lean angle sensor.

d. Measure the lean angle sensor out put volt-

age.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2395CHECKING THE STARTER MOTOR OPERA-

TION

1. Check:

• Coolant temperature sensor

Does not operate Perform the electric

starting system troubleshooting, starting

with step 4.

Refer to “ELECTRIC STARTING SYSTEM”

on page 9-6.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the positive battery terminal “1” and

starter motor lead “2” with a jumper lead “3”.

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it. Crankshaft position sensor resis-

tance

228–342 (Gy–B)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Gray “1”

• Negative tester probe

Black “2”

Lean angle sensor out put voltage

Less than 45° “a”

0.4–1.4V

More than 45° “b”

3.7–4.4V

12

Gy B

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness– lean angle sensor

(6P)

90890-03209

Test harness– lean angle sensor

(6P)

YU-03209

• Positive tester probe

Yellow/Green “1”

• Negative tester probe

Black/Blue “2”

2 1

aa

bON ON

Page 412 of 430

ELECTRICAL COMPONENTS

9-78

b. Measure the resistance of the resister.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

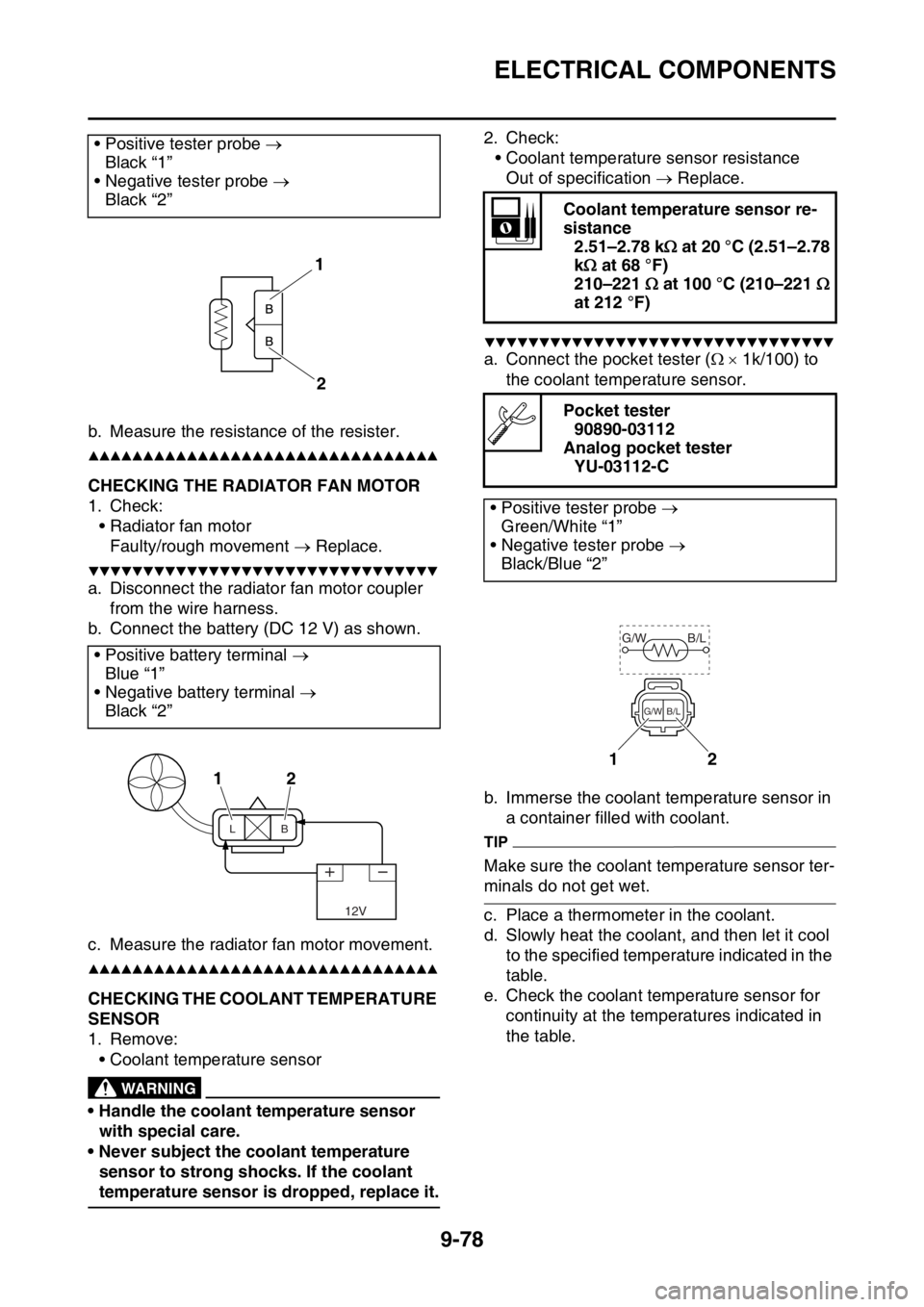

EAS2GB2400CHECKING THE RADIATOR FAN MOTOR

1. Check:

• Radiator fan motor

Faulty/rough movement Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the radiator fan motor coupler

from the wire harness.

b. Connect the battery (DC 12 V) as shown.

c. Measure the radiator fan motor movement.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2401CHECKING THE COOLANT TEMPERATURE

SENSOR

1. Remove:

• Coolant temperature sensor

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.2. Check:

• Coolant temperature sensor resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k/100) to

the coolant temperature sensor.

b. Immerse the coolant temperature sensor in

a container filled with coolant.

TIP

Make sure the coolant temperature sensor ter-

minals do not get wet.

c. Place a thermometer in the coolant.

d. Slowly heat the coolant, and then let it cool

to the specified temperature indicated in the

table.

e. Check the coolant temperature sensor for

continuity at the temperatures indicated in

the table. • Positive tester probe

Black “1”

• Negative tester probe

Black “2”

• Positive battery terminal

Blue “1”

• Negative battery terminal

Black “2”

1

2

12

12V

LB

Coolant temperature sensor re-

sistance

2.51–2.78 k at 20 °C (2.51–2.78

k at 68 °F)

210–221 at 100 °C (210–221

at 212 °F)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Green/White “1”

• Negative tester probe

Black/Blue “2”

12

G/W B/L

B/L G/W

Page 420 of 430

TROUBLESHOOTING

10-3

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

2. Air filter

• Clogged air filter element

Chassis

1. Brake(s)

• Dragging brake

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

2. Ignition system

• Faulty ECU

• Faulty coolant temperature sensor

EAS2GB2418OVERCOOLING

Cooling system

1. Coolant temperature sensor

• Faulty coolant temperature sensor

EAS2GB2419POOR BRAKING PERFORMANCE

Chassis

1. Brake(s)

• Worn brake pad

• Worn brake disc

• Air in hydraulic brake system

• Leaking brake fluid

• Defective master cylinder kit

• Faulty brake caliper kit

• Faulty brake caliper seal

• Loose union bolt

• Damaged brake hose

• Oil or grease on the brake disc

• Oil or grease on the brake pad

• Incorrect brake fluid level

EAS2GB2420FRONT FORK OIL LEAKING

Chassis

1. Front fork

• Bent, damaged, or rusty inner tube

• Cracked or damaged outer tube

• Improperly installed oil seal

• Damaged oil seal lip

• Incorrect oil level (high)

• Loose damper rod assembly bolt

• Damaged damper rod assembly bolt copper

washer

• Cracked or damaged cap bolt O-ring

EAS2GB2421FAULTY FRONT FORK LEGS

Chassis

1. Front fork

• Bent or damaged inner tube

• Bent or damaged outer tube

• Broken fork spring

• Bent or damaged damper rod

• Incorrect oil viscosity

• Incorrect oil level

EAS2GB2422UNSTABLE HANDLING

Chassis

1. Handlebar

• Bent or improperly installed handlebar

2. Steering head components

• Improperly installed upper bracket

• Improperly installed lower bracket

(improperly tightened ring nut)

• Bent steering stem

• Damaged ball bearing or bearing race

3. Front fork leg (s)

• Uneven oil levels (both front fork legs)

• Unevenly tensioned fork spring (both front

fork legs)

• Broken fork spring

• Bent or damaged inner tube

• Bent or damaged outer tube

4. Swingarm

• Worn bearing or bushing

• Bent or damaged swingarm

5. Rear shock absorber assembly (-ies)

• Faulty rear shock absorber spring

• Leaking oil or gas

6. Tire (s)

• Uneven tire pressures (front and rear)

• Incorrect tire pressure

• Uneven tire wear

7. Wheel (s)

• Incorrect wheel balance

• Broken or loose spoke

• Damaged wheel bearing

• Bent or loose wheel axle

• Excessive wheel runout

8. Frame

• Bent frame

• Damaged steering head pipe

• Improperly installed bearing race

Page 422 of 430

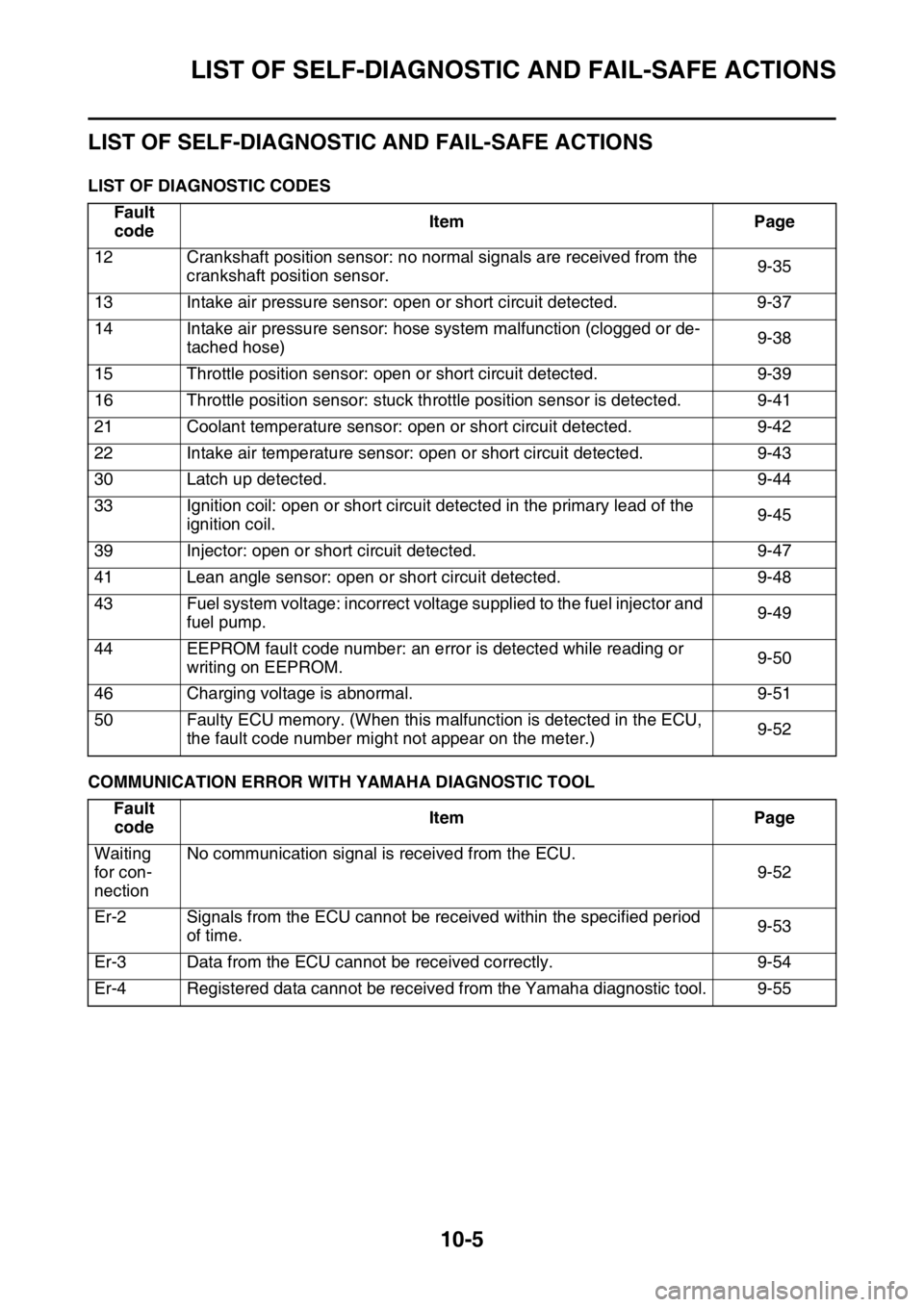

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

10-5

EAS2GB2426

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

LIST OF DIAGNOSTIC CODES

COMMUNICATION ERROR WITH YAMAHA DIAGNOSTIC TOOLFault

codeItem Page

12 Crankshaft position sensor: no normal signals are received from the

crankshaft position sensor.9-35

13 Intake air pressure sensor: open or short circuit detected. 9-37

14 Intake air pressure sensor: hose system malfunction (clogged or de-

tached hose)9-38

15 Throttle position sensor: open or short circuit detected. 9-39

16 Throttle position sensor: stuck throttle position sensor is detected. 9-41

21 Coolant temperature sensor: open or short circuit detected. 9-42

22 Intake air temperature sensor: open or short circuit detected. 9-43

30 Latch up detected. 9-44

33 Ignition coil: open or short circuit detected in the primary lead of the

ignition coil.9-45

39 Injector: open or short circuit detected. 9-47

41 Lean angle sensor: open or short circuit detected. 9-48

43 Fuel system voltage: incorrect voltage supplied to the fuel injector and

fuel pump.9-49

44 EEPROM fault code number: an error is detected while reading or

writing on EEPROM.9-50

46 Charging voltage is abnormal. 9-51

50 Faulty ECU memory. (When this malfunction is detected in the ECU,

the fault code number might not appear on the meter.)9-52

Fault

codeItem Page

Waiting

for con-

nectionNo communication signal is received from the ECU.

9-52

Er-2 Signals from the ECU cannot be received within the specified period

of time.9-53

Er-3 Data from the ECU cannot be received correctly. 9-54

Er-4 Registered data cannot be received from the Yamaha diagnostic tool. 9-55

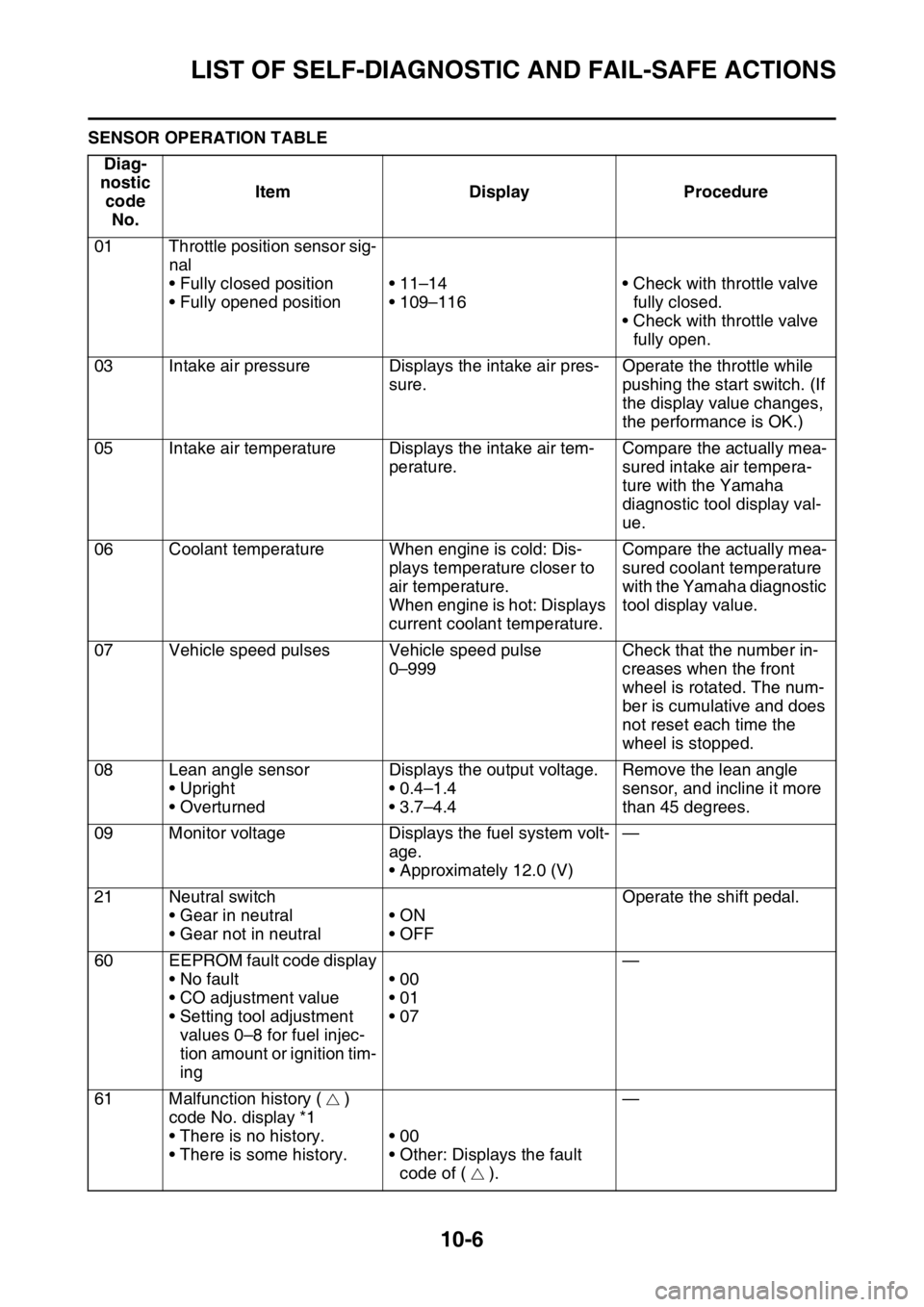

Page 423 of 430

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

10-6

SENSOR OPERATION TABLE

Diag-

nostic

code

No.Item Display Procedure

01 Throttle position sensor sig-

nal

• Fully closed position

• Fully opened position• 11–14

• 109–116• Check with throttle valve

fully closed.

• Check with throttle valve

fully open.

03 Intake air pressure Displays the intake air pres-

sure.Operate the throttle while

pushing the start switch. (If

the display value changes,

the performance is OK.)

05 Intake air temperature Displays the intake air tem-

perature.Compare the actually mea-

sured intake air tempera-

ture with the Yamaha

diagnostic tool display val-

ue.

06 Coolant temperature When engine is cold: Dis-

plays temperature closer to

air temperature.

When engine is hot: Displays

current coolant temperature.Compare the actually mea-

sured coolant temperature

with the Yamaha diagnostic

tool display value.

07 Vehicle speed pulses Vehicle speed pulse

0–999Check that the number in-

creases when the front

wheel is rotated. The num-

ber is cumulative and does

not reset each time the

wheel is stopped.

08 Lean angle sensor

• Upright

• OverturnedDisplays the output voltage.

• 0.4–1.4

• 3.7–4.4Remove the lean angle

sensor, and incline it more

than 45 degrees.

09 Monitor voltage Displays the fuel system volt-

age.

• Approximately 12.0 (V)—

21 Neutral switch

• Gear in neutral

• Gear not in neutral•ON

•OFFOperate the shift pedal.

60 EEPROM fault code display

• No fault

• CO adjustment value

• Setting tool adjustment

values 0–8 for fuel injec-

tion amount or ignition tim-

ing•00

•01

•07—

61 Malfunction history ( )

code No. display *1

• There is no history.

• There is some history.•00

• Other: Displays the fault

code of ( ).—