length YAMAHA WR 250F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 7 of 430

EAS2GB2005

SAFETY INFORMATION

THIS MACHINE IS DESIGNED STRICTLY FOR COMPETITION USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine to be operated on any public street, road, or highway. Off-road

use on public lands may also be illegal. Please check local regulations before riding.

• THIS MACHINE IS TO BE OPERATED BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this machine at maximum power until you are totally familiar with its char-

acteristics.

• THIS MACHINE IS DESIGNED TO BE RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this machine.

• ALWAYS WEAR PROTECTIVE APPAREL.

When operating this machine, always wear an approved helmet with goggles or a face shield. Also

wear heavy boots, gloves, and protective clothing. Always wear proper fitting clothing that will not

be caught in any of the moving parts or controls of the machine.

• ALWAYS MAINTAIN YOUR MACHINE IN PROPER WORKING ORDER.

For safety and reliability, the machine must be properly maintained. Always perform the pre-oper-

ation checks indicated in this manual.

Correcting a mechanical problem before you ride may prevent an accident.

• GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any gasoline on the engine or ex-

haust system. Never refuel in the vicinity of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline, inhale excess gasoline vapors, or allow any gasoline to get

into your eyes, contact a doctor immediately. If any gasoline spills onto your skin or clothing, imme-

diately wash skin areas with soap and water, and change your clothes.

• ONLY OPERATE THE MACHINE IN AN AREA WITH ADEQUATE VENTILATION.

Never start the engine or let it run for any length of time in an enclosed area. Exhaust fumes are

poisonous. These fumes contain carbon monoxide, which by itself is odorless and colorless. Car-

bon monoxide is a dangerous gas which can cause unconsciousness or can be lethal.

• PARK THE MACHINE CAREFULLY; TURN OFF THE ENGINE.

Always turn off the engine if you are going to leave the machine. Do not park the machine on a slope

or soft ground as it may fall over.

• THE ENGINE, EXHAUST PIPE AND MUFFLER WILL BE VERY HOT AFTER THE ENGINE HAS

BEEN RUN.

Be careful not to touch them or to allow any clothing item to contact them during inspection or repair.

• PROPERLY SECURE THE MACHINE BEFORE TRANSPORTING IT.

For safety, drain the gasoline from the fuel tank before transporting the vehicle.

Page 21 of 430

FEATURES

1-7

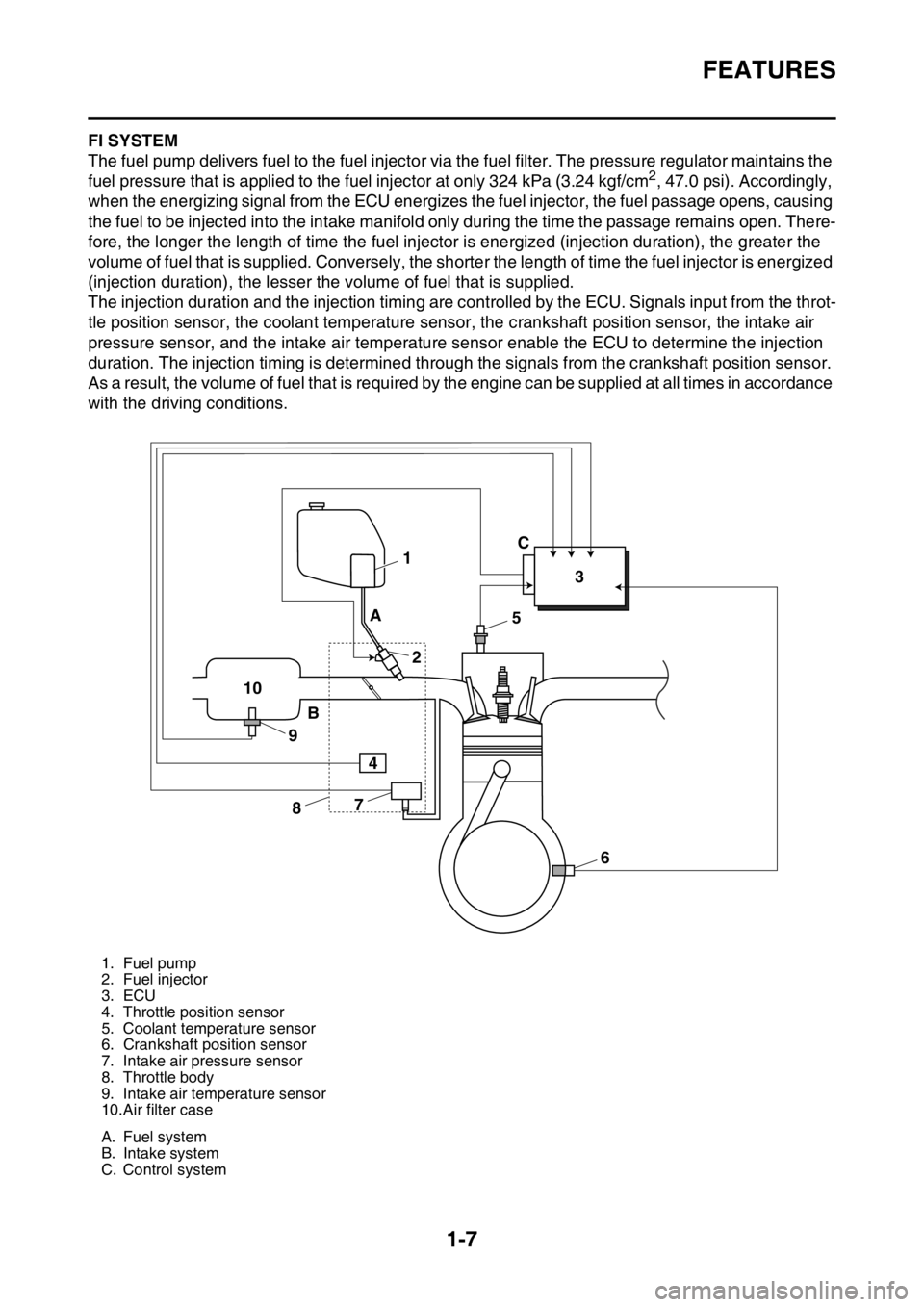

EAS2GB2015FI SYSTEM

The fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the

fuel pressure that is applied to the fuel injector at only 324 kPa (3.24 kgf/cm

2, 47.0 psi). Accordingly,

when the energizing signal from the ECU energizes the fuel injector, the fuel passage opens, causing

the fuel to be injected into the intake manifold only during the time the passage remains open. There-

fore, the longer the length of time the fuel injector is energized (injection duration), the greater the

volume of fuel that is supplied. Conversely, the shorter the length of time the fuel injector is energized

(injection duration), the lesser the volume of fuel that is supplied.

The injection duration and the injection timing are controlled by the ECU. Signals input from the throt-

tle position sensor, the coolant temperature sensor, the crankshaft position sensor, the intake air

pressure sensor, and the intake air temperature sensor enable the ECU to determine the injection

duration. The injection timing is determined through the signals from the crankshaft position sensor.

As a result, the volume of fuel that is required by the engine can be supplied at all times in accordance

with the driving conditions.

1. Fuel pump

2. Fuel injector

3. ECU

4. Throttle position sensor

5. Coolant temperature sensor

6. Crankshaft position sensor

7. Intake air pressure sensor

8. Throttle body

9. Intake air temperature sensor

10.Air filter case

A. Fuel system

B. Intake system

C. Control system

1

23

5

6 7

8 9 10A

BC

4

Page 46 of 430

STARTING AND BREAK-IN

1-32

EAS2GB2050

STARTING AND BREAK-IN

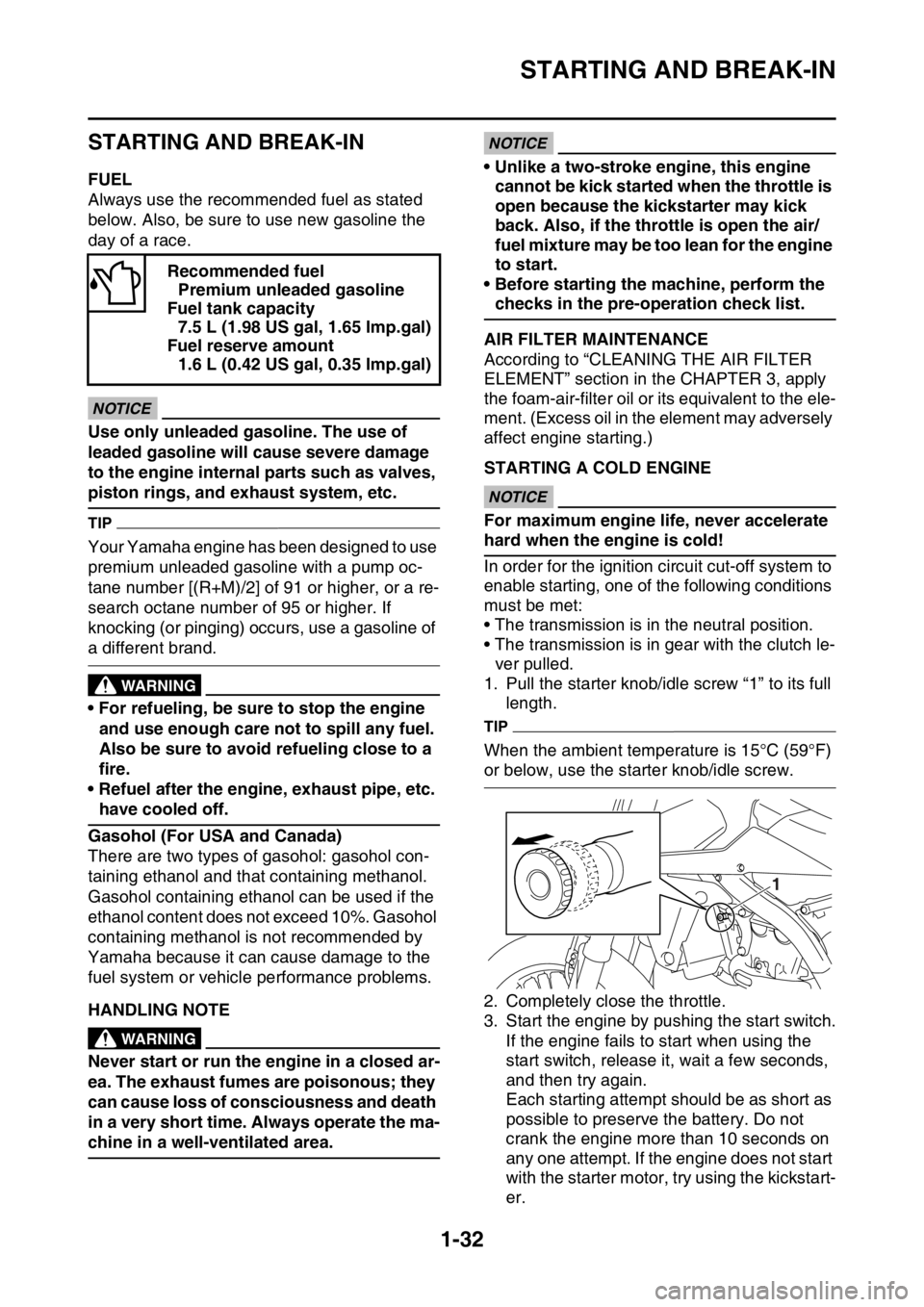

EAS2GB2051FUEL

Always use the recommended fuel as stated

below. Also, be sure to use new gasoline the

day of a race.

ECA

NOTICE

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

TIP

Your Yamaha engine has been designed to use

premium unleaded gasoline with a pump oc-

tane number [(R+M)/2] of 91 or higher, or a re-

search octane number of 95 or higher. If

knocking (or pinging) occurs, use a gasoline of

a different brand.

EWA

WARNING

• For refueling, be sure to stop the engine

and use enough care not to spill any fuel.

Also be sure to avoid refueling close to a

fire.

• Refuel after the engine, exhaust pipe, etc.

have cooled off.

Gasohol (For USA and Canada)

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.

Gasohol containing ethanol can be used if the

ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by

Yamaha because it can cause damage to the

fuel system or vehicle performance problems.

EAS2GB2052HANDLING NOTEEWA

WARNING

Never start or run the engine in a closed ar-

ea. The exhaust fumes are poisonous; they

can cause loss of consciousness and death

in a very short time. Always operate the ma-

chine in a well-ventilated area.

ECA

NOTICE

• Unlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kickstarter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the engine

to start.

• Before starting the machine, perform the

checks in the pre-operation check list.

EAS2GB2053AIR FILTER MAINTENANCE

According to “CLEANING THE AIR FILTER

ELEMENT” section in the CHAPTER 3, apply

the foam-air-filter oil or its equivalent to the ele-

ment. (Excess oil in the element may adversely

affect engine starting.)

EAS2GB2054STARTING A COLD ENGINEECA

NOTICE

For maximum engine life, never accelerate

hard when the engine is cold!

In order for the ignition circuit cut-off system to

enable starting, one of the following conditions

must be met:

• The transmission is in the neutral position.

• The transmission is in gear with the clutch le-

ver pulled.

1. Pull the starter knob/idle screw “1” to its full

length.

TIP

When the ambient temperature is 15°C (59°F)

or below, use the starter knob/idle screw.

2. Completely close the throttle.

3. Start the engine by pushing the start switch.

If the engine fails to start when using the

start switch, release it, wait a few seconds,

and then try again.

Each starting attempt should be as short as

possible to preserve the battery. Do not

crank the engine more than 10 seconds on

any one attempt. If the engine does not start

with the starter motor, try using the kickstart-

er. Recommended fuel

Premium unleaded gasoline

Fuel tank capacity

7.5 L (1.98 US gal, 1.65 lmp.gal)

Fuel reserve amount

1.6 L (0.42 US gal, 0.35 lmp.gal)

1

Page 56 of 430

GENERAL SPECIFICATIONS

2-1

EAS2GB2063

GENERAL SPECIFICATIONS

Model

Model 2GB1 (USA)

2GB2 (CAN)

2GB3 (EUR)

2GB4 (AUS) (NZL) (ZAF)

Dimensions

Overall length 2165 mm (85.2 in)

Overall width 825 mm (32.5 in)

Overall height 1280 mm (50.4 in)

Seat height 965 mm (38.0 in)

Wheelbase 1465 mm (57.7 in)

Ground clearance 325 mm (12.8 in)

Weight

Curb weight 117 kg (258 lb) (USA) (CAN)

118 kg (260 lb) (EUR) (AUS) (NZL) (ZAF)

Page 59 of 430

ENGINE SPECIFICATIONS

2-4

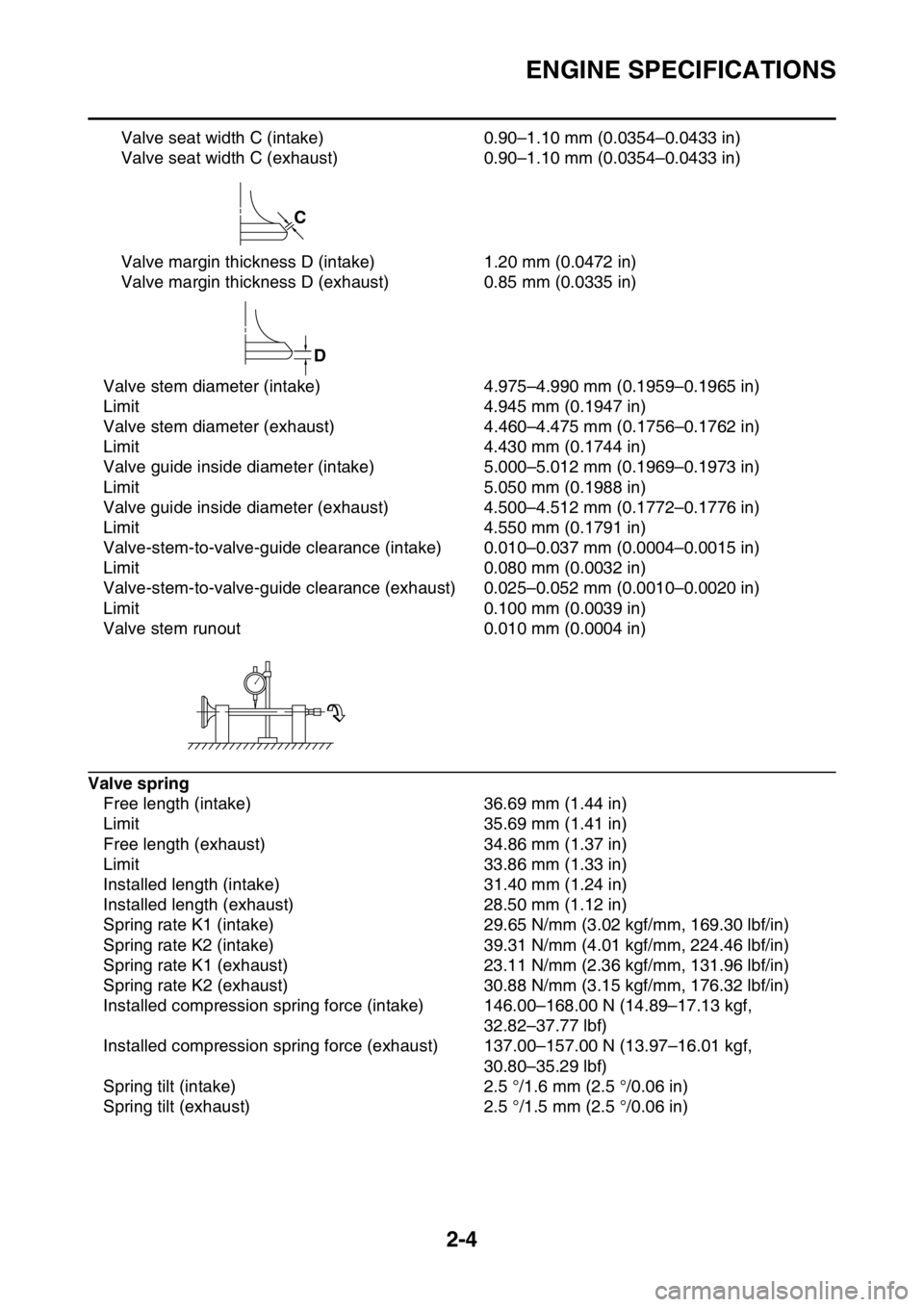

Valve seat width C (intake) 0.90–1.10 mm (0.0354–0.0433 in)

Valve seat width C (exhaust) 0.90–1.10 mm (0.0354–0.0433 in)

Valve margin thickness D (intake) 1.20 mm (0.0472 in)

Valve margin thickness D (exhaust) 0.85 mm (0.0335 in)

Valve stem diameter (intake) 4.975–4.990 mm (0.1959–0.1965 in)

Limit 4.945 mm (0.1947 in)

Valve stem diameter (exhaust) 4.460–4.475 mm (0.1756–0.1762 in)

Limit 4.430 mm (0.1744 in)

Valve guide inside diameter (intake) 5.000–5.012 mm (0.1969–0.1973 in)

Limit 5.050 mm (0.1988 in)

Valve guide inside diameter (exhaust) 4.500–4.512 mm (0.1772–0.1776 in)

Limit 4.550 mm (0.1791 in)

Valve-stem-to-valve-guide clearance (intake) 0.010–0.037 mm (0.0004–0.0015 in)

Limit 0.080 mm (0.0032 in)

Valve-stem-to-valve-guide clearance (exhaust) 0.025–0.052 mm (0.0010–0.0020 in)

Limit 0.100 mm (0.0039 in)

Valve stem runout 0.010 mm (0.0004 in)

Valve spring

Free length (intake) 36.69 mm (1.44 in)

Limit 35.69 mm (1.41 in)

Free length (exhaust) 34.86 mm (1.37 in)

Limit 33.86 mm (1.33 in)

Installed length (intake) 31.40 mm (1.24 in)

Installed length (exhaust) 28.50 mm (1.12 in)

Spring rate K1 (intake) 29.65 N/mm (3.02 kgf/mm, 169.30 lbf/in)

Spring rate K2 (intake) 39.31 N/mm (4.01 kgf/mm, 224.46 lbf/in)

Spring rate K1 (exhaust) 23.11 N/mm (2.36 kgf/mm, 131.96 lbf/in)

Spring rate K2 (exhaust) 30.88 N/mm (3.15 kgf/mm, 176.32 lbf/in)

Installed compression spring force (intake) 146.00–168.00 N (14.89–17.13 kgf,

32.82–37.77 lbf)

Installed compression spring force (exhaust) 137.00–157.00 N (13.97–16.01 kgf,

30.80–35.29 lbf)

Spring tilt (intake) 2.5 °/1.6 mm (2.5 °/0.06 in)

Spring tilt (exhaust) 2.5 °/1.5 mm (2.5 °/0.06 in)

C

D

Page 61 of 430

ENGINE SPECIFICATIONS

2-6

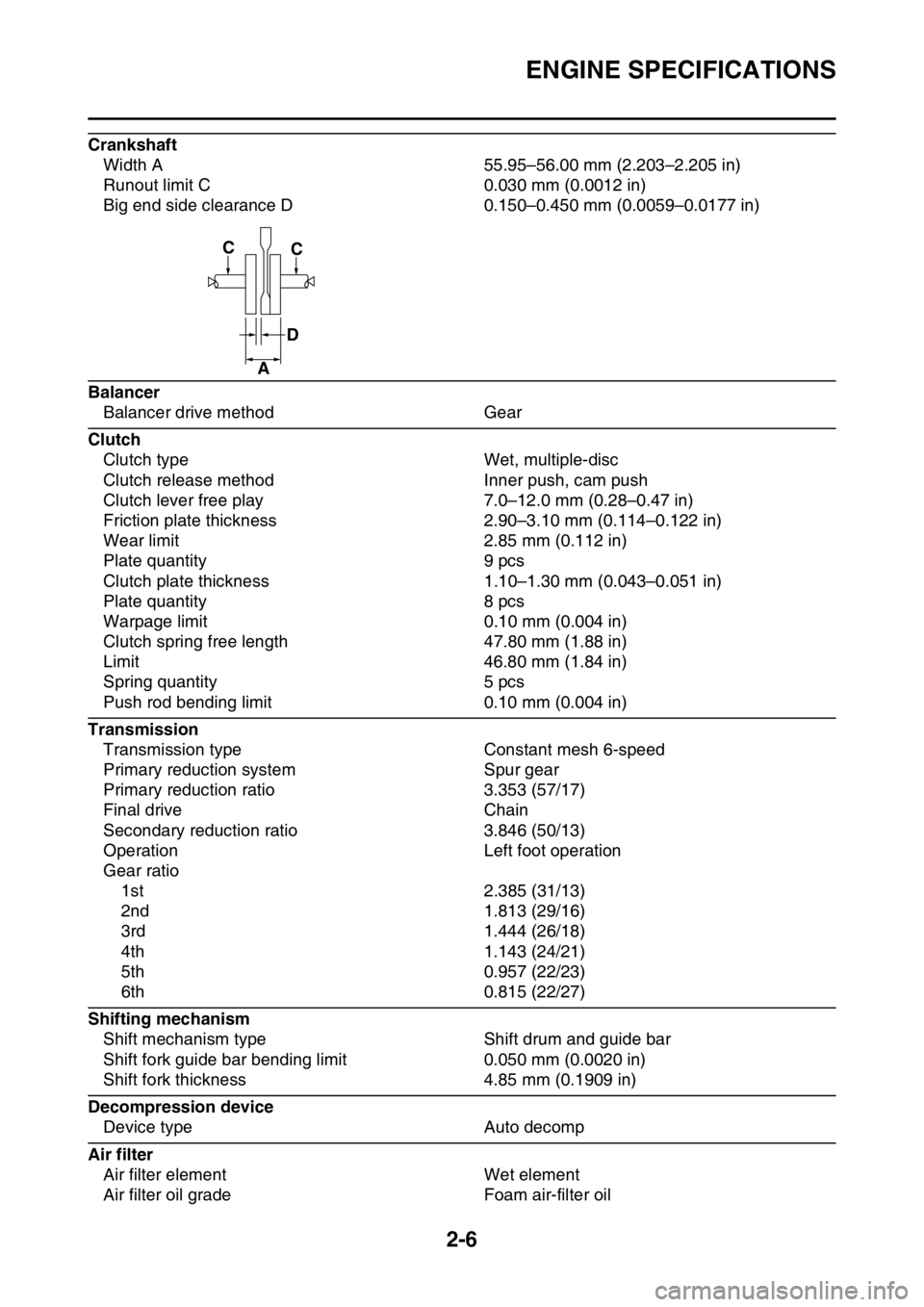

Crankshaft

Width A 55.95–56.00 mm (2.203–2.205 in)

Runout limit C 0.030 mm (0.0012 in)

Big end side clearance D 0.150–0.450 mm (0.0059–0.0177 in)

Balancer

Balancer drive method Gear

Clutch

Clutch type Wet, multiple-disc

Clutch release method Inner push, cam push

Clutch lever free play 7.0–12.0 mm (0.28–0.47 in)

Friction plate thickness 2.90–3.10 mm (0.114–0.122 in)

Wear limit 2.85 mm (0.112 in)

Plate quantity 9 pcs

Clutch plate thickness 1.10–1.30 mm (0.043–0.051 in)

Plate quantity 8 pcs

Warpage limit 0.10 mm (0.004 in)

Clutch spring free length 47.80 mm (1.88 in)

Limit 46.80 mm (1.84 in)

Spring quantity 5 pcs

Push rod bending limit 0.10 mm (0.004 in)

Transmission

Transmission type Constant mesh 6-speed

Primary reduction system Spur gear

Primary reduction ratio 3.353 (57/17)

Final drive Chain

Secondary reduction ratio 3.846 (50/13)

Operation Left foot operation

Gear ratio

1st 2.385 (31/13)

2nd 1.813 (29/16)

3rd 1.444 (26/18)

4th 1.143 (24/21)

5th 0.957 (22/23)

6th 0.815 (22/27)

Shifting mechanism

Shift mechanism type Shift drum and guide bar

Shift fork guide bar bending limit 0.050 mm (0.0020 in)

Shift fork thickness 4.85 mm (0.1909 in)

Decompression device

Device type Auto decomp

Air filter

Air filter element Wet element

Air filter oil grade Foam air-filter oil

CC

D

A

Page 64 of 430

CHASSIS SPECIFICATIONS

2-9

Brake pad lining thickness (outer) 4.4 mm (0.17 in)

Limit 1.0 mm (0.04 in)

Master cylinder inside diameter 9.52 mm (0.37 in)

Caliper cylinder inside diameter 22.65 mm 2 (0.89 in 2)

Recommended brake fluid DOT 4

Rear brake

Type Single disc brake

Operation Right foot operation

Rear disc brake

Disc outside diameter thickness 245 4.0 mm (9.6 0.16 in)

Brake disc thickness limit 3.5 mm (0.14 in)

Brake disc runout limit (as measured on wheel) 0.15 mm (0.0059 in)

Brake pad lining thickness (inner) 6.4 mm (0.25 in)

Limit 1.0 mm (0.04 in)

Brake pad lining thickness (outer) 6.4 mm (0.25 in)

Limit 1.0 mm (0.04 in)

Master cylinder inside diameter 11.0 mm (0.43 in)

Caliper cylinder inside diameter 25.40 mm 1 (1.00 in 1)

Recommended brake fluid DOT 4

Steering

Steering bearing type Taper roller bearing

Center to lock angle (left) 43.0 °

Center to lock angle (right) 43.0 °

Front suspension

Type Telescopic fork

Spring/shock absorber type Coil spring/oil damper

Front fork travel 310.0 mm (12.20 in)

Fork spring free length 470.0 mm (18.50 in)

Limit 465.0 mm (18.31 in)

Fork spring installed length 470.0 mm (18.50 in)

Spring rate K1 4.40 N/mm (0.45 kgf/mm, 25.12 lbf/in)

Spring stroke K1 0.0–310.0 mm (0.00–12.20 in)

Inner tube outer diameter 48 mm (1.9 in)

Inner tube bending limit 0.2 mm (0.01 in)

Optional spring available Yes

Recommended oil Suspension oil S1

Quantity 540.0 cm

3 (18.26 US oz, 19.05 Imp.oz)

Rebound damping adjusting positions

* Position in which the adjuster is turned in finger tight

Minimum 20 click (s) out*

Standard 10 click (s) out*

Maximum Fully turned in

Compression damping adjusting positions

* Position in which the adjuster is turned in finger tight

Minimum 20 click (s) out*

Standard 11 click (s) out*

Maximum (hard) Fully turned in

Page 65 of 430

CHASSIS SPECIFICATIONS

2-10

Rear suspension

Type Swingarm (link suspension)

Spring/shock absorber type Coil spring/gas-oil damper

Rear shock absorber assembly travel 126.0 mm (4.96 in)

Spring free length 275.0 mm (10.83 in)

Spring installed length 265.0 mm (10.43 in)

Spring rate K1 54.00 N/mm (5.51 kgf/mm, 308.34 lbf/in)

Spring stroke K1 0.0–150.0 mm (0.00–5.91 in)

Optional spring available Yes

Enclosed gas/air pressure (STD) 980 kPa (9.8 kgf/cm

2, 139.4 psi)

Spring preload adjusting positions

Minimum Position in which the spring is turned in 1.5 mm

(0.06 in) from its free length.

Standard Position in which the spring is turned in 10 mm

(0.39 in) from its free length.

Maximum Position in which the spring is turned in 18 mm

(0.71 in) from its free length.

Rebound damping adjusting positions

* Position in which the adjuster is turned in finger tight

Minimum 30 click (s) out*

Standard 14 click (s) out*

Maximum Fully turned in

Compression damping adjusting positions

(for fast compression damping)

* Position in which the adjuster is turned in finger tight

Minimum 2 turn (s) out*

Standard 1-1/4 turn (s) out*

Maximum Fully turned in

Compression damping adjusting positions

(for slow compression damping)

* Position in which the adjuster is turned in finger tight

Minimum 20 click (s) out*

Standard 10 click (s) out*

Maximum Fully turned in

Swingarm

Swingarm end free play limit (radial) 1.0 mm (0.04 in)

Swingarm end free play limit (axial) 0.2–0.9 mm (0.01–0.04 in)

Drive chain

Size/manufacturer 520VM2/DAIDO

Number of links 114

Drive chain slack 50–60 mm (1.97–2.36 in)

15-link length limit 239.3 mm (9.42 in)

Page 66 of 430

ELECTRICAL SPECIFICATIONS

2-11

EAS2GB2066

ELECTRICAL SPECIFICATIONS

Voltage

System voltage 12 V

Ignition system

Ignition system TCI

Advancer type Digital

Ignition timing (B.T.D.C.) 10.0 ° at 2000 r/min

Engine control unit

Model/manufacturer 2GB0/YAMAHA (USA) (CAN)

2GB1/YAMAHA (EUR) (AUS) (NZL) (ZAF)

Ignition coil

Minimum ignition spark gap 6.0 mm (0.24 in)

Primary coil resistance 2.16–2.64

Secondary coil resistance 8.64–12.96 k

AC magneto

Standard output 14.0 V, 160 W at 5000 r/min

Stator coil resistance 0.528–0.792 (W–W)

Rectifier/regulator

Regulator type Semi conductor-short circuit

No load regulated voltage 14.1–14.9 V

Rectifier capacity (DC) 23.0 A

Battery

Model YTZ7S (F)

Voltage, capacity 12 V, 6.0 Ah

Specific gravity 1.31

Manufacturer GS YUASA

Ten hour rate charging current 0.60 A

Headlight

Bulb type Halogen bulb

Bulb voltage, wattage quantity

Headlight 12 V, 35 W/35 W 1

Tail/brake light LED

Meter lighting EL (Electroluminescent)

Indicator light

Fuel level warning light 12 V, 1.7 W 1

Engine trouble warning light 12 V, 1.7 W 1

Electric starting system

System type Constant mesh

Starter motor

Power output 0.35 kW

Armature coil resistance 0.0189–0.0231

Brush overall length 7.0 mm (0.28 in)

Limit 3.50 mm (0.14 in)

Brush spring force 3.92–5.88 N (400–600 gf, 14.11–21.17 oz)

Commutator diameter 17.6 mm (0.69 in)

Limit 16.6 mm (0.65 in)

Mica undercut (depth) 1.50 mm (0.06 in)

Page 108 of 430

PERIODIC MAINTENANCE

3-4

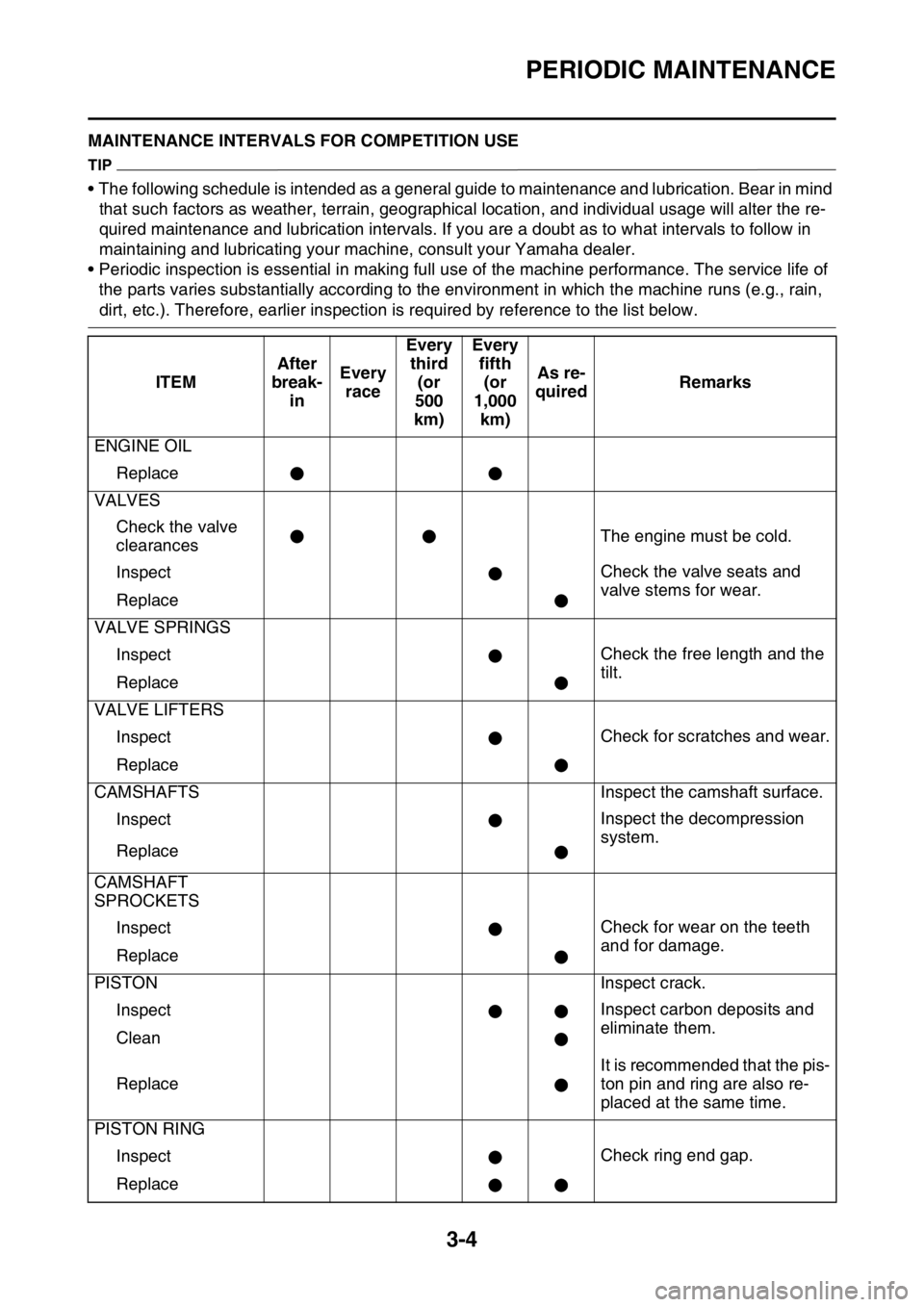

EAS2GB2080MAINTENANCE INTERVALS FOR COMPETITION USE

TIP

• The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the re-

quired maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

• Periodic inspection is essential in making full use of the machine performance. The service life of

the parts varies substantially according to the environment in which the machine runs (e.g., rain,

dirt, etc.). Therefore, earlier inspection is required by reference to the list below.

ITEMAfter

break-

inEvery

raceEvery

third

(or

500

km)Every

fifth

(or

1,000

km)As re-

quiredRemarks

ENGINE OIL

Replace

VALVES

Check the valve

clearancesThe engine must be cold.

InspectCheck the valve seats and

valve stems for wear.

Replace

VALVE SPRINGS

InspectCheck the free length and the

tilt.

Replace

VALVE LIFTERS

InspectCheck for scratches and wear.

Replace

CAMSHAFTS Inspect the camshaft surface.

InspectInspect the decompression

system.

Replace

CAMSHAFT

SPROCKETS

InspectCheck for wear on the teeth

and for damage.

Replace

PISTON Inspect crack.

InspectInspect carbon deposits and

eliminate them.

Clean

ReplaceIt is recommended that the pis-

ton pin and ring are also re-

placed at the same time.

PISTON RING

InspectCheck ring end gap.

Replace