relay YAMAHA WR 250F 2017 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 388 of 432

FUEL INJECTION SYSTEM

9-52

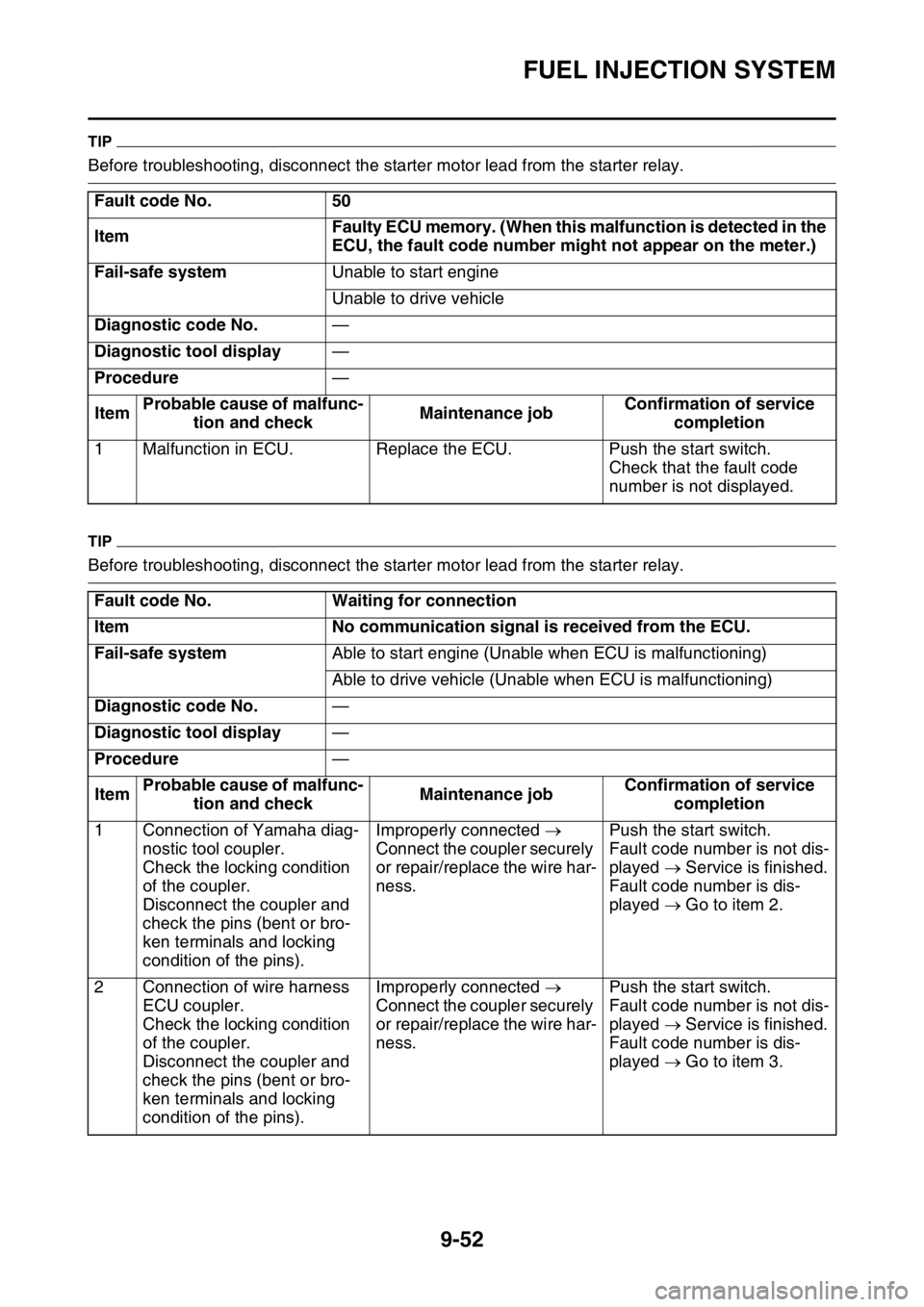

TIP

Before troubleshooting, disconnect the starter motor lead from the starter relay.

TIP

Before troubleshooting, disconnect the starter motor lead from the starter relay. Fault code No. 50

ItemFaulty ECU memory. (When this malfunction is detected in the

ECU, the fault code number might not appear on the meter.)

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.—

Diagnostic tool display—

Procedure—

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Malfunction in ECU. Replace the ECU. Push the start switch.

Check that the fault code

number is not displayed.

Fault code No. Waiting for connection

Item No communication signal is received from the ECU.

Fail-safe systemAble to start engine (Unable when ECU is malfunctioning)

Able to drive vehicle (Unable when ECU is malfunctioning)

Diagnostic code No.—

Diagnostic tool display—

Procedure—

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of Yamaha diag-

nostic tool coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3.

Page 391 of 432

FUEL INJECTION SYSTEM

9-55

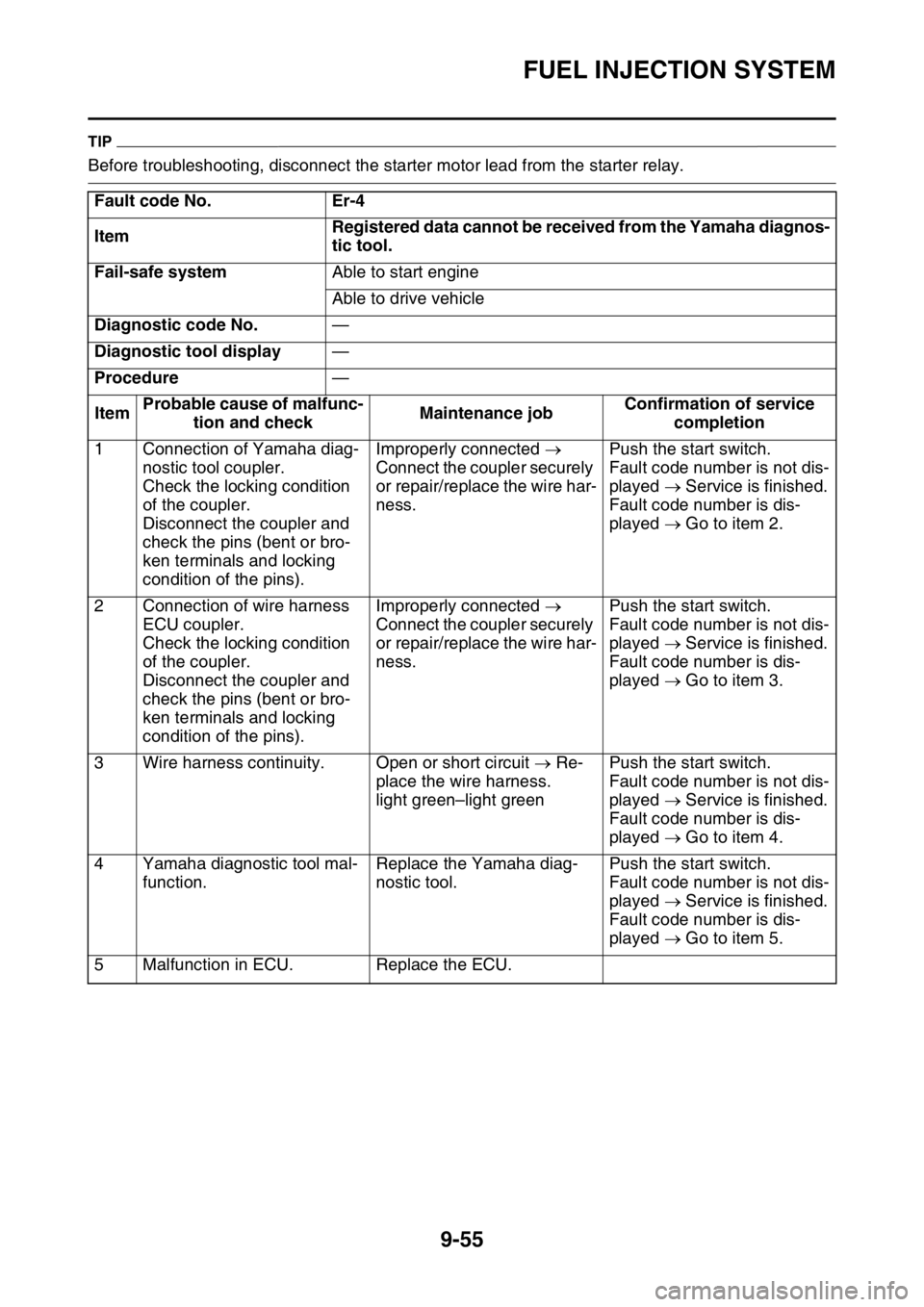

TIP

Before troubleshooting, disconnect the starter motor lead from the starter relay.

Fault code No. Er-4

ItemRegistered data cannot be received from the Yamaha diagnos-

tic tool.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.—

Diagnostic tool display—

Procedure—

ItemProbable cause of malfunc-

tion and checkMaintenance jobConfirmation of service

completion

1 Connection of Yamaha diag-

nostic tool coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

light green–light greenPush the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 4.

4 Yamaha diagnostic tool mal-

function.Replace the Yamaha diag-

nostic tool.Push the start switch.

Fault code number is not dis-

played Service is finished.

Fault code number is dis-

played Go to item 5.

5 Malfunction in ECU. Replace the ECU.

Page 393 of 432

FUEL PUMP SYSTEM

9-57

1. Joint connector

2. Joint connector

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

26.Fuel pump

30.Joint connector

36.Engine stop switch

48.Frame ground

Page 399 of 432

ELECTRICAL COMPONENTS

9-63

1. Intake air temperature sensor

2. Intake air pressure sensor

3. Throttle position sensor

4. Starter relay

5. Main fuse

6. Headlight relay

7. Starting circuit cut-off relay

8. Lean angle sensor

9. Radiator fan motor fuse

10.Radiator fan motor relay

11.Main relay

12.Coolant temperature sensor

Page 408 of 432

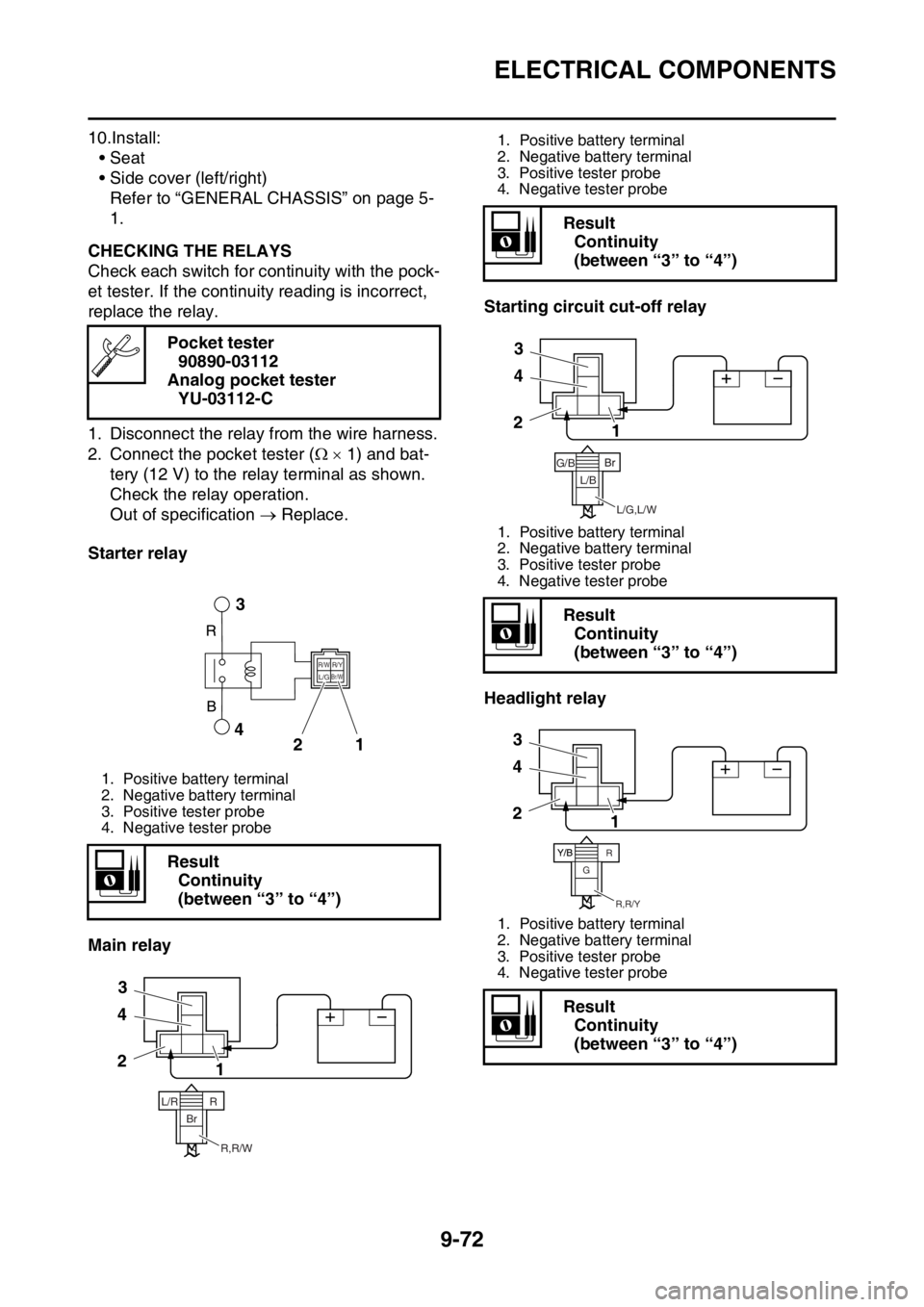

ELECTRICAL COMPONENTS

9-72

10.Install:

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GBB386CHECKING THE RELAYS

Check each switch for continuity with the pock-

et tester. If the continuity reading is incorrect,

replace the relay.

1. Disconnect the relay from the wire harness.

2. Connect the pocket tester ( 1) and bat-

tery (12 V) to the relay terminal as shown.

Check the relay operation.

Out of specification Replace.

Starter relay

Main relayStarting circuit cut-off relay

Headlight relay Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

1. Positive battery terminal

2. Negative battery terminal

3. Positive tester probe

4. Negative tester probe

Result

Continuity

(between “3” to “4”)

21 3

4

R/WBr/WR/YL/G

1 23

4

L/R

BrR

R,R/W

1. Positive battery terminal

2. Negative battery terminal

3. Positive tester probe

4. Negative tester probe

Result

Continuity

(between “3” to “4”)

1. Positive battery terminal

2. Negative battery terminal

3. Positive tester probe

4. Negative tester probe

Result

Continuity

(between “3” to “4”)

1. Positive battery terminal

2. Negative battery terminal

3. Positive tester probe

4. Negative tester probe

Result

Continuity

(between “3” to “4”)

1 23

4

G/B

L/B

L/G,L/W

1 23

4

R,R/Y

GR

Page 409 of 432

ELECTRICAL COMPONENTS

9-73

Radiator fan motor relay

EAS2GBB387CHECKING THE DIODE

1. Check:

•Diode

Out of specification Replace.

TIP

The pocket tester and the analog pocket tester

readings are shown in the following table.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Disconnect the diode from the wire harness.b. Connect the pocket tester ( 1) to the di-

ode coupler as shown.

c. Check the diode for continuity.

d. Check the diode for no continuity.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB388CHECKING THE IGNITION SPARK GAP

1. Check:

• Ignition spark gap

Out of specification Perform the ignition

system troubleshooting, starting with step 4.

Refer to “TROUBLESHOOTING” on page 9-

4.

TIP

If the ignition spark gap is within specification,

the ignition system circuit is operating normally.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the spark plug cap from the spark

plug.

b. Connect the ignition checker “1” as shown.

c. Push the engine stop switch.

d. Measure the ignition spark gap “a”.

1. Positive battery terminal

2. Negative battery terminal

3. Positive tester probe

4. Negative tester probe

Result

Continuity

(between “3” to “4”)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

No continuity

Tester positive lead Sky blue

“1”

Tester negative lead Green/

Black “2”

Continuity

Tester positive lead Green/

Black “2”

Tester negative lead Sky blue

“1”

No continuity

Tester positive lead Red “3”

Tester negative lead Red/Blue

“4”

Continuity

Tester positive lead Red/Blue

“4”

Tester negative lead Red “3”

1 23

4

P/L

R/L

R/W

Br,R/W

Minimum ignition spark gap

6.0 mm (0.24 in)

Ignition checker

90890-06754

Oppama pet–4000 spark checker

YM-34487

2. Spark plug cap

2

1

4

3

R Sb

G/B R/L

Page 420 of 432

TROUBLESHOOTING

10-1

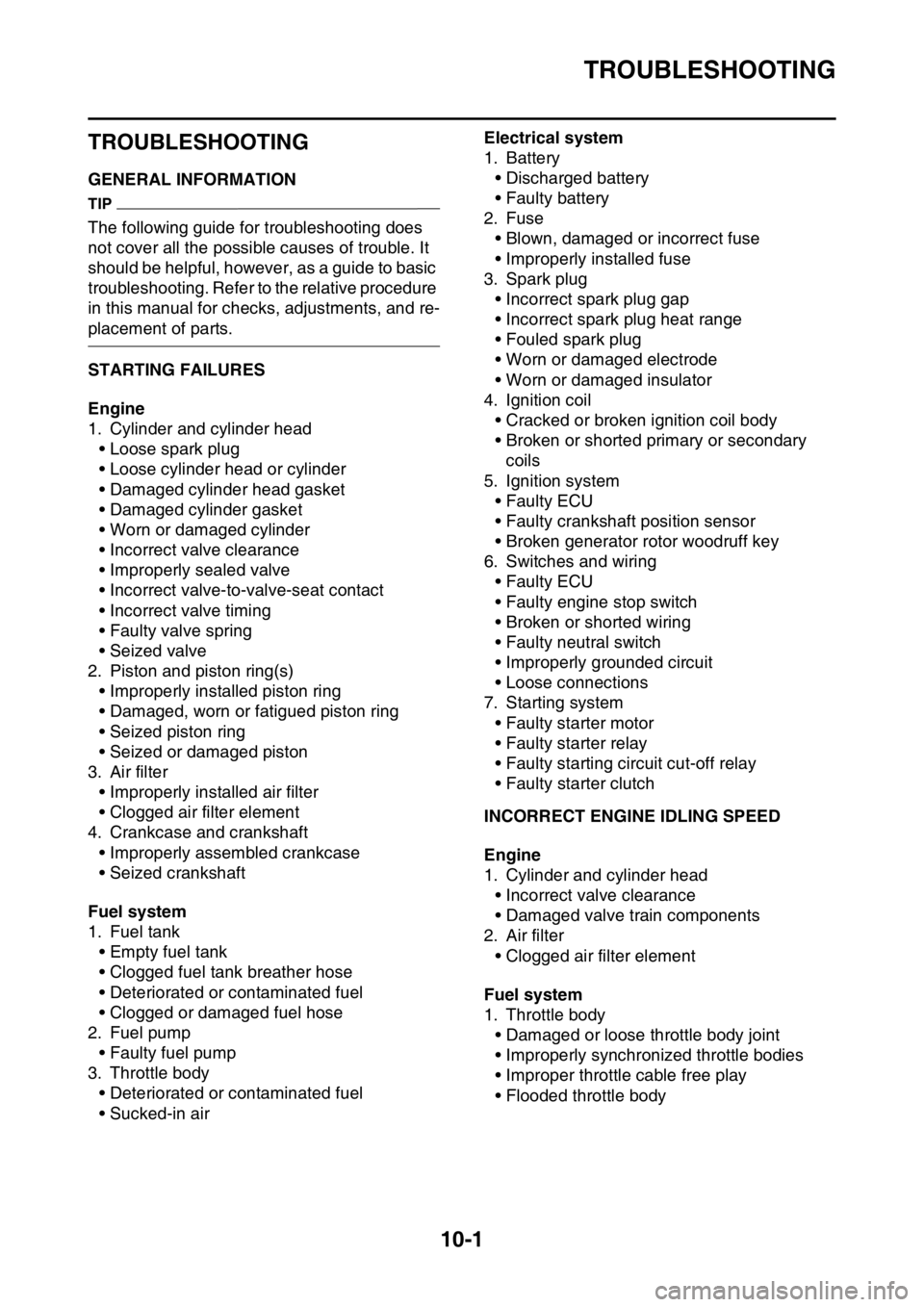

EAS2GBB405

TROUBLESHOOTING

EAS2GBB406GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re-

placement of parts.

EAS2GBB407STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in airElectrical system

1. Battery

• Discharged battery

• Faulty battery

2. Fuse

• Blown, damaged or incorrect fuse

• Improperly installed fuse

3. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

4. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

5. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

6. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

7. Starting system

• Faulty starter motor

• Faulty starter relay

• Faulty starting circuit cut-off relay

• Faulty starter clutch

EAS2GBB408INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Page 426 of 432

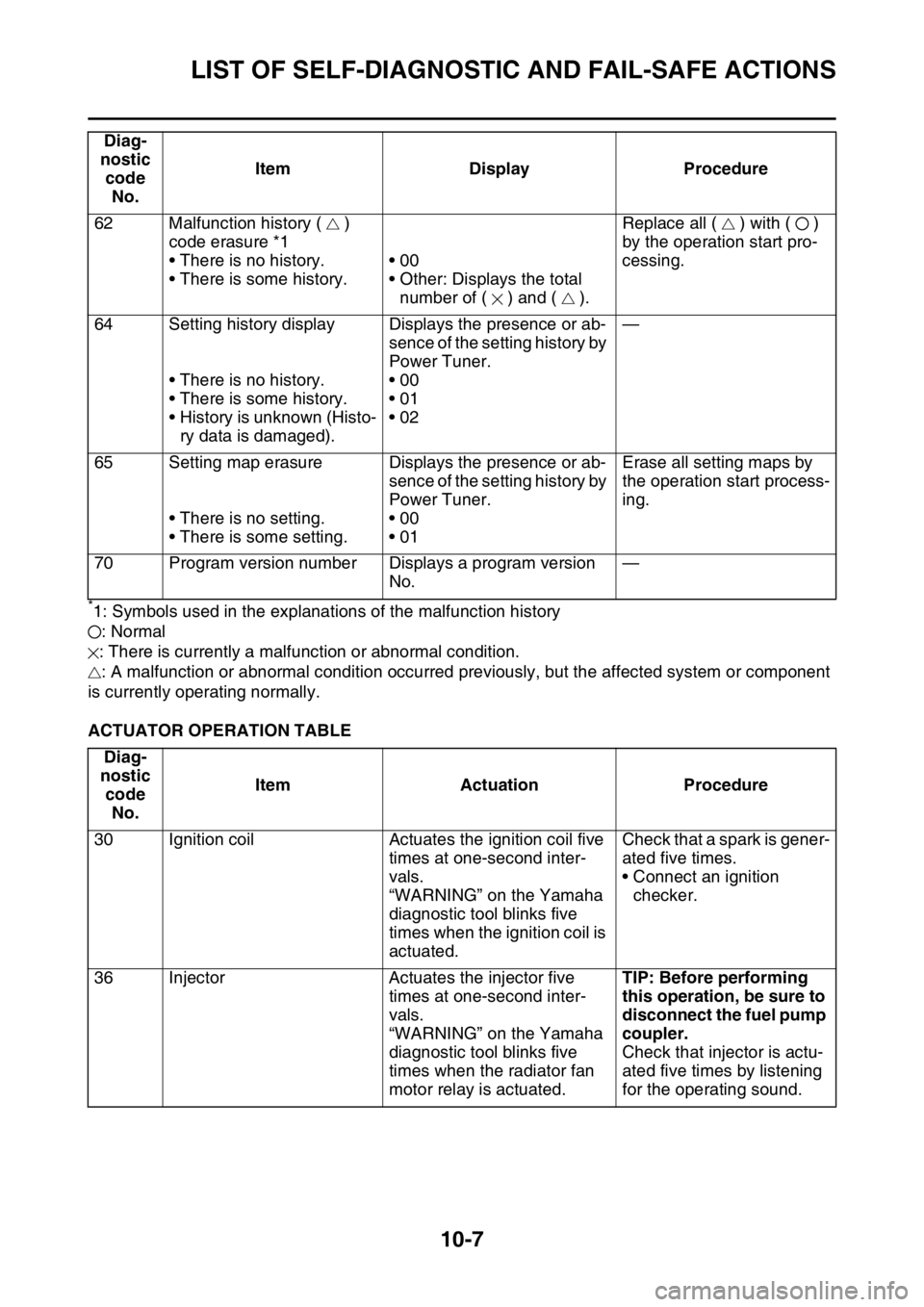

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

10-7

*1: Symbols used in the explanations of the malfunction history

: Normal

: There is currently a malfunction or abnormal condition.

: A malfunction or abnormal condition occurred previously, but the affected system or component

is currently operating normally.

ACTUATOR OPERATION TABLE62 Malfunction history ( )

code erasure *1

• There is no history.

• There is some history.•00

• Other: Displays the total

number of ( ) and ( ).Replace all ( ) with ( )

by the operation start pro-

cessing.

64 Setting history display

• There is no history.

• There is some history.

• History is unknown (Histo-

ry data is damaged).Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01

•02—

65 Setting map erasure

• There is no setting.

• There is some setting.Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01Erase all setting maps by

the operation start process-

ing.

70 Program version number Displays a program version

No.—

Diag-

nostic

code

No.Item Actuation Procedure

30 Ignition coil Actuates the ignition coil five

times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the ignition coil is

actuated.Check that a spark is gener-

ated five times.

• Connect an ignition

checker.

36 Injector Actuates the injector five

times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the radiator fan

motor relay is actuated.TIP: Before performing

this operation, be sure to

disconnect the fuel pump

coupler.

Check that injector is actu-

ated five times by listening

for the operating sound. Diag-

nostic

code

No.Item Display Procedure

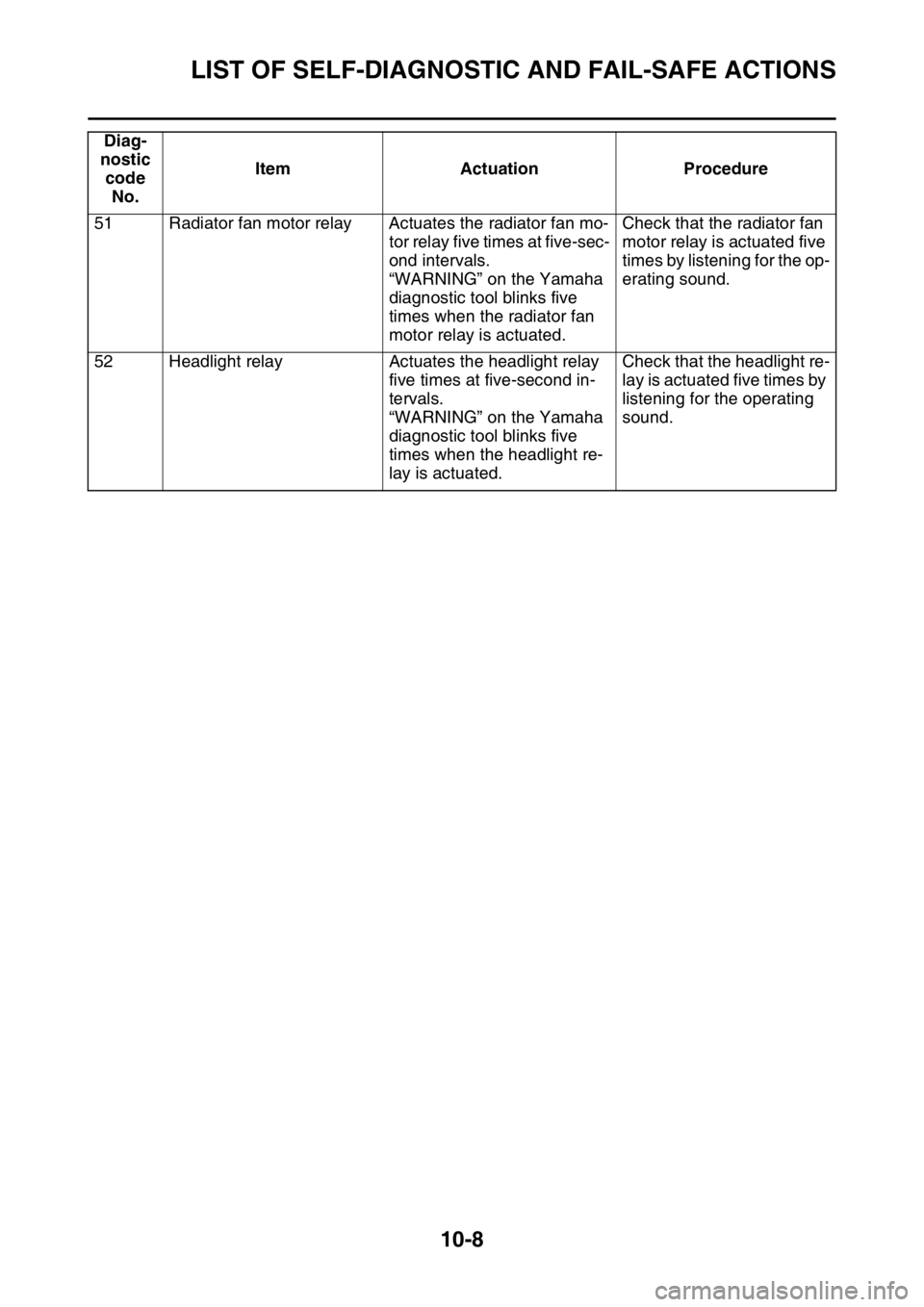

Page 427 of 432

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

10-8

51 Radiator fan motor relay Actuates the radiator fan mo-

tor relay five times at five-sec-

ond intervals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the radiator fan

motor relay is actuated.Check that the radiator fan

motor relay is actuated five

times by listening for the op-

erating sound.

52 Headlight relay Actuates the headlight relay

five times at five-second in-

tervals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the headlight re-

lay is actuated.Check that the headlight re-

lay is actuated five times by

listening for the operating

sound. Diag-

nostic

code

No.Item Actuation Procedure

Page 428 of 432

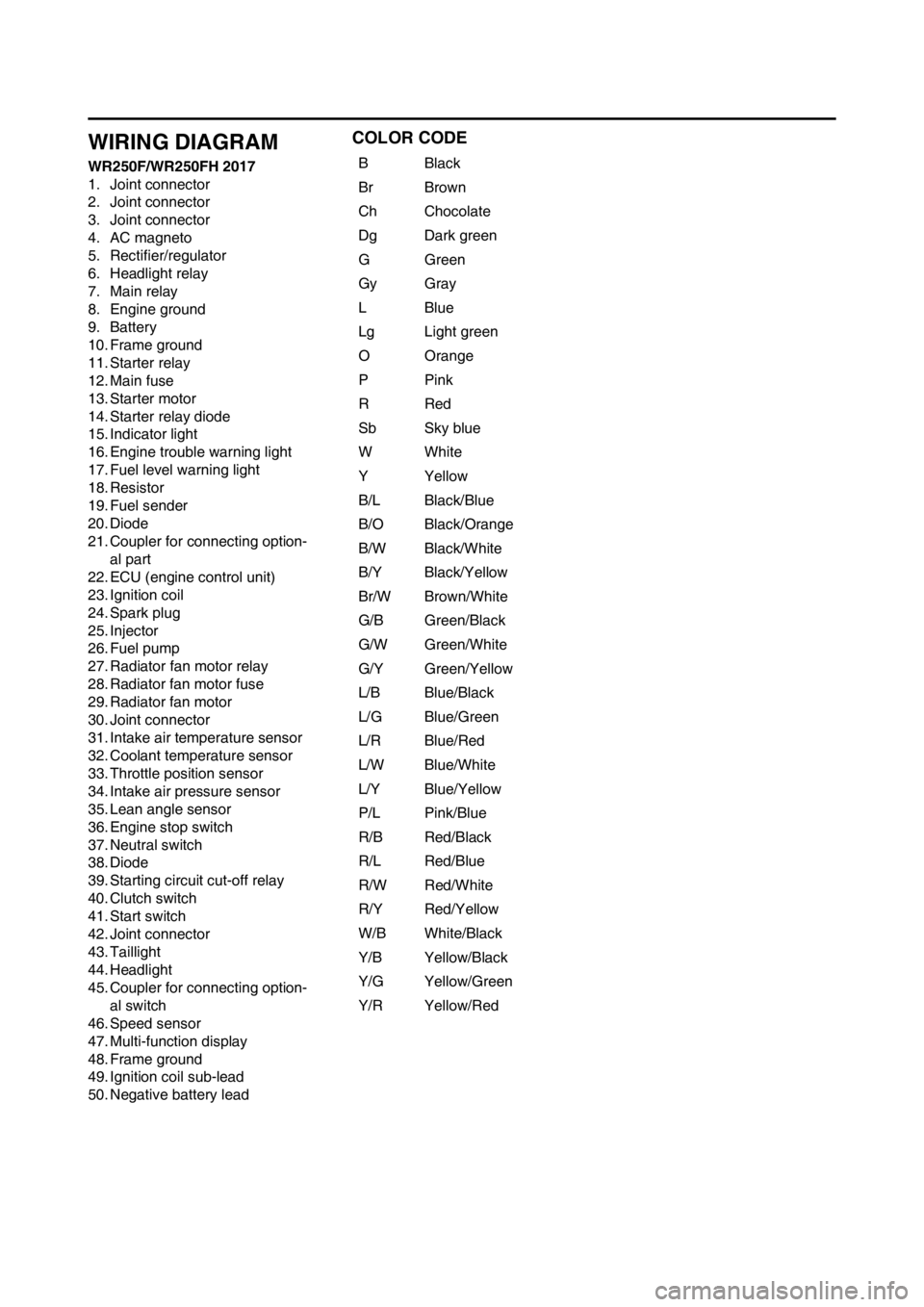

EAS2GBB426

WIRING DIAGRAM

WR250F/WR250FH 2017

1. Joint connector

2. Joint connector

3. Joint connector

4. AC magneto

5. Rectifier/regulator

6. Headlight relay

7. Main relay

8. Engine ground

9. Battery

10. Frame ground

11. Starter relay

12. Main fuse

13. Starter motor

14. Starter relay diode

15. Indicator light

16. Engine trouble warning light

17. Fuel level warning light

18. Resistor

19. Fuel sender

20. Diode

21. Coupler for connecting option-

al part

22. ECU (engine control unit)

23. Ignition coil

24. Spark plug

25. Injector

26. Fuel pump

27. Radiator fan motor relay

28. Radiator fan motor fuse

29. Radiator fan motor

30. Joint connector

31. Intake air temperature sensor

32. Coolant temperature sensor

33. Throttle position sensor

34. Intake air pressure sensor

35. Lean angle sensor

36. Engine stop switch

37. Neutral switch

38. Diode

39. Starting circuit cut-off relay

40. Clutch switch

41. Start switch

42. Joint connector

43. Taillight

44. Headlight

45. Coupler for connecting option-

al switch

46. Speed sensor

47. Multi-function display

48. Frame ground

49. Ignition coil sub-lead

50. Negative battery lead

EAS2GBB427

COLOR CODE

BBlack

Br Brown

Ch Chocolate

Dg Dark green

G Green

Gy Gray

LBlue

Lg Light green

O Orange

PPink

RRed

Sb Sky blue

WWhite

Y Yellow

B/L Black/Blue

B/O Black/Orange

B/W Black/White

B/Y Black/Yellow

Br/W Brown/White

G/B Green/Black

G/W Green/White

G/Y Green/Yellow

L/B Blue/Black

L/G Blue/Green

L/R Blue/Red

L/W Blue/White

L/Y Blue/Yellow

P/L Pink/Blue

R/B Red/Black

R/L Red/Blue

R/W Red/White

R/Y Red/Yellow

W/B White/Black

Y/B Yellow/Black

Y/G Yellow/Green

Y/R Yellow/Red