engine oil YAMAHA WR 250F 2016 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 250F, Model: YAMAHA WR 250F 2016Pages: 428, PDF Size: 14.13 MB

Page 137 of 428

CHASSIS

3-37

c. Turn the front fork to the right and left a few

times, and make sure that the steering ro-

tates smoothly. If it does not turn smoothly,

remove the lower bracket and check the up-

per and lower bearings.

Refer to “STEERING HEAD” on page 5-53.

d. Loosen the ring nut fully turn and then tight-

en it to specification with a steering nut

wrench.

EWA

WARNING

Do not overtighten the lower ring nut.

e. Check the steering head for looseness or

binding by turning the front fork all the way in

both directions. If any binding is felt, remove

the lower bracket and check the upper and

lower bearings.

Refer to “STEERING HEAD” on page 5-53.

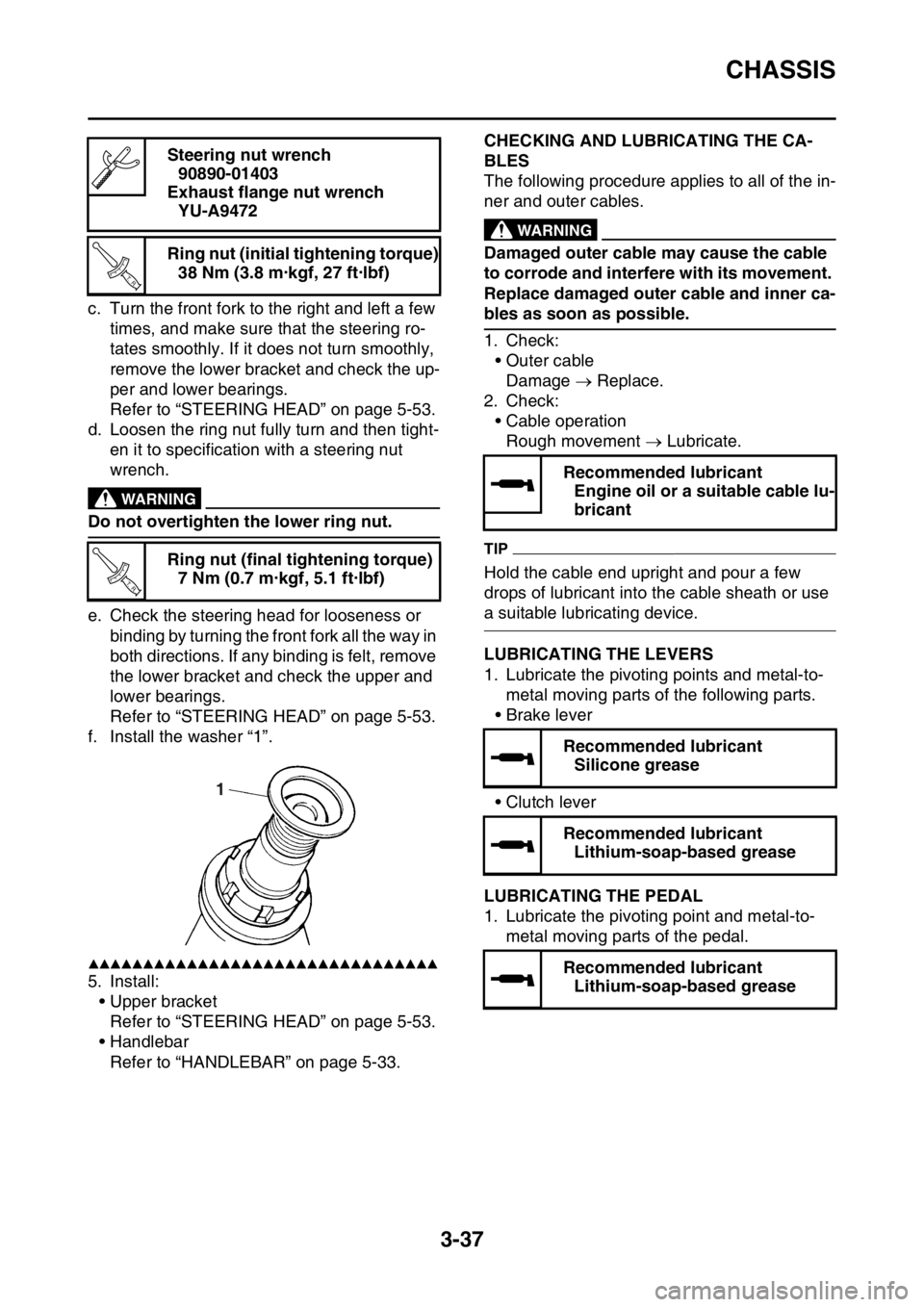

f. Install the washer “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Upper bracket

Refer to “STEERING HEAD” on page 5-53.

• Handlebar

Refer to “HANDLEBAR” on page 5-33.

EAS2GB7124CHECKING AND LUBRICATING THE CA-

BLES

The following procedure applies to all of the in-

ner and outer cables.

EWA

WARNING

Damaged outer cable may cause the cable

to corrode and interfere with its movement.

Replace damaged outer cable and inner ca-

bles as soon as possible.

1. Check:

• Outer cable

Damage Replace.

2. Check:

• Cable operation

Rough movement Lubricate.

TIP

Hold the cable end upright and pour a few

drops of lubricant into the cable sheath or use

a suitable lubricating device.

EAS2GB7125LUBRICATING THE LEVERS

1. Lubricate the pivoting points and metal-to-

metal moving parts of the following parts.

•Brake lever

• Clutch lever

EAS2GB7126LUBRICATING THE PEDAL

1. Lubricate the pivoting point and metal-to-

metal moving parts of the pedal. Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

Ring nut (initial tightening torque)

38 Nm (3.8 m·kgf, 27 ft·lbf)

Ring nut (final tightening torque)

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

T R..

1

Recommended lubricant

Engine oil or a suitable cable lu-

bricant

Recommended lubricant

Silicone grease

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

Page 138 of 428

CHASSIS

3-38

EAS2GB7127LUBRICATING THE DRIVE CHAIN

The drive chain consists of many interacting

parts. If the drive chain is not maintained prop-

erly, it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rubber

O-rings between each side plate. Steam clean-

ing, high-pressure washing, certain solvents,

and the use of a coarse brush can damage

these O-rings. Therefore, use only kerosene to

clean the drive chain. Wipe the drive chain dry

and thoroughly lubricate it with engine oil or

chain lubricant that is suitable for O-ring chains.

Do not use any other lubricants on the drive

chain since they may contain solvents that

could damage the O-rings.

EAS2GB7128LUBRICATING THE SIDESTAND

Lubricate the pivoting point and metal-to-metal

moving parts of the sidestand.

EAS2GB7129CHECKING THE CHASSIS FASTENERS

Make sure that all nuts, bolts, and screws are

properly tightened.

Refer to “CHASSIS TIGHTENING TORQUES”

on page 2-16.Recommended lubricant

Chain lubricant suitable for O-

ring chains

Recommended lubricant

Lithium-soap-based grease

Page 191 of 428

HANDLEBAR

5-37

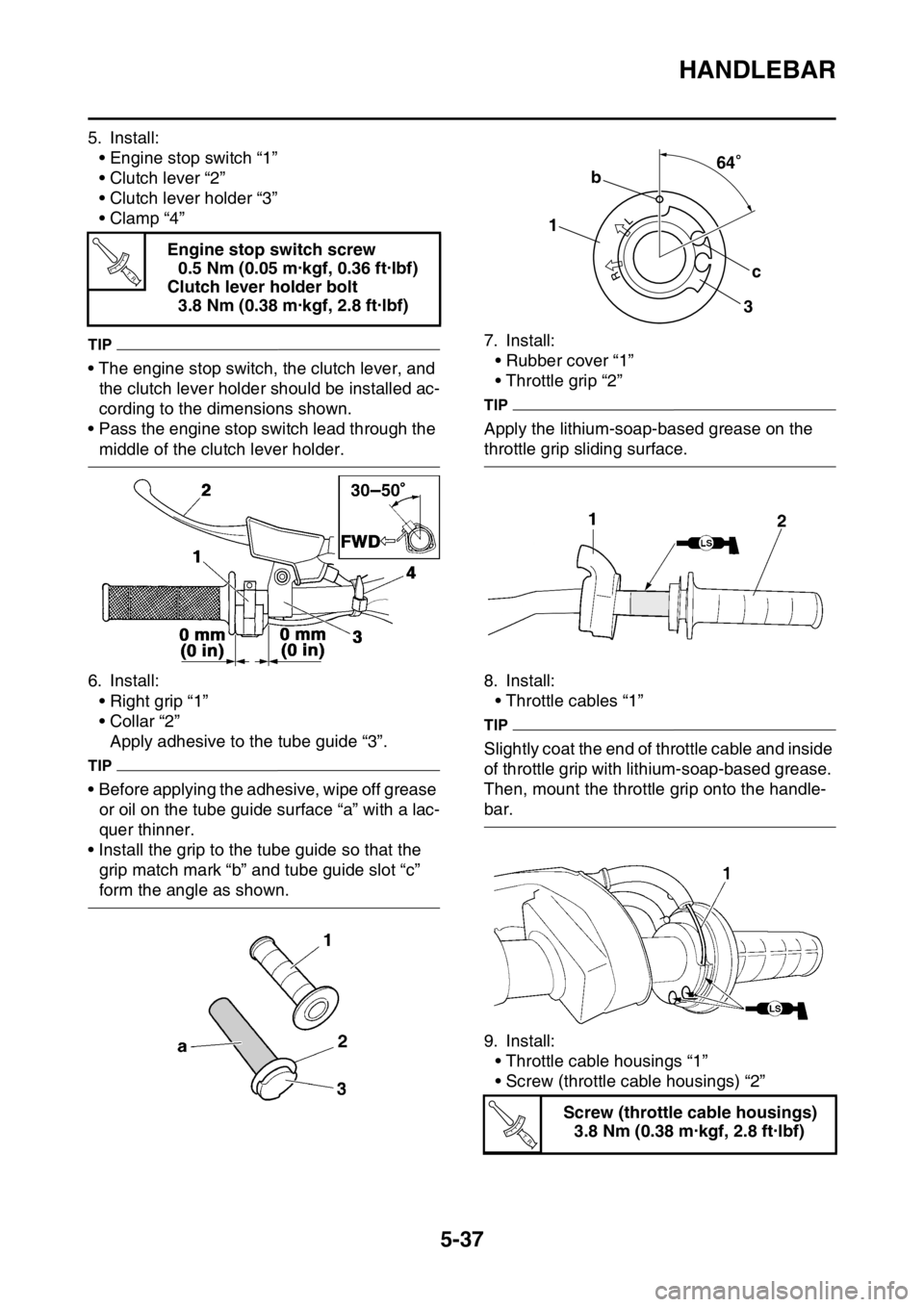

5. Install:

• Engine stop switch “1”

• Clutch lever “2”

• Clutch lever holder “3”

•Clamp “4”

TIP

• The engine stop switch, the clutch lever, and

the clutch lever holder should be installed ac-

cording to the dimensions shown.

• Pass the engine stop switch lead through the

middle of the clutch lever holder.

6. Install:

• Right grip “1”

• Collar “2”

Apply adhesive to the tube guide “3”.

TIP

• Before applying the adhesive, wipe off grease

or oil on the tube guide surface “a” with a lac-

quer thinner.

• Install the grip to the tube guide so that the

grip match mark “b” and tube guide slot “c”

form the angle as shown.7. Install:

• Rubber cover “1”

• Throttle grip “2”

TIP

Apply the lithium-soap-based grease on the

throttle grip sliding surface.

8. Install:

• Throttle cables “1”

TIP

Slightly coat the end of throttle cable and inside

of throttle grip with lithium-soap-based grease.

Then, mount the throttle grip onto the handle-

bar.

9. Install:

• Throttle cable housings “1”

• Screw (throttle cable housings) “2”

EWA

Engine stop switch screw

0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Clutch lever holder bolt

3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

Screw (throttle cable housings)

3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

64

1b

c

3 64

T R..

Page 232 of 428

ENGINE REMOVAL

6-3

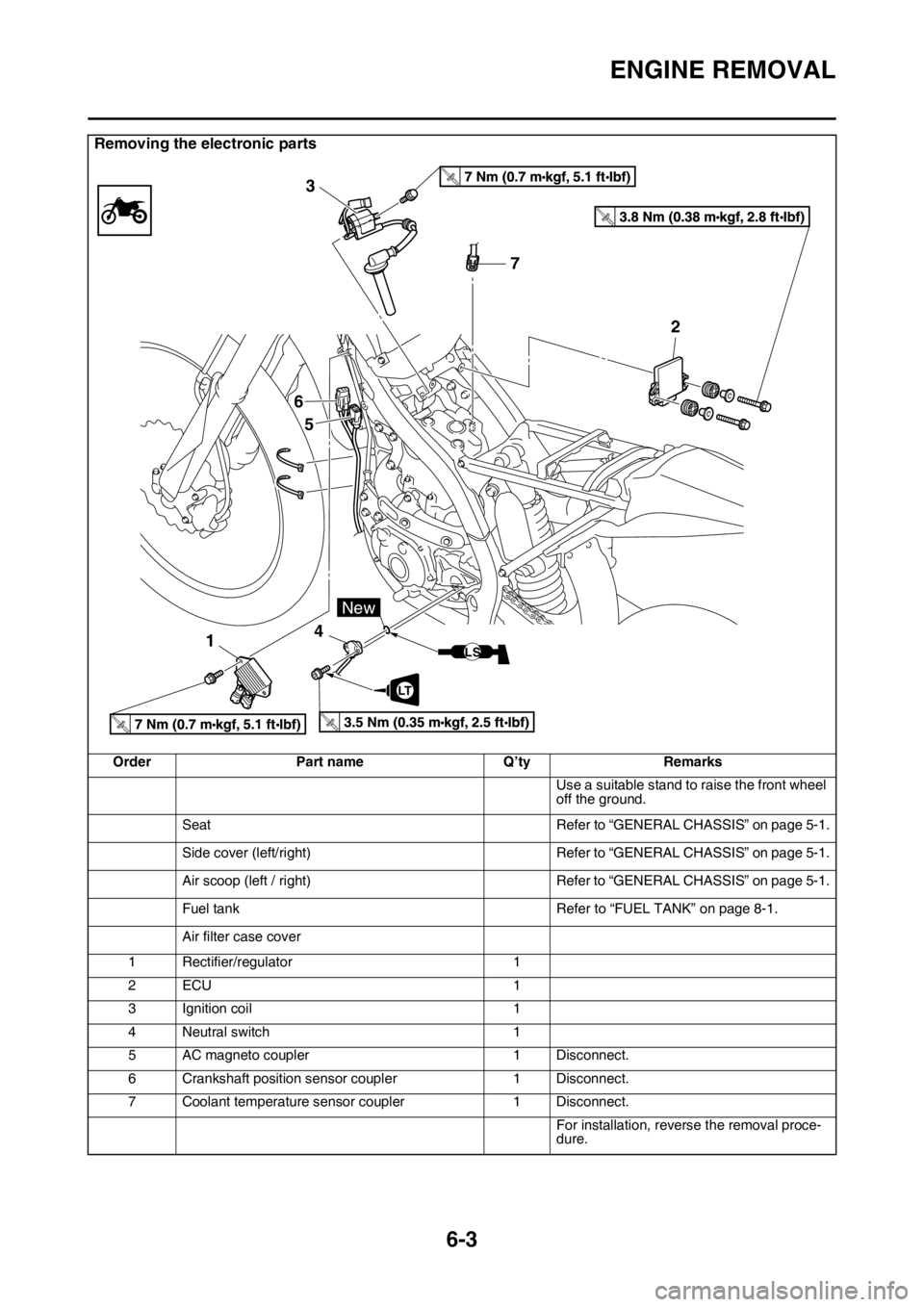

Removing the electronic parts

Order Part name Q’ty Remarks

Use a suitable stand to raise the front wheel

off the ground.

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Air filter case cover

1 Rectifier/regulator 1

2ECU 1

3 Ignition coil 1

4 Neutral switch 1

5 AC magneto coupler 1 Disconnect.

6 Crankshaft position sensor coupler 1 Disconnect.

7 Coolant temperature sensor coupler 1 Disconnect.

For installation, reverse the removal proce-

dure.

T.R.

T.R.

T.R.T.R.

7 3

6

5

142

LT

New

LS

Page 245 of 428

CAMSHAFT

6-16

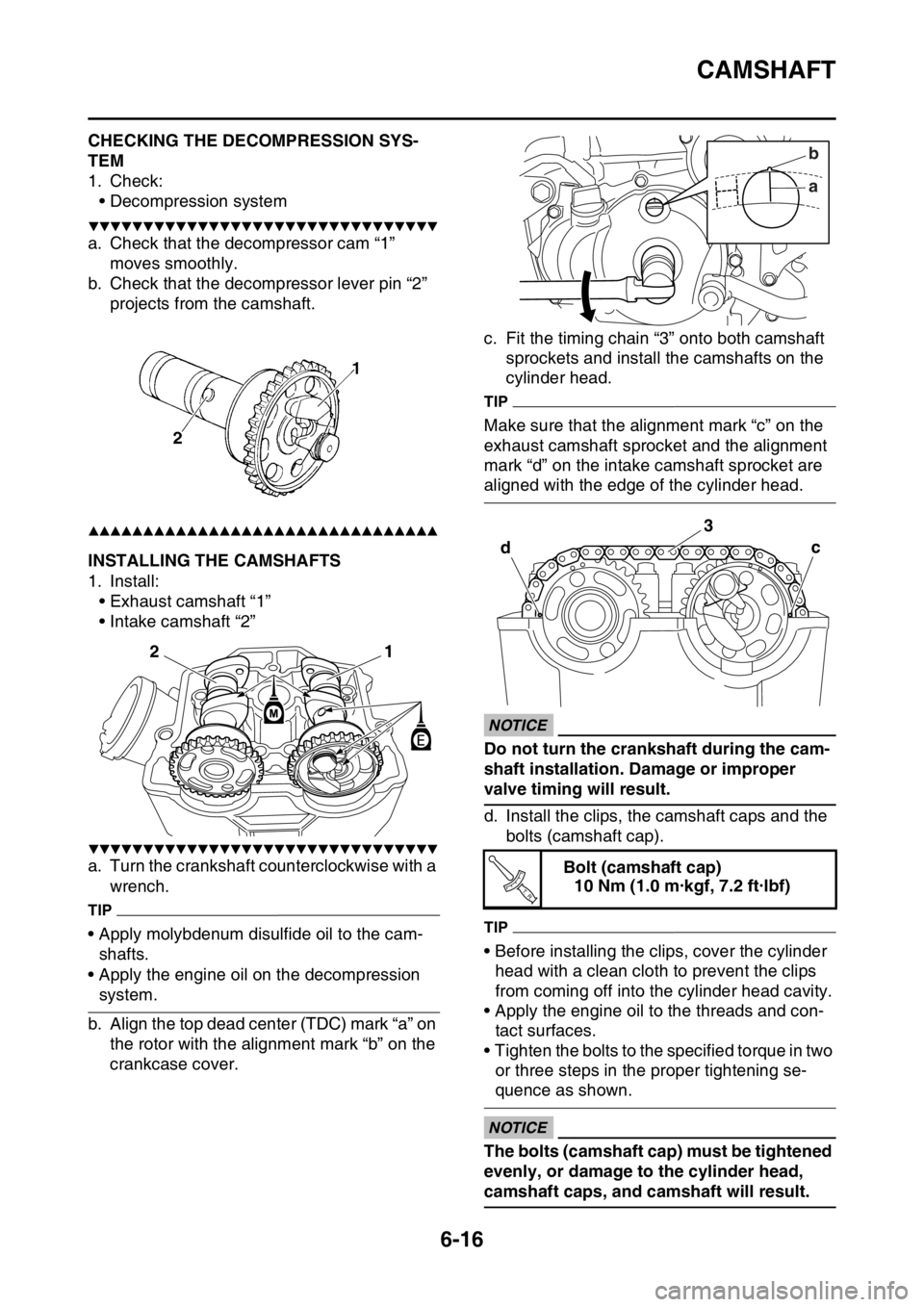

EAS2GB7242CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:

• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2”

projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB7243INSTALLING THE CAMSHAFTS

1. Install:

• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-

shafts.

• Apply the engine oil on the decompression

system.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA

NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the

bolts (camshaft cap).

TIP

• Before installing the clips, cover the cylinder

head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Apply the engine oil to the threads and con-

tact surfaces.

• Tighten the bolts to the specified torque in two

or three steps in the proper tightening se-

quence as shown.

ECA

NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

ab

dc

3

T R..

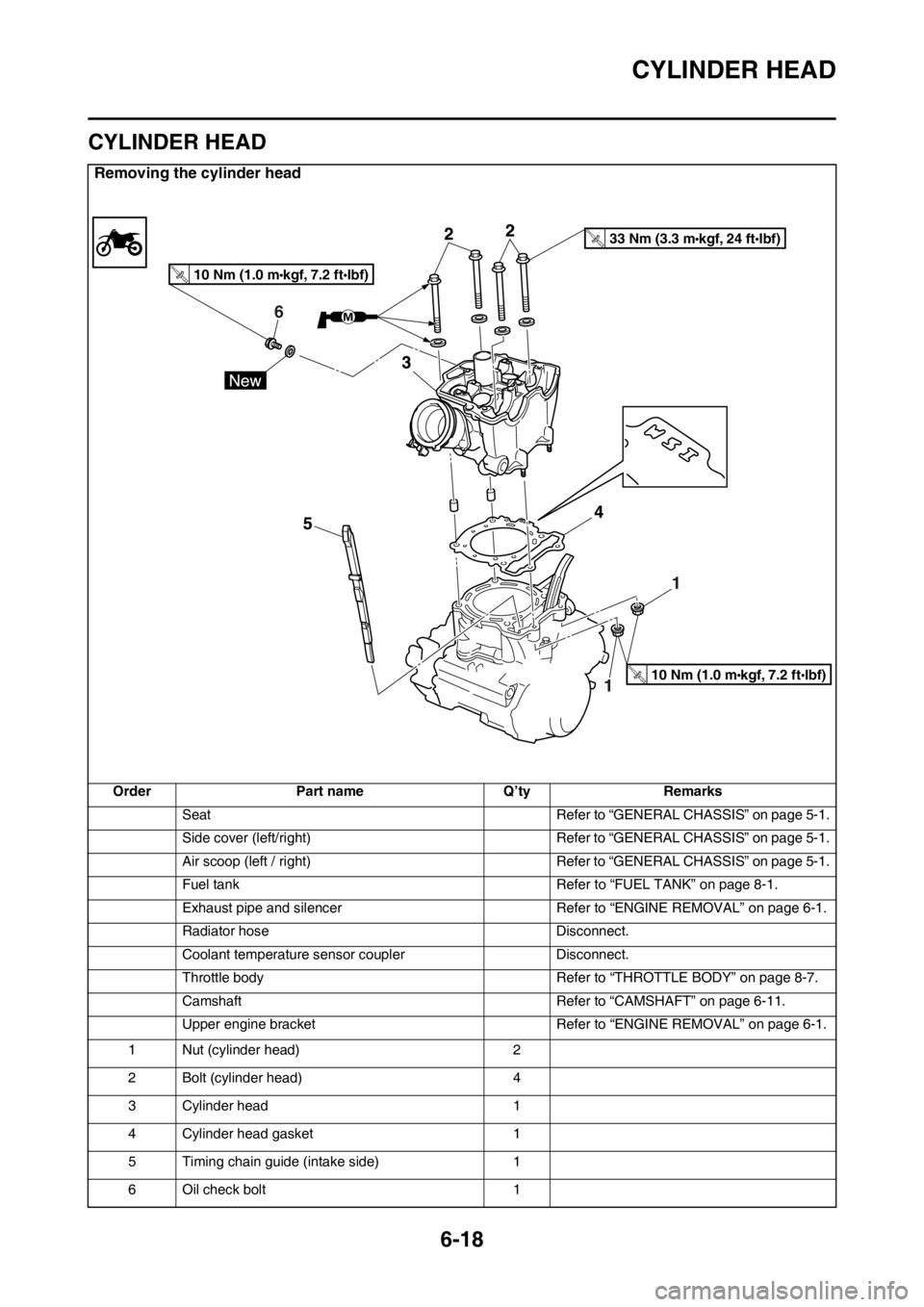

Page 247 of 428

CYLINDER HEAD

6-18

EAS2GB7244

CYLINDER HEAD

Removing the cylinder head

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Exhaust pipe and silencer Refer to “ENGINE REMOVAL” on page 6-1.

Radiator hose Disconnect.

Coolant temperature sensor coupler Disconnect.

Throttle body Refer to “THROTTLE BODY” on page 8-7.

Camshaft Refer to “CAMSHAFT” on page 6-11.

Upper engine bracket Refer to “ENGINE REMOVAL” on page 6-1.

1 Nut (cylinder head) 2

2 Bolt (cylinder head) 4

3 Cylinder head 1

4 Cylinder head gasket 1

5 Timing chain guide (intake side) 1

6 Oil check bolt 1

6

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

33 Nm (3.3 m kgf, 24 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

Page 263 of 428

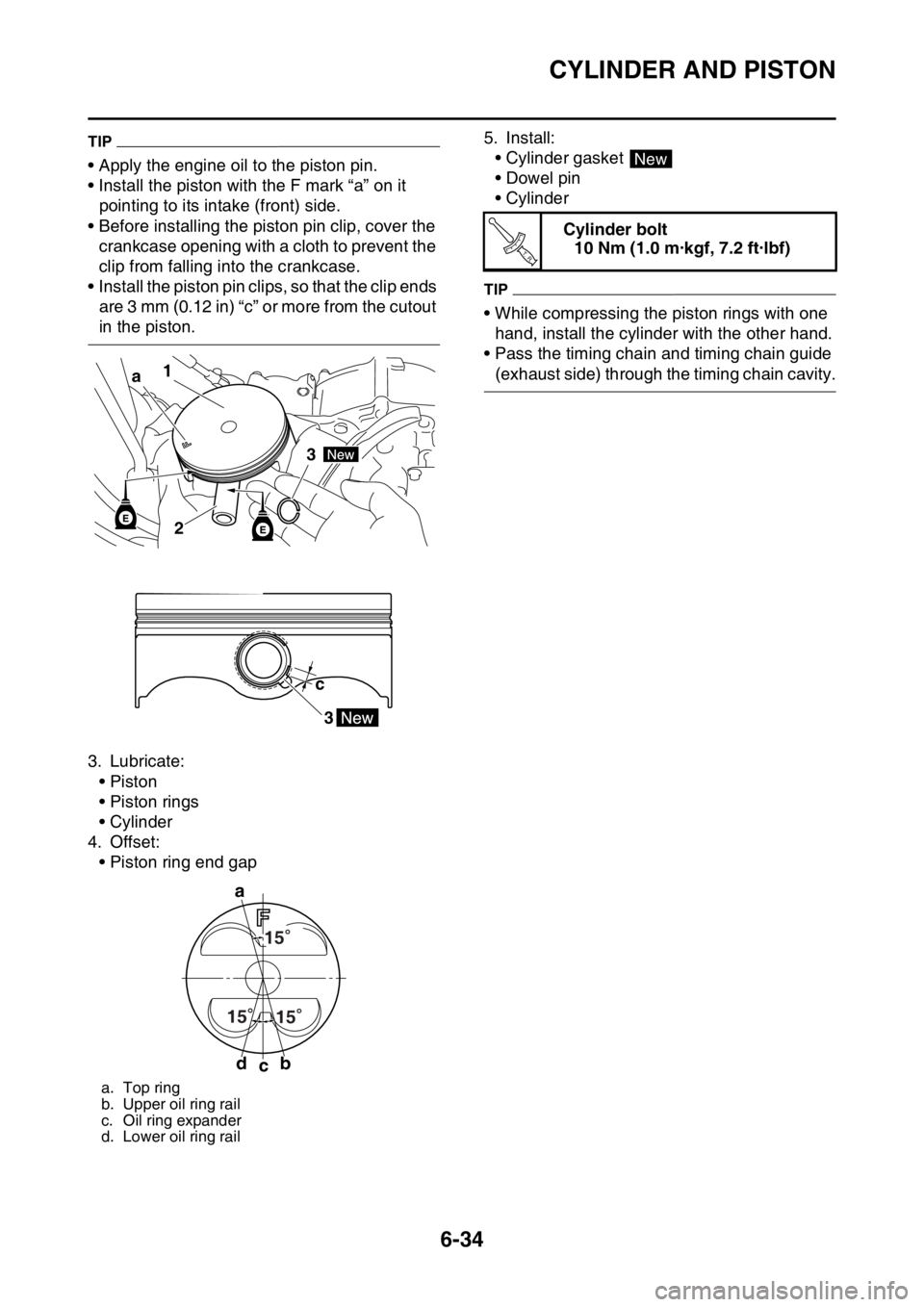

CYLINDER AND PISTON

6-34

TIP

• Apply the engine oil to the piston pin.

• Install the piston with the F mark “a” on it

pointing to its intake (front) side.

• Before installing the piston pin clip, cover the

crankcase opening with a cloth to prevent the

clip from falling into the crankcase.

• Install the piston pin clips, so that the clip ends

are 3 mm (0.12 in) “c” or more from the cutout

in the piston.

3. Lubricate:

•Piston

• Piston rings

• Cylinder

4. Offset:

• Piston ring end gap5. Install:

• Cylinder gasket

• Dowel pin

• Cylinder

TIP

• While compressing the piston rings with one

hand, install the cylinder with the other hand.

• Pass the timing chain and timing chain guide

(exhaust side) through the timing chain cavity.

a. Top ring

b. Upper oil ring rail

c. Oil ring expander

d. Lower oil ring rail

1

3

2 a

3 c

a

db

c15

15

15

Cylinder bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

New

T R..

Page 269 of 428

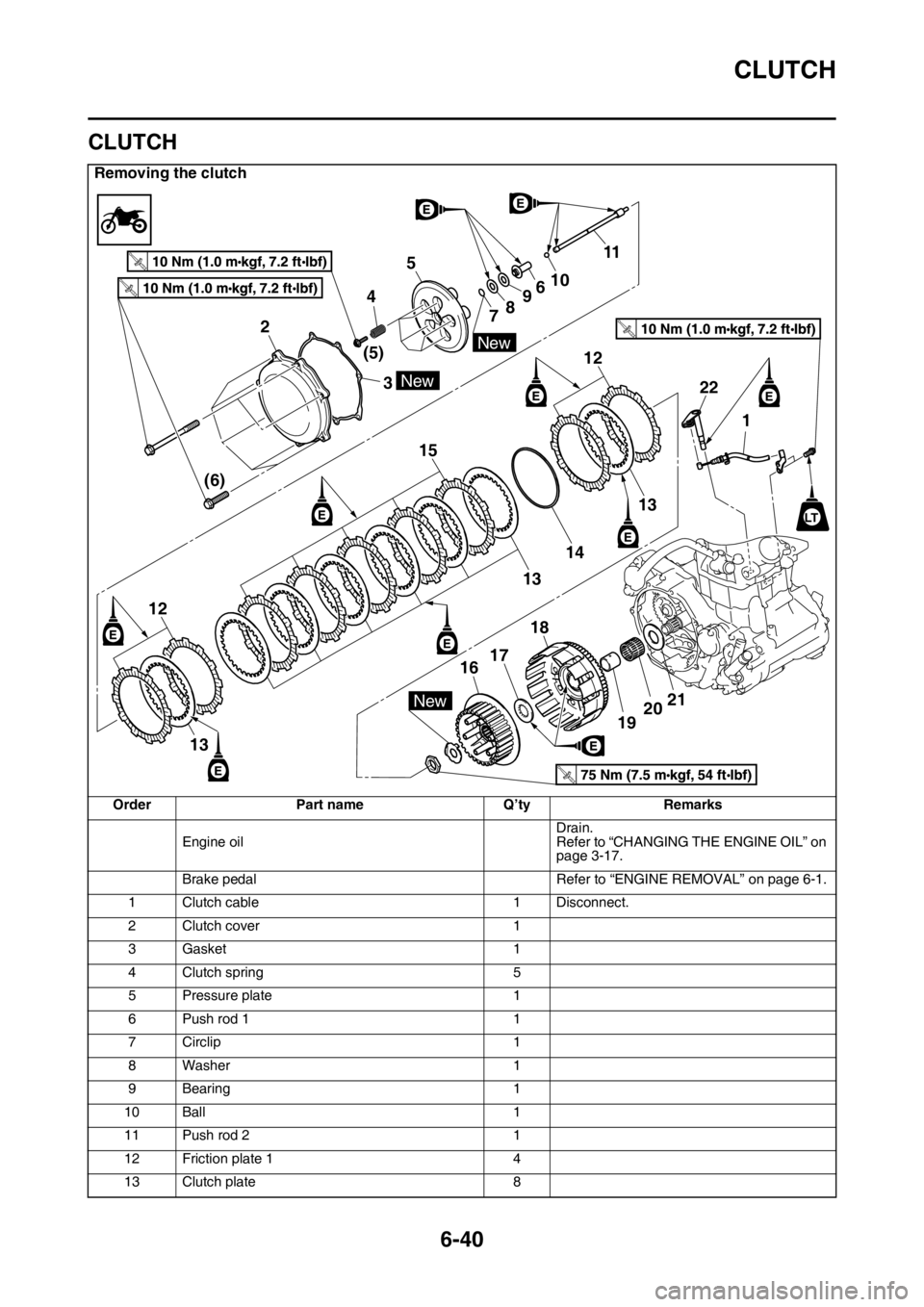

CLUTCH

6-40

EAS2GB7265

CLUTCH

Removing the clutch

Order Part name Q’ty Remarks

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-17.

Brake pedal Refer to “ENGINE REMOVAL” on page 6-1.

1 Clutch cable 1 Disconnect.

2 Clutch cover 1

3Gasket 1

4 Clutch spring 5

5 Pressure plate 1

6 Push rod 1 1

7 Circlip 1

8Washer 1

9 Bearing 1

10 Ball 1

11 Push rod 2 1

12 Friction plate 1 4

13 Clutch plate 8

New

New

New

2

3 45

(5)

(6)78961011

12

22

1

15

12

13

13

18

1920 17

16

14

13

T.R.

T.R.

T.R.

T.R.

LT

21

Page 271 of 428

CLUTCH

6-42

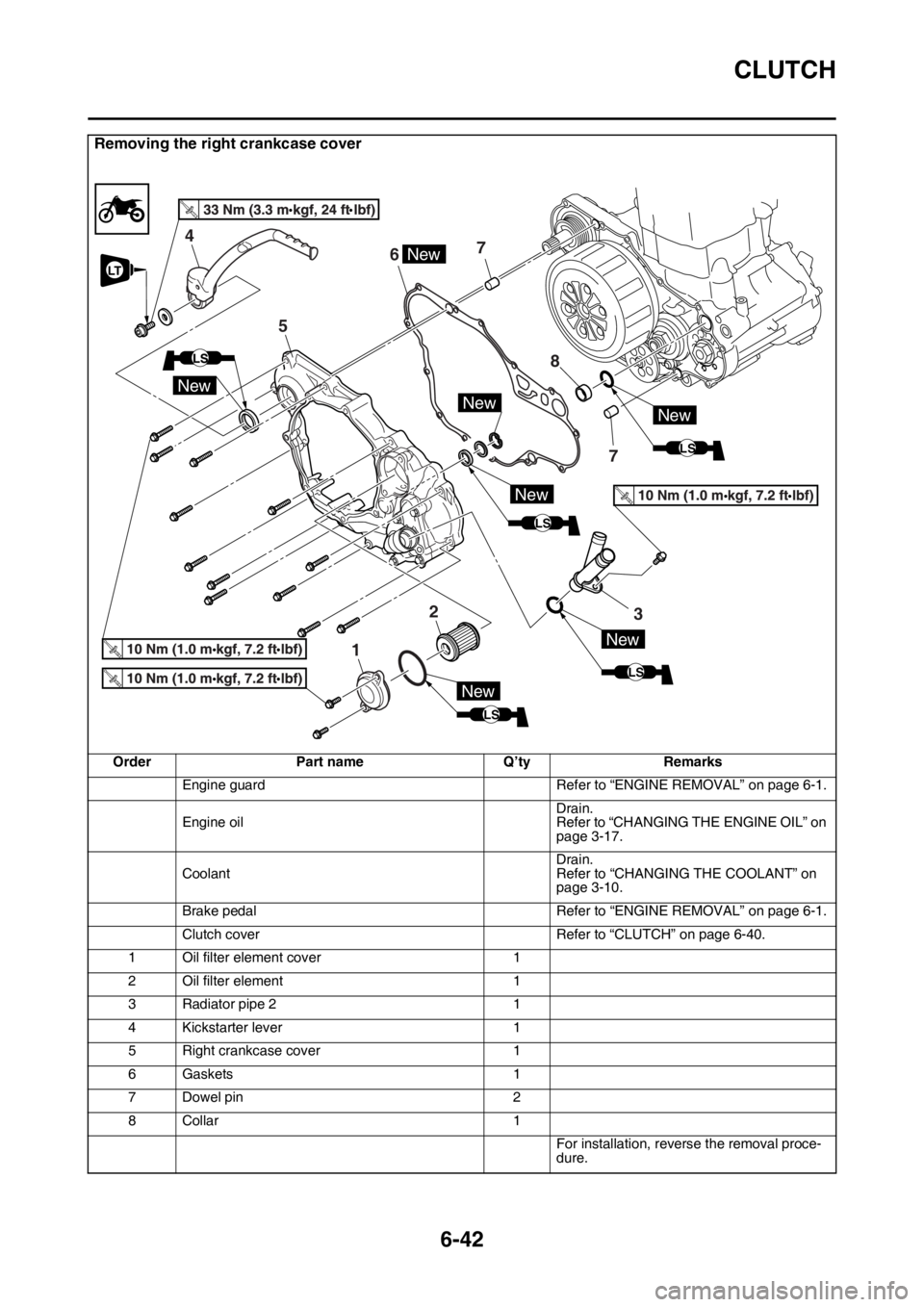

Removing the right crankcase cover

Order Part name Q’ty Remarks

Engine guard Refer to “ENGINE REMOVAL” on page 6-1.

Engine oilDrain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-17.

CoolantDrain.

Refer to “CHANGING THE COOLANT” on

page 3-10.

Brake pedal Refer to “ENGINE REMOVAL” on page 6-1.

Clutch cover Refer to “CLUTCH” on page 6-40.

1 Oil filter element cover 1

2 Oil filter element 1

3 Radiator pipe 2 1

4 Kickstarter lever 1

5 Right crankcase cover 1

6 Gaskets 1

7 Dowel pin 2

8Collar 1

For installation, reverse the removal proce-

dure.

T.R.

LS

New

New

67

2

5

4

1

7 8

New

3

LS

New

New

LS

NewNew

LT

LS

Page 274 of 428

CLUTCH

6-45

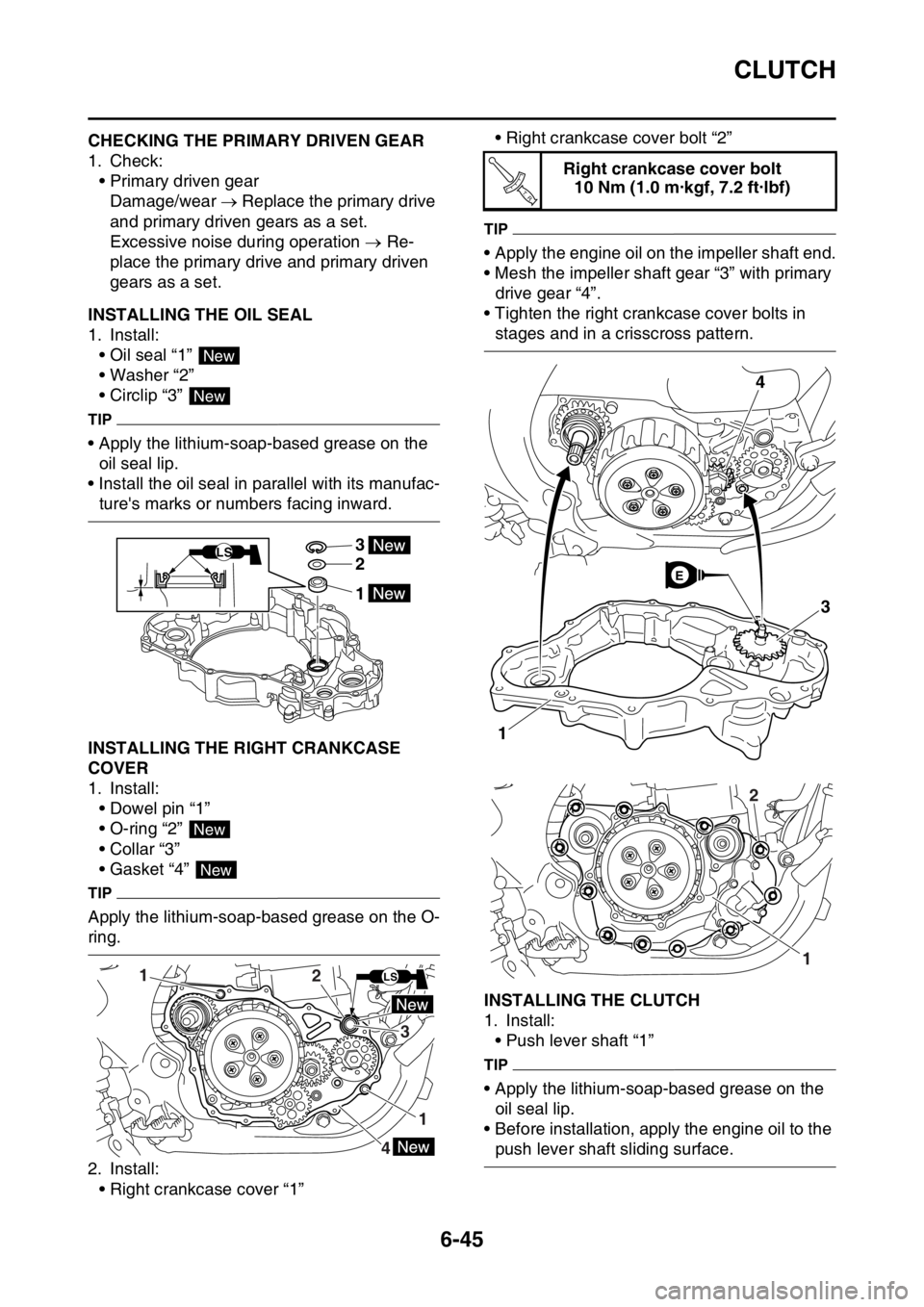

EAS2GB7276CHECKING THE PRIMARY DRIVEN GEAR

1. Check:

• Primary driven gear

Damage/wear Replace the primary drive

and primary driven gears as a set.

Excessive noise during operation Re-

place the primary drive and primary driven

gears as a set.

EAS2GB7277INSTALLING THE OIL SEAL

1. Install:

• Oil seal “1”

• Washer “2”

• Circlip “3”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Install the oil seal in parallel with its manufac-

ture's marks or numbers facing inward.

EAS2GB7278INSTALLING THE RIGHT CRANKCASE

COVER

1. Install:

• Dowel pin “1”

• O-ring “2”

• Collar “3”

• Gasket “4”

TIP

Apply the lithium-soap-based grease on the O-

ring.

2. Install:

• Right crankcase cover “1”• Right crankcase cover bolt “2”

TIP

• Apply the engine oil on the impeller shaft end.

• Mesh the impeller shaft gear “3” with primary

drive gear “4”.

• Tighten the right crankcase cover bolts in

stages and in a crisscross pattern.

EAS2GB7279INSTALLING THE CLUTCH

1. Install:

• Push lever shaft “1”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Before installation, apply the engine oil to the

push lever shaft sliding surface.

New

New

3

2

1

LS

New

New

1

1

3

2

4

LS

Right crankcase cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

T R..

3

1

4

E

1

2