fuel YAMAHA WR 250F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 7 of 430

EAS2GB2005

SAFETY INFORMATION

THIS MACHINE IS DESIGNED STRICTLY FOR COMPETITION USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine to be operated on any public street, road, or highway. Off-road

use on public lands may also be illegal. Please check local regulations before riding.

• THIS MACHINE IS TO BE OPERATED BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this machine at maximum power until you are totally familiar with its char-

acteristics.

• THIS MACHINE IS DESIGNED TO BE RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this machine.

• ALWAYS WEAR PROTECTIVE APPAREL.

When operating this machine, always wear an approved helmet with goggles or a face shield. Also

wear heavy boots, gloves, and protective clothing. Always wear proper fitting clothing that will not

be caught in any of the moving parts or controls of the machine.

• ALWAYS MAINTAIN YOUR MACHINE IN PROPER WORKING ORDER.

For safety and reliability, the machine must be properly maintained. Always perform the pre-oper-

ation checks indicated in this manual.

Correcting a mechanical problem before you ride may prevent an accident.

• GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any gasoline on the engine or ex-

haust system. Never refuel in the vicinity of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline, inhale excess gasoline vapors, or allow any gasoline to get

into your eyes, contact a doctor immediately. If any gasoline spills onto your skin or clothing, imme-

diately wash skin areas with soap and water, and change your clothes.

• ONLY OPERATE THE MACHINE IN AN AREA WITH ADEQUATE VENTILATION.

Never start the engine or let it run for any length of time in an enclosed area. Exhaust fumes are

poisonous. These fumes contain carbon monoxide, which by itself is odorless and colorless. Car-

bon monoxide is a dangerous gas which can cause unconsciousness or can be lethal.

• PARK THE MACHINE CAREFULLY; TURN OFF THE ENGINE.

Always turn off the engine if you are going to leave the machine. Do not park the machine on a slope

or soft ground as it may fall over.

• THE ENGINE, EXHAUST PIPE AND MUFFLER WILL BE VERY HOT AFTER THE ENGINE HAS

BEEN RUN.

Be careful not to touch them or to allow any clothing item to contact them during inspection or repair.

• PROPERLY SECURE THE MACHINE BEFORE TRANSPORTING IT.

For safety, drain the gasoline from the fuel tank before transporting the vehicle.

Page 11 of 430

1

2

3

4

5

6

7

8

9

10

TOCTOC

TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND ADJUST-

MENTS

TUNING

CHASSIS

ENGINE

COOLING SYSTEM

FUEL SYSTEM

ELECTRICAL SYSTEM

TROUBLESHOOTING

Page 13 of 430

1

GENERAL INFORMATION

LOCATION OF IMPORTANT LABELS............................................................ 1-1

DESCRIPTION.................................................................................................. 1-4

IDENTIFICATION............................................................................................. 1-5

VEHICLE IDENTIFICATION NUMBER ...................................................... 1-5

ENGINE SERIAL NUMBER ....................................................................... 1-5

VEHICLE EMISSION CONTROL INFORMATION LABEL......................... 1-5

FEATURES....................................................................................................... 1-6

OUTLINE OF THE FI SYSTEM .................................................................. 1-6

FI SYSTEM................................................................................................. 1-7

INCLUDED PARTS.......................................................................................... 1-8

SPARK PLUG WRENCH ........................................................................... 1-8

NIPPLE WRENCH...................................................................................... 1-8

HANDLEBAR PROTECTOR ...................................................................... 1-8

FUEL HOSE JOINT COVER ...................................................................... 1-8

COUPLER FOR CONNECTING OPTIONAL PART................................... 1-8

IMPORTANT INFORMATION.......................................................................... 1-9

PREPARATION FOR REMOVAL AND DISASSEMBLY............................ 1-9

REPLACEMENT PARTS............................................................................ 1-9

GASKETS, OIL SEALS AND O-RINGS ................................................... 1-10

LOCK WASHERS/PLATES AND COTTER PINS .................................... 1-10

BEARINGS AND OIL SEALS ................................................................... 1-10

CIRCLIPS ................................................................................................. 1-10

BASIC SERVICE INFORMATION.................................................................. 1-11

ELECTRICAL SYSTEM............................................................................ 1-11

SPECIAL TOOLS........................................................................................... 1-15

Page 14 of 430

CONTROL FUNCTIONS................................................................................ 1-21

INDICATOR LIGHTS AND WARNING LIGHTS ....................................... 1-21

ENGINE STOP SWITCH .......................................................................... 1-21

START SWITCH....................................................................................... 1-21

CLUTCH LEVER...................................................................................... 1-21

SHIFT PEDAL .......................................................................................... 1-22

KICKSTARTER LEVER............................................................................ 1-22

THROTTLE GRIP ..................................................................................... 1-22

FRONT BRAKE LEVER ........................................................................... 1-22

REAR BRAKE PEDAL.............................................................................. 1-22

SIDESTAND ............................................................................................. 1-23

STARTER KNOB/IDLE ADJUSTING SCREW ......................................... 1-23

FUEL TANK CAP ..................................................................................... 1-23

MULTI-FUNCTION DISPLAY......................................................................... 1-24

DESCRIPTION ......................................................................................... 1-24

BASIC MODE ........................................................................................... 1-24

CHANGEOVER TO BASIC MODE/RACE MODE.................................... 1-25

RACE MODE ............................................................................................ 1-26

FUNCTION DIAGRAM ............................................................................. 1-30

STARTING AND BREAK-IN.......................................................................... 1-32

FUEL ........................................................................................................ 1-32

HANDLING NOTE .................................................................................... 1-32

AIR FILTER MAINTENANCE ................................................................... 1-32

STARTING A COLD ENGINE .................................................................. 1-32

STARTING A WARM ENGINE ................................................................. 1-33

BREAK-IN PROCEDURES ...................................................................... 1-34

MAINTENANCE AFTER BREAK-IN.............................................................. 1-35

MAJOR MAINTENANCE .......................................................................... 1-35

TORQUE-CHECK POINTS............................................................................ 1-36

MOTORCYCLE CARE AND STORAGE........................................................ 1-38

CARE........................................................................................................ 1-38

STORAGE ................................................................................................ 1-39

Page 18 of 430

DESCRIPTION

1-4

EAS2GB2009

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur-

chased.1. Clutch lever 12. Headlight

2. Multi-function display 13. Radiator

3. Front brake lever 14. Coolant drain bolt

4. Throttle grip 15. Rear brake pedal

5. Start switch 16. Air filter

6. Radiator cap 17. Drive chain

7. Fuel tank cap 18. Shift pedal

8. Engine stop switch 19. Oil level check window

9. Taillight 20. Starter knob/idle screw

10. Fuel tank 21. Front fork

11. Kickstarter lever

32 1

8

10

91112 1376

54

15 14 21 20 19 18 1716

Page 20 of 430

FEATURES

1-6

EAS20170

FEATURES

EAS2GB2014OUTLINE OF THE FI SYSTEM

The main function of a fuel supply system is to provide fuel to the combustion chamber at the opti-

mum air-fuel ratio in accordance with the engine operating conditions and the atmospheric tempera-

ture. In the conventional carburetor system, the air-fuel ratio of the mixture to be supplied to the

combustion chamber is determined by the amount of intake air and fuel that is measured on the basis

of the jets to be used in the carburetor.

Despite the same amount of intake air, the fuel amount requirement varies with the engine operating

conditions (acceleration, deceleration, and operation under a heavy load). The carburetor that mea-

sures fuel through the use of jets are provided with various auxiliary devices, so that the optimum air

fuel ratio can be obtained to accommodate frequent changes in the operating conditions of the en-

gine. This model has adopted an electronically controlled fuel injection (FI) system, in place of the

conventional carburetor system. This system can obtain the optimum air-fuel ratio required by the

engine at all times by using a microprocessor that regulates the fuel injection amount according to

the engine operating conditions detected by various sensors.

1. Fuel injector

2. Throttle position sensor

3. Intake air pressure sensor

4. Engine trouble warning light

5. Intake air temperature sensor

6. ECU

7. Fuel pump

8. Battery

9. Lean angle sensor

10.Crankshaft position sensor

11.Coolant temperature sensor

12.Ignition coil

13.Speed sensor

748

9 10 116 5 123

12

13

Page 21 of 430

FEATURES

1-7

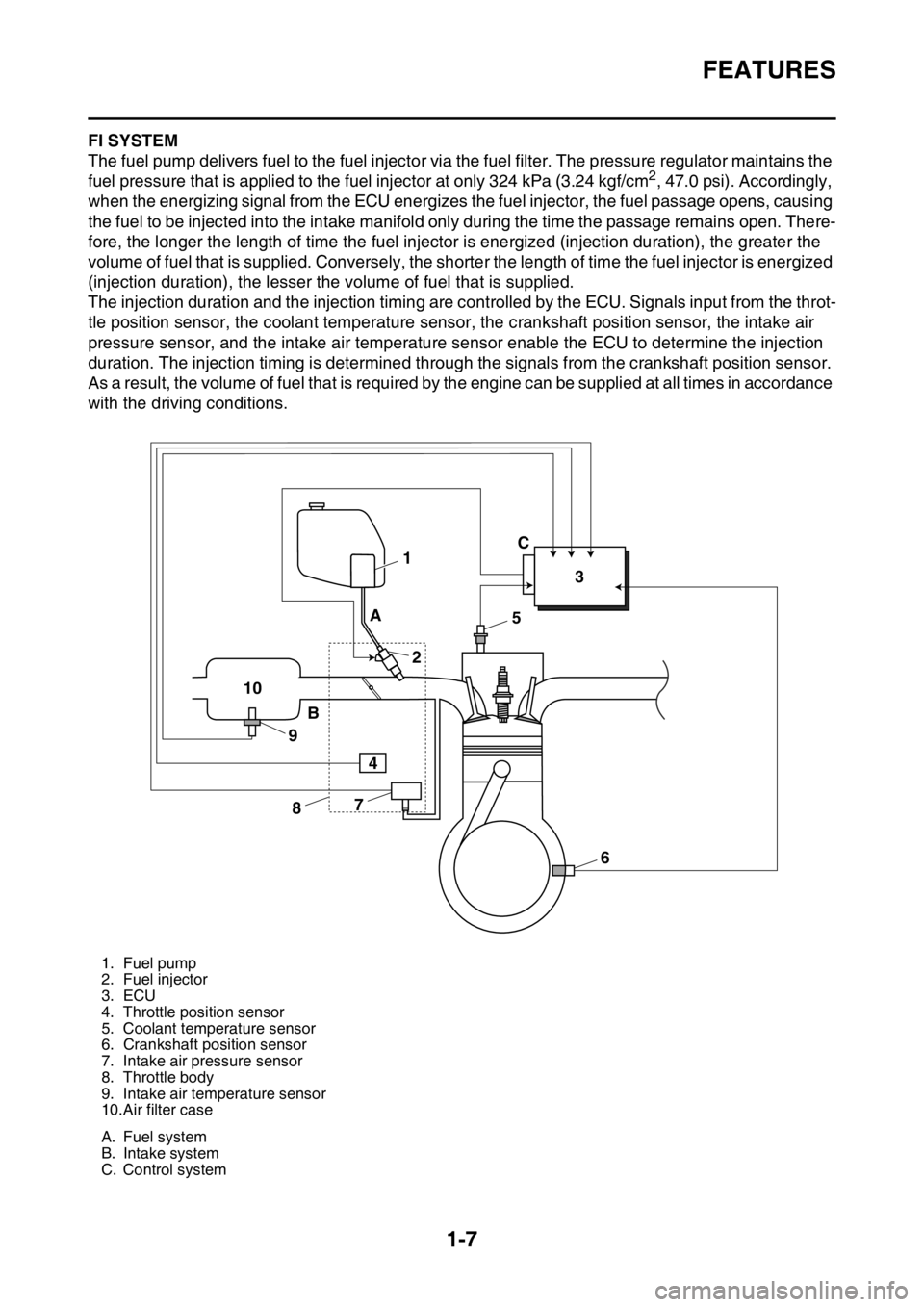

EAS2GB2015FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the

fuel pressure that is applied to the fuel injector at only 324 kPa (3.24 kgf/cm

2, 47.0 psi). Accordingly,

when the energizing signal from the ECU energizes the fuel injector, the fuel passage opens, causing

the fuel to be injected into the intake manifold only during the time the passage remains open. There-

fore, the longer the length of time the fuel injector is energized (injection duration), the greater the

volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is energized

(injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals input from the throt-

tle position sensor, the coolant temperature sensor, the crankshaft position sensor, the intake air

pressure sensor, and the intake air temperature sensor enable the ECU to determine the injection

duration. The injection timing is determined through the signals from the crankshaft position sensor.

As a result, the volume of fuel that is required by the engine can be supplied at all times in accordance

with the driving conditions.

1. Fuel pump

2. Fuel injector

3. ECU

4. Throttle position sensor

5. Coolant temperature sensor

6. Crankshaft position sensor

7. Intake air pressure sensor

8. Throttle body

9. Intake air temperature sensor

10.Air filter case

A. Fuel system

B. Intake system

C. Control system

1

23

5

6 7

8 9 10A

BC

4

Page 22 of 430

INCLUDED PARTS

1-8

EAS2GB2016

INCLUDED PARTS

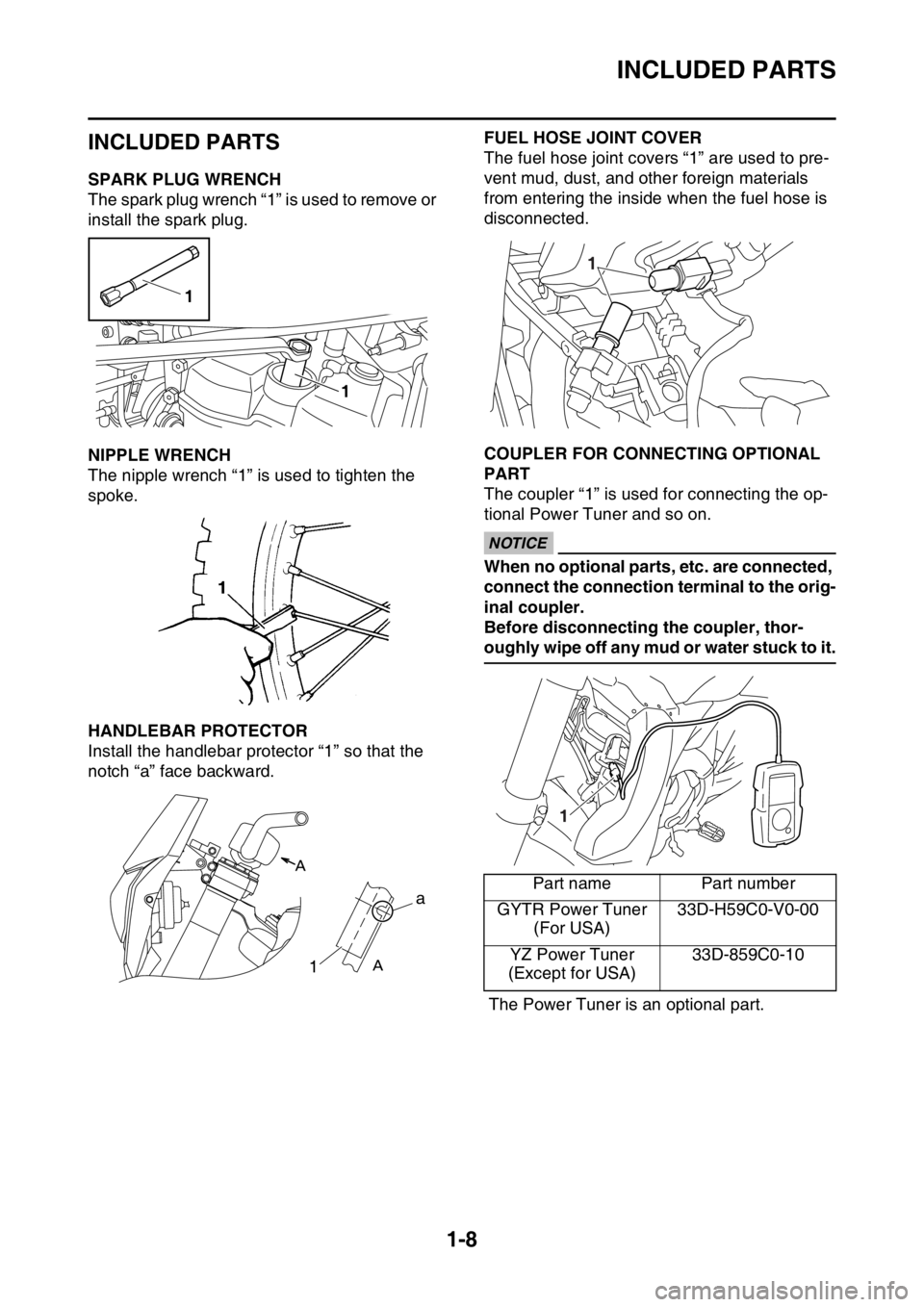

EAS2GB2017SPARK PLUG WRENCH

The spark plug wrench “1” is used to remove or

install the spark plug.

EAS2GB2018NIPPLE WRENCH

The nipple wrench “1” is used to tighten the

spoke.

EAS2GB2019HANDLEBAR PROTECTOR

Install the handlebar protector “1” so that the

notch “a” face backward.

EAS2GB2020

FUEL HOSE JOINT COVER

The fuel hose joint covers “1” are used to pre-

vent mud, dust, and other foreign materials

from entering the inside when the fuel hose is

disconnected.

EAS2GB2021COUPLER FOR CONNECTING OPTIONAL

PART

The coupler “1” is used for connecting the op-

tional Power Tuner and so on.

ECA

NOTICE

When no optional parts, etc. are connected,

connect the connection terminal to the orig-

inal coupler.

Before disconnecting the coupler, thor-

oughly wipe off any mud or water stuck to it.

The Power Tuner is an optional part.

1

1

1

aPart name Part number

GYTR Power Tuner

(For USA)33D-H59C0-V0-00

YZ Power Tuner

(Except for USA)33D-859C0-10

1

1

Page 31 of 430

SPECIAL TOOLS

1-17

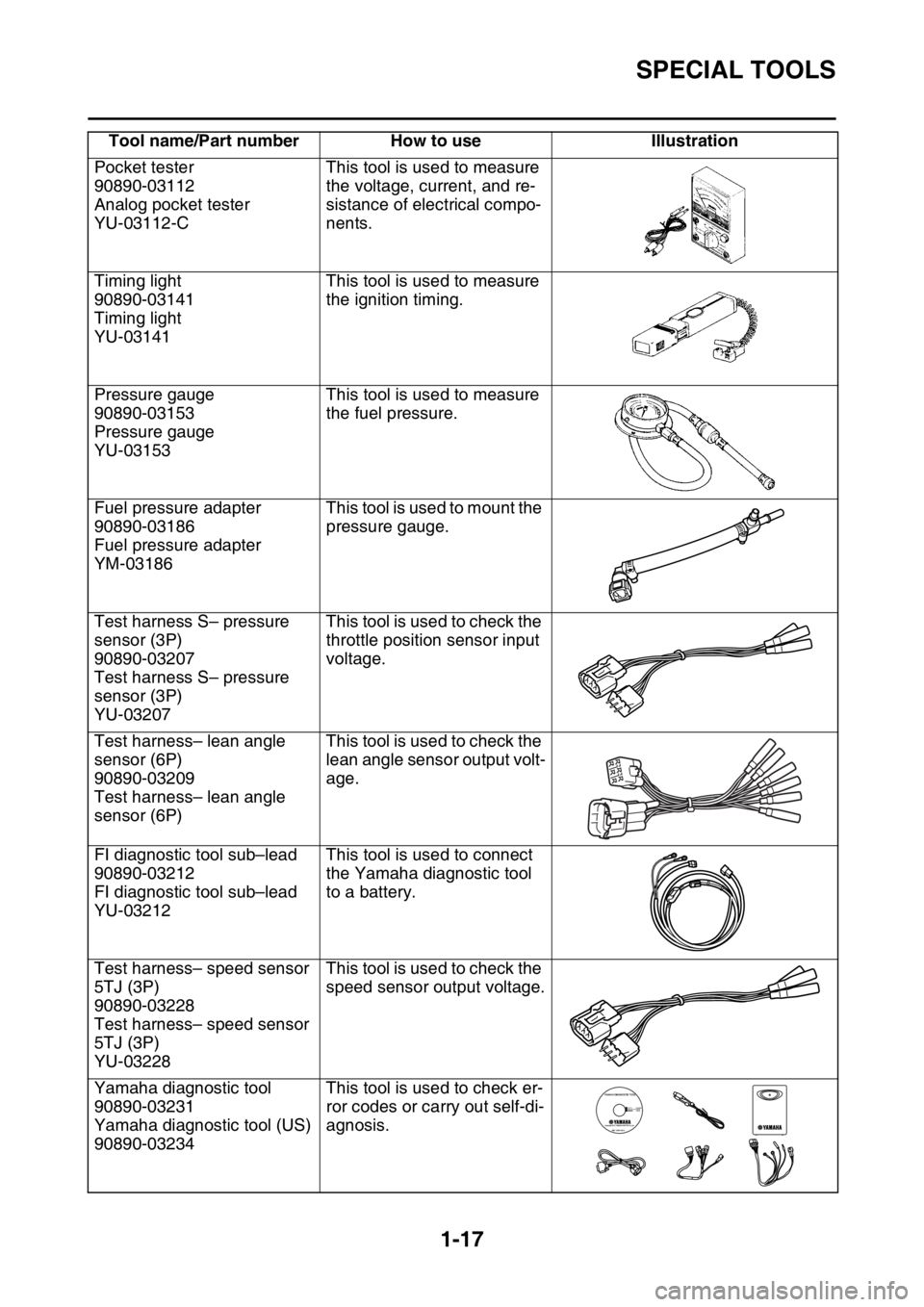

Pocket tester

90890-03112

Analog pocket tester

YU-03112-CThis tool is used to measure

the voltage, current, and re-

sistance of electrical compo-

nents.

Timing light

90890-03141

Timing light

YU-03141This tool is used to measure

the ignition timing.

Pressure gauge

90890-03153

Pressure gauge

YU-03153This tool is used to measure

the fuel pressure.

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186This tool is used to mount the

pressure gauge.

Test harness S– pressure

sensor (3P)

90890-03207

Test harness S– pressure

sensor (3P)

YU-03207This tool is used to check the

throttle position sensor input

voltage.

Test harness– lean angle

sensor (6P)

90890-03209

Test harness– lean angle

sensor (6P)This tool is used to check the

lean angle sensor output volt-

age.

FI diagnostic tool sub–lead

90890-03212

FI diagnostic tool sub–lead

YU-03212This tool is used to connect

the Yamaha diagnostic tool

to a battery.

Test harness– speed sensor

5TJ (3P)

90890-03228

Test harness– speed sensor

5TJ (3P)

YU-03228This tool is used to check the

speed sensor output voltage.

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234This tool is used to check er-

ror codes or carry out self-di-

agnosis. Tool name/Part number How to use Illustration

Page 35 of 430

CONTROL FUNCTIONS

1-21

EAS2GB2031

CONTROL FUNCTIONS

EAS2GB2032INDICATOR LIGHTS AND WARNING

LIGHTS

1. Engine trouble warning light “ ”

2. Fuel level warning light “ ”

Fuel level warning light “ ”

This warning light comes on when the fuel level

drops below approximately 1.6 L (0.42 US gal,

0.35 Imp.gal). When this occurs, refuel as soon

as possible.

The electrical circuit of the warning light can be

checked by pushing the start switch. The warn-

ing light should come on for a few seconds, and

then go off.

If the warning light does not come on initially

when the start switch is pushed, or if the warn-

ing light remains on, have a Yamaha dealer

check the electrical circuit.

Engine trouble warning light “ ”

This warning light comes on or flashes if a prob-

lem is detected in the electrical circuit monitor-

ing the engine. If this occurs, have a Yamaha

dealer check the vehicle.

The electrical circuit of the warning light can be

checked by pushing the start switch. The warn-

ing light should come on for a few seconds, and

then go off.

If the warning light does not come on initially

when the start switch is pushed, or if the warn-

ing light remains on, have a Yamaha dealer

check the electrical circuit.

EAS2GB2033ENGINE STOP SWITCH

The engine stop switch “1” is located on the left

handlebar. Continue pushing the engine stop

switch till the engine comes to a stop.

After the engine stops, the multi-function dis-

play will go off and the power supply to the ECU

(Electronic Control Unit) will be cut off if the en-

gine stop switch is pushed and held.

TIP

The multi-function display will go off after one

minute if the engine stop switch is not pushed.

EAS2GB2034START SWITCH

The start switch “1” is located on the right han-

dlebar. Push this switch to crank the engine

with the starter.

EAS2GB2035CLUTCH LEVER

The clutch lever “1” is located on the left han-

dlebar. The clutch lever disengages or engag-

es the clutch.

Pull the clutch lever toward the handlebar to

disengage the clutch, and release the lever to

engage the clutch.

12