engine YAMAHA WR 400F 2000 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: WR 400F, Model: YAMAHA WR 400F 2000Pages: 654, PDF Size: 60.12 MB

Page 87 of 654

2 - 16

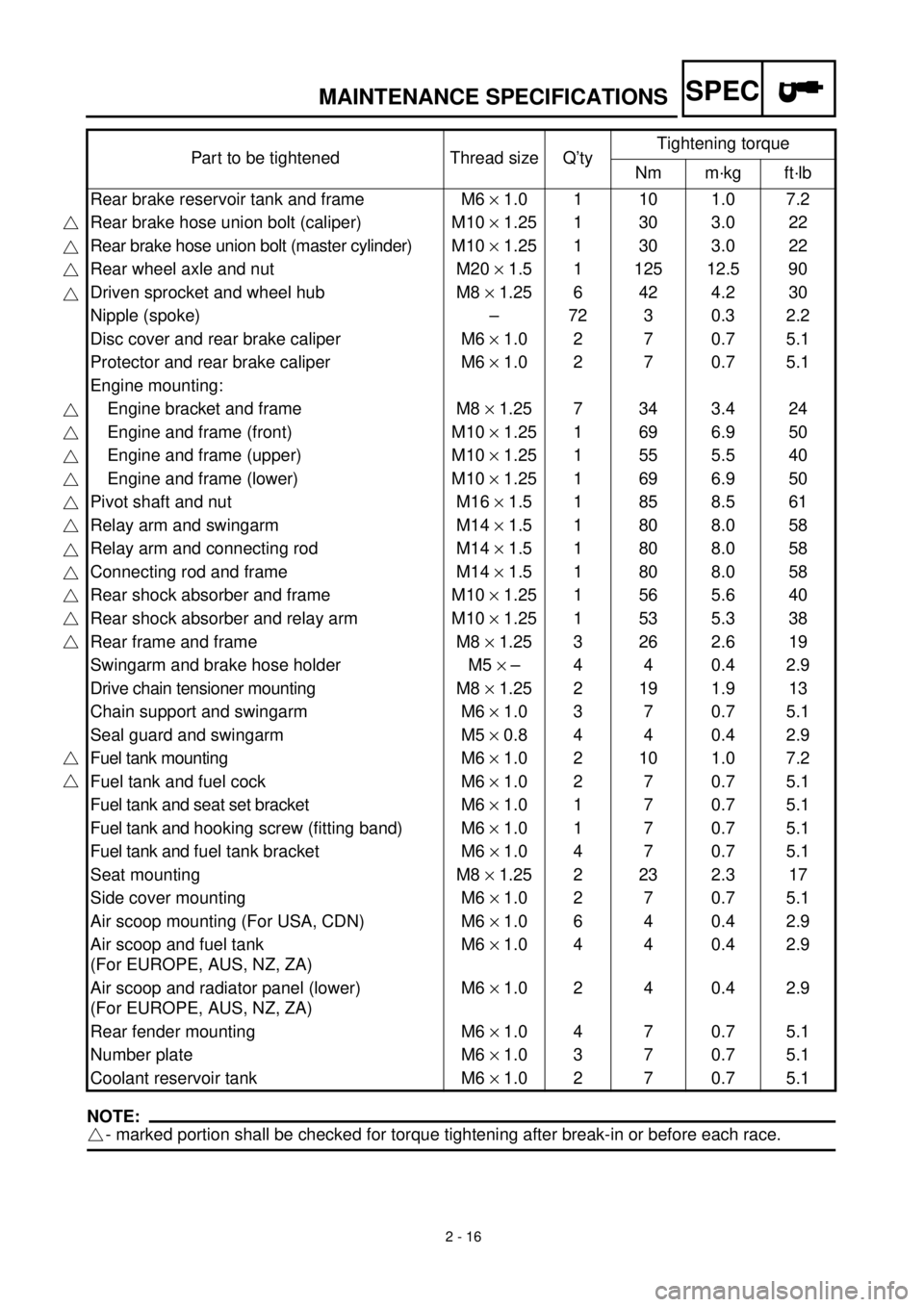

SPECMAINTENANCE SPECIFICATIONS

HINWEIS:NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear brake reservoir tank and frame M6 ´ 1.0 1 10 1.0 7.2

Rear brake hose union bolt (caliper) M10 ´ 1.25 1 30 3.0 22

Rear brake hose union bolt (master cylinder)M10 ´ 1.25 1 30 3.0 22

Rear wheel axle and nut M20 ´ 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 ´ 1.25 6 42 4.2 30

Nipple (spoke) – 72 3 0.3 2.2

Disc cover and rear brake caliper M6 ´ 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 ´ 1.0 2 7 0.7 5.1

Engine mounting:

Engine bracket and frame M8 ´ 1.25 7 34 3.4 24

Engine and frame (front) M10 ´ 1.25 1 69 6.9 50

Engine and frame (upper) M10 ´ 1.25 1 55 5.5 40

Engine and frame (lower) M10 ´ 1.25 1 69 6.9 50

Pivot shaft and nut M16 ´ 1.5 1 85 8.5 61

Relay arm and swingarm M14 ´ 1.5 1 80 8.0 58

Relay arm and connecting rod M14 ´ 1.5 1 80 8.0 58

Connecting rod and frame M14 ´ 1.5 1 80 8.0 58

Rear shock absorber and frame M10 ´ 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 ´ 1.25 1 53 5.3 38

Rear frame and frame M8 ´ 1.25 3 26 2.6 19

Swingarm and brake hose holder M5 ´ – 4 4 0.4 2.9

Drive chain tensioner mounting M8 ´ 1.25 2 19 1.9 13

Chain support and swingarm M6 ´ 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 ´ 0.8 4 4 0.4 2.9

Fuel tank mounting M6 ´ 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 ´ 1.0 2 7 0.7 5.1

Fuel tank and seat set bracket M6 ´ 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 ´ 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 ´ 1.0 4 7 0.7 5.1

Seat mounting M8 ´ 1.25 2 23 2.3 17

Side cover mounting M6 ´ 1.0 2 7 0.7 5.1

Air scoop mounting (For USA, CDN) M6 ´ 1.0 6 4 0.4 2.9

Air scoop and fuel tank

(For EUROPE, AUS, NZ, ZA)M6 ´ 1.0 4 4 0.4 2.9

Air scoop and radiator panel (lower)

(For EUROPE, AUS, NZ, ZA)M6 ´ 1.0 2 4 0.4 2.9

Rear fender mounting M6 ´ 1.0 4 7 0.7 5.1

Number plate M6 ´ 1.0 3 7 0.7 5.1

Coolant reservoir tank M6 ´ 1.0 2 7 0.7 5.1

Page 89 of 654

2 - 18

SPEC

GENERAL TORQUE SPECIFICATIONS/

DEFINITION OF UNITS

EC220001

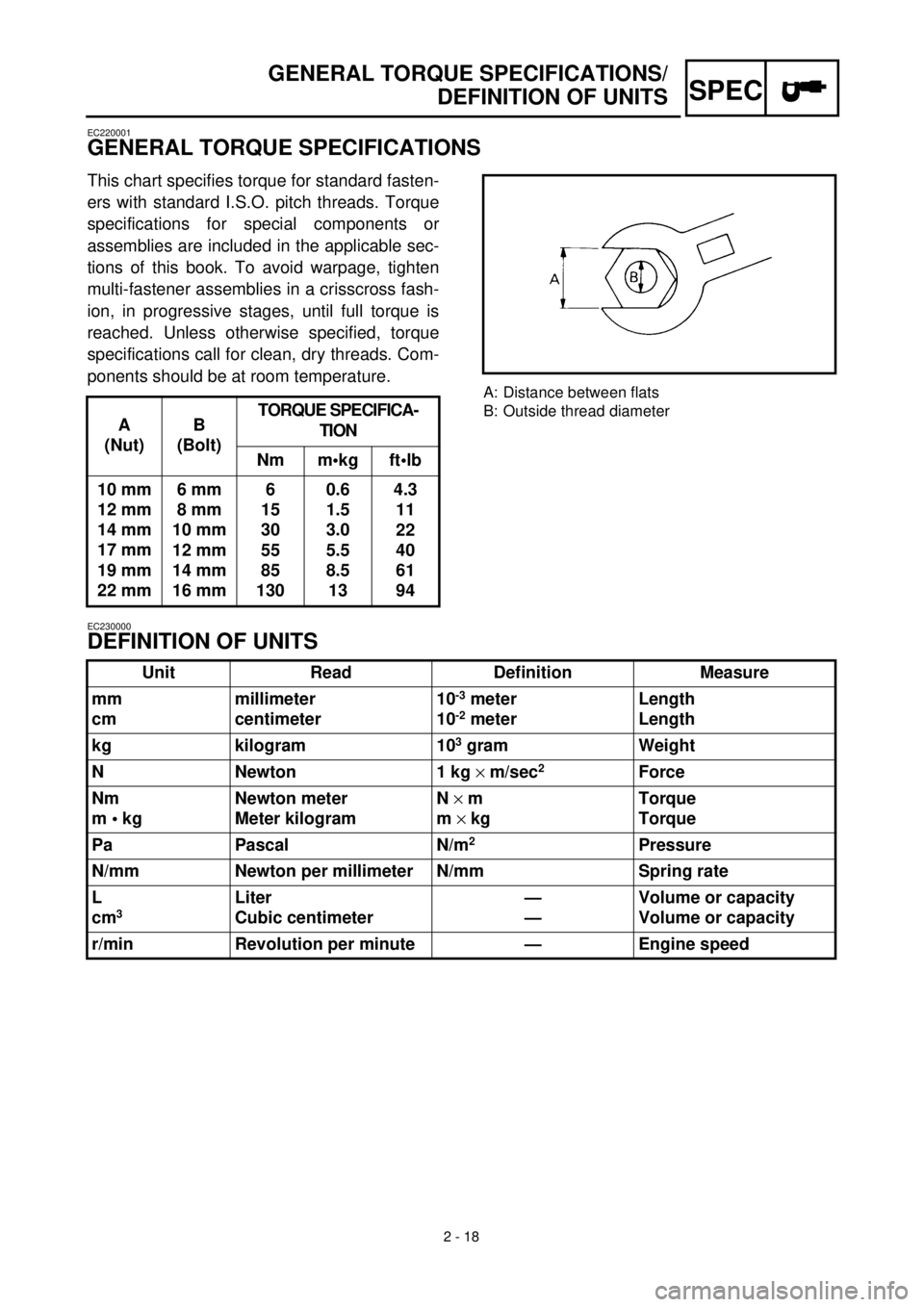

GENERAL TORQUE SPECIFICATIONS

This chart specifies torque for standard fasten-

ers with standard I.S.O. pitch threads. Torque

specifications for special components or

assemblies are included in the applicable sec-

tions of this book. To avoid warpage, tighten

multi-fastener assemblies in a crisscross fash-

ion, in progressive stages, until full torque is

reached. Unless otherwise specified, torque

specifications call for clean, dry threads. Com-

ponents should be at room temperature.

A

(Nut)B

(Bolt)TORQUE SPECIFICA-

TION

Nm m•kg ft•lb

10 mm

12 mm

14 mm

17 mm

19 mm

22 mm6 mm

8 mm

10 mm

12 mm

14 mm

16 mm6

15

30

55

85

1300.6

1.5

3.0

5.5

8.5

134.3

11

22

40

61

94

A: Distance between flats

B: Outside thread diameter

EC230000

DEFINITION OF UNITS

Unit Read Definition Measure

mm

cmmillimeter

centimeter10

-3

meter

10

-2

meterLength

Length

kg kilogram 10

3

gram Weight

N Newton 1 kg

´

m/sec

2

Force

Nm

m • kgNewton meter

Meter kilogramN

´

m

m

´

kgTorque

Torque

Pa Pascal N/m

2

Pressure

N/mm Newton per millimeter N/mm Spring rate

L

cm

3

Liter

Cubic centimeter—

—Volume or capacity

Volume or capacity

r/min Revolution per minute — Engine speed

Page 148 of 654

2 - 21

SPEC

CABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1

Hose guide

2

Brake hose

3

Regulator

4

Fuel tank breather hose

5

Oil tank breather hose

6

Clamp

7

“ENGINE STOP” button lead

8

Sub wire harness

9

Tail light lead

0

TPS (throttle position sensor) lead

A

Neutral switch lead

B

Oil hose

C

Cylinder head breather hose

D

CDI magneto lead

E

Hose holder

F

Clutch cable

G

Decompression cable

H

Lights switch lead

I

Carburetor breather hose

J

Overflow hose

K

Coolant reservoir tank breather hose

Pass the fuel tank breather

hose behind handlebar, then

insert it into the steering shaft

hole.

õ

Pass the decompression

cable, “ENGINE STOP” but-

ton lead and lights switch lead

under where the oil hose is

attached.

‚

Pass the “ENGINE STOP” but-

ton lead, regulator lead and

lights switch lead along the

inner and side of the decom-

pression cable.

ë

Fasten the CDI magneto lead,

neutral switch lead “ENGINE

STOP” button lead and lights

switch lead to the frame with a

plastic locking tie.äPass the “ENGINE STOP”

button lead and lights switch

lead along the inner side of

the oil tank breather hose.

ìFasten the sub wire harness,

“ENGINE STOP” button lead

and lights switch lead to the

frame with a plastic locking

tie.

íPass the cylinder head

breather hose along the right

side of the oil tank breather

hose.

îFasten the sub wire harness

to the frame with a plastic

locking tie and cut off the tie

end.

éFasten the TPS lead (in the

sub wire harness) under the

frame.

Page 149 of 654

SPEC

CHEMINEMENT DES CABLES

KABELFÜHRUNG

DIAGRAMA DE RUTA DE CABLES

KABELFÜHRUNG

1Kabelführung

2Bremsschlauch

3Regler

4Kraftstofftank-Belüftungsschlauch

5Öltank-Belüftungsschlauch

6Kabelbinder

7Motorstoppschalter-Kabel

8Nebenkabelsatz

9Rücklicht

0Drosselklappensensor-Kabel

ALeerlaufschalter-Kabel

BÖlschlauch

CZylinderkopf-Entlüftungsschlauch

DCDI-Schwungradmagnetzünder-Ka-

bel

ESchlauchhalterung

FKupplungszug

GDekompressionszug

HLichtschalterleitung

IVergaser-Entlüftungsschlauch

JAuslaufschutzschlauch

KKühlmittelausgleichstank-Lüftungs-

schlauch

Den Kraftstofftank-Belüftungs-

schlauch zwischen Lenker und Zugs-

trebe führen und das Ende durch die

Bohrung im Nummerschild führen.

õDen Dekompressionszug hinter dem

Öltank-Belüftungsschlauch und über

das Öltankrohr führen.

‚Das Motorstoppschalter-Kabel hinter

dem Dekompressionszug führen.

ëDas CDI-Schwungradmagnetzünder-

Kabel, Leerlaufschalter-Kabel und

Motorstoppschalter-Kabel mit wieder-

verwenden. Kabelbinder am Rahmen

befestigen.

äDas Motorstoppschalter-Kabel hinter

dem Öltank-Belüftungsschlauch füh-

ren.

ìDen Nebenkabelbaum und das Mo-

torstoppschalter-Kabel mit mehrf. ver-

wendb. Kabelbinder am Rahmen be-

festigen.

íDen Zylinderkopf-Entlüftungs-

schlauch rechts vom Öltank-Belüf-

tungsschlauch führen.

îDen Nebenkabelbaum mit einem Ka-

belbinder am Rahmen befestigen,

und das Schlauchbandende ab-

schneiden.

éDie TPS-Leitung (im Nebenkabel-

baum) unter dem Rahmen verlegen.

CHEMINEMENT DES

CABLES

1Guide de flexible

2Tuyau de frein

3Régulateur

4Reniflard de réservoir d’essence

5Reniflard de réservoir d’huile

6Bride

7Fil de bouton d’arrêt du moteur

“ENGINE STOP”

8Faisceau de fils secondaires

9Fil de feux arrière

0Fil de TPS (copteur du papillon d’accélé-

ration)

AFil de contacteur de point mort

BFlexible d’huile

CReniflard de culasse

DFil de magnéto CDI

ESupport de flexible

FCâble d’embrayage

GCâble du décompresseur

HFil de commutateur de feux

IReniflard de carburateur

JFlexible de trop-plein

KFlexible de reniflard du réservoir de

liquide de refroidissement

Faire passer le flexible de reniflard du

réservoir d’essence derrière le guidon,

puis l’insérer dans le trou de l’axe de la

colonne de direction.

õFaire passer le câble de décompression, le

fil de bouton d’arrêt du moteur “ENGINE

STOP” et le fil de commutateur de feux

sous l’endroit où le flexible d’huile est

attaché.

‚Faire passer le fil de bouton d’arrêt du

moteur “ENGINE STOP”, le fil de régu-

lateur et le fil de commutateur de feux le

long du côté intérieur du câble de décom-

pression.

ëAttacher le fil de magnéto CDI, le fil de

commutateur de point mort, le fil du bou-

ton d’arrêt du moteur “ENGINE STOP”

et le fil de commutateur de feux au cadre

à l’aide d’une attache en plastique.

äFaire passer le fil de bouton d’arrêt du

moteur “ENGINE STOP” et le fil de com-

mutateur de feux le long du côté intérieur

du flexible de reniflard du réservoir

d’huile.

ìAttacher le faisceau de fils secondaires, le

fil de bouton d’arrêt du moteur “ENGINE

STOP” et le fil de commutateur de feux

au cadre à l'aide d’une attache en plasti-

que.

íFaire passer le reniflard de culasse le long

du côté droit du reniflard du réservoir

d’huile.

îAttacher le faisceau de fils secondaires au

cadre à l’aide d’une attache en plastique

et couper l’extrémité de l’attache.

éAttacher le fil de TPS (dans le faisceau de

fils secondaires) sous le cadre.

2 - 21

DIAGRAMA DE RUTA DE

CABLES

1Guía del tubo

2Tubo del freno

3Regulador

4Tubo respiradero del depósito de combus-

tible

5Tubo respiradero del depósito de aceite

6Abrazadera

7Cable del botón de parada del motor

“ENGINE STOP”

8Sub-cableado

9Cable de la luz trasera

0Cable TPS (sensor de posición del acele-

rador)

ACable del interruptor de punto muerto

BTubo de aceite

CTubo respiradero de la culata

DCable del magneto CDI

ESoporte del tubo

FCable del embrague

GCable de descompresión

HCable del interruptor de las luces

ITubo respiradero del carburador

JTubo de desbordamiento

KTubo respiradero del depósito de reserva

del refrigerante

Pasar el tubo respiradero del depósito de

combustible por detrás del manillar y des-

pués insertarlo en del orificio del eje de la

dirección.

õPasar el cable de descompresión, el cable

del botón de parada del motor “ENGINE

STOP” y el cable del interruptor de las

luces por debajo de la zona de colocación

del tubo de aceite.

‚Pasar el cable del botón de parada del

motor “ENGINE STOP”, el cable del

regulador y el cable del interruptor de las

luces por la parte interna y lateral del

cable de descompresión.

ëSujetar el cable del magneto CDI, el cable

del interruptor de punto muerto, el cable

del botón de parada del motor “ENGINE

STOP” y el cable del interruptor de las

luces al bastidor mediante una conexión

plástica de cierre.

äPasar el cable del botón de parada del

motor “ENGINE STOP” y el cable del

interruptor de las luces por la parte interna

lateral del tubo respiradero del depósito

de aceite.

ìSujetar el sub-cableado, el cable del botón

de parada del motor “ENGINE STOP” y

el cable del interruptor de las luces al bas-

tidor mediante una conexión plástica de

cierre.

íPasar el tubo respiradero de la culata por

el lado derecho del tubo respiradero del

depósito de aceite.

îSujetar el sub-cableado al bastidor

mediante una conexión plástica de cierre

y cortar el extremo de la conexión.

éSujetar el cable TPS (del sub-cableado)

por debajo del bastidor.

Page 154 of 654

2 - 24

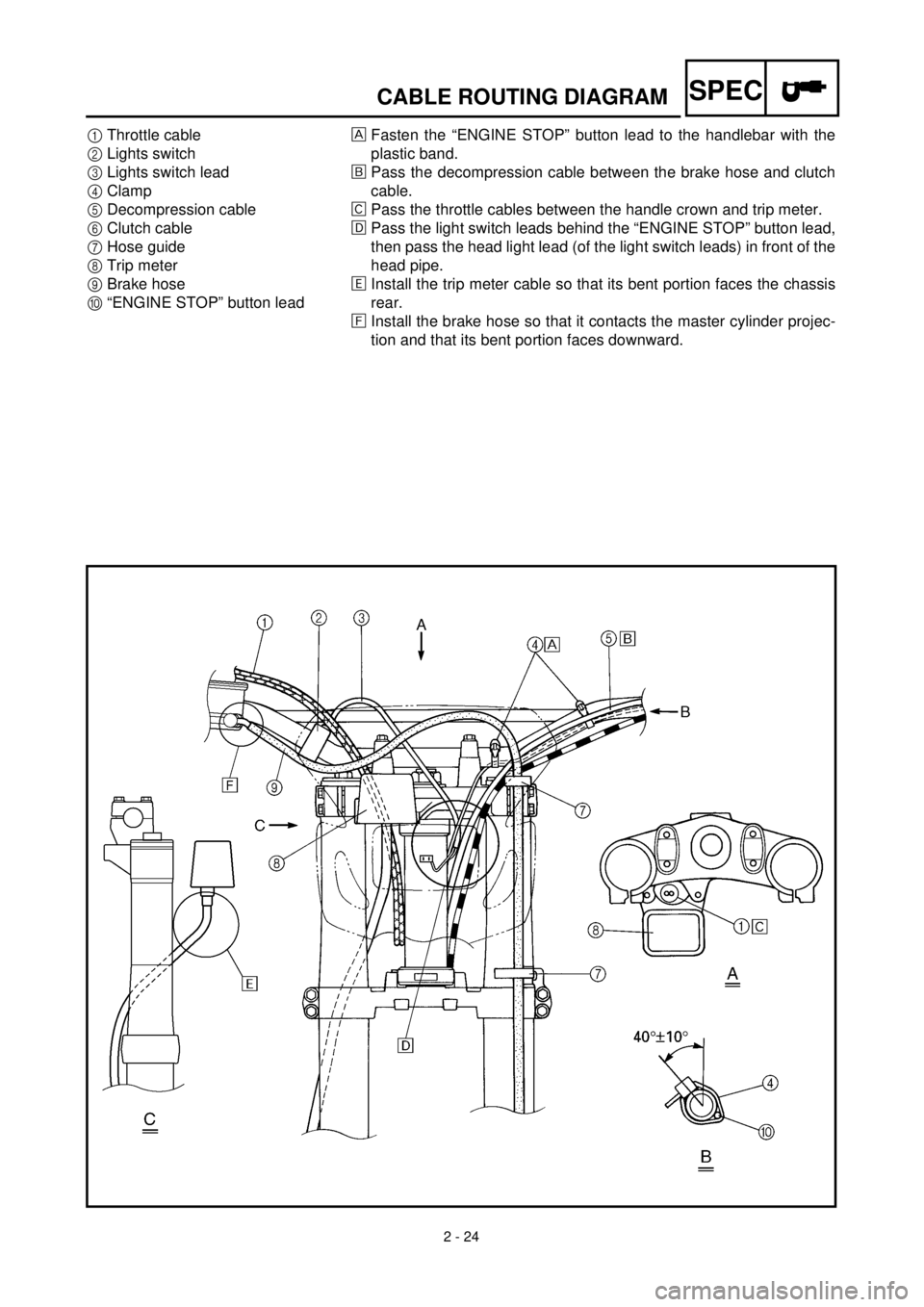

SPECCABLE ROUTING DIAGRAM

1Throttle cable

2Lights switch

3Lights switch lead

4Clamp

5Decompression cable

6Clutch cable

7Hose guide

8Trip meter

9Brake hose

0“ENGINE STOP” button leadFasten the “ENGINE STOP” button lead to the handlebar with the

plastic band.

õPass the decompression cable between the brake hose and clutch

cable.

‚Pass the throttle cables between the handle crown and trip meter.

ëPass the light switch leads behind the “ENGINE STOP” button lead,

then pass the head light lead (of the light switch leads) in front of the

head pipe.

äInstall the trip meter cable so that its bent portion faces the chassis

rear.

ìInstall the brake hose so that it contacts the master cylinder projec-

tion and that its bent portion faces downward.

Page 155 of 654

SPEC

CHEMINEMENT DES CABLES

KABELFÜHRUNG

DIAGRAMA DE RUTA DE CABLES

1Gaszug

2Dekompressionshebel

3Lichtschalterkabel

4Kabelbinder

5Dekompressionszug

6Kupplungszug

7Kabelführung

8Tageskilometerzähler

9Bremsschlauch

0Motorstoppschalter-Kabel

Das Motorstoppschalter-Kabel mit

mehrf. verwendb. Kabelbinder am

Lenker befestigen.

õDen Dekompressionszug zwischen

Bremsschlauch und Kupplungszug

führen.

‚Die Gaszüge zwischen obere Gabel-

brücke und Tageskilometerzähler füh-

ren.

ëDie Lichtschalterleitung hinter der Lei-

tung des “MOTORSTOPPSCHAL-

TERS” durchführen, und die Schein-

werferleitung (der

Lichtschalterleitung) vor der Frontröh-

re verlegen.

äDie Tageskilometerzählerwelle so

montieren, daß ihre Krümmung zum

Rahmnehinterteil weist.

ìDer Metallstutzen des Brems-

schlauchs muß an der Nase des

Hauptbremszylinders anliegen und

die Krümmung nach unten weisen. 1Câble d’accélération

2Interrupteur lumières

3Fil de l’interrupteur lumières

4Bride

5Câble du décompresseur

6Câble d’embrayage

7Guide de flexible

8Compteur de vitesse

9Tuyau de frein

0Fil de bouton d’arrêt du moteur

“ENGINE STOP”

Fixer le fil de bouton d’arrêt du moteur

“ENGINE STOP” au guidon à l’aide

d’une attache en plastique.

õFaire passer le câble de décompression

entre le flexible de frein et le câble

d’embrayage.

‚Faire passer le câbles d’accélération entre

la couronne de guidon et le totalisateur

journalier.

ëFaire passer le fil de commutateur de feux

derrière le fil de bouton d’arrêt de moteur

“ENGINE STOP” et amener le fil de pro-

jecteurs (du fil de commutateur de feux)

devant le tuyau avant.

äMonter le câble du totalisateur journalier

en dirigeant sa partie recourbée vers

l’arrière du cadre.

ìMonter le flexible de frein en veillant à ce

qu’il touche la projection du maître cylin-

dre et que sa partie recourbée soit dirigée

vers le bas.

2 - 24

1Cable del acelerador

2Interruptor de las luces

3Cable del interruptor de las luces

4Abrazadera

5Cable de descompresión

6Cable del embrague

7Guía del tubo

8Medidor de trayecto

9Tubo del freno

0Cable del botón de parada del motor

“ENGINE STOP”

Sujetar el cable del botón de parada del

motor “ENGINE STOP” al manillar con

una banda plástica.

õPasar el cable de descompresión entre el

tubo de freno y el cable del embrague.

‚Pasar los cables del acelerador entre la tija

superior del manillar y el medidor de tra-

yecto.

ëPasar el cable del interruptor de las luces

de trás del cable del botón de parada del

motor “ENGINE STOP” y traer el cable

de faro (del cable de interruptor de las

luces) enfrenbe del tubo del cabezal.

äInstalar el cable del medidor de trayecto

de forma que su parte doblada quede

orientada hacia el chasis trasero.

ìInstalar el tubo de freno de forma que

quede en contacto el saliente del cilindro

principal y su parte doblada quede orien-

tada hacia abajo.

Page 156 of 654

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

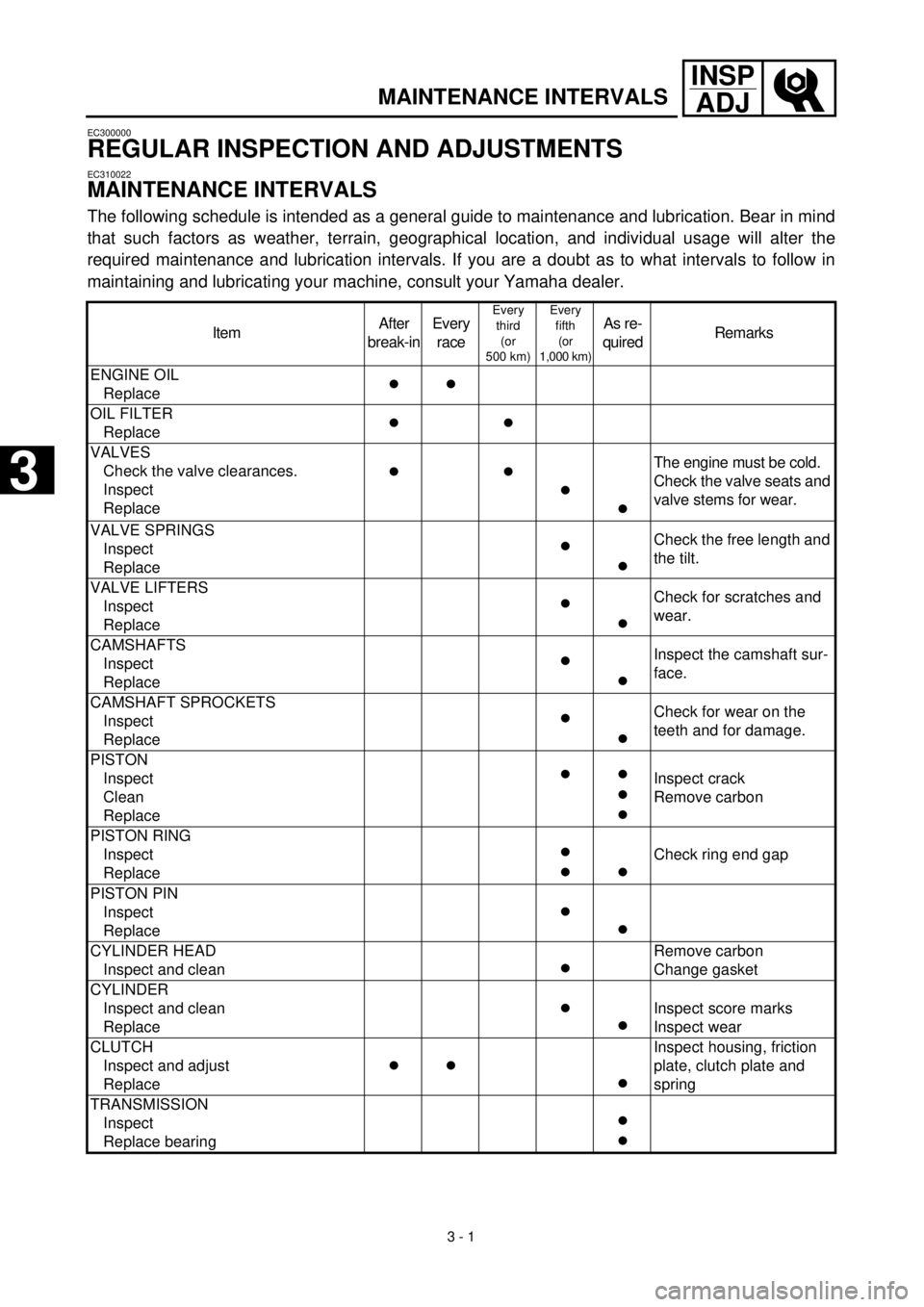

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

EC310022

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)

As re-

quiredRemarks

ENGINE OIL

Replace

cc

OIL FILTER

Replace

cc

VALVES

Check the valve clearances.

Inspect

Replace

cc

c

c

The engine must be cold.

Check the valve seats and

valve stems for wear.

VALVE SPRINGS

Inspect

Replace

c

c

Check the free length and

the tilt.

VALVE LIFTERS

Inspect

Replace

c

c

Check for scratches and

wear.

CAMSHAFTS

Inspect

Replace

c

c

Inspect the camshaft sur-

face.

CAMSHAFT SPROCKETS

Inspect

Replace

c

c

Check for wear on the

teeth and for damage.

PISTON

Inspect

Clean

Replace

cc

c

c

Inspect crack

Remove carbon

PISTON RING

Inspect

Replace

c

cc

Check ring end gap

PISTON PIN

Inspect

Replace

c

c

CYLINDER HEAD

Inspect and clean

c

Remove carbon

Change gasket

CYLINDER

Inspect and clean

Replace

c

c

Inspect score marks

Inspect wear

CLUTCH

Inspect and adjust

Replace

cc

c

Inspect housing, friction

plate, clutch plate and

spring

TRANSMISSION

Inspect

Replace bearing

c

c

3

Page 168 of 654

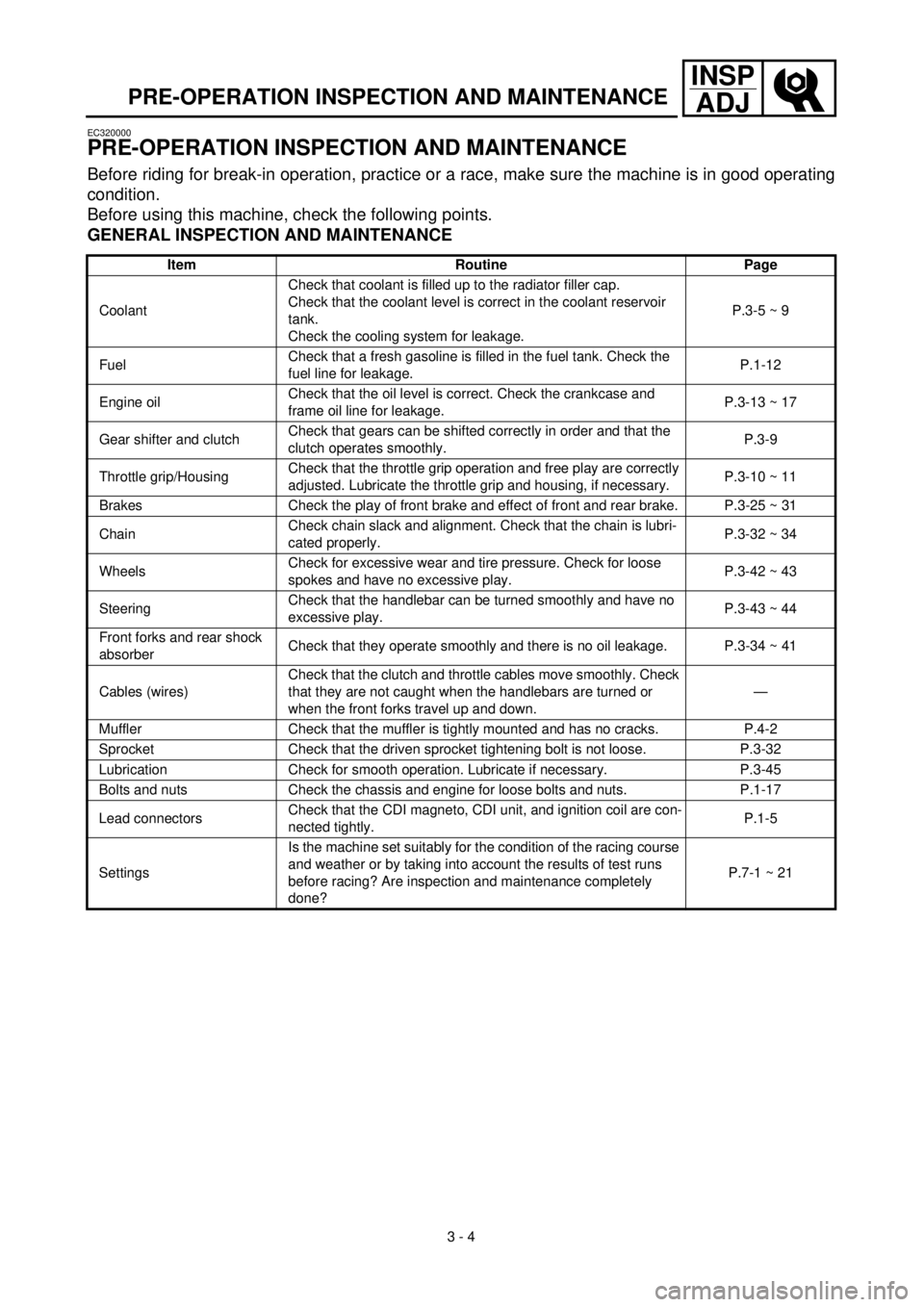

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator filler cap.

Check that the coolant level is correct in the coolant reservoir

tank.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-12

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-13 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

ChainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-32 ~ 34

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-42 ~ 43

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-43 ~ 44

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-34 ~ 41

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks. P.4-2

Sprocket Check that the driven sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-45

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-17

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-5

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 21

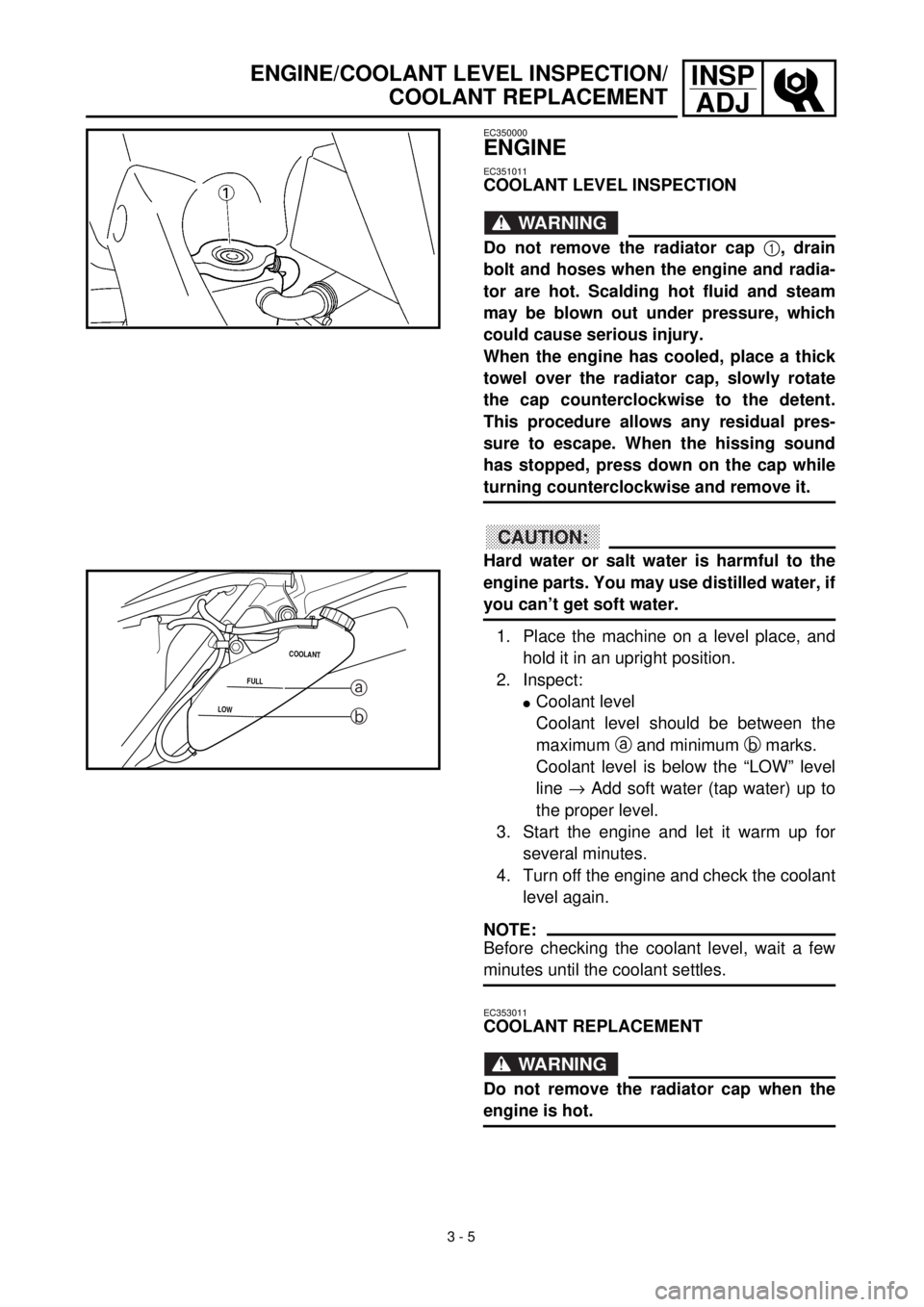

Page 172 of 654

3 - 5

INSP

ADJ

EC350000

ENGINE

EC351011

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap

1

, drain

bolt and hoses when the engine and radia-

tor are hot. Scalding hot fluid and steam

may be blown out under pressure, which

could cause serious injury.

When the engine has cooled, place a thick

towel over the radiator cap, slowly rotate

the cap counterclockwise to the detent.

This procedure allows any residual pres-

sure to escape. When the hissing sound

has stopped, press down on the cap while

turning counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

1. Place the machine on a level place, and

hold it in an upright position.

2. Inspect:

l

Coolant level

Coolant level should be between the

maximum

a

and minimum

b

marks.

Coolant level is below the “LOW” level

line

®

Add soft water (tap water) up to

the proper level.

3. Start the engine and let it warm up for

several minutes.

4. Turn off the engine and check the coolant

level again.

NOTE:

Before checking the coolant level, wait a few

minutes until the coolant settles.

LOWFULLCOOLANT

a

b

EC353011

COOLANT REPLACEMENT

WARNING

Do not remove the radiator cap when the

engine is hot.

ENGINE/COOLANT LEVEL INSPECTION/

COOLANT REPLACEMENT

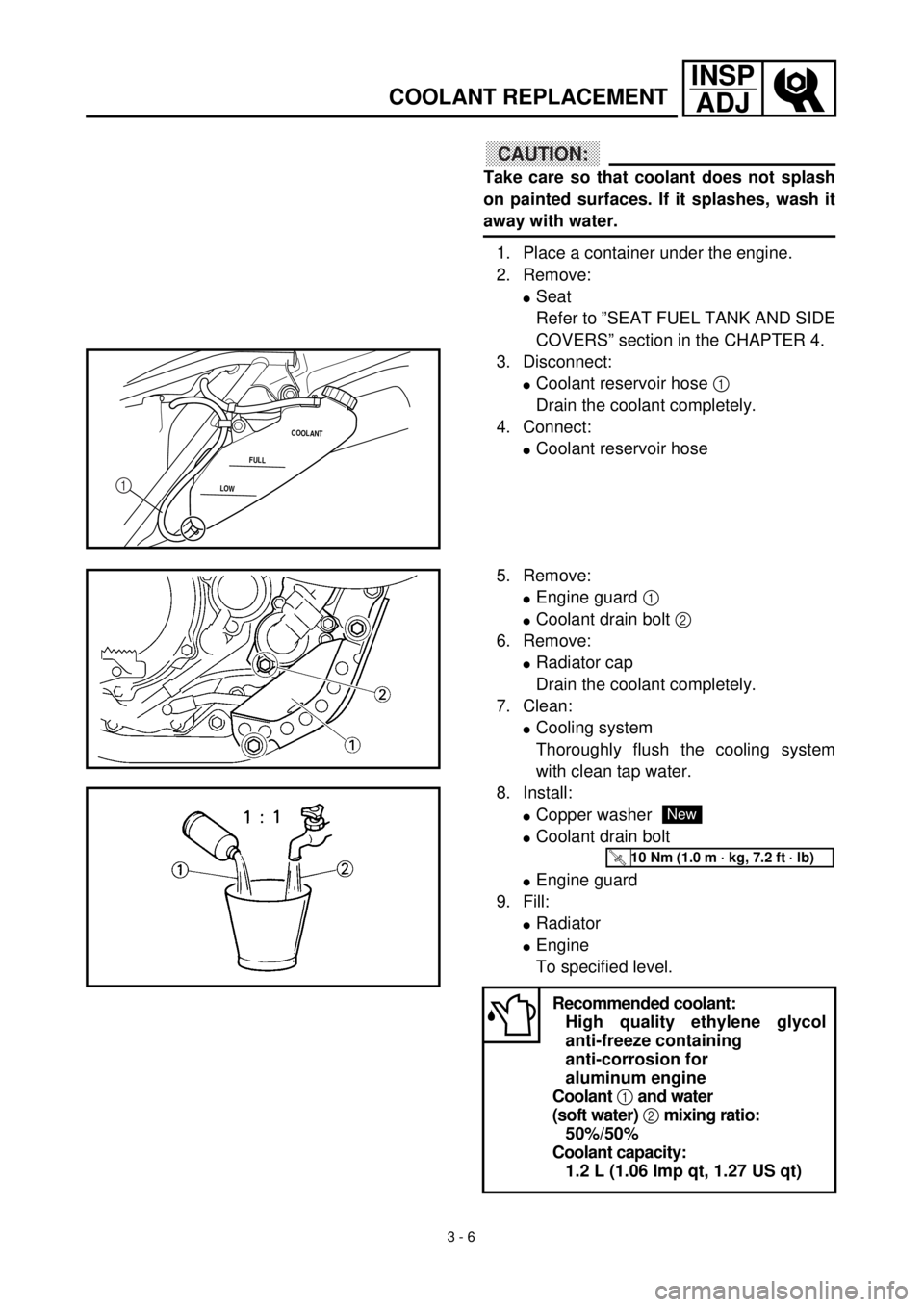

Page 174 of 654

3 - 6

INSP

ADJ

COOLANT REPLACEMENT

CAUTION:

Take care so that coolant does not splash

on painted surfaces. If it splashes, wash it

away with water.

1. Place a container under the engine.

2. Remove:

l

Seat

Refer to ”SEAT FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

3. Disconnect:

l

Coolant reservoir hose

1

Drain the coolant completely.

4. Connect:

l

Coolant reservoir hose

LOWFULLCOOLANT1

5. Remove:

l

Engine guard

1

l

Coolant drain bolt

2

6. Remove:

l

Radiator cap

Drain the coolant completely.

7. Clean:

l

Cooling system

Thoroughly flush the cooling system

with clean tap water.

8. Install:

l

Copper washer

l

Coolant drain bolt

l

Engine guard

9. Fill:

l

Radiator

l

Engine

To specified level.

Recommended coolant:

High quality ethylene glycol

anti-freeze containing

anti-corrosion for

aluminum engine

Coolant

1 and water

(soft water) 2 mixing ratio:

50%/50%

Coolant capacity:

1.2 L (1.06 Imp qt, 1.27 US qt)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)