plug YAMAHA WR 250F 2015 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 181 of 430

REAR BRAKE

5-23

EAS2GB2182

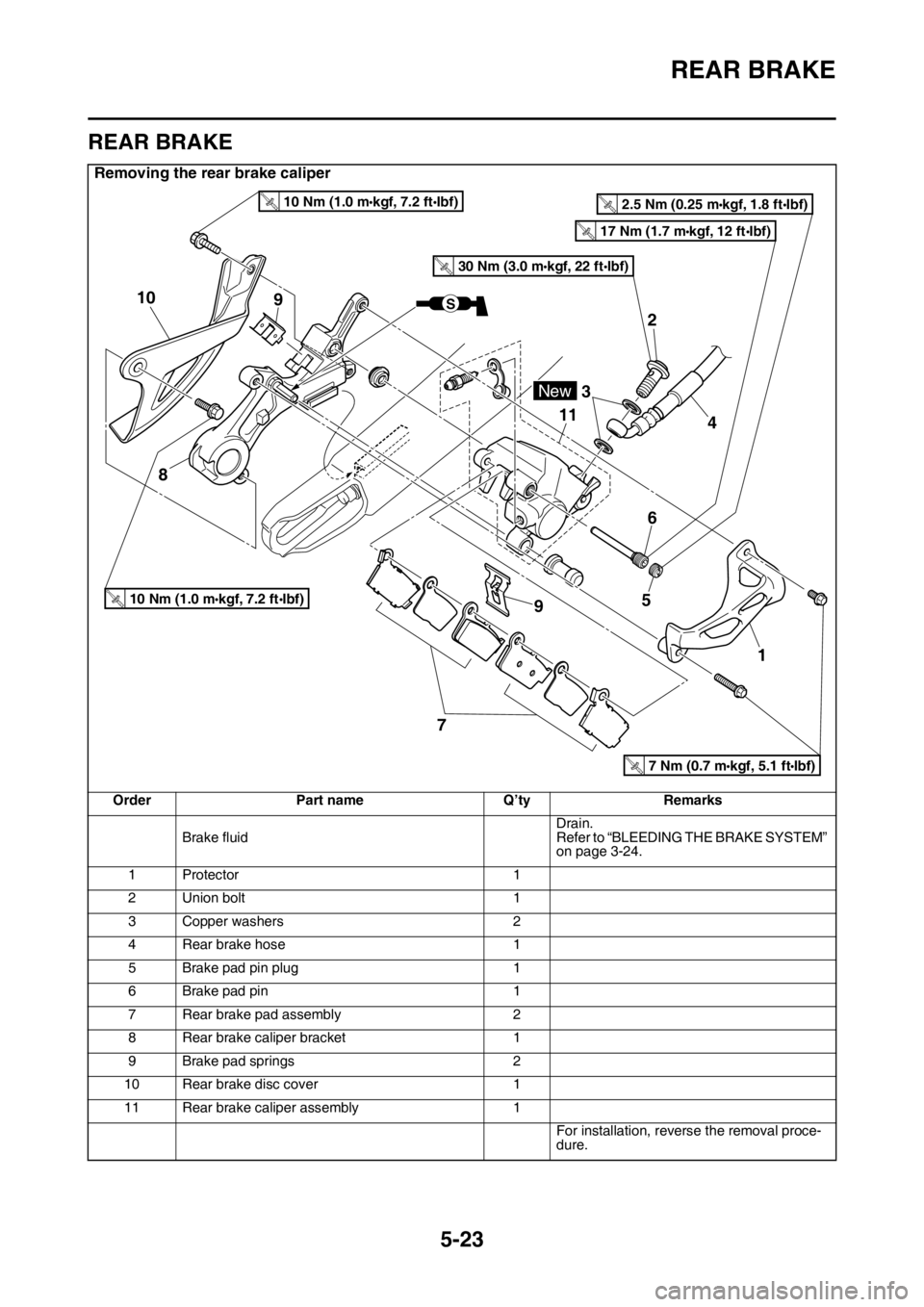

REAR BRAKE

Removing the rear brake caliper

Order Part name Q’ty Remarks

Brake fluidDrain.

Refer to “BLEEDING THE BRAKE SYSTEM”

on page 3-24.

1 Protector 1

2 Union bolt 1

3 Copper washers 2

4 Rear brake hose 1

5 Brake pad pin plug 1

6 Brake pad pin 1

7 Rear brake pad assembly 2

8 Rear brake caliper bracket 1

9 Brake pad springs 2

10 Rear brake disc cover 1

11 Rear brake caliper assembly 1

For installation, reverse the removal proce-

dure.

2

3

4 11

56

79

1

8

9 10

2.5 Nm (0.25 m•kgf, 1.8 ft•Ibf)T.R.

10 Nm (1.0 m•kgf, 7.2 ft•Ibf)T.R.

10 Nm (1.0 m•kgf, 7.2 ft•Ibf)T.R.

17 Nm (1.7 m•kgf, 12 ft•Ibf)T.R.

30 Nm (3.0 m•kgf, 22 ft•Ibf)T.R.

New

S

7 Nm (0.7 m•kgf, 5.1 ft•Ibf)T.R.

Page 187 of 430

REAR BRAKE

5-29

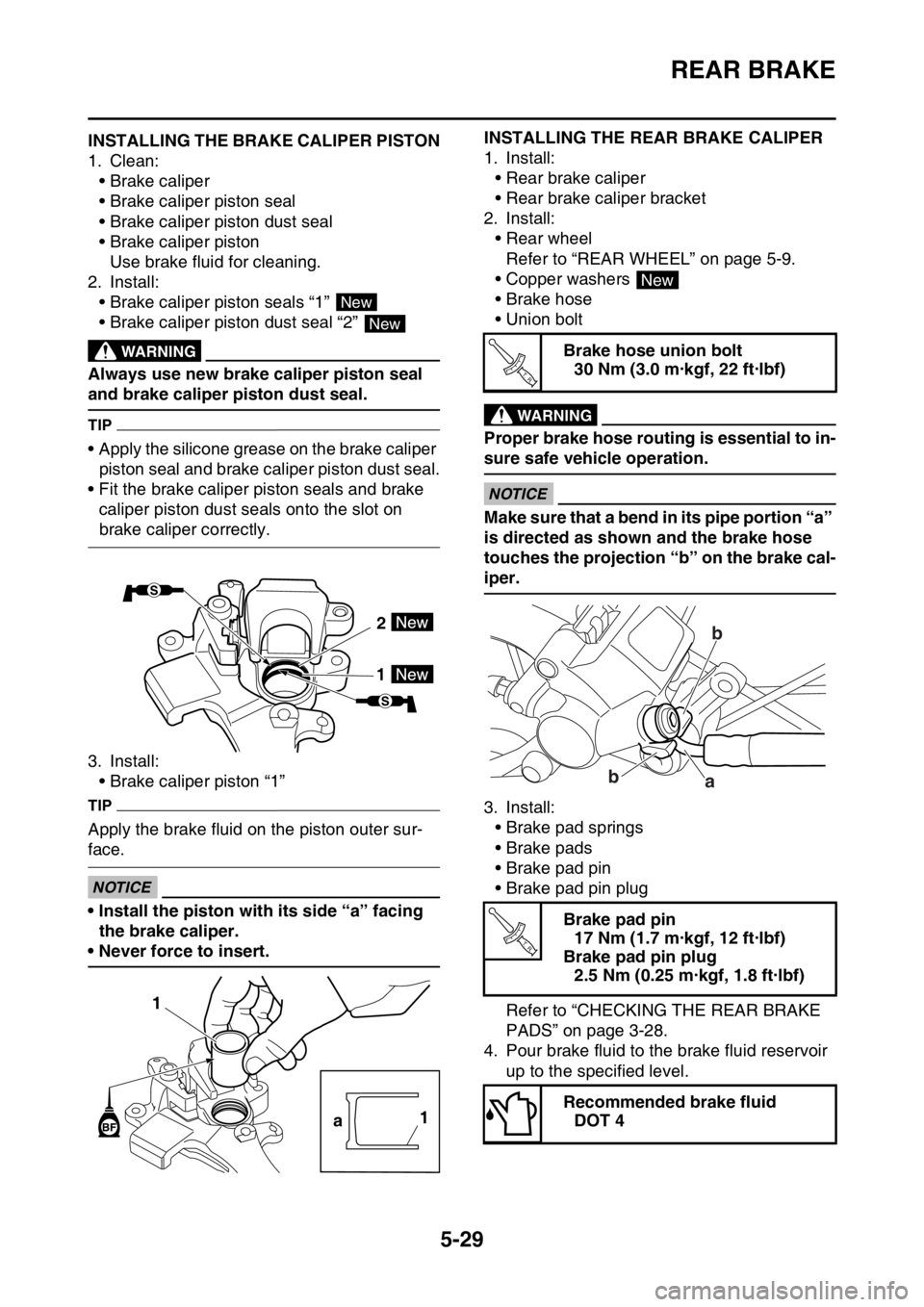

EAS2GB2189INSTALLING THE BRAKE CALIPER PISTON

1. Clean:

• Brake caliper

• Brake caliper piston seal

• Brake caliper piston dust seal

• Brake caliper piston

Use brake fluid for cleaning.

2. Install:

• Brake caliper piston seals “1”

• Brake caliper piston dust seal “2”

EWA

WARNING

Always use new brake caliper piston seal

and brake caliper piston dust seal.

TIP

• Apply the silicone grease on the brake caliper

piston seal and brake caliper piston dust seal.

• Fit the brake caliper piston seals and brake

caliper piston dust seals onto the slot on

brake caliper correctly.

3. Install:

• Brake caliper piston “1”

TIP

Apply the brake fluid on the piston outer sur-

face.

ECA

NOTICE

• Install the piston with its side “a” facing

the brake caliper.

• Never force to insert.

EAS2GB2190

INSTALLING THE REAR BRAKE CALIPER

1. Install:

• Rear brake caliper

• Rear brake caliper bracket

2. Install:

• Rear wheel

Refer to “REAR WHEEL” on page 5-9.

• Copper washers

• Brake hose

• Union bolt

EWA

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.

ECA

NOTICE

Make sure that a bend in its pipe portion “a”

is directed as shown and the brake hose

touches the projection “b” on the brake cal-

iper.

3. Install:

• Brake pad springs

• Brake pads

• Brake pad pin

• Brake pad pin plug

Refer to “CHECKING THE REAR BRAKE

PADS” on page 3-28.

4. Pour brake fluid to the brake fluid reservoir

up to the specified level.

New

New

2

1

1

a1

Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

Brake pad pin

17 Nm (1.7 m·kgf, 12 ft·lbf)

Brake pad pin plug

2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Recommended brake fluid

DOT 4

New

T R..

b

b

a

T R..

Page 242 of 430

CAMSHAFT

6-11

EAS2GB2239

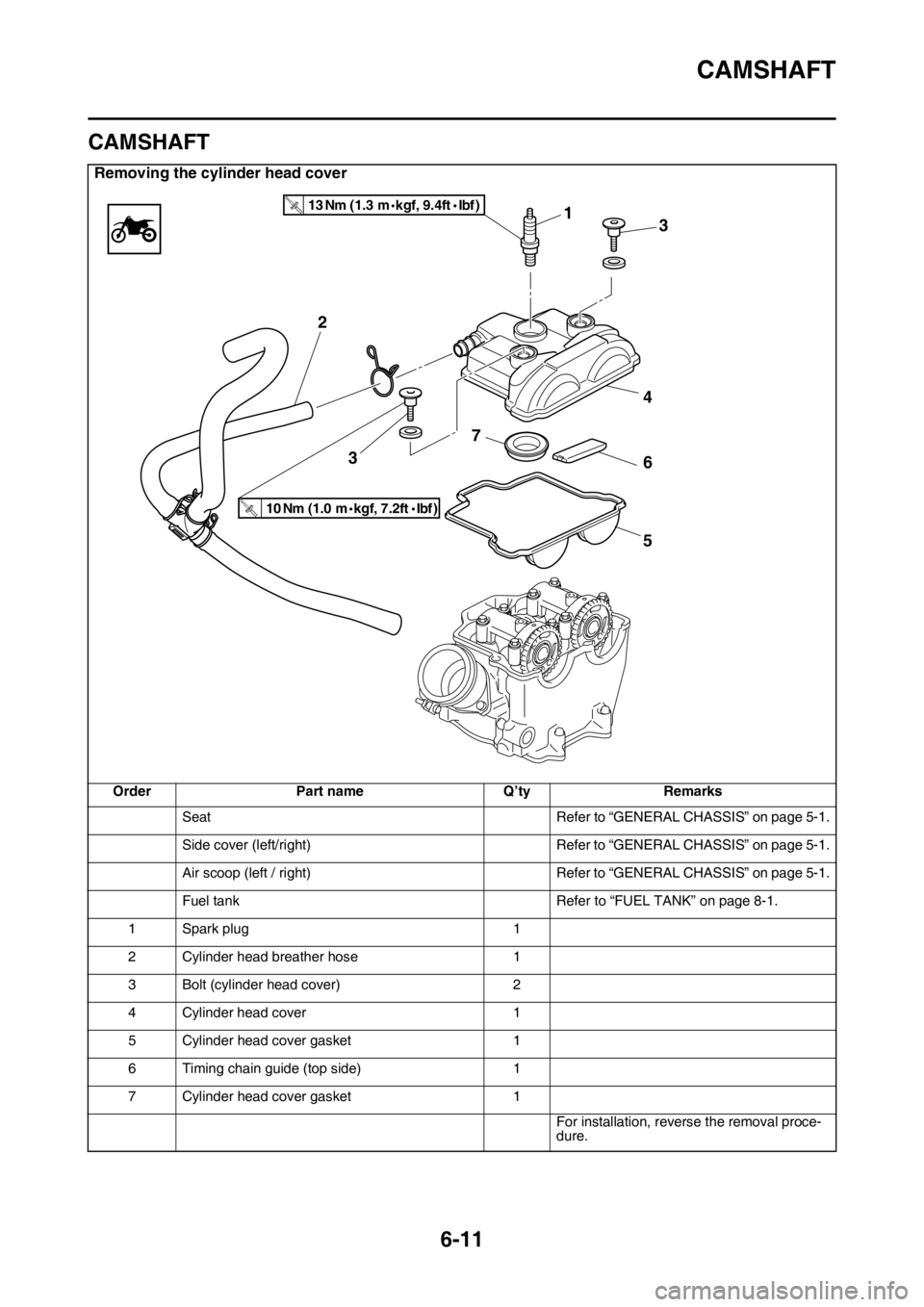

CAMSHAFT

Removing the cylinder head cover

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

1 Spark plug 1

2 Cylinder head breather hose 1

3 Bolt (cylinder head cover) 2

4 Cylinder head cover 1

5 Cylinder head cover gasket 1

6 Timing chain guide (top side) 1

7 Cylinder head cover gasket 1

For installation, reverse the removal proce-

dure.

1

4

6 7

5 2

3

10 Nm (1.0 m kgf, 7.2 ft Ibf )T.R.

13 Nm (1.3 m kgf, 9.4 ft Ibf )T.R.

3

Page 248 of 430

CAMSHAFT

6-17

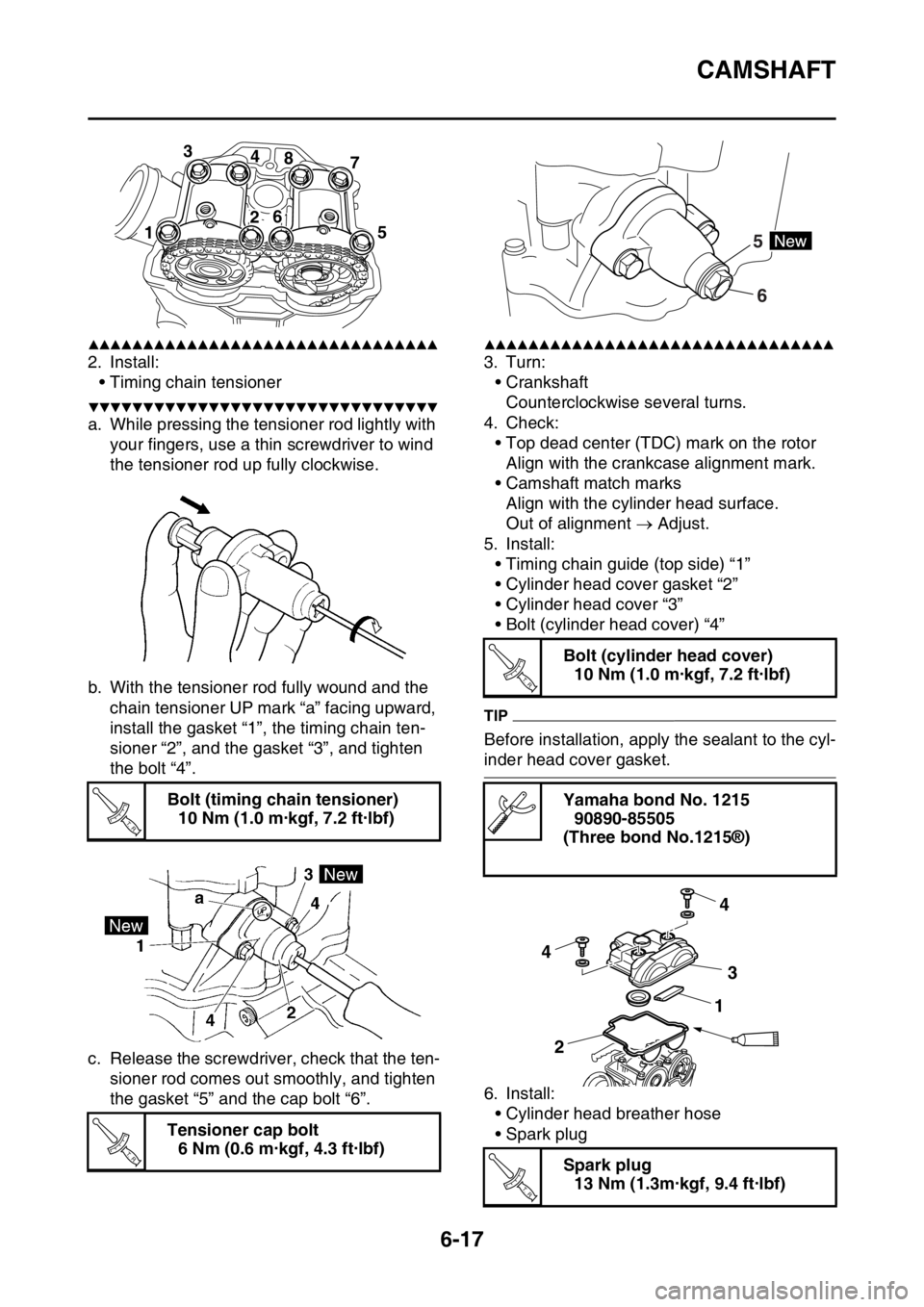

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Install:

• Timing chain tensioner

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver to wind

the tensioner rod up fully clockwise.

b. With the tensioner rod fully wound and the

chain tensioner UP mark “a” facing upward,

install the gasket “1”, the timing chain ten-

sioner “2”, and the gasket “3”, and tighten

the bolt “4”.

c. Release the screwdriver, check that the ten-

sioner rod comes out smoothly, and tighten

the gasket “5” and the cap bolt “6”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Turn:

• Crankshaft

Counterclockwise several turns.

4. Check:

• Top dead center (TDC) mark on the rotor

Align with the crankcase alignment mark.

• Camshaft match marks

Align with the cylinder head surface.

Out of alignment Adjust.

5. Install:

• Timing chain guide (top side) “1”

• Cylinder head cover gasket “2”

• Cylinder head cover “3”

• Bolt (cylinder head cover) “4”

TIP

Before installation, apply the sealant to the cyl-

inder head cover gasket.

6. Install:

• Cylinder head breather hose

• Spark plug Bolt (timing chain tensioner)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tensioner cap bolt

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

3

4

8

7

15

26

T R..

T R..

Bolt (cylinder head cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)

Spark plug

13 Nm (1.3m·kgf, 9.4 ft·lbf)

6 5

T R..

4

4

3

21

T R..

Page 251 of 430

CYLINDER HEAD

6-20

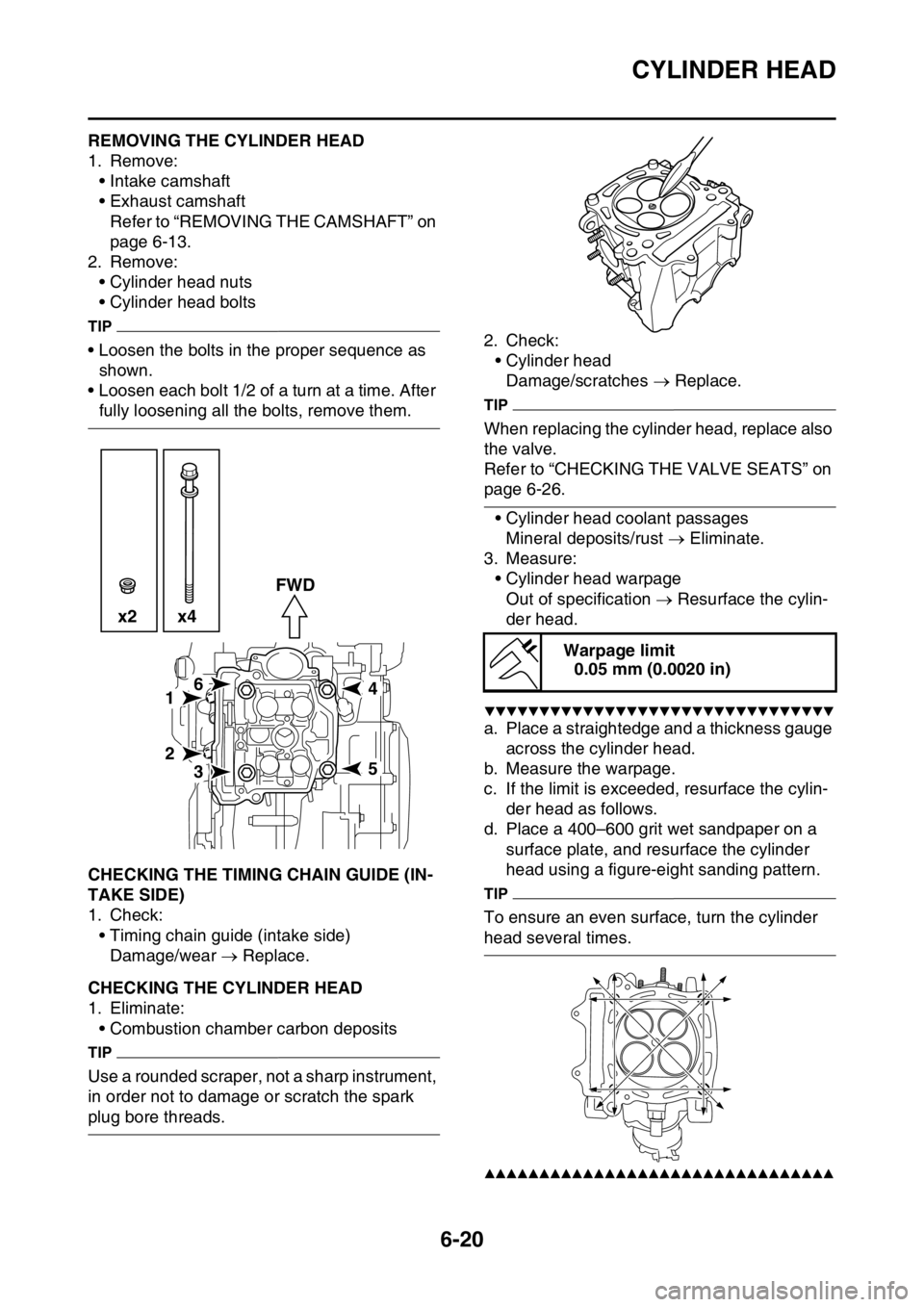

EAS2GB2247REMOVING THE CYLINDER HEAD

1. Remove:

• Intake camshaft

• Exhaust camshaft

Refer to “REMOVING THE CAMSHAFT” on

page 6-13.

2. Remove:

• Cylinder head nuts

• Cylinder head bolts

TIP

• Loosen the bolts in the proper sequence as

shown.

• Loosen each bolt 1/2 of a turn at a time. After

fully loosening all the bolts, remove them.

EAS2GB2248CHECKING THE TIMING CHAIN GUIDE (IN-

TAKE SIDE)

1. Check:

• Timing chain guide (intake side)

Damage/wear Replace.

EAS2GB2249CHECKING THE CYLINDER HEAD

1. Eliminate:

• Combustion chamber carbon deposits

TIP

Use a rounded scraper, not a sharp instrument,

in order not to damage or scratch the spark

plug bore threads.2. Check:

• Cylinder head

Damage/scratches Replace.

TIP

When replacing the cylinder head, replace also

the valve.

Refer to “CHECKING THE VALVE SEATS” on

page 6-26.

• Cylinder head coolant passages

Mineral deposits/rust Eliminate.

3. Measure:

• Cylinder head warpage

Out of specification Resurface the cylin-

der head.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Place a straightedge and a thickness gauge

across the cylinder head.

b. Measure the warpage.

c. If the limit is exceeded, resurface the cylin-

der head as follows.

d. Place a 400–600 grit wet sandpaper on a

surface plate, and resurface the cylinder

head using a figure-eight sanding pattern.

TIP

To ensure an even surface, turn the cylinder

head several times.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

61

2

35

4 x2 x4FWD

Warpage limit

0.05 mm (0.0020 in)

Page 334 of 430

ELECTRICAL COMPONENTS....................................................................... 9-60

CHECKING THE SWITCHES .................................................................. 9-64

CHECKING THE BULBS AND BULB SOCKETS .................................... 9-67

CHECKING THE FUSES ......................................................................... 9-68

CHECKING AND CHARGING THE BATTERY ........................................ 9-69

CHECKING THE RELAYS ....................................................................... 9-72

CHECKING THE DIODE .......................................................................... 9-73

CHECKING THE IGNITION SPARK GAP................................................ 9-73

CHECKING THE SPARK PLUG CAP ...................................................... 9-73

CHECKING THE IGNITION COIL ............................................................ 9-74

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 9-74

CHECKING THE LEAN ANGLE SENSOR............................................... 9-75

CHECKING THE STARTER MOTOR OPERATION ................................ 9-75

CHECKING THE STATOR COIL ............................................................. 9-76

CHECKING THE RECTIFIER/REGULATOR ........................................... 9-76

CHECKING THE SPEED SENSOR ......................................................... 9-77

CHECKING THE FUEL SENDER ............................................................ 9-77

CHECKING THE RESISTER ................................................................... 9-77

CHECKING THE RADIATOR FAN MOTOR ............................................ 9-78

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 9-78

CHECKING THE THROTTLE POSITION SENSOR ................................ 9-79

CHECKING THE THROTTLE POSITION SENSOR INPUT VOLTAGE .. 9-79

CHECKING THE INTAKE AIR PRESSURE SENSOR ............................ 9-80

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 9-80

CHECKING THE FUEL INJECTOR ......................................................... 9-81

Page 337 of 430

IGNITION SYSTEM

9-3

1. Joint connector

2. Joint connector

4. AC magneto

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

23.Ignition coil

24.Spark plug

30.Joint connector

35.Lean angle sensor

36.Engine stop switch

48.Frame ground

Page 338 of 430

IGNITION SYSTEM

9-4

EAS2GB2361TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Fuel tank

1. Check the fuse.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Replace the fuse(s).

OK

2. Check the battery.

Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69.NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the spark plug.

Refer to “CHECKING THE FUSES”

on page 9-68.NG

Re-gap or replace the spark plug.

OK

4. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 9-73.OK

The ignition system is normal.

NG

5. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 9-74.NG

Replace the ignition coil.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 9-74.NG

Replace the stator assembly.

OK

7. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 9-64.NG

Replace the engine stop switch.

OK

Page 404 of 430

ELECTRICAL COMPONENTS

9-70

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Charge:

• Battery

(refer to the appropriate charging method)

EWA

WARNING

Do not quick charge a battery.

ECA

NOTICE

• Do not use a high-rate battery charger

since it forces a high-amperage current

into the battery quickly and can cause bat-

tery overheating and battery plate dam-

age.

• If it is impossible to regulate the charging

current on the battery charger, be careful

not to overcharge the battery.• When charging a battery, be sure to re-

move it from the vehicle. (If charging has

to be done with the battery mounted on the

vehicle, disconnect the negative battery

lead from the battery terminal.)

• To reduce the chance of sparks, do not

plug in the battery charger until the battery

charger leads are connected to the bat-

tery.

• Before removing the battery charger lead

clips from the battery terminals, be sure to

turn off the battery charger.

• Make sure the battery charger lead clips

are in full contact with the battery terminal

and that they are not shorted. A corroded

battery charger lead clip may generate

heat in the contact area and a weak clip

spring may cause sparks.

• If the battery becomes hot to the touch at

any time during the charging process, dis-

connect the battery charger and let the

battery cool before reconnecting it. Hot

batteries can explode!

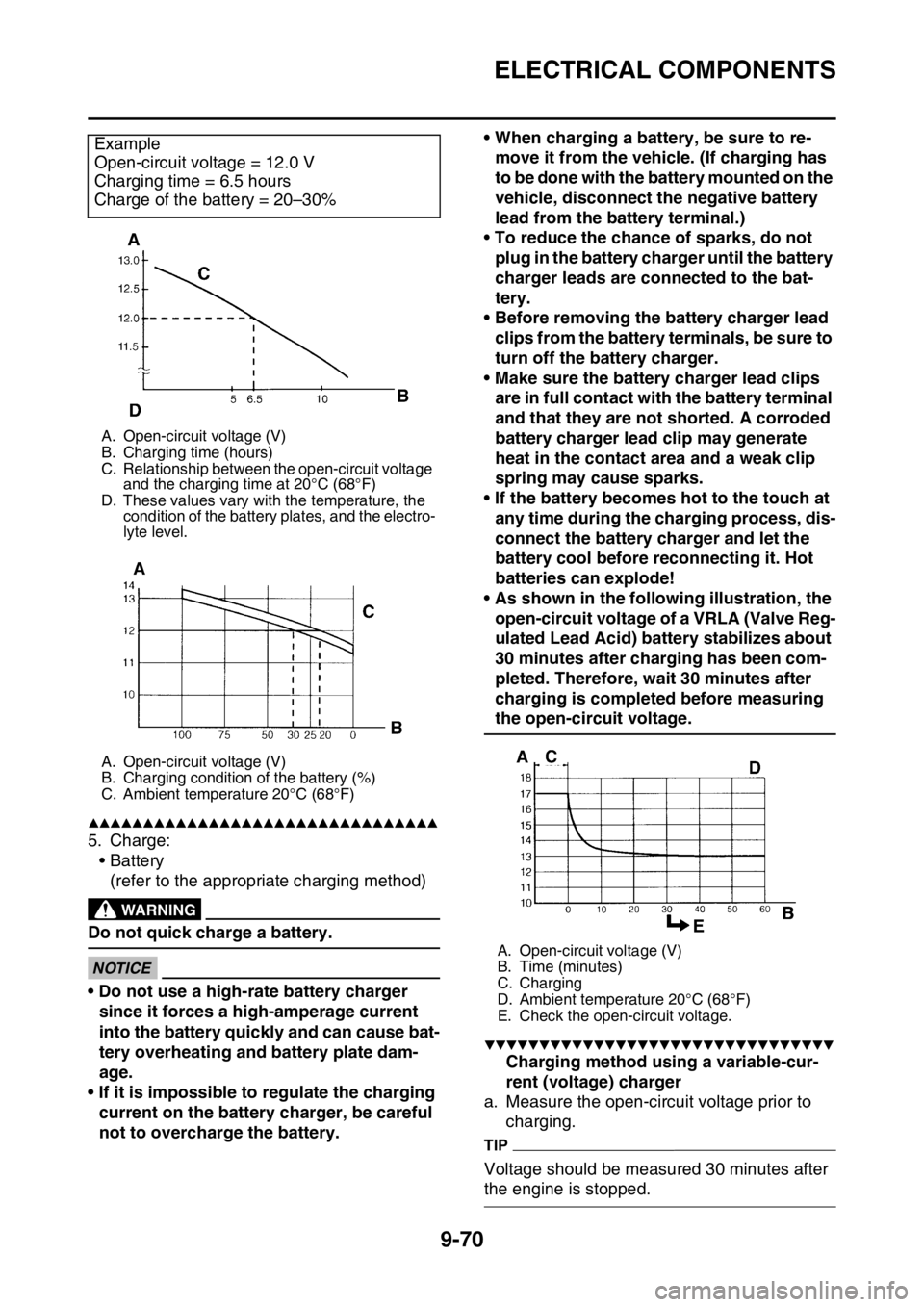

• As shown in the following illustration, the

open-circuit voltage of a VRLA (Valve Reg-

ulated Lead Acid) battery stabilizes about

30 minutes after charging has been com-

pleted. Therefore, wait 30 minutes after

charging is completed before measuring

the open-circuit voltage.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Charging method using a variable-cur-

rent (voltage) charger

a. Measure the open-circuit voltage prior to

charging.

TIP

Voltage should be measured 30 minutes after

the engine is stopped. Example

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20–30%

A. Open-circuit voltage (V)

B. Charging time (hours)

C. Relationship between the open-circuit voltage

and the charging time at 20°C (68°F)

D. These values vary with the temperature, the

condition of the battery plates, and the electro-

lyte level.

A. Open-circuit voltage (V)

B. Charging condition of the battery (%)

C. Ambient temperature 20°C (68°F)

A. Open-circuit voltage (V)

B. Time (minutes)

C. Charging

D. Ambient temperature 20°C (68°F)

E. Check the open-circuit voltage.

Page 407 of 430

ELECTRICAL COMPONENTS

9-73

EAS2GB2389CHECKING THE DIODE

1. Check:

•Diode

Out of specification Replace.

TIP

The pocket tester and the analog pocket tester

readings are shown in the following table.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the diode from the wire harness.

b. Connect the pocket tester ( 1) to the di-

ode coupler as shown.

c. Check the diode for continuity.

d. Check the diode for no continuity.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2390CHECKING THE IGNITION SPARK GAP

1. Check:

• Ignition spark gap

Out of specification Perform the ignition

system troubleshooting, starting with step 4.

Refer to “TROUBLESHOOTING” on page 9-

4.

TIP

If the ignition spark gap is within specification,

the ignition system circuit is operating normally.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the spark plug cap from the spark

plug.

b. Connect the ignition checker “1” as shown.

c. Push the engine stop switch.

d. Measure the ignition spark gap “a”.

e. Crank the engine by pushing the start switch

and gradually increase the spark gap until a

misfire occurs.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2391CHECKING THE SPARK PLUG CAP

1. Remove:

• Spark plug cap

(from the spark plug lead)

2. Check:

• Spark plug cap resistance

Out of specification Replace. Result

Continuity

(between “3” to “4”)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

No continuity

Tester positive lead Sky blue

“1”

Tester negative lead Green/

Black “2”

Continuity

Tester positive lead Green/

Black “2”

Tester negative lead Sky blue

“1”

No continuity

Tester positive lead Red “3”

Tester negative lead Red/Blue

“4”

Continuity

Tester positive lead Red/Blue

“4”

Tester negative lead Red “3”

2

1

4

3

R Sb

G/B R/L

Minimum ignition spark gap

6.0 mm (0.24 in)

Ignition checker

90890-06754

Oppama pet–4000 spark checker

YM-34487

2. Spark plug cap

Spark plug cap resistance

10 k