engine oil YAMAHA WR 250F 2016 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250F, Model: YAMAHA WR 250F 2016Pages: 428, PDF Size: 14.13 MB

Page 275 of 428

CLUTCH

6-46

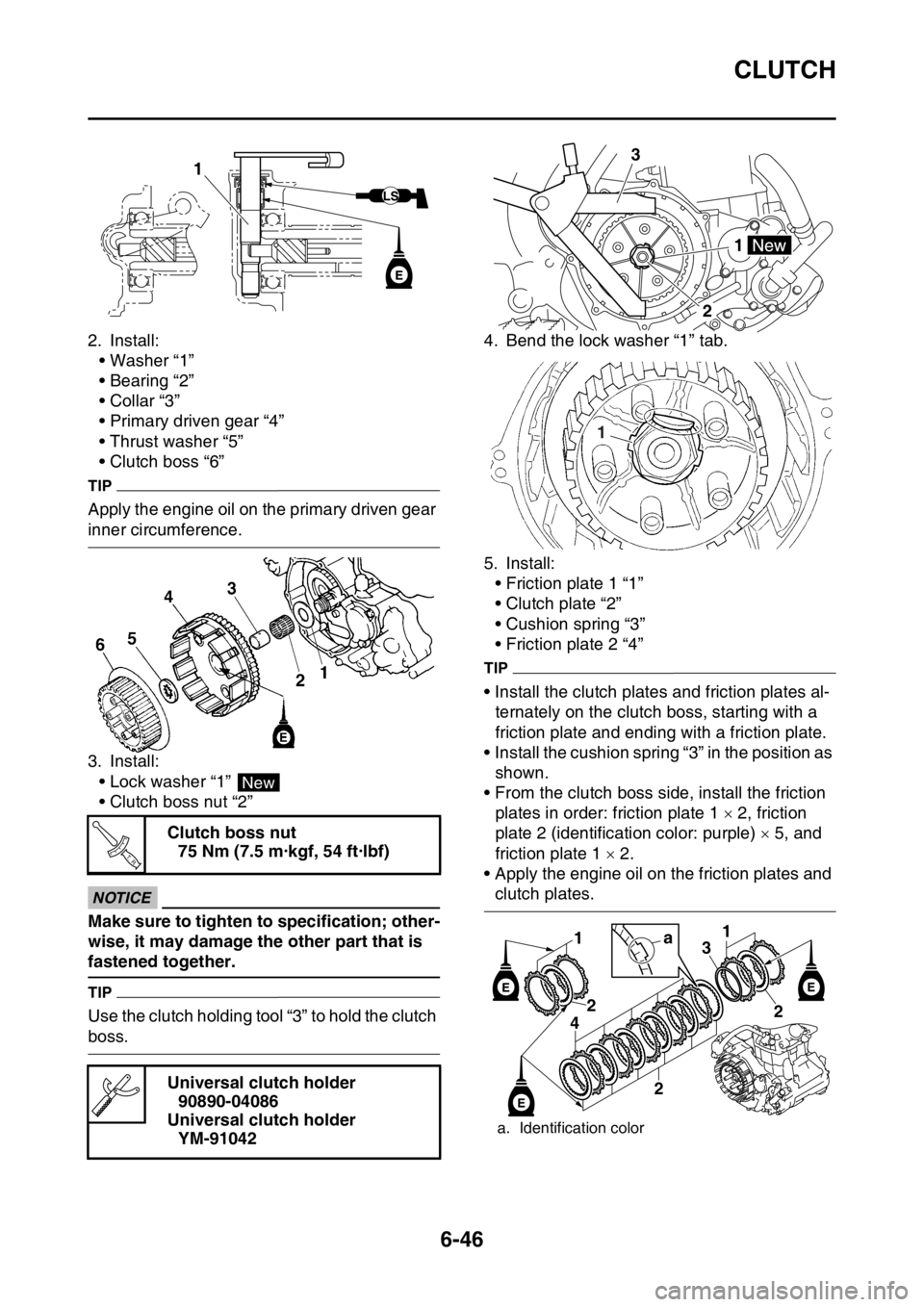

2. Install:

• Washer “1”

• Bearing “2”

• Collar “3”

• Primary driven gear “4”

• Thrust washer “5”

• Clutch boss “6”

TIP

Apply the engine oil on the primary driven gear

inner circumference.

3. Install:

• Lock washer “1”

• Clutch boss nut “2”

ECA

NOTICE

Make sure to tighten to specification; other-

wise, it may damage the other part that is

fastened together.

TIP

Use the clutch holding tool “3” to hold the clutch

boss.4. Bend the lock washer “1” tab.

5. Install:

• Friction plate 1 “1”

• Clutch plate “2”

• Cushion spring “3”

• Friction plate 2 “4”

TIP

• Install the clutch plates and friction plates al-

ternately on the clutch boss, starting with a

friction plate and ending with a friction plate.

• Install the cushion spring “3” in the position as

shown.

• From the clutch boss side, install the friction

plates in order: friction plate 1 2, friction

plate 2 (identification color: purple) 5, and

friction plate 1 2.

• Apply the engine oil on the friction plates and

clutch plates. Clutch boss nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Universal clutch holder

90890-04086

Universal clutch holder

YM-91042

1

New

T R..

a. Identification color

3

21

1

1

2

4

2

1

3

2

a

Page 276 of 428

CLUTCH

6-47

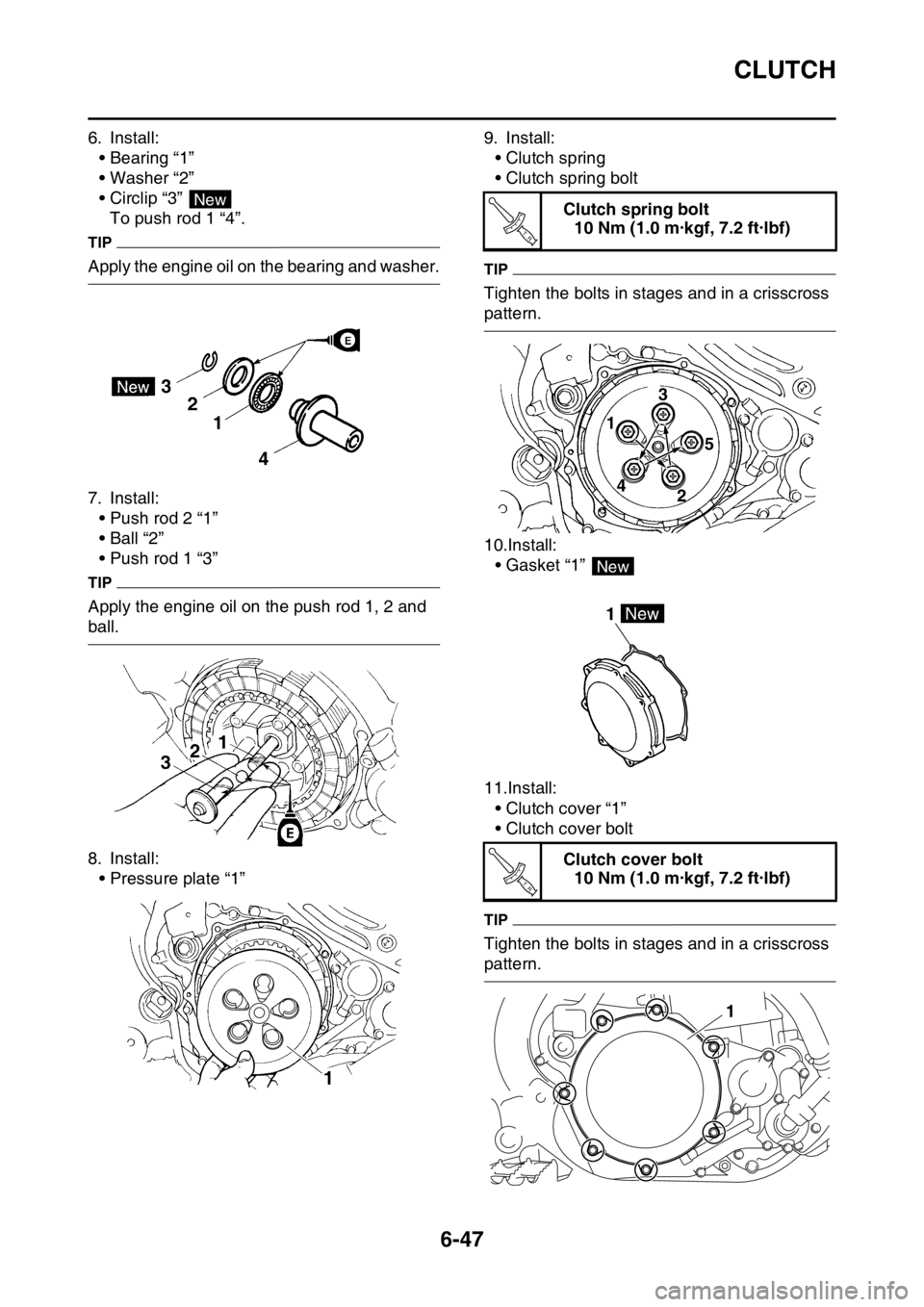

6. Install:

• Bearing “1”

• Washer “2”

• Circlip “3”

To push rod 1 “4”.

TIP

Apply the engine oil on the bearing and washer.

7. Install:

• Push rod 2 “1”

•Ball “2”

• Push rod 1 “3”

TIP

Apply the engine oil on the push rod 1, 2 and

ball.

8. Install:

• Pressure plate “1”9. Install:

• Clutch spring

• Clutch spring bolt

TIP

Tighten the bolts in stages and in a crisscross

pattern.

10.Install:

• Gasket “1”

11.Install:

• Clutch cover “1”

• Clutch cover bolt

TIP

Tighten the bolts in stages and in a crisscross

pattern.

NewClutch spring bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Clutch cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

T R..

1

2 3

45

New

T R..

1

Page 280 of 428

KICKSTATER

6-51

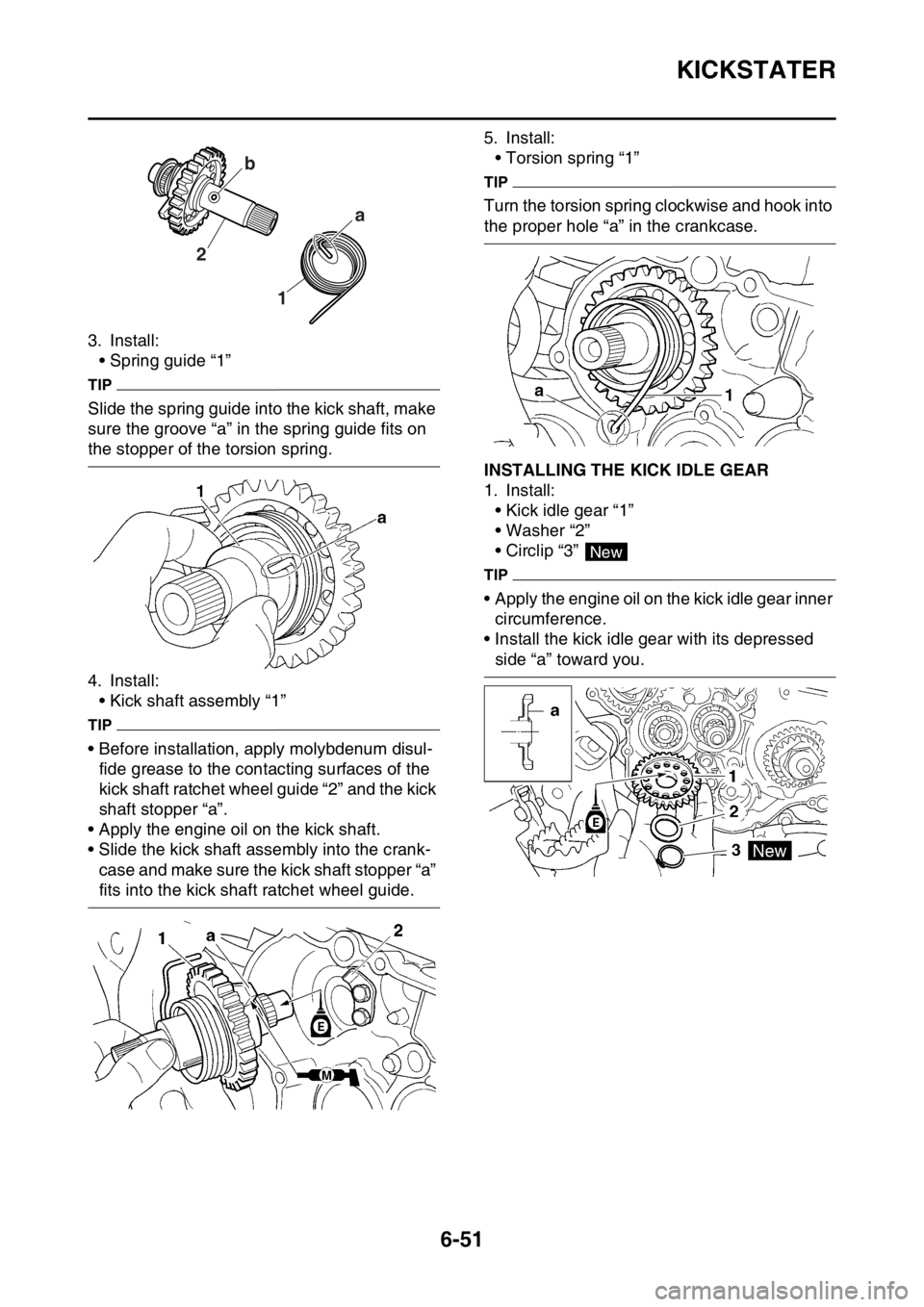

3. Install:

• Spring guide “1”

TIP

Slide the spring guide into the kick shaft, make

sure the groove “a” in the spring guide fits on

the stopper of the torsion spring.

4. Install:

• Kick shaft assembly “1”

TIP

• Before installation, apply molybdenum disul-

fide grease to the contacting surfaces of the

kick shaft ratchet wheel guide “2” and the kick

shaft stopper “a”.

• Apply the engine oil on the kick shaft.

• Slide the kick shaft assembly into the crank-

case and make sure the kick shaft stopper “a”

fits into the kick shaft ratchet wheel guide.5. Install:

• Torsion spring “1”

TIP

Turn the torsion spring clockwise and hook into

the proper hole “a” in the crankcase.

EAS2GB7286INSTALLING THE KICK IDLE GEAR

1. Install:

• Kick idle gear “1”

• Washer “2”

• Circlip “3”

TIP

• Apply the engine oil on the kick idle gear inner

circumference.

• Install the kick idle gear with its depressed

side “a” toward you.

1 2a b

New

Page 283 of 428

SHIFT SHAFT

6-54

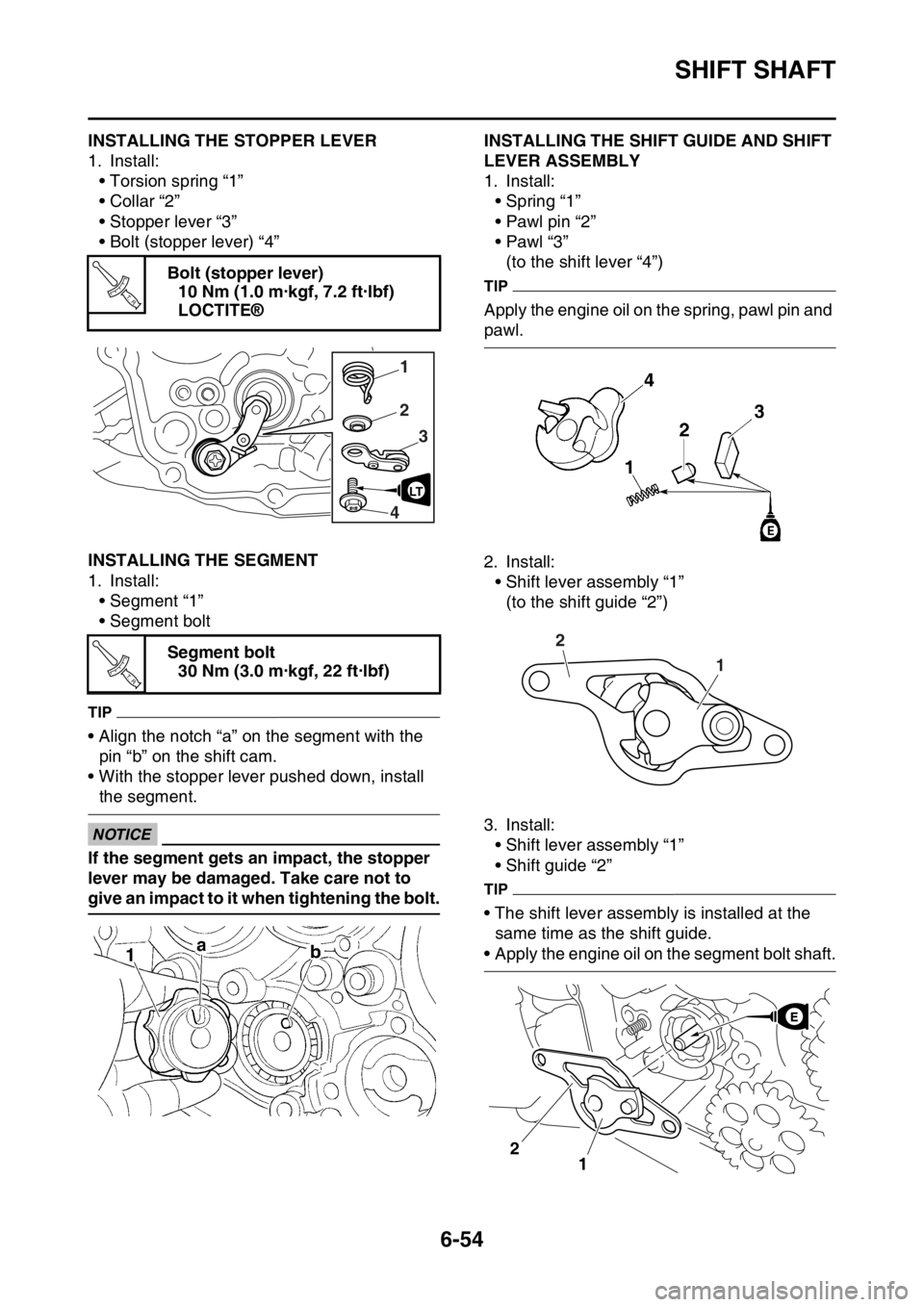

EAS2GB7293INSTALLING THE STOPPER LEVER

1. Install:

• Torsion spring “1”

• Collar “2”

• Stopper lever “3”

• Bolt (stopper lever) “4”

EAS2GB7294INSTALLING THE SEGMENT

1. Install:

• Segment “1”

• Segment bolt

TIP

• Align the notch “a” on the segment with the

pin “b” on the shift cam.

• With the stopper lever pushed down, install

the segment.

ECA

NOTICE

If the segment gets an impact, the stopper

lever may be damaged. Take care not to

give an impact to it when tightening the bolt.

EAS2GB7295INSTALLING THE SHIFT GUIDE AND SHIFT

LEVER ASSEMBLY

1. Install:

• Spring “1”

• Pawl pin “2”

•Pawl “3”

(to the shift lever “4”)

TIP

Apply the engine oil on the spring, pawl pin and

pawl.

2. Install:

• Shift lever assembly “1”

(to the shift guide “2”)

3. Install:

• Shift lever assembly “1”

• Shift guide “2”

TIP

• The shift lever assembly is installed at the

same time as the shift guide.

• Apply the engine oil on the segment bolt shaft. Bolt (stopper lever)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Segment bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

T R..

2 1

3

4

LT

T R..1

2

1 2

Page 284 of 428

SHIFT SHAFT

6-55

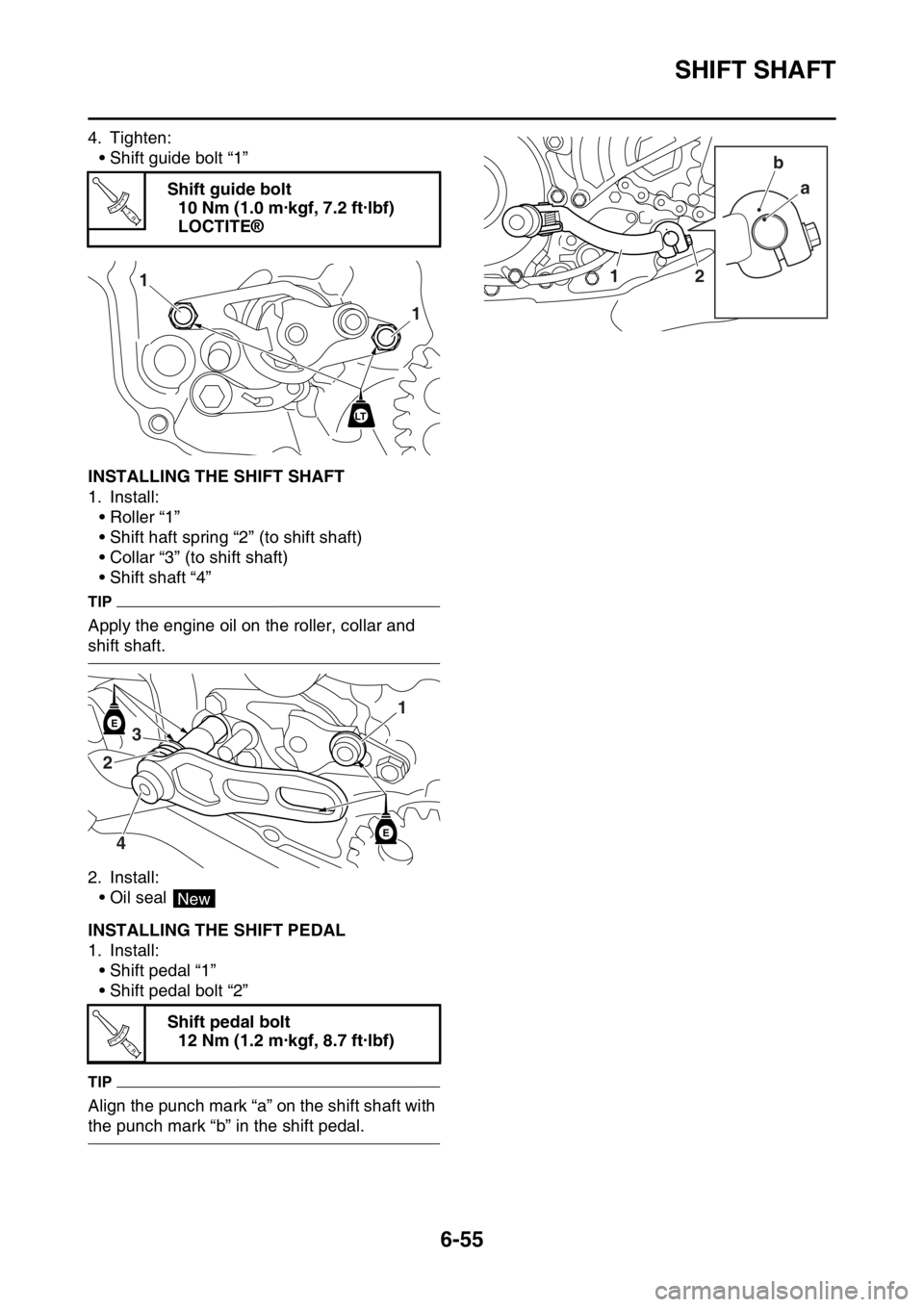

4. Tighten:

• Shift guide bolt “1”

EAS2GB7296INSTALLING THE SHIFT SHAFT

1. Install:

• Roller “1”

• Shift haft spring “2” (to shift shaft)

• Collar “3” (to shift shaft)

• Shift shaft “4”

TIP

Apply the engine oil on the roller, collar and

shift shaft.

2. Install:

• Oil seal

EAS2GB7297INSTALLING THE SHIFT PEDAL

1. Install:

• Shift pedal “1”

• Shift pedal bolt “2”

TIP

Align the punch mark “a” on the shift shaft with

the punch mark “b” in the shift pedal.Shift guide bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

Shift pedal bolt

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

T R..

1 1

LT

E

E

1

23

4

New

T R..

a

12b

Page 288 of 428

OIL PUMP AND BALANCER GEAR

6-59

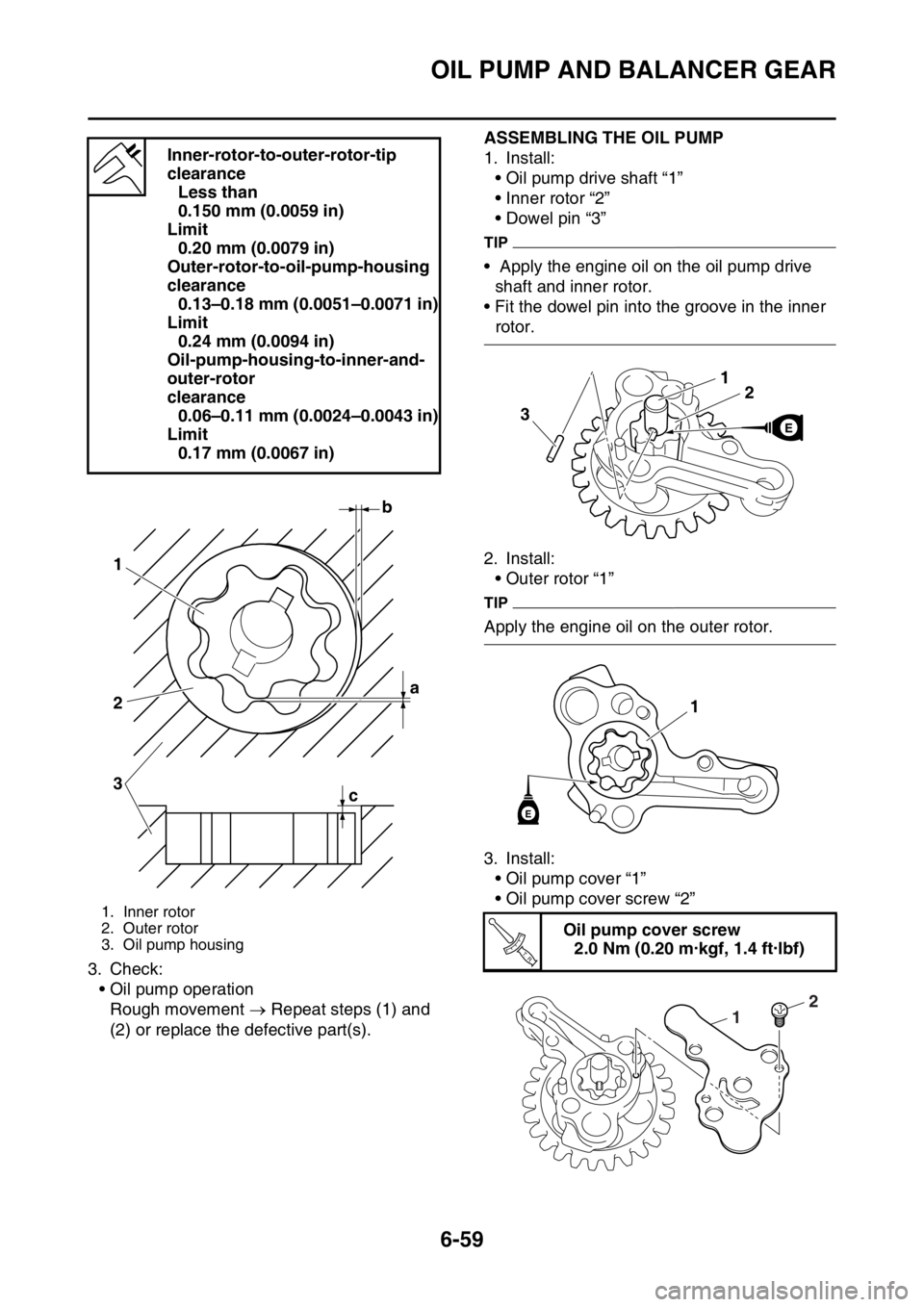

3. Check:

• Oil pump operation

Rough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS2GB7303

ASSEMBLING THE OIL PUMP

1. Install:

• Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive

shaft and inner rotor.

• Fit the dowel pin into the groove in the inner

rotor.

2. Install:

• Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:

• Oil pump cover “1”

• Oil pump cover screw “2” Inner-rotor-to-outer-rotor-tip

clearance

Less than

0.150 mm (0.0059 in)

Limit

0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing

clearance

0.13–0.18 mm (0.0051–0.0071 in)

Limit

0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-

outer-rotor

clearance

0.06–0.11 mm (0.0024–0.0043 in)

Limit

0.17 mm (0.0067 in)

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a 1

2

3

c

Oil pump cover screw

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

21

3

1

E

T R..

2

1

Page 289 of 428

OIL PUMP AND BALANCER GEAR

6-60

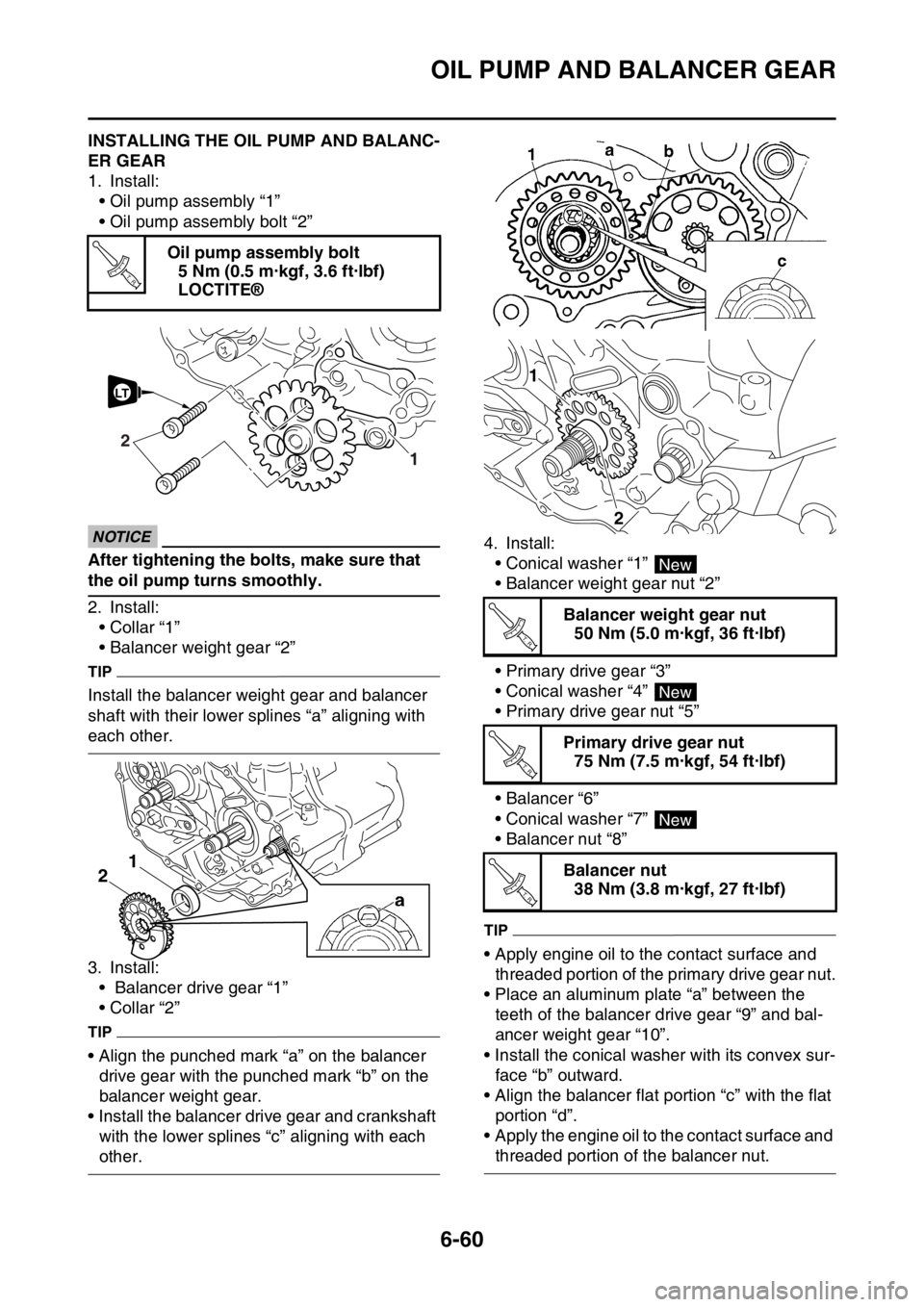

EAS2GB7304INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:

• Oil pump assembly “1”

• Oil pump assembly bolt “2”

ECA

NOTICE

After tightening the bolts, make sure that

the oil pump turns smoothly.

2. Install:

• Collar “1”

• Balancer weight gear “2”

TIP

Install the balancer weight gear and balancer

shaft with their lower splines “a” aligning with

each other.

3. Install:

• Balancer drive gear “1”

• Collar “2”

TIP

• Align the punched mark “a” on the balancer

drive gear with the punched mark “b” on the

balancer weight gear.

• Install the balancer drive gear and crankshaft

with the lower splines “c” aligning with each

other.4. Install:

• Conical washer “1”

• Balancer weight gear nut “2”

• Primary drive gear “3”

• Conical washer “4”

• Primary drive gear nut “5”

•Balancer “6”

• Conical washer “7”

• Balancer nut “8”

TIP

• Apply engine oil to the contact surface and

threaded portion of the primary drive gear nut.

• Place an aluminum plate “a” between the

teeth of the balancer drive gear “9” and bal-

ancer weight gear “10”.

• Install the conical washer with its convex sur-

face “b” outward.

• Align the balancer flat portion “c” with the flat

portion “d”.

• Apply the engine oil to the contact surface and

threaded portion of the balancer nut. Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

T R..

1

2

LT

21

Balancer weight gear nut

50 Nm (5.0 m·kgf, 36 ft·lbf)

Primary drive gear nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Balancer nut

38 Nm (3.8 m·kgf, 27 ft·lbf)

1

2

New

T R..

New

T R..

New

T R..

Page 291 of 428

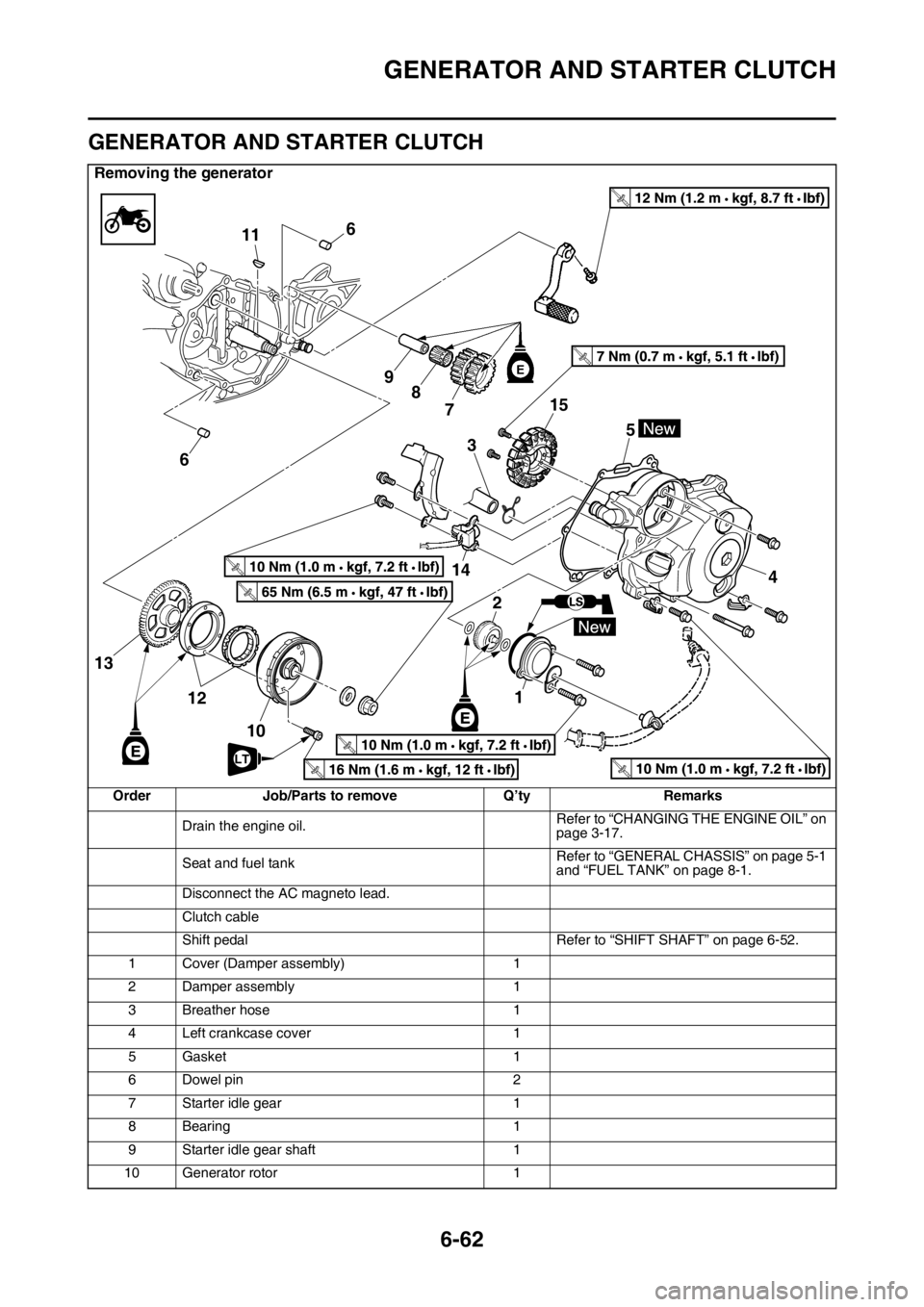

GENERATOR AND STARTER CLUTCH

6-62

EAS2GB7305

GENERATOR AND STARTER CLUTCH

Removing the generator

Order Job/Parts to remove Q’ty Remarks

Drain the engine oil.Refer to “CHANGING THE ENGINE OIL” on

page 3-17.

Seat and fuel tankRefer to “GENERAL CHASSIS” on page 5-1

and “FUEL TANK” on page 8-1.

Disconnect the AC magneto lead.

Clutch cable

Shift pedal Refer to “SHIFT SHAFT” on page 6-52.

1 Cover (Damper assembly) 1

2 Damper assembly 1

3 Breather hose 1

4 Left crankcase cover 1

5Gasket 1

6 Dowel pin 2

7 Starter idle gear 1

8 Bearing 1

9 Starter idle gear shaft 1

10 Generator rotor 1

T R..

T R..

6

611

9

8

7

2

3

1

14

4 5

12

10

13

T R..

T R..

T R..LTT R..

T R..

15

Page 294 of 428

GENERATOR AND STARTER CLUTCH

6-65

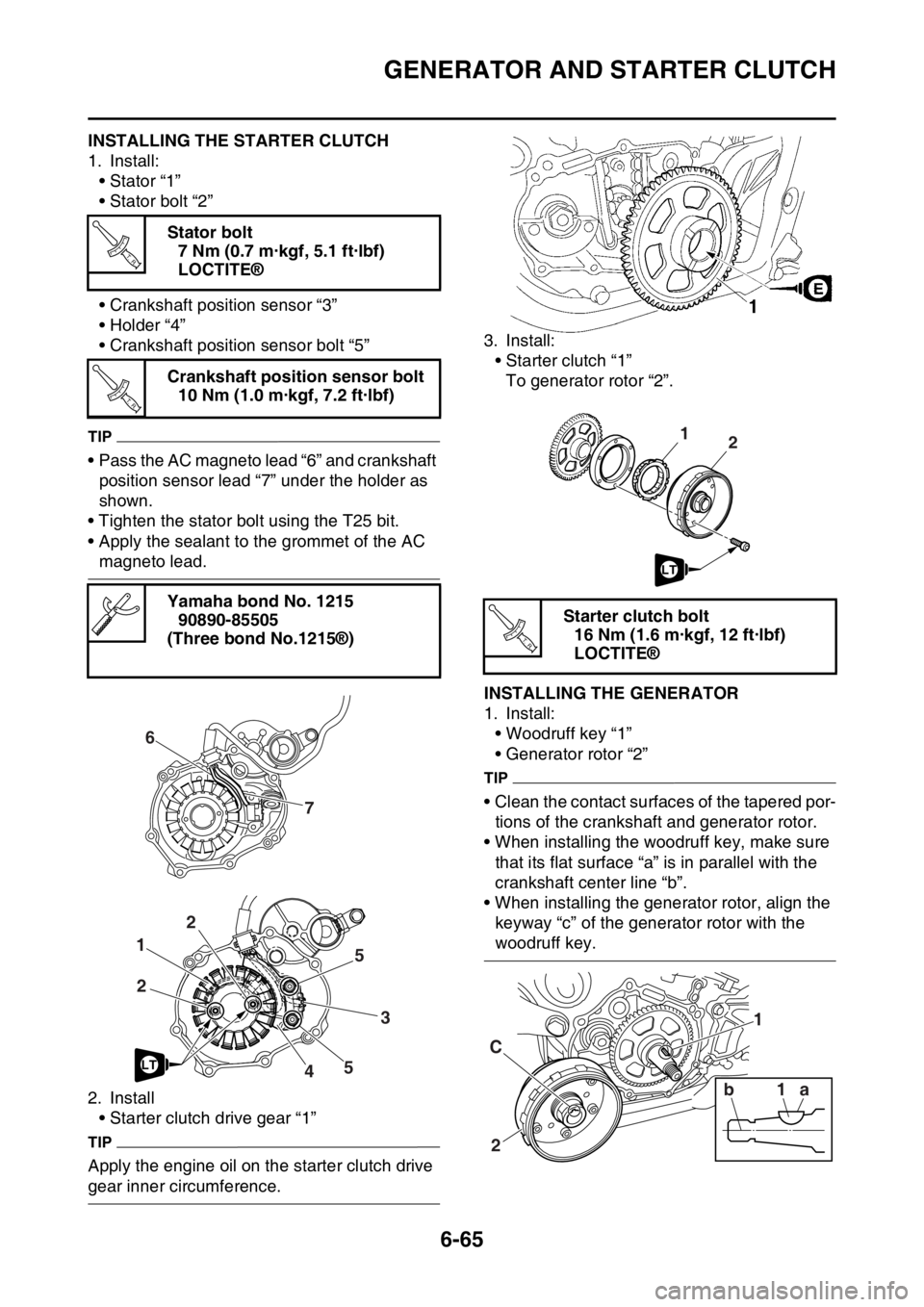

EAS2GB7308INSTALLING THE STARTER CLUTCH

1. Install:

• Stator “1”

• Stator bolt “2”

• Crankshaft position sensor “3”

• Holder “4”

• Crankshaft position sensor bolt “5”

TIP

• Pass the AC magneto lead “6” and crankshaft

position sensor lead “7” under the holder as

shown.

• Tighten the stator bolt using the T25 bit.

• Apply the sealant to the grommet of the AC

magneto lead.

2. Install

• Starter clutch drive gear “1”

TIP

Apply the engine oil on the starter clutch drive

gear inner circumference.3. Install:

• Starter clutch “1”

To generator rotor “2”.

EAS2GB7309INSTALLING THE GENERATOR

1. Install:

• Woodruff key “1”

• Generator rotor “2”

TIP

• Clean the contact surfaces of the tapered por-

tions of the crankshaft and generator rotor.

• When installing the woodruff key, make sure

that its flat surface “a” is in parallel with the

crankshaft center line “b”.

• When installing the generator rotor, align the

keyway “c” of the generator rotor with the

woodruff key. Stator bolt

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LOCTITE®

Crankshaft position sensor bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)

T R..

T R..

6

7

1

3

22

5

5

4LT

Starter clutch bolt

16 Nm (1.6 m·kgf, 12 ft·lbf)

LOCTITE®

21

LT

T R..

2 C1 1

1a b

Page 295 of 428

GENERATOR AND STARTER CLUTCH

6-66

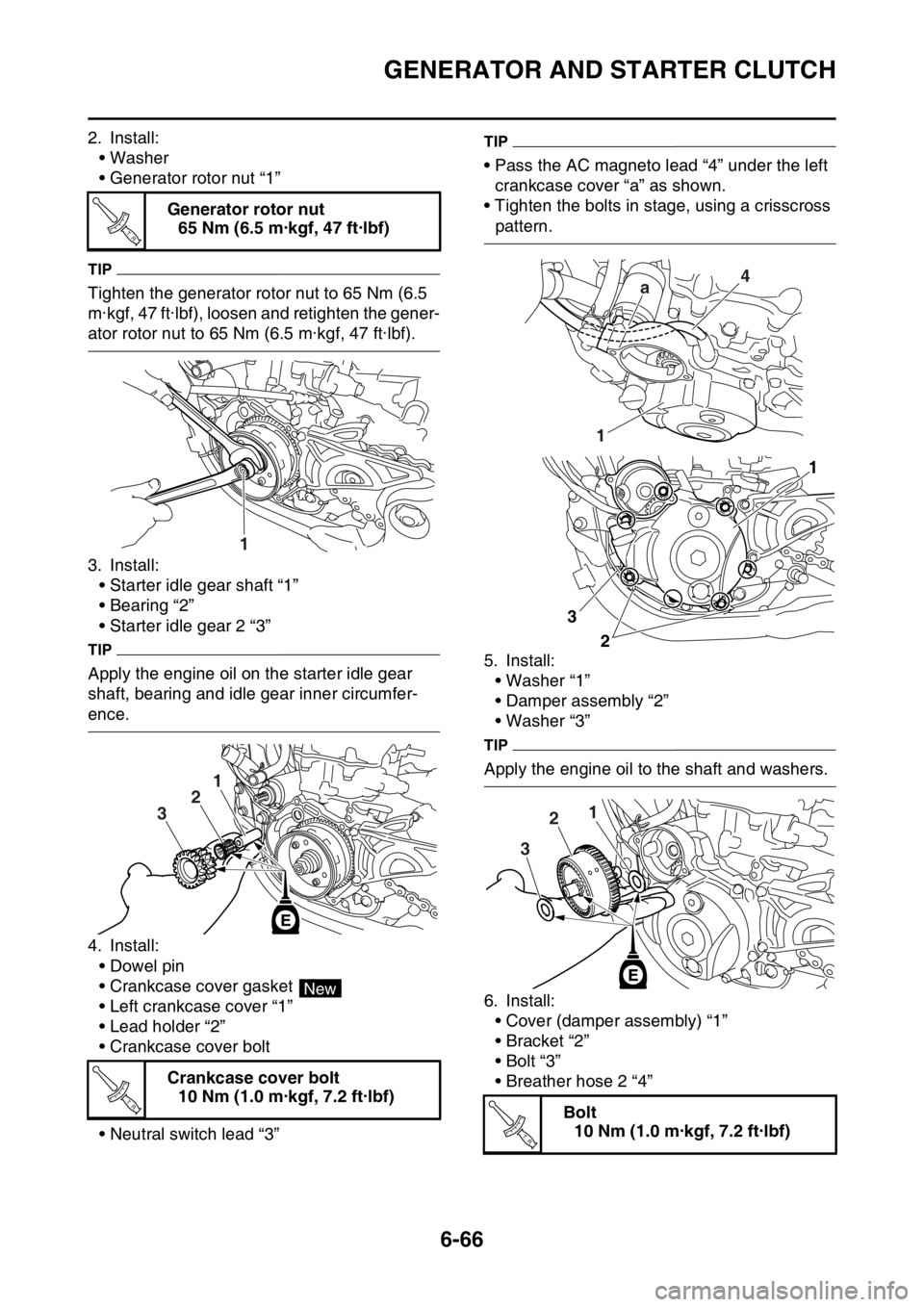

2. Install:

• Washer

• Generator rotor nut “1”

TIP

Tighten the generator rotor nut to 65 Nm (6.5

m·kgf, 47 ft·lbf), loosen and retighten the gener-

ator rotor nut to 65 Nm (6.5 m·kgf, 47 ft·lbf).

3. Install:

• Starter idle gear shaft “1”

• Bearing “2”

• Starter idle gear 2 “3”

TIP

Apply the engine oil on the starter idle gear

shaft, bearing and idle gear inner circumfer-

ence.

4. Install:

• Dowel pin

• Crankcase cover gasket

• Left crankcase cover “1”

• Lead holder “2”

• Crankcase cover bolt

• Neutral switch lead “3”

TIP

• Pass the AC magneto lead “4” under the left

crankcase cover “a” as shown.

• Tighten the bolts in stage, using a crisscross

pattern.

5. Install:

• Washer “1”

• Damper assembly “2”

• Washer “3”

TIP

Apply the engine oil to the shaft and washers.

6. Install:

• Cover (damper assembly) “1”

• Bracket “2”

•Bolt “3”

• Breather hose 2 “4” Generator rotor nut

65 Nm (6.5 m·kgf, 47 ft·lbf)

Crankcase cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

T R..

1

1

21

2

3

New

T R..Bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

4

1a

1

2

3

21

2

3

T R..