fuel filter YAMAHA WR 250F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 14 of 430

CONTROL FUNCTIONS................................................................................ 1-21

INDICATOR LIGHTS AND WARNING LIGHTS ....................................... 1-21

ENGINE STOP SWITCH .......................................................................... 1-21

START SWITCH....................................................................................... 1-21

CLUTCH LEVER...................................................................................... 1-21

SHIFT PEDAL .......................................................................................... 1-22

KICKSTARTER LEVER............................................................................ 1-22

THROTTLE GRIP ..................................................................................... 1-22

FRONT BRAKE LEVER ........................................................................... 1-22

REAR BRAKE PEDAL.............................................................................. 1-22

SIDESTAND ............................................................................................. 1-23

STARTER KNOB/IDLE ADJUSTING SCREW ......................................... 1-23

FUEL TANK CAP ..................................................................................... 1-23

MULTI-FUNCTION DISPLAY......................................................................... 1-24

DESCRIPTION ......................................................................................... 1-24

BASIC MODE ........................................................................................... 1-24

CHANGEOVER TO BASIC MODE/RACE MODE.................................... 1-25

RACE MODE ............................................................................................ 1-26

FUNCTION DIAGRAM ............................................................................. 1-30

STARTING AND BREAK-IN.......................................................................... 1-32

FUEL ........................................................................................................ 1-32

HANDLING NOTE .................................................................................... 1-32

AIR FILTER MAINTENANCE ................................................................... 1-32

STARTING A COLD ENGINE .................................................................. 1-32

STARTING A WARM ENGINE ................................................................. 1-33

BREAK-IN PROCEDURES ...................................................................... 1-34

MAINTENANCE AFTER BREAK-IN.............................................................. 1-35

MAJOR MAINTENANCE .......................................................................... 1-35

TORQUE-CHECK POINTS............................................................................ 1-36

MOTORCYCLE CARE AND STORAGE........................................................ 1-38

CARE........................................................................................................ 1-38

STORAGE ................................................................................................ 1-39

Page 18 of 430

DESCRIPTION

1-4

EAS2GB2009

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur-

chased.1. Clutch lever 12. Headlight

2. Multi-function display 13. Radiator

3. Front brake lever 14. Coolant drain bolt

4. Throttle grip 15. Rear brake pedal

5. Start switch 16. Air filter

6. Radiator cap 17. Drive chain

7. Fuel tank cap 18. Shift pedal

8. Engine stop switch 19. Oil level check window

9. Taillight 20. Starter knob/idle screw

10. Fuel tank 21. Front fork

11. Kickstarter lever

32 1

8

10

91112 1376

54

15 14 21 20 19 18 1716

Page 21 of 430

FEATURES

1-7

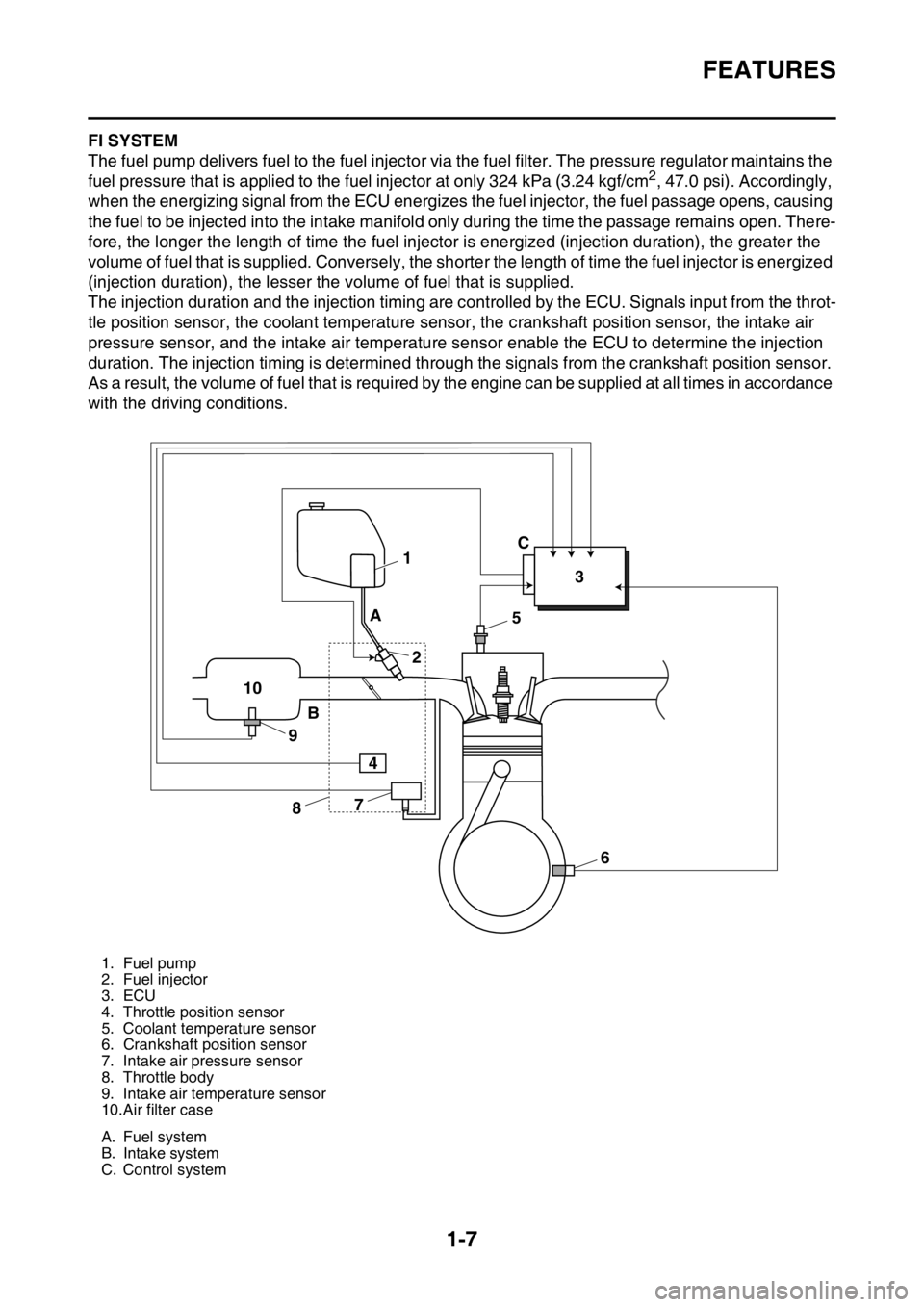

EAS2GB2015FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the

fuel pressure that is applied to the fuel injector at only 324 kPa (3.24 kgf/cm

2, 47.0 psi). Accordingly,

when the energizing signal from the ECU energizes the fuel injector, the fuel passage opens, causing

the fuel to be injected into the intake manifold only during the time the passage remains open. There-

fore, the longer the length of time the fuel injector is energized (injection duration), the greater the

volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is energized

(injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals input from the throt-

tle position sensor, the coolant temperature sensor, the crankshaft position sensor, the intake air

pressure sensor, and the intake air temperature sensor enable the ECU to determine the injection

duration. The injection timing is determined through the signals from the crankshaft position sensor.

As a result, the volume of fuel that is required by the engine can be supplied at all times in accordance

with the driving conditions.

1. Fuel pump

2. Fuel injector

3. ECU

4. Throttle position sensor

5. Coolant temperature sensor

6. Crankshaft position sensor

7. Intake air pressure sensor

8. Throttle body

9. Intake air temperature sensor

10.Air filter case

A. Fuel system

B. Intake system

C. Control system

1

23

5

6 7

8 9 10A

BC

4

Page 46 of 430

STARTING AND BREAK-IN

1-32

EAS2GB2050

STARTING AND BREAK-IN

EAS2GB2051FUEL

Always use the recommended fuel as stated

below. Also, be sure to use new gasoline the

day of a race.

ECA

NOTICE

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

TIP

Your Yamaha engine has been designed to use

premium unleaded gasoline with a pump oc-

tane number [(R+M)/2] of 91 or higher, or a re-

search octane number of 95 or higher. If

knocking (or pinging) occurs, use a gasoline of

a different brand.

EWA

WARNING

• For refueling, be sure to stop the engine

and use enough care not to spill any fuel.

Also be sure to avoid refueling close to a

fire.

• Refuel after the engine, exhaust pipe, etc.

have cooled off.

Gasohol (For USA and Canada)

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.

Gasohol containing ethanol can be used if the

ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by

Yamaha because it can cause damage to the

fuel system or vehicle performance problems.

EAS2GB2052HANDLING NOTEEWA

WARNING

Never start or run the engine in a closed ar-

ea. The exhaust fumes are poisonous; they

can cause loss of consciousness and death

in a very short time. Always operate the ma-

chine in a well-ventilated area.

ECA

NOTICE

• Unlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kickstarter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the engine

to start.

• Before starting the machine, perform the

checks in the pre-operation check list.

EAS2GB2053AIR FILTER MAINTENANCE

According to “CLEANING THE AIR FILTER

ELEMENT” section in the CHAPTER 3, apply

the foam-air-filter oil or its equivalent to the ele-

ment. (Excess oil in the element may adversely

affect engine starting.)

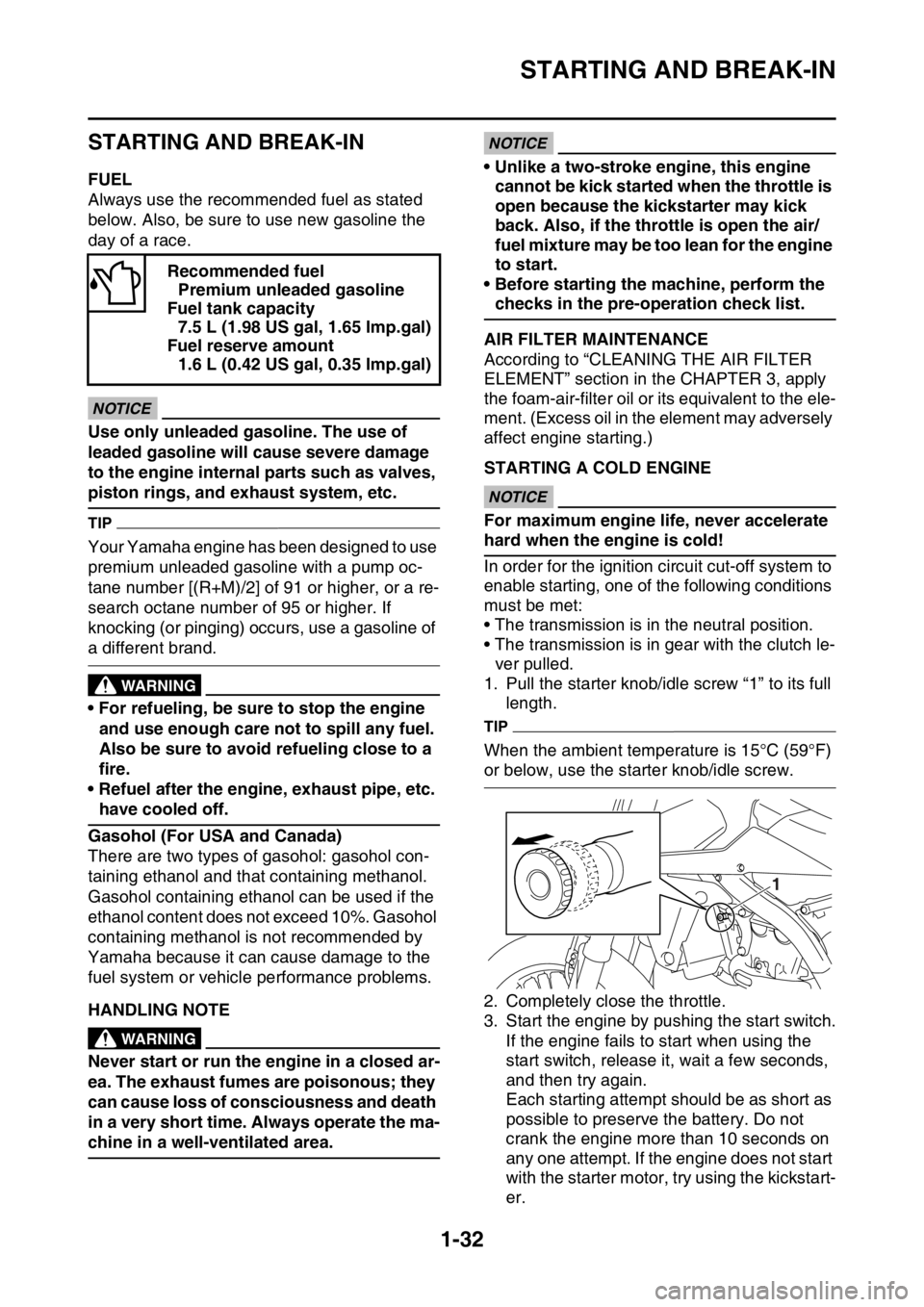

EAS2GB2054STARTING A COLD ENGINEECA

NOTICE

For maximum engine life, never accelerate

hard when the engine is cold!

In order for the ignition circuit cut-off system to

enable starting, one of the following conditions

must be met:

• The transmission is in the neutral position.

• The transmission is in gear with the clutch le-

ver pulled.

1. Pull the starter knob/idle screw “1” to its full

length.

TIP

When the ambient temperature is 15°C (59°F)

or below, use the starter knob/idle screw.

2. Completely close the throttle.

3. Start the engine by pushing the start switch.

If the engine fails to start when using the

start switch, release it, wait a few seconds,

and then try again.

Each starting attempt should be as short as

possible to preserve the battery. Do not

crank the engine more than 10 seconds on

any one attempt. If the engine does not start

with the starter motor, try using the kickstart-

er. Recommended fuel

Premium unleaded gasoline

Fuel tank capacity

7.5 L (1.98 US gal, 1.65 lmp.gal)

Fuel reserve amount

1.6 L (0.42 US gal, 0.35 lmp.gal)

1

Page 57 of 430

ENGINE SPECIFICATIONS

2-2

EAS2GB2064

ENGINE SPECIFICATIONS

Engine

Engine type Liquid cooled 4-stroke, DOHC

Displacement 250 cm

3

Cylinder arrangement Single cylinder

Bore stroke 77.0 53.6 mm (3.0 2.1 in)

Compression ratio 13.5:1

Starting system Electric starter and kickstarter

Fuel

Recommended fuel Premium unleaded gasoline only

Fuel tank capacity 7.5 L (1.98 US gal, 1.65 Imp.gal)

Fuel reserve amount 1.6 L (0.42 US gal, 0.35 Imp.gal)

Engine oil

Lubrication system Wet sump

Recommended brand YAMALUBE

Type SAE 10W-30, SAE 10W-40, SAE 10W-50,

SAE 15W-40, SAE 20W-40 or SAE 20W-50

Recommended engine oil grade API service SG type or higher, JASO standard

MA

Engine oil quantity

Quantity (disassembled) 1.10 L (1.16 US qt, 0.97 Imp.qt)

Without oil filter element replacement 0.83 L (0.88 US qt, 0.73 Imp.qt)

With oil filter element replacement 0.85 L (0.90 US qt, 0.75 Imp.qt)

Oil filter

Oil filter type Paper

Bypass valve opening pressure 40.0–80.0 kPa (0.40–0.80 kgf/cm

2,

5.8–11.6 psi)

Oil pump

Oil pump type Trochoid

Inner-rotor-to-outer-rotor-tip clearance Less than 0.150 mm (0.0059 in)

Limit 0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing clearance 0.13–0.18 mm (0.0051–0.0071 in)

Limit 0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-outer-rotor

clearance 0.06–0.11 mm (0.0024–0.0043 in)

Limit 0.17 mm (0.0067 in)

Cooling system

Radiator capacity (including all routes) 1.00 L (1.06 US qt, 0.88 Imp.qt)

Radiator capacity 0.56 L (0.60 US qt, 0.50 Imp.qt)

Radiator cap opening pressure 107.9–137.3 kPa (1.08–1.37 kg/cm

2,

15.6–19.9 psi)

Radiator core

Width 112.6 mm (4.43 in)

Height 235.0 mm (9.25 in)

Depth 28.0 mm (1.10 in)

Water pump

Water pump type Single suction centrifugal pump

Spark plug

Manufacturer/model NGK/LMAR8G

Spark plug gap 0.7–0.8 mm (0.028–0.031 in)

Page 91 of 430

CABLE ROUTING DIAGRAM

2-36

1. Clamp

2. Cylinder head breather hose

3. Throttle position sensor lead

4. Joint coupler

5. Intake air temperature sensor coupler

6. Intake air pressure sensor lead

7. Wire harness

8. Injector lead

9. Throttle body

10. Injector coupler

11. Starter motor lead

12. Plastic band

13. Fuel sender coupler

14. High tension cord

15. Spark plug cap

16. Cylinder head cover

17. Fuel hose

18. Fuel sender

19. Sub-wire harness

20. Crankcase breather hose

21. Radiator breather hose

22. Radiator hose

23. Down tube

24. Starter motor

25. Neutral switch lead

26. AC magneto lead

27. Clutch cable

28. Radiator

29. Air filter case breather hose

30. Breather hose clamp

31. Grommet (high tension cord)

32. ECU

33. Air filter case

34. Sub-wire harness coupler

35. Engine bracket

A. Fix the wire harness, clutch switch lead and start

switch lead by the plastic clamp, and insert the

projection of the plastic clamp into the hole in the

sheet metal of the radiator.

B. Route each lead so that the leads are not pinched

between the tank rail and air filter joint.

C. Insert the projection of the wire harness into the

hole in the frame.

D. Route the cylinder head breather hose without it

crossing the starter motor lead.

E. Pass the cylinder head breather hose between

the throttle cable and rectifier/regulator lead.

F. Connect the sub-wire harness to the wire har-

ness.

G. Pass the high tension cord above the fuel hose.

H. ±10°

I. Install the spark plug cap with this facing the right

of the vehicle.

J. Push the spark plug cap home, where there shall

be no gap between it and the cylinder head cover.

K. Pass the radiator breather hose between the

down tubes.

L. Apply adhesive to the slit and inside of the grom-

met, and then fix the grommet according to the

specified dimensions.

M. Pass the sub-wire harness between the ECU and

the air filter case.

N. Insert the coupler of the sub-wire harness into the

rib of the air filter case.

O. Route the radiator breather hose through be-

tween the radiator hose, down tube and engine

bracket.

Page 93 of 430

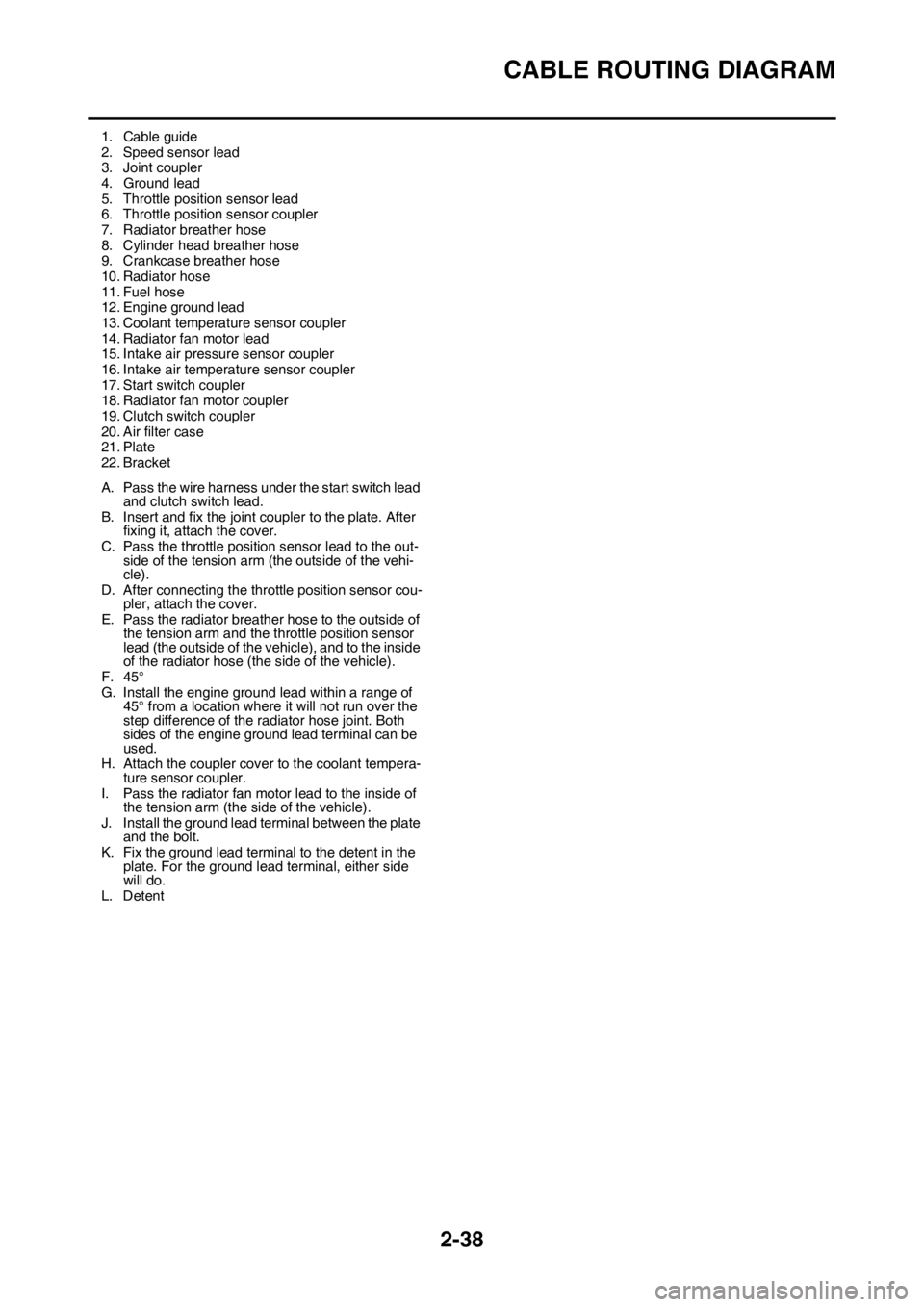

CABLE ROUTING DIAGRAM

2-38

1. Cable guide

2. Speed sensor lead

3. Joint coupler

4. Ground lead

5. Throttle position sensor lead

6. Throttle position sensor coupler

7. Radiator breather hose

8. Cylinder head breather hose

9. Crankcase breather hose

10. Radiator hose

11. Fuel hose

12. Engine ground lead

13. Coolant temperature sensor coupler

14. Radiator fan motor lead

15. Intake air pressure sensor coupler

16. Intake air temperature sensor coupler

17. Start switch coupler

18. Radiator fan motor coupler

19. Clutch switch coupler

20. Air filter case

21. Plate

22. Bracket

A. Pass the wire harness under the start switch lead

and clutch switch lead.

B. Insert and fix the joint coupler to the plate. After

fixing it, attach the cover.

C. Pass the throttle position sensor lead to the out-

side of the tension arm (the outside of the vehi-

cle).

D. After connecting the throttle position sensor cou-

pler, attach the cover.

E. Pass the radiator breather hose to the outside of

the tension arm and the throttle position sensor

lead (the outside of the vehicle), and to the inside

of the radiator hose (the side of the vehicle).

F. 45°

G. Install the engine ground lead within a range of

45° from a location where it will not run over the

step difference of the radiator hose joint. Both

sides of the engine ground lead terminal can be

used.

H. Attach the coupler cover to the coolant tempera-

ture sensor coupler.

I. Pass the radiator fan motor lead to the inside of

the tension arm (the side of the vehicle).

J. Install the ground lead terminal between the plate

and the bolt.

K. Fix the ground lead terminal to the detent in the

plate. For the ground lead terminal, either side

will do.

L. Detent

Page 103 of 430

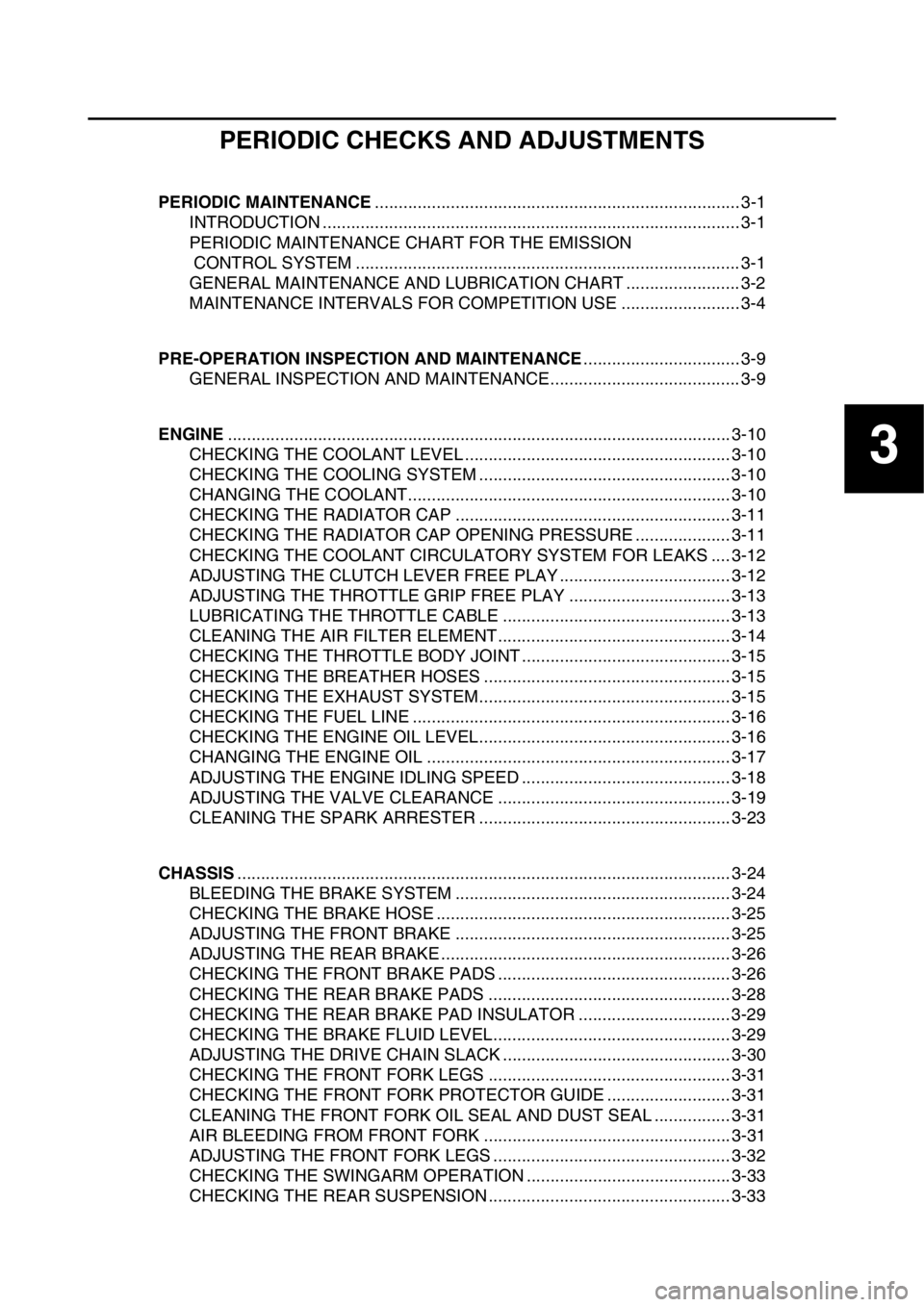

3

PERIODIC CHECKS AND ADJUSTMENTS

PERIODIC MAINTENANCE............................................................................. 3-1

INTRODUCTION ........................................................................................ 3-1

PERIODIC MAINTENANCE CHART FOR THE EMISSION

CONTROL SYSTEM ................................................................................. 3-1

GENERAL MAINTENANCE AND LUBRICATION CHART ........................ 3-2

MAINTENANCE INTERVALS FOR COMPETITION USE ......................... 3-4

PRE-OPERATION INSPECTION AND MAINTENANCE................................. 3-9

GENERAL INSPECTION AND MAINTENANCE........................................ 3-9

ENGINE.......................................................................................................... 3-10

CHECKING THE COOLANT LEVEL ........................................................ 3-10

CHECKING THE COOLING SYSTEM ..................................................... 3-10

CHANGING THE COOLANT.................................................................... 3-10

CHECKING THE RADIATOR CAP .......................................................... 3-11

CHECKING THE RADIATOR CAP OPENING PRESSURE .................... 3-11

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-12

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-12

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-13

LUBRICATING THE THROTTLE CABLE ................................................ 3-13

CLEANING THE AIR FILTER ELEMENT................................................. 3-14

CHECKING THE THROTTLE BODY JOINT ............................................ 3-15

CHECKING THE BREATHER HOSES .................................................... 3-15

CHECKING THE EXHAUST SYSTEM..................................................... 3-15

CHECKING THE FUEL LINE ................................................................... 3-16

CHECKING THE ENGINE OIL LEVEL..................................................... 3-16

CHANGING THE ENGINE OIL ................................................................ 3-17

ADJUSTING THE ENGINE IDLING SPEED ............................................ 3-18

ADJUSTING THE VALVE CLEARANCE ................................................. 3-19

CLEANING THE SPARK ARRESTER ..................................................... 3-23

CHASSIS........................................................................................................ 3-24

BLEEDING THE BRAKE SYSTEM .......................................................... 3-24

CHECKING THE BRAKE HOSE .............................................................. 3-25

ADJUSTING THE FRONT BRAKE .......................................................... 3-25

ADJUSTING THE REAR BRAKE ............................................................. 3-26

CHECKING THE FRONT BRAKE PADS ................................................. 3-26

CHECKING THE REAR BRAKE PADS ................................................... 3-28

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-29

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-29

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-30

CHECKING THE FRONT FORK LEGS ................................................... 3-31

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-31

CLEANING THE FRONT FORK OIL SEAL AND DUST SEAL ................ 3-31

AIR BLEEDING FROM FRONT FORK .................................................... 3-31

ADJUSTING THE FRONT FORK LEGS .................................................. 3-32

CHECKING THE SWINGARM OPERATION ........................................... 3-33

CHECKING THE REAR SUSPENSION ................................................... 3-33

Page 105 of 430

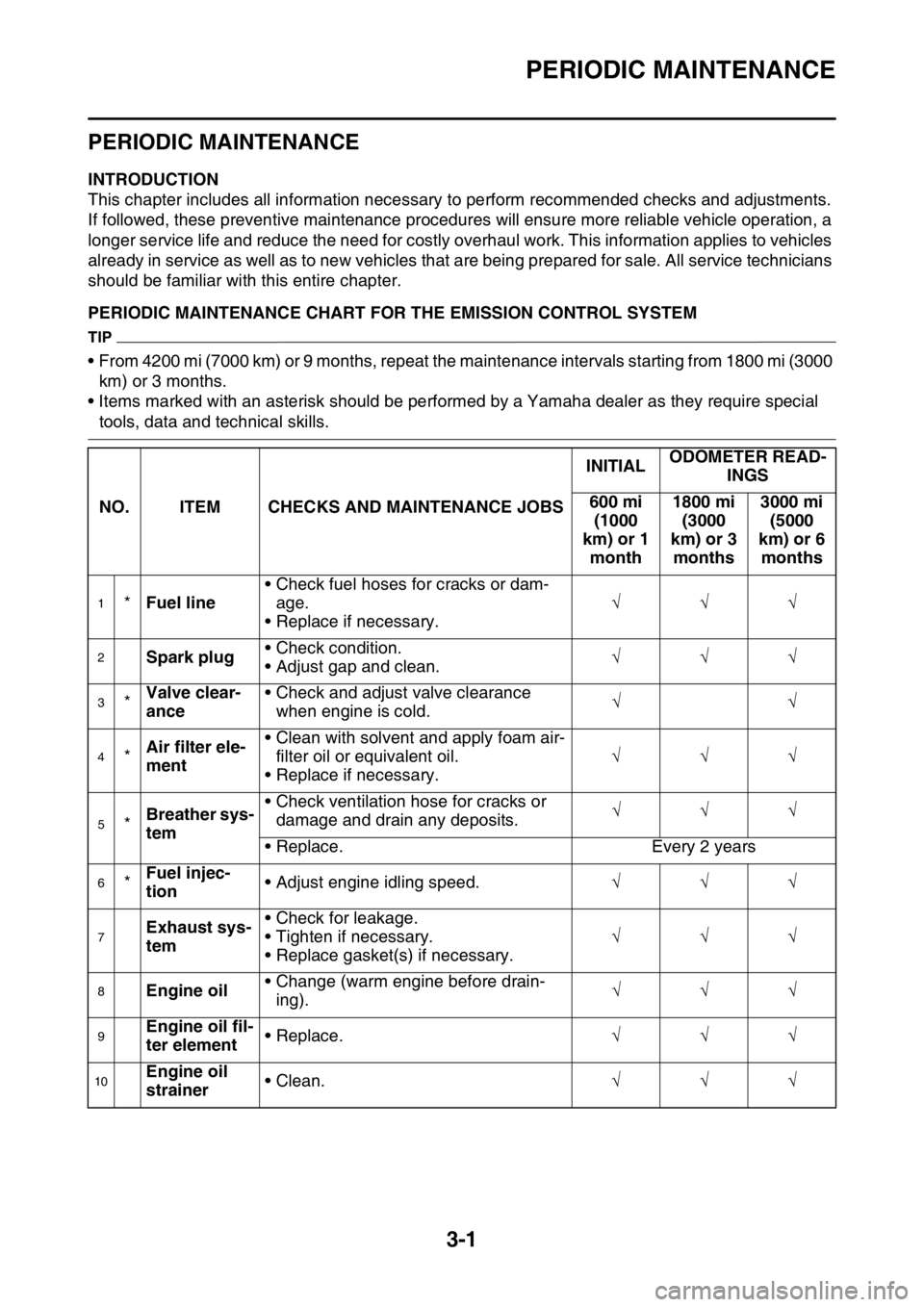

PERIODIC MAINTENANCE

3-1

EAS2GB2076

PERIODIC MAINTENANCE

EAS2GB2077INTRODUCTION

This chapter includes all information necessary to perform recommended checks and adjustments.

If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a

longer service life and reduce the need for costly overhaul work. This information applies to vehicles

already in service as well as to new vehicles that are being prepared for sale. All service technicians

should be familiar with this entire chapter.

EAS2GB2078PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL SYSTEM

TIP

• From 4200 mi (7000 km) or 9 months, repeat the maintenance intervals starting from 1800 mi (3000

km) or 3 months.

• Items marked with an asterisk should be performed by a Yamaha dealer as they require special

tools, data and technical skills.

NO. ITEM CHECKS AND MAINTENANCE JOBSINITIALODOMETER READ-

INGS

600 mi

(1000

km) or 1

month1800 mi

(3000

km) or 3

months3000 mi

(5000

km) or 6

months

1*Fuel line• Check fuel hoses for cracks or dam-

age.

• Replace if necessary.

2Spark plug• Check condition.

• Adjust gap and clean.

3*Valve clear-

ance• Check and adjust valve clearance

when engine is cold.

4*Air filter ele-

ment• Clean with solvent and apply foam air-

filter oil or equivalent oil.

• Replace if necessary.

5*Breather sys-

tem• Check ventilation hose for cracks or

damage and drain any deposits.

• Replace. Every 2 years

6*Fuel injec-

tion• Adjust engine idling speed.

7Exhaust sys-

tem• Check for leakage.

• Tighten if necessary.

• Replace gasket(s) if necessary.

8Engine oil• Change (warm engine before drain-

ing).

9Engine oil fil-

ter element• Replace.

10Engine oil

strainer• Clean.

Page 110 of 430

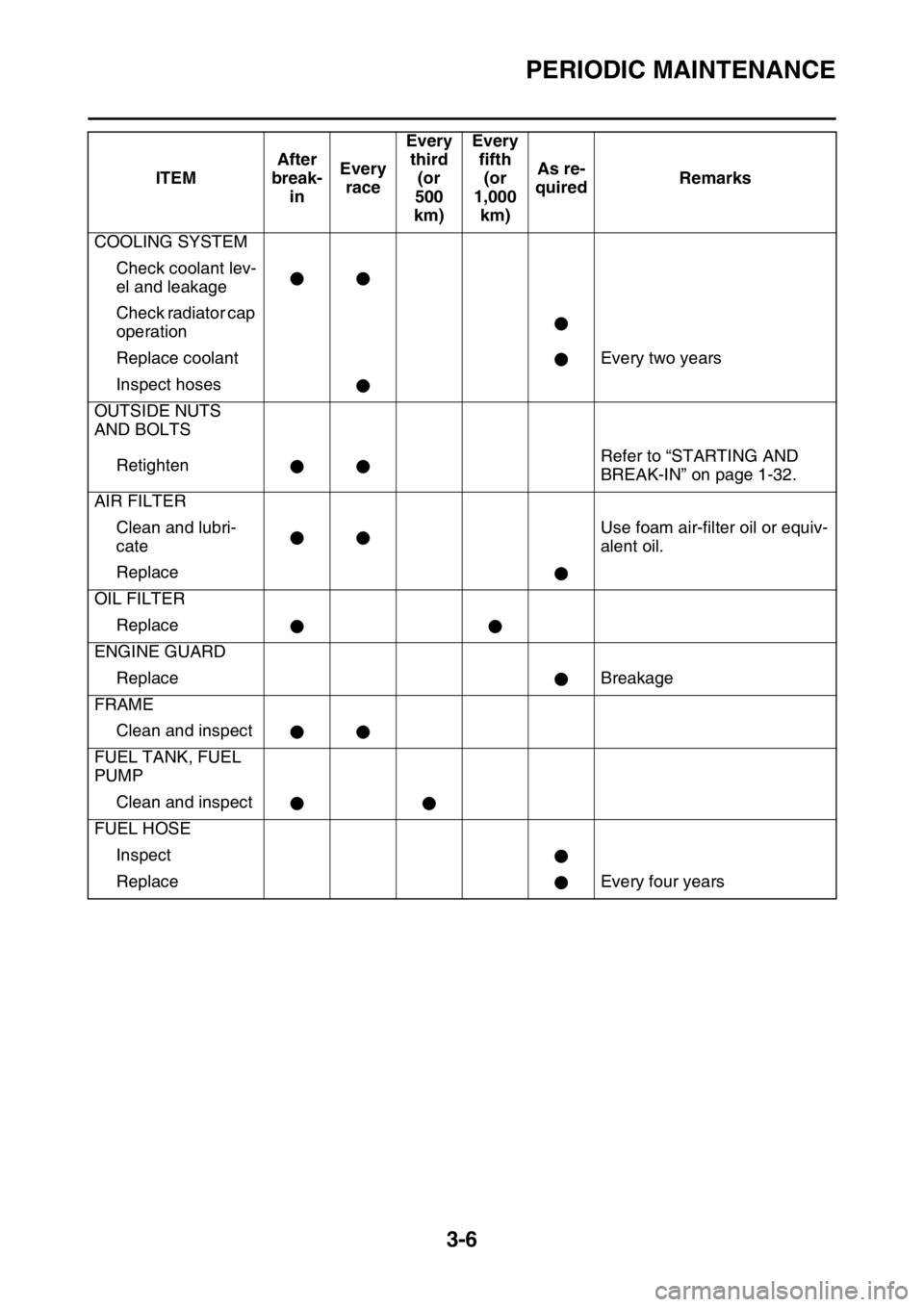

PERIODIC MAINTENANCE

3-6

COOLING SYSTEM

Check coolant lev-

el and leakage

Check radiator cap

operation

Replace coolant Every two years

Inspect hoses

OUTSIDE NUTS

AND BOLTS

RetightenRefer to “STARTING AND

BREAK-IN” on page 1-32.

AIR FILTER

Clean and lubri-

cateUse foam air-filter oil or equiv-

alent oil.

Replace

OIL FILTER

Replace

ENGINE GUARD

Replace Breakage

FRAME

Clean and inspect

FUEL TANK, FUEL

PUMP

Clean and inspect

FUEL HOSE

Inspect

Replace Every four yearsITEMAfter

break-

inEvery

raceEvery

third

(or

500

km)Every

fifth

(or

1,000

km)As re-

quiredRemarks