YAMAHA WR 250F 2016 Owners Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250F, Model: YAMAHA WR 250F 2016Pages: 428, PDF Size: 14.13 MB

Page 221 of 428

SWINGARM

5-67

EAS2GB7220INSTALLING THE SWINGARM

1. Lubricate:

‚ÄĘ Bearing

‚ÄĘCollars

‚ÄĘ Spacers

‚ÄĘ Oil seal

‚ÄĘ Pivot shaft

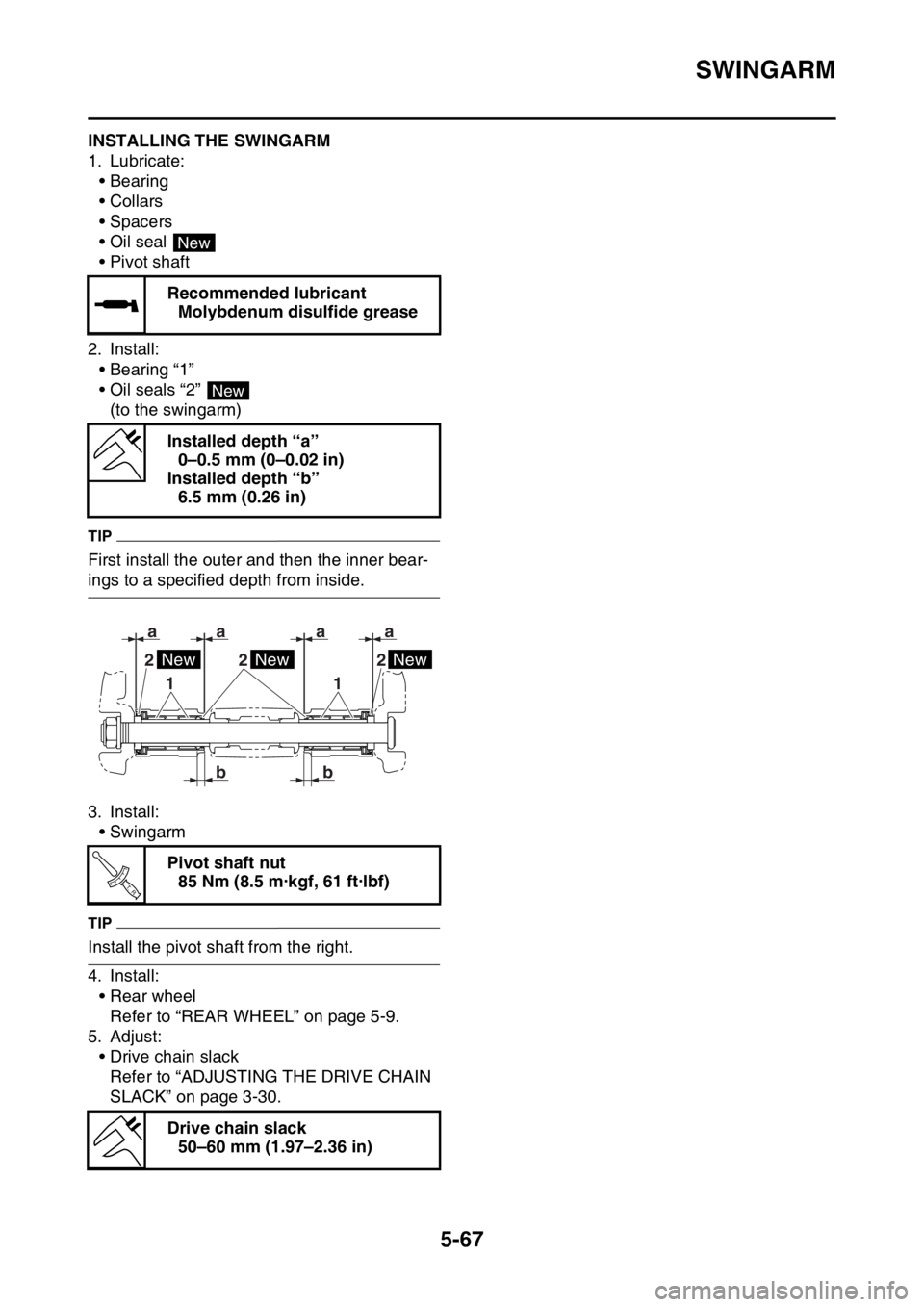

2. Install:

‚ÄĘ Bearing ‚Äú1‚ÄĚ

‚ÄĘ Oil seals ‚Äú2‚ÄĚ

(to the swingarm)

TIP

First install the outer and then the inner bear-

ings to a specified depth from inside.

3. Install:

‚ÄĘ Swingarm

TIP

Install the pivot shaft from the right.

4. Install:

‚ÄĘ Rear wheel

Refer to ‚ÄúREAR WHEEL‚ÄĚ on page 5-9.

5. Adjust:

‚ÄĘ Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK‚ÄĚ on page 3-30.Recommended lubricant

Molybdenum disulfide grease

Installed depth ‚Äúa‚ÄĚ

0‚Äď0.5 mm (0‚Äď0.02 in)

Installed depth ‚Äúb‚ÄĚ

6.5 mm (0.26 in)

Pivot shaft nut

85 Nm (8.5 m·kgf, 61 ft·lbf)

Drive chain slack

50‚Äď60 mm (1.97‚Äď2.36 in)

New

New

2 22

1 1

aaa

b ba

NewNewNew

T R..

Page 222 of 428

CHAIN DRIVE

5-68

EAS2GB7221

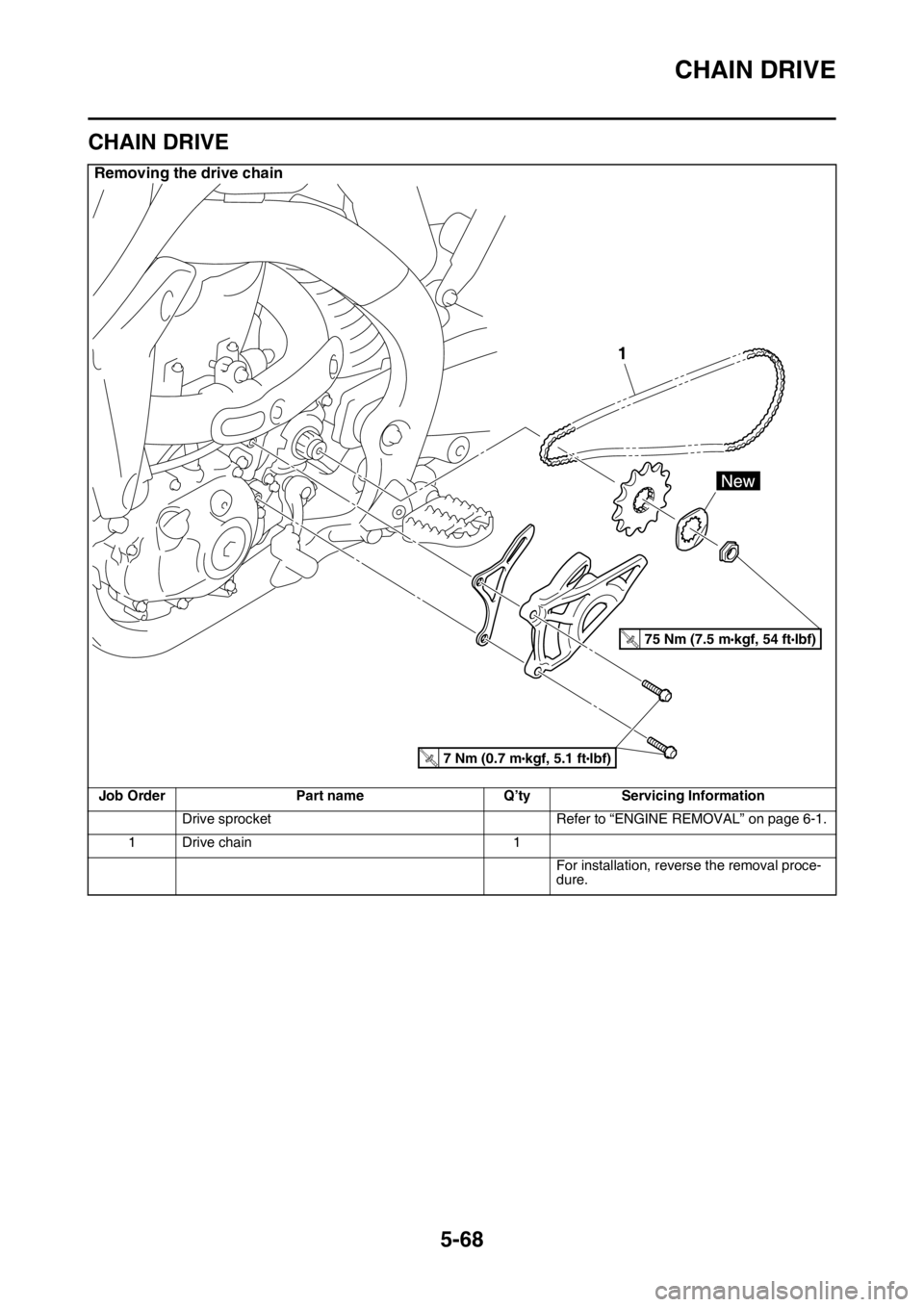

CHAIN DRIVE

Removing the drive chain

Job Order Part name Q’ty Servicing Information

Drive sprocket Refer to ‚ÄúENGINE REMOVAL‚ÄĚ on page 6-1.

1 Drive chain 1

For installation, reverse the removal proce-

dure.

1

T.R.75 Nm (7.5 mlbf) kgf, 54 ft

T.R.7 Nm (0.7 mlbf) kgf, 5.1 ft

Page 223 of 428

CHAIN DRIVE

5-69

EAS23420REMOVING THE DRIVE CHAIN

1. Stand the vehicle on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

TIP

Place the vehicle on a suitable stand so that the

rear wheel is elevated.

2. Remove:

‚ÄĘDrive chain

TIP

Cut the drive chain with the drive chain cut &

rivet tool. (Use goods on the market)

EAS23441CHECKING THE DRIVE CHAIN

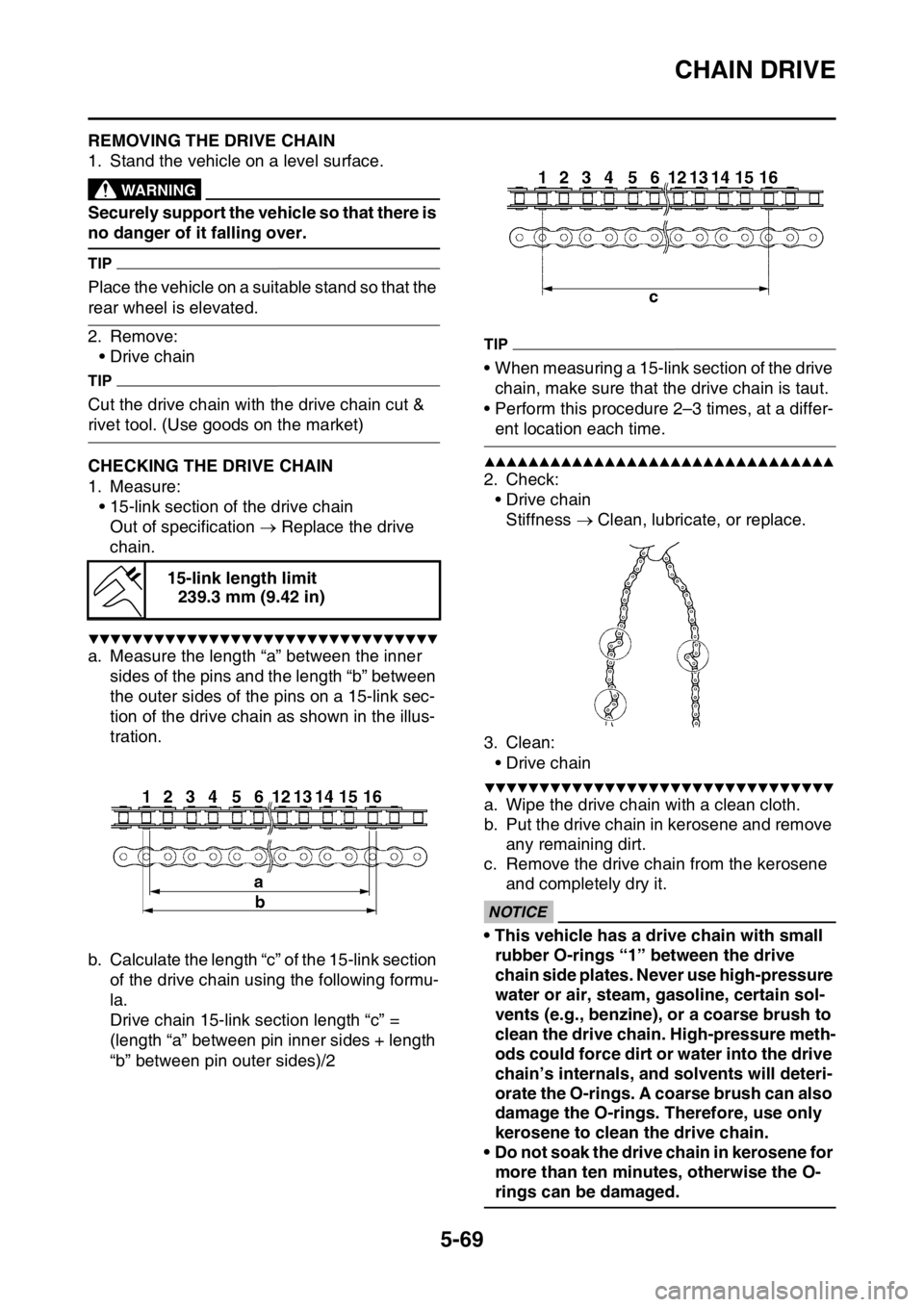

1. Measure:

‚ÄĘ 15-link section of the drive chain

Out of specification Ôāģ Replace the drive

chain.

‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ

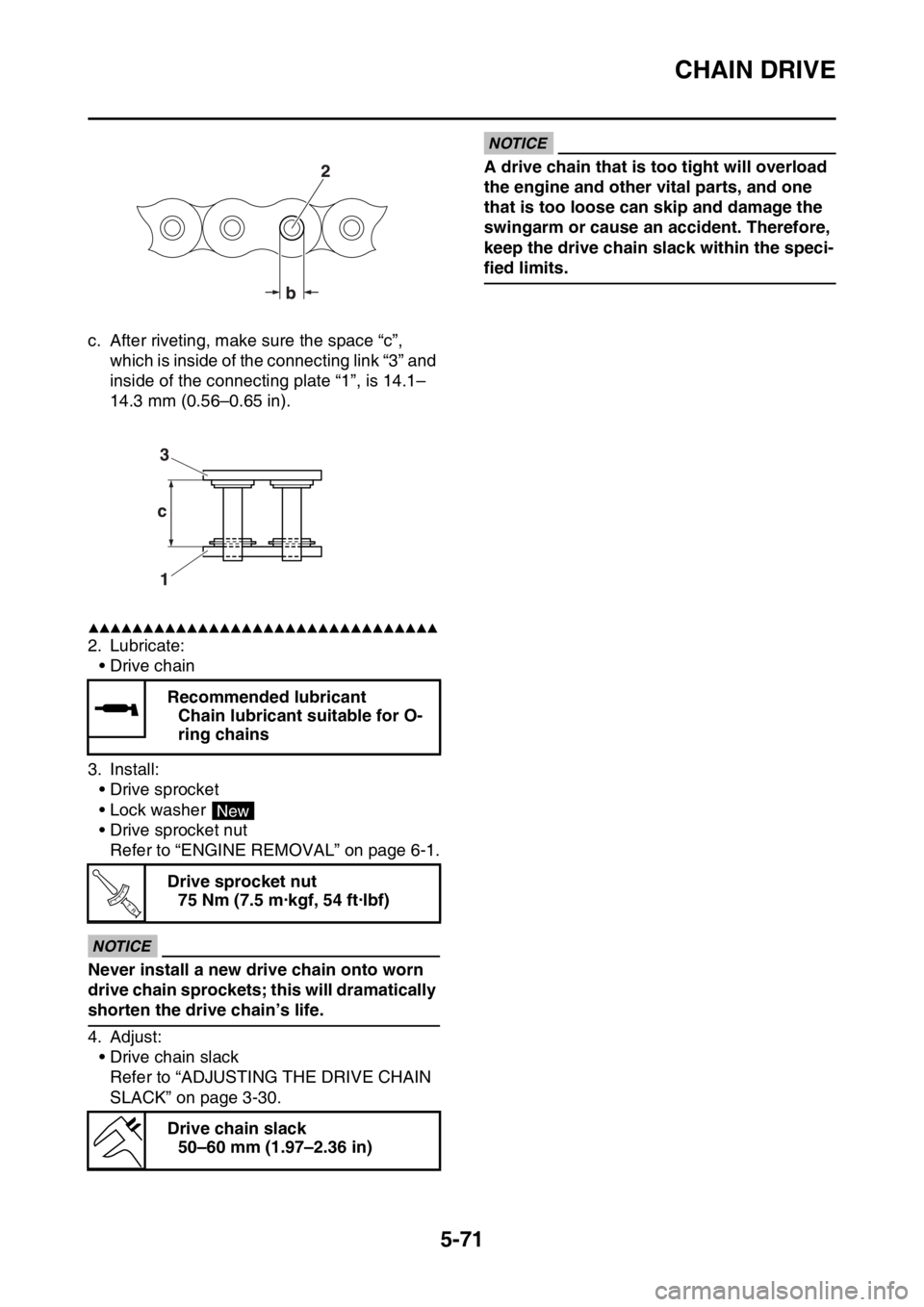

a. Measure the length ‚Äúa‚ÄĚ between the inner

sides of the pins and the length ‚Äúb‚ÄĚ between

the outer sides of the pins on a 15-link sec-

tion of the drive chain as shown in the illus-

tration.

b. Calculate the length ‚Äúc‚ÄĚ of the 15-link section

of the drive chain using the following formu-

la.

Drive chain 15-link section length ‚Äúc‚ÄĚ =

(length ‚Äúa‚ÄĚ between pin inner sides + length

‚Äúb‚ÄĚ between pin outer sides)/2

TIP

‚ÄĘ When measuring a 15-link section of the drive

chain, make sure that the drive chain is taut.

‚ÄĘ Perform this procedure 2‚Äď3 times, at a differ-

ent location each time.

‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤

2. Check:

‚ÄĘDrive chain

Stiffness Ôāģ Clean, lubricate, or replace.

3. Clean:

‚ÄĘDrive chain

‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ

a. Wipe the drive chain with a clean cloth.

b. Put the drive chain in kerosene and remove

any remaining dirt.

c. Remove the drive chain from the kerosene

and completely dry it.

ECA

NOTICE

‚ÄĘ This vehicle has a drive chain with small

rubber O-rings ‚Äú1‚ÄĚ between the drive

chain side plates. Never use high-pressure

water or air, steam, gasoline, certain sol-

vents (e.g., benzine), or a coarse brush to

clean the drive chain. High-pressure meth-

ods could force dirt or water into the drive

chain’s internals, and solvents will deteri-

orate the O-rings. A coarse brush can also

damage the O-rings. Therefore, use only

kerosene to clean the drive chain.

‚ÄĘ Do not soak the drive chain in kerosene for

more than ten minutes, otherwise the O-

rings can be damaged. 15-link length limit

239.3 mm (9.42 in)

Page 224 of 428

CHAIN DRIVE

5-70

‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤

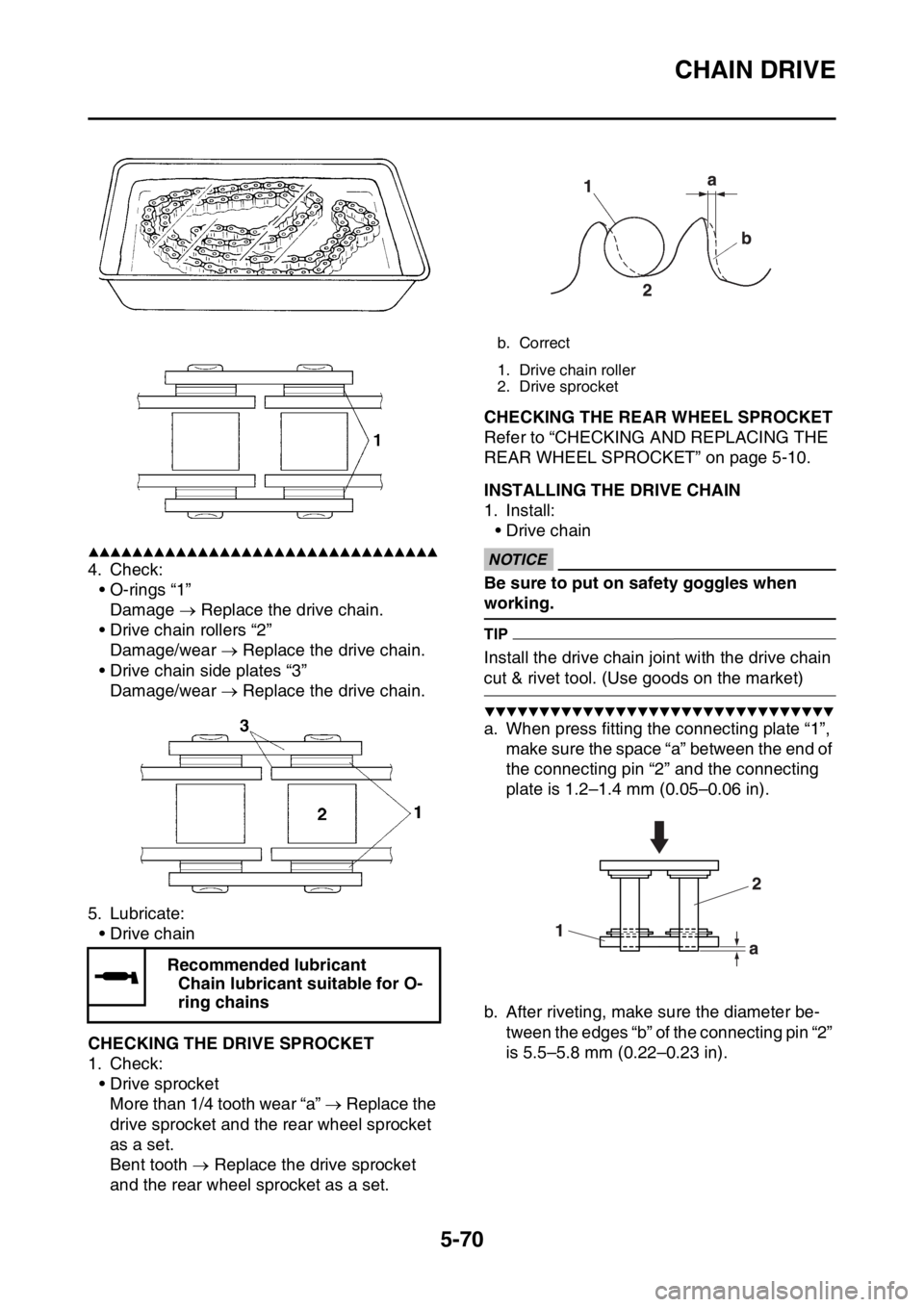

4. Check:

‚ÄĘ O-rings ‚Äú1‚ÄĚ

Damage Ôāģ Replace the drive chain.

‚ÄĘ Drive chain rollers ‚Äú2‚ÄĚ

Damage/wear Ôāģ Replace the drive chain.

‚ÄĘ Drive chain side plates ‚Äú3‚ÄĚ

Damage/wear Ôāģ Replace the drive chain.

5. Lubricate:

‚ÄĘDrive chain

EAS2GB7222CHECKING THE DRIVE SPROCKET

1. Check:

‚ÄĘ Drive sprocket

More than 1/4 tooth wear ‚Äúa‚ÄĚ Ôāģ Replace the

drive sprocket and the rear wheel sprocket

as a set.

Bent tooth Ôāģ Replace the drive sprocket

and the rear wheel sprocket as a set.

EAS2GB7223CHECKING THE REAR WHEEL SPROCKET

Refer to “CHECKING AND REPLACING THE

REAR WHEEL SPROCKET‚ÄĚ on page 5-10.

EAS2GB7224INSTALLING THE DRIVE CHAIN

1. Install:

‚ÄĘDrive chain

ECA

NOTICE

Be sure to put on safety goggles when

working.

TIP

Install the drive chain joint with the drive chain

cut & rivet tool. (Use goods on the market)

‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ‚Ėľ

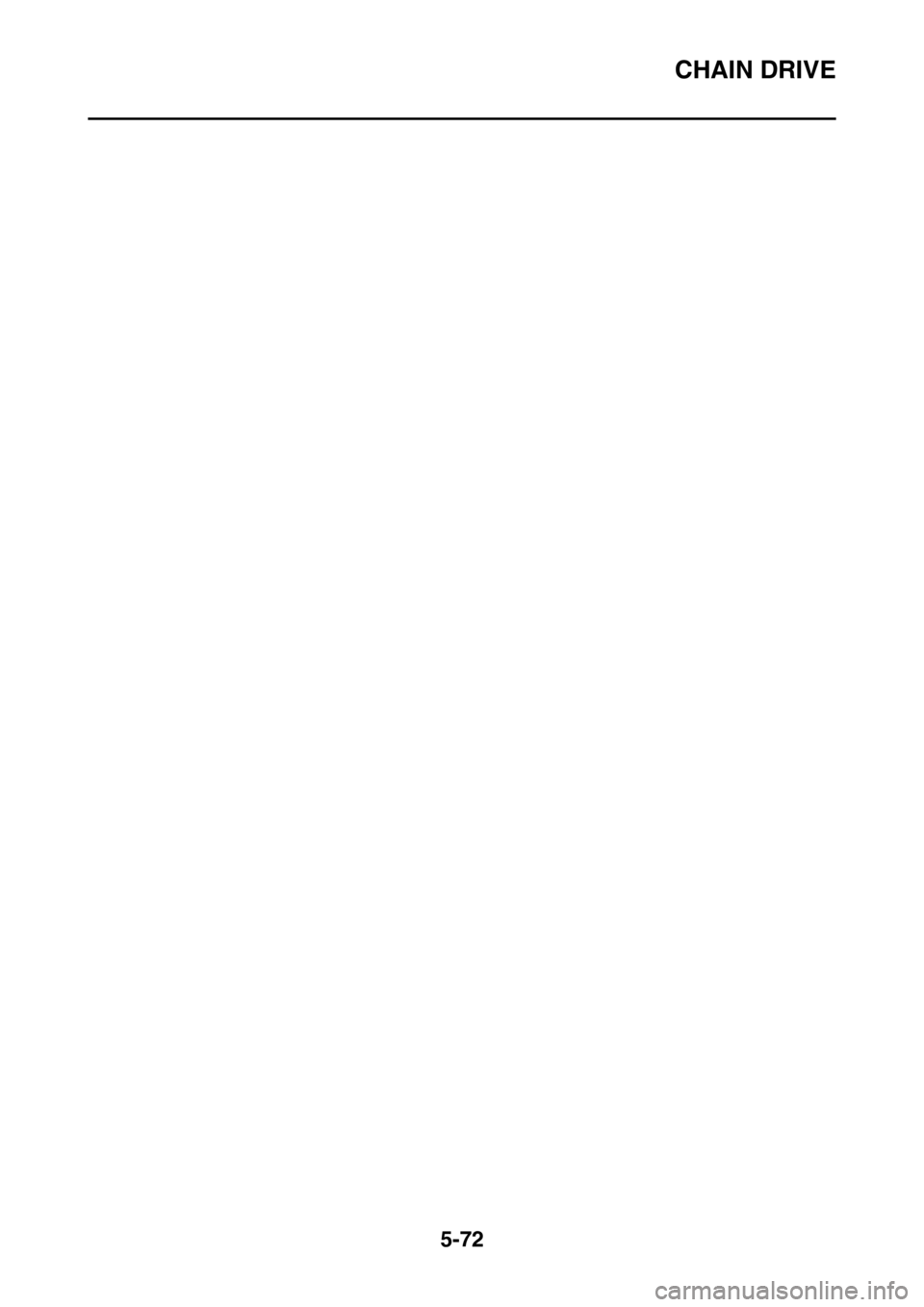

a. When press fitting the connecting plate ‚Äú1‚ÄĚ,

make sure the space ‚Äúa‚ÄĚ between the end of

the connecting pin ‚Äú2‚ÄĚ and the connecting

plate is 1.2‚Äď1.4 mm (0.05‚Äď0.06 in).

b. After riveting, make sure the diameter be-

tween the edges ‚Äúb‚ÄĚ of the connecting pin ‚Äú2‚ÄĚ

is 5.5‚Äď5.8 mm (0.22‚Äď0.23 in). Recommended lubricant

Chain lubricant suitable for O-

ring chains

b. Correct

1. Drive chain roller

2. Drive sprocket

Page 225 of 428

CHAIN DRIVE

5-71

c. After riveting, make sure the space ‚Äúc‚ÄĚ,

which is inside of the connecting link ‚Äú3‚ÄĚ and

inside of the connecting plate ‚Äú1‚ÄĚ, is 14.1‚Äď

14.3 mm (0.56‚Äď0.65 in).

‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤‚Ė≤

2. Lubricate:

‚ÄĘDrive chain

3. Install:

‚ÄĘ Drive sprocket

‚ÄĘ Lock washer

‚ÄĘ Drive sprocket nut

Refer to ‚ÄúENGINE REMOVAL‚ÄĚ on page 6-1.

ECA

NOTICE

Never install a new drive chain onto worn

drive chain sprockets; this will dramatically

shorten the drive chain’s life.

4. Adjust:

‚ÄĘ Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK‚ÄĚ on page 3-30.

ECA

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

Recommended lubricant

Chain lubricant suitable for O-

ring chains

Drive sprocket nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Drive chain slack

50‚Äď60 mm (1.97‚Äď2.36 in)

New

T R..

Page 226 of 428

CHAIN DRIVE

5-72

Page 227 of 428

6

ENGINE

ENGINE REMOVAL......................................................................................... 6-1

REMOVING THE SILENCER ..................................................................... 6-6

REMOVING THE EXHAUST PIPE 2.......................................................... 6-6

REMOVING THE DRIVE SPROCKET ....................................................... 6-6

REMOVING THE ENGINE ......................................................................... 6-7

CLEANING THE SPARK ARRESTER ....................................................... 6-7

CHECKING THE SILENCER AND EXHAUST PIPE.................................. 6-8

INSTALLING THE ENGINE........................................................................ 6-8

INSTALLING THE BRAKE PEDAL ............................................................ 6-9

INSTALLING THE DRIVE SPROCKET...................................................... 6-9

INSTALLING THE EXHAUST PIPE AND MUFFLER................................. 6-9

CAMSHAFT.................................................................................................... 6-11

REMOVING THE CAMSHAFT ................................................................. 6-13

CHECKING THE CAMSHAFT.................................................................. 6-14

CHECKING THE TIMING CHAIN AND CAMSHAFT SPROCKET .......... 6-15

CHECKING THE TIMING CHAIN TENSIONERS .................................... 6-15

CHECKING THE DECOMPRESSION SYSTEM...................................... 6-16

INSTALLING THE CAMSHAFTS ............................................................. 6-16

CYLINDER HEAD........................................................................................... 6-18

REMOVING THE CYLINDER HEAD........................................................ 6-20

CHECKING THE TIMING CHAIN GUIDE (INTAKE SIDE) ...................... 6-20

CHECKING THE CYLINDER HEAD ........................................................ 6-20

INSTALLING THE CYLINDER HEAD ...................................................... 6-21

VALVES AND VALVE SPRINGS................................................................... 6-22

REMOVING THE VALVES ....................................................................... 6-23

CHECKING THE VALVES AND VALVE GUIDES ................................... 6-24

CHECKING THE VALVE SEATS ............................................................. 6-26

CHECKING THE VALVE SPRINGS......................................................... 6-27

CHECKING THE VALVE LIFTERS .......................................................... 6-28

INSTALLING THE VALVES ..................................................................... 6-28

CYLINDER AND PISTON............................................................................... 6-30

REMOVING THE PISTON ....................................................................... 6-31

CHECKING THE CYLINDER AND PISTON ............................................ 6-31

CHECKING THE PISTON RINGS............................................................ 6-32

CHECKING THE PISTON PIN ................................................................. 6-33

INSTALLING THE PISTON AND CYLINDER .......................................... 6-33

ELECTRIC STARTER.................................................................................... 6-35

CHECKING THE STARTER MOTOR ...................................................... 6-37

ASSEMBLING THE STARTER MOTOR .................................................. 6-38

Page 228 of 428

CLUTCH......................................................................................................... 6-40

REMOVING THE CLUTCH ...................................................................... 6-43

CHECKING THE FRICTION PLATES...................................................... 6-43

CHECKING THE CLUTCH PLATES ........................................................ 6-43

CHECKING THE CLUTCH SPRINGS...................................................... 6-43

CHECKING THE CLUTCH HOUSING ..................................................... 6-44

CHECKING THE CLUTCH BOSS ............................................................ 6-44

CHECKING THE PRESSURE PLATE ..................................................... 6-44

CHECKING THE PUSH LEVER SHAFT .................................................. 6-44

CHECKING THE CLUTCH PUSH RODS ................................................ 6-44

CHECKING THE PRIMARY DRIVE GEAR .............................................. 6-44

CHECKING THE PRIMARY DRIVEN GEAR ........................................... 6-45

INSTALLING THE OIL SEAL................................................................... 6-45

INSTALLING THE RIGHT CRANKCASE COVER ................................... 6-45

INSTALLING THE CLUTCH ..................................................................... 6-45

INSTALLING THE KICKSTARTER LEVER ............................................. 6-48

KICKSTATER................................................................................................. 6-49

REMOVING THE KICK SHAFT ASSEMBLY ........................................... 6-50

CHECKING THE KICK SHAFT AND RATCHET WHEEL ........................ 6-50

CHECKING THE KICK GEAR, KICK IDLE GEAR AND RATCHET

WHEEL .................................................................................................... 6-50

INSTALLING THE KICK SHAFT ASSEMBLY .......................................... 6-50

INSTALLING THE KICK IDLE GEAR ....................................................... 6-51

SHIFT SHAFT................................................................................................. 6-52

REMOVING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 6-53

REMOVING THE SEGMENT ................................................................... 6-53

CHECKING THE SHIFT SHAFT .............................................................. 6-53

CHECKING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 6-53

CHECKING THE STOPPER LEVER ....................................................... 6-53

INSTALLING THE STOPPER LEVER ..................................................... 6-54

INSTALLING THE SEGMENT.................................................................. 6-54

INSTALLING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ....... 6-54

INSTALLING THE SHIFT SHAFT ............................................................ 6-55

INSTALLING THE SHIFT PEDAL ............................................................ 6-55

OIL PUMP AND BALANCER GEAR............................................................. 6-56

REMOVING THE BALANCER ................................................................. 6-58

CHECKING THE PRIMARY DRIVE GEAR, BALANCER SHAFT DRIVE

GEAR, AND BALANCER WEIGHT GEAR .............................................. 6-58

CHECKING THE BALANCER .................................................................. 6-58

CHECKING THE OIL PUMP .................................................................... 6-58

ASSEMBLING THE OIL PUMP ................................................................ 6-59

INSTALLING THE OIL PUMP AND BALANCER GEAR .......................... 6-60

Page 229 of 428

GENERATOR AND STARTER CLUTCH....................................................... 6-62

REMOVING THE GENERATOR .............................................................. 6-64

CHECKING THE STARTER CLUTCH ..................................................... 6-64

INSTALLING THE STARTER CLUTCH ................................................... 6-65

INSTALLING THE GENERATOR............................................................. 6-65

CRANKCASE................................................................................................. 6-68

DISASSEMBLING THE CRANKCASE..................................................... 6-71

REMOVING THE CRANKCASE BEARING ............................................. 6-71

CHECKING THE TIMING CHAIN, TIMING CHAIN GUIDE,

OIL STRAINER ........................................................................................ 6-71

CHECKING THE CRANKCASE ............................................................... 6-71

INSTALLING THE OIL SEAL................................................................... 6-72

ASSEMBLING THE CRANKCASE........................................................... 6-72

CRANKSHAFT ASSEMBLY AND BALANCER SHAFT............................... 6-73

REMOVING THE CRANKSHAFT ASSEMBLY ........................................ 6-74

CHECKING THE CRANKSHAFT ASSEMBLY......................................... 6-74

INSTALLING THE CRANKSHAFT ASSEMBLY....................................... 6-75

INSTALLING THE BALANCER SHAFT ................................................... 6-75

TRANSMISSION............................................................................................. 6-76

REMOVING THE TRANSMISSION ......................................................... 6-77

CHECKING THE SHIFT FORKS.............................................................. 6-77

CHECKING THE SHIFT DRUM ASSEMBLY ........................................... 6-78

CHECKING THE TRANSMISSION .......................................................... 6-78

INSTALLING THE TRANSMISSION ........................................................ 6-78

Page 230 of 428

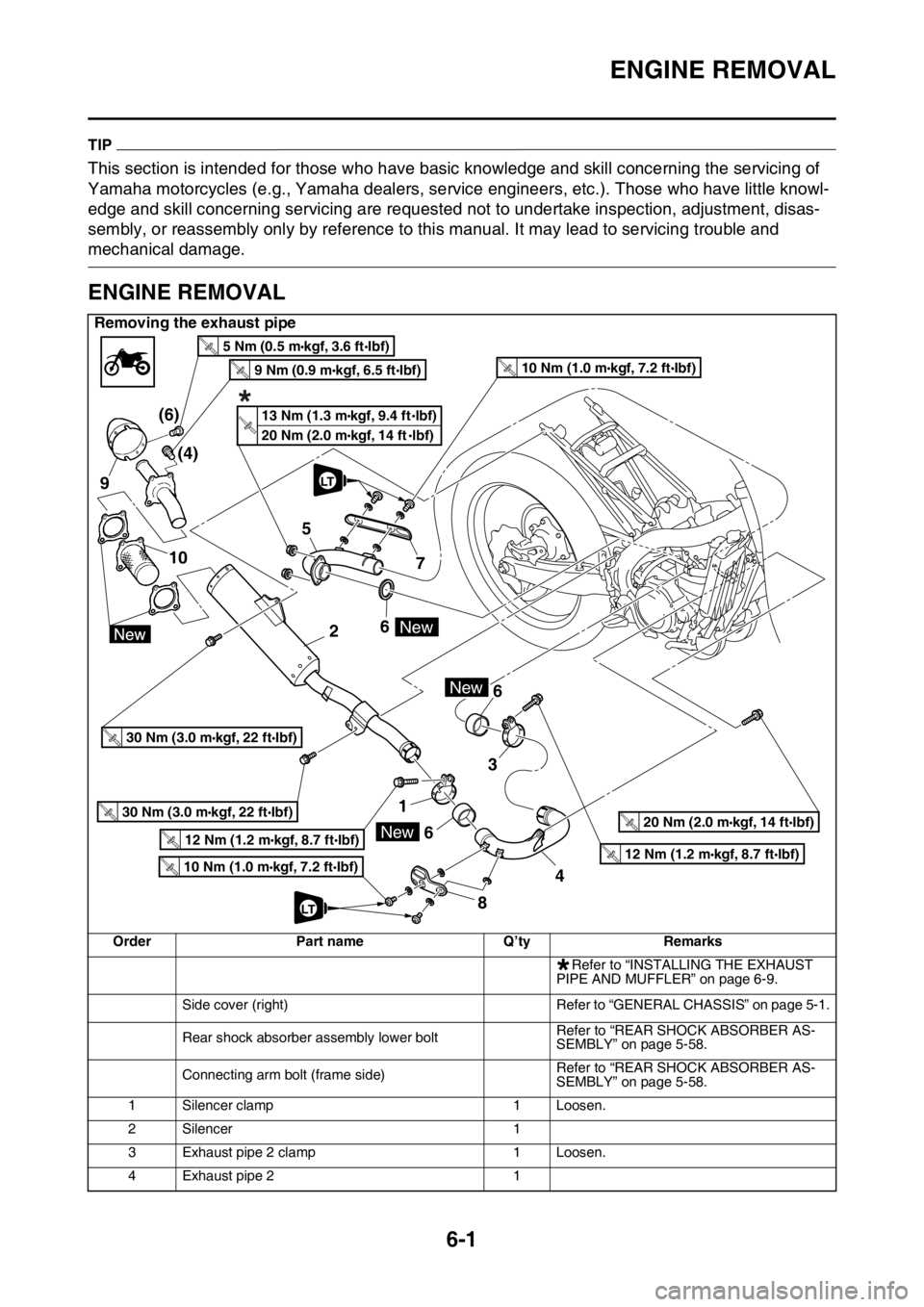

ENGINE REMOVAL

6-1

EAS2GB7225

TIP

This section is intended for those who have basic knowledge and skill concerning the servicing of

Yamaha motorcycles (e.g., Yamaha dealers, service engineers, etc.). Those who have little knowl-

edge and skill concerning servicing are requested not to undertake inspection, adjustment, disas-

sembly, or reassembly only by reference to this manual. It may lead to servicing trouble and

mechanical damage.

EAS2GB7226

ENGINE REMOVAL

Removing the exhaust pipe

Order Part name Q’ty Remarks

Refer to “INSTALLING THE EXHAUST

PIPE AND MUFFLER‚ÄĚ on page 6-9.

Side cover (right) Refer to ‚ÄúGENERAL CHASSIS‚ÄĚ on page 5-1.

Rear shock absorber assembly lower boltRefer to “REAR SHOCK ABSORBER AS-

SEMBLY‚ÄĚ on page 5-58.

Connecting arm bolt (frame side)Refer to “REAR SHOCK ABSORBER AS-

SEMBLY‚ÄĚ on page 5-58.

1 Silencer clamp 1 Loosen.

2 Silencer 1

3 Exhaust pipe 2 clamp 1 Loosen.

4 Exhaust pipe 2 1

105 9

26

1

66

3

84 7 (4) (6)

30 Nm (3.0 m kgf, 22 ft Ibf)T

.R.

30 Nm (3.0 m kgf, 22 ft Ibf)T

.R.

New

New

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

20 Nm (2.0 m kgf, 14 ft Ibf)T

.R.New

LT

LT

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.9 Nm (0.9 m kgf, 6.5 ft Ibf)T

.R.

5 Nm (0.5 m kgf, 3.6 ft Ibf)T

.R.

T

.R.*kgf 13 Nm (1.3 m , 9.4 ft lbf)

kgf, 14 ft 20 Nm (2.0 m lbf)

*