engine YAMAHA WR 400F 2000 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: WR 400F, Model: YAMAHA WR 400F 2000Pages: 654, PDF Size: 60.12 MB

Page 212 of 654

3 - 24

INSP

ADJ

SPARK ARRESTER CLEANING (For USA)

WARNING

lBe sure the exhaust pipe and muffler are

cool before cleaning the spark arrester.

lDo not start the engine when cleaning the

exhaust system.

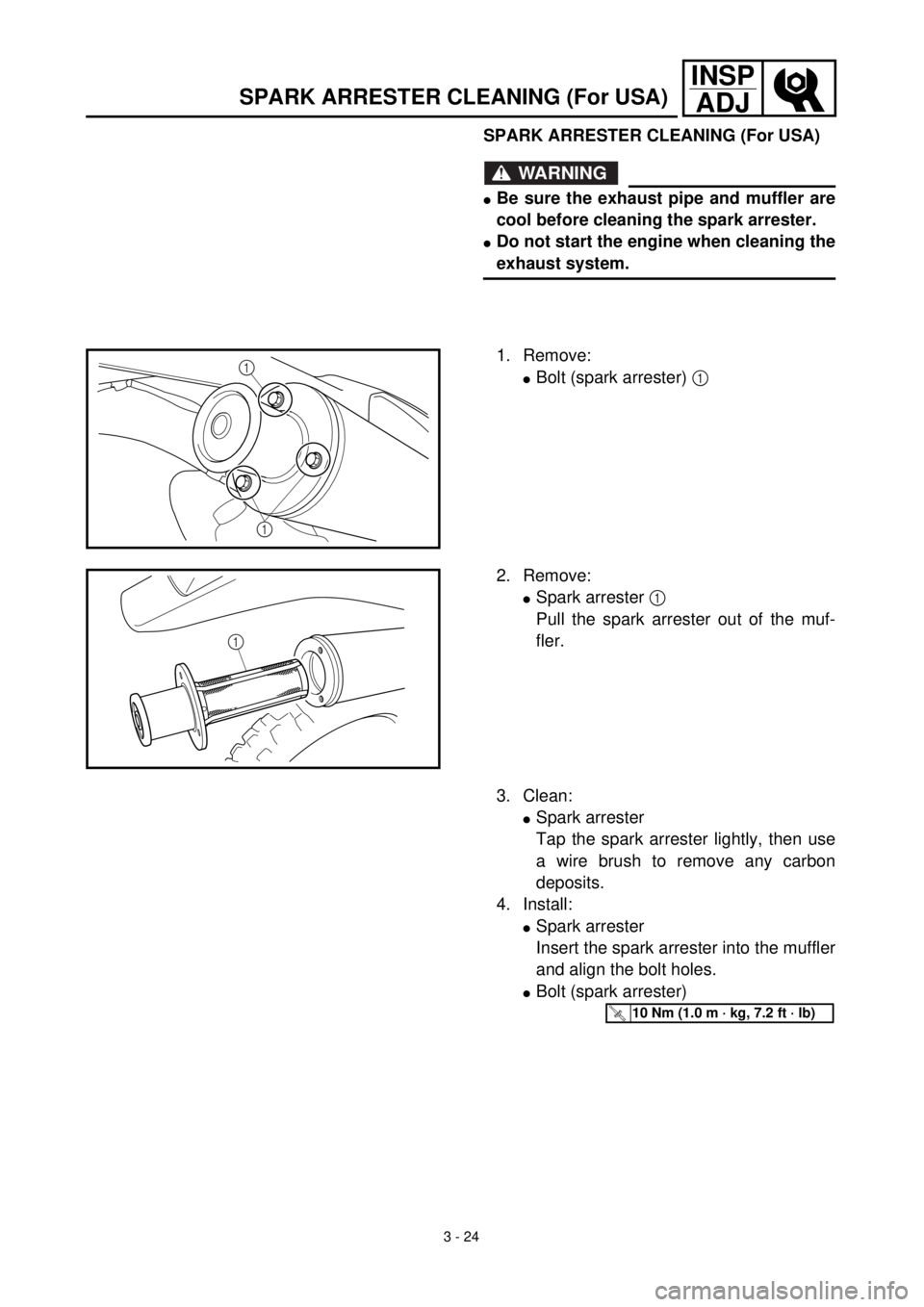

1. Remove:

lBolt (spark arrester) 1 1

1

2. Remove:

lSpark arrester 1

Pull the spark arrester out of the muf-

fler.

1

3. Clean:

lSpark arrester

Tap the spark arrester lightly, then use

a wire brush to remove any carbon

deposits.

4. Install:

lSpark arrester

Insert the spark arrester into the muffler

and align the bolt holes.

lBolt (spark arrester)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

SPARK ARRESTER CLEANING (For USA)

Page 230 of 654

3 - 33

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

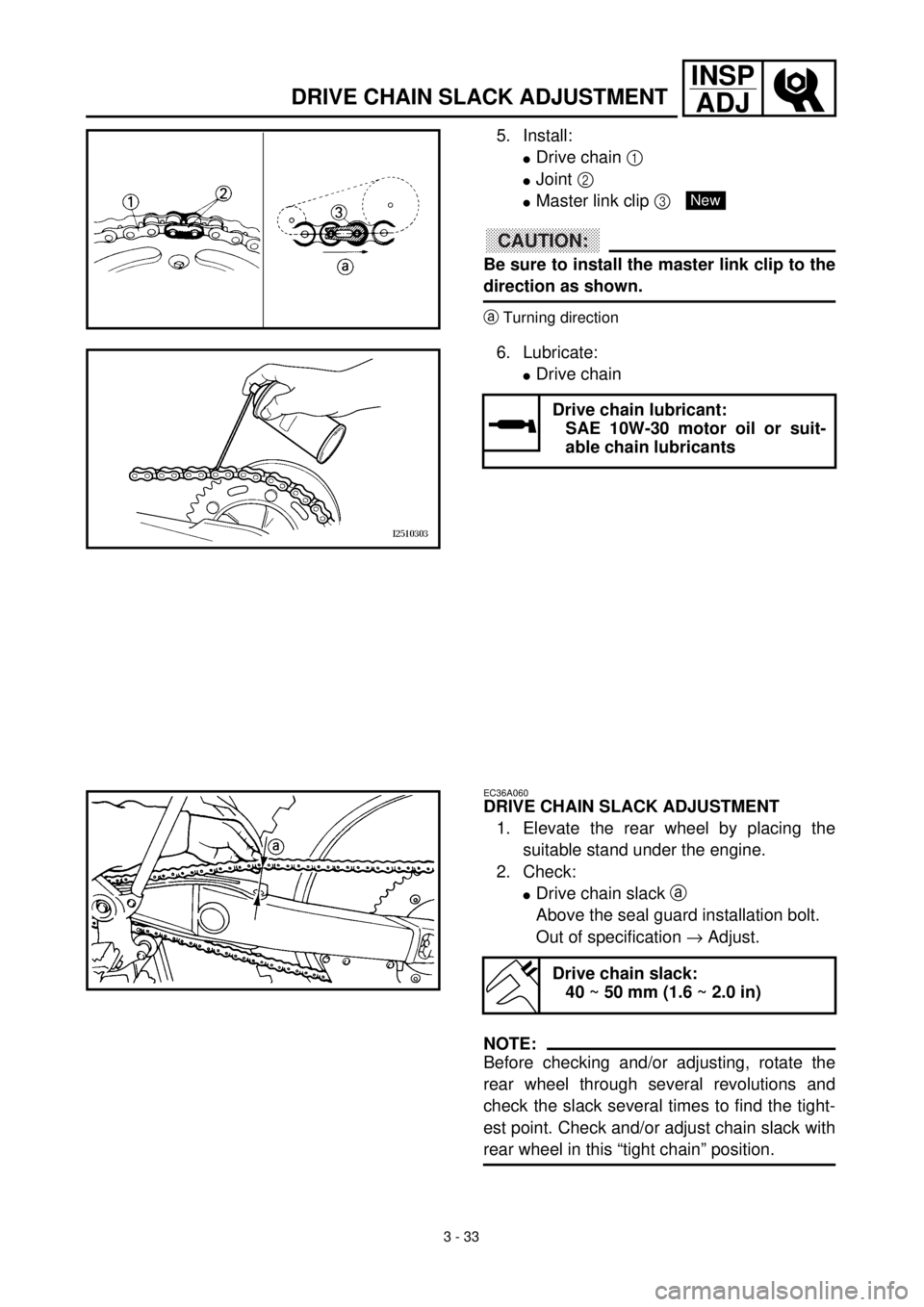

5. Install:

lDrive chain 1

lJoint 2

lMaster link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction

6. Lubricate:

lDrive chain

Drive chain lubricant:

SAE 10W-30 motor oil or suit-

able chain lubricants

New

EC36A060

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Check:

lDrive chain slack a

Above the seal guard installation bolt.

Out of specification ® Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

40 ~ 50 mm (1.6 ~ 2.0 in)

Page 232 of 654

3 - 34

INSP

ADJ

FRONT FORK INSPECTION

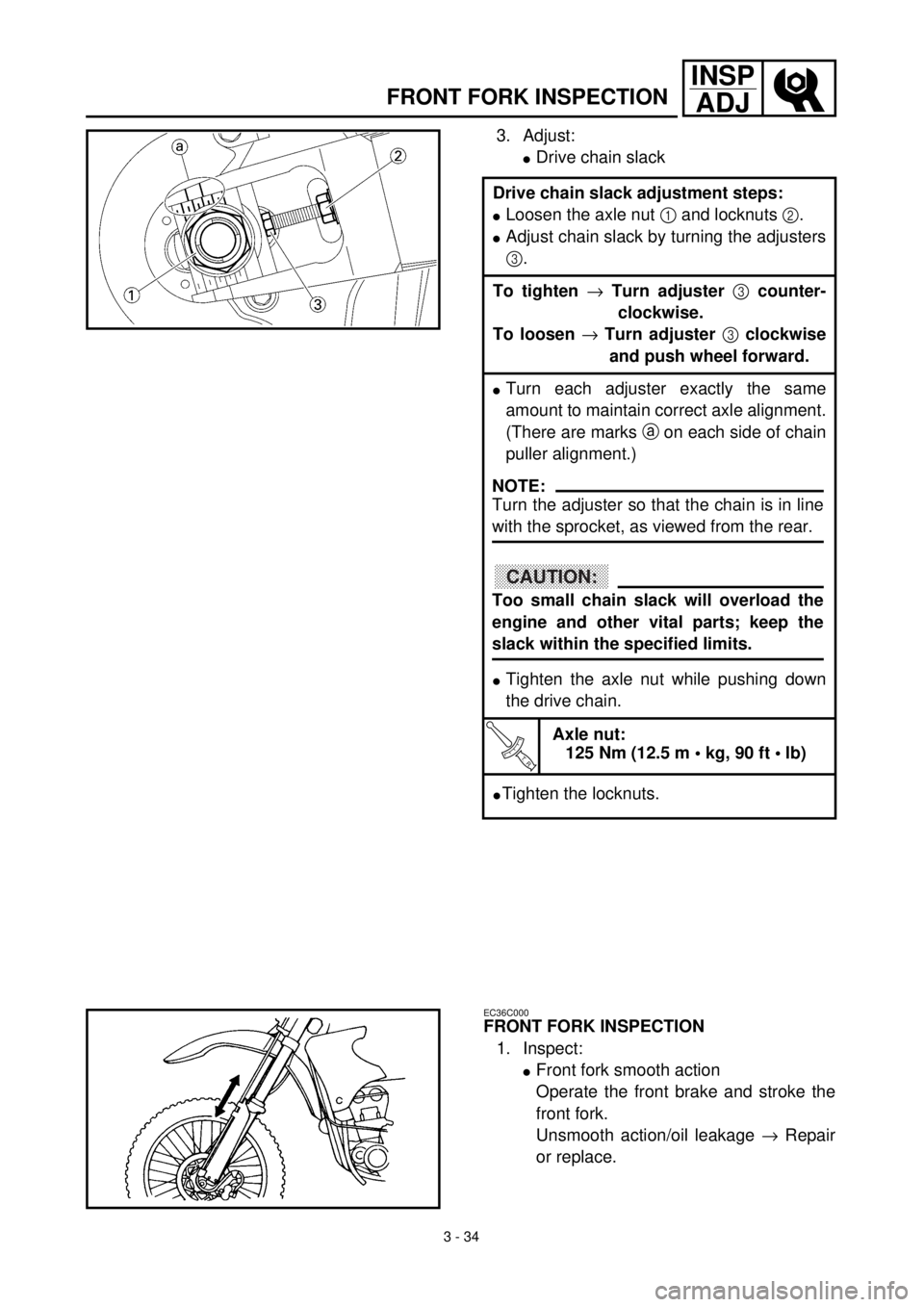

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the axle nut 1 and locknuts 2.

lAdjust chain slack by turning the adjusters

3.

To tighten ® Turn adjuster 3 counter-

clockwise.

To loosen ® Turn adjuster 3 clockwise

and push wheel forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

lTighten the axle nut while pushing down

the drive chain.

T R..

Axle nut:

125 Nm (12.5 m • kg, 90 ft • lb)

lTighten the locknuts.

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

EC36C000

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage ® Repair

or replace.

Page 240 of 654

3 - 38

INSP

ADJREAR SHOCK ABSORBER SPRING PRELOAD

ADJUSTMENT

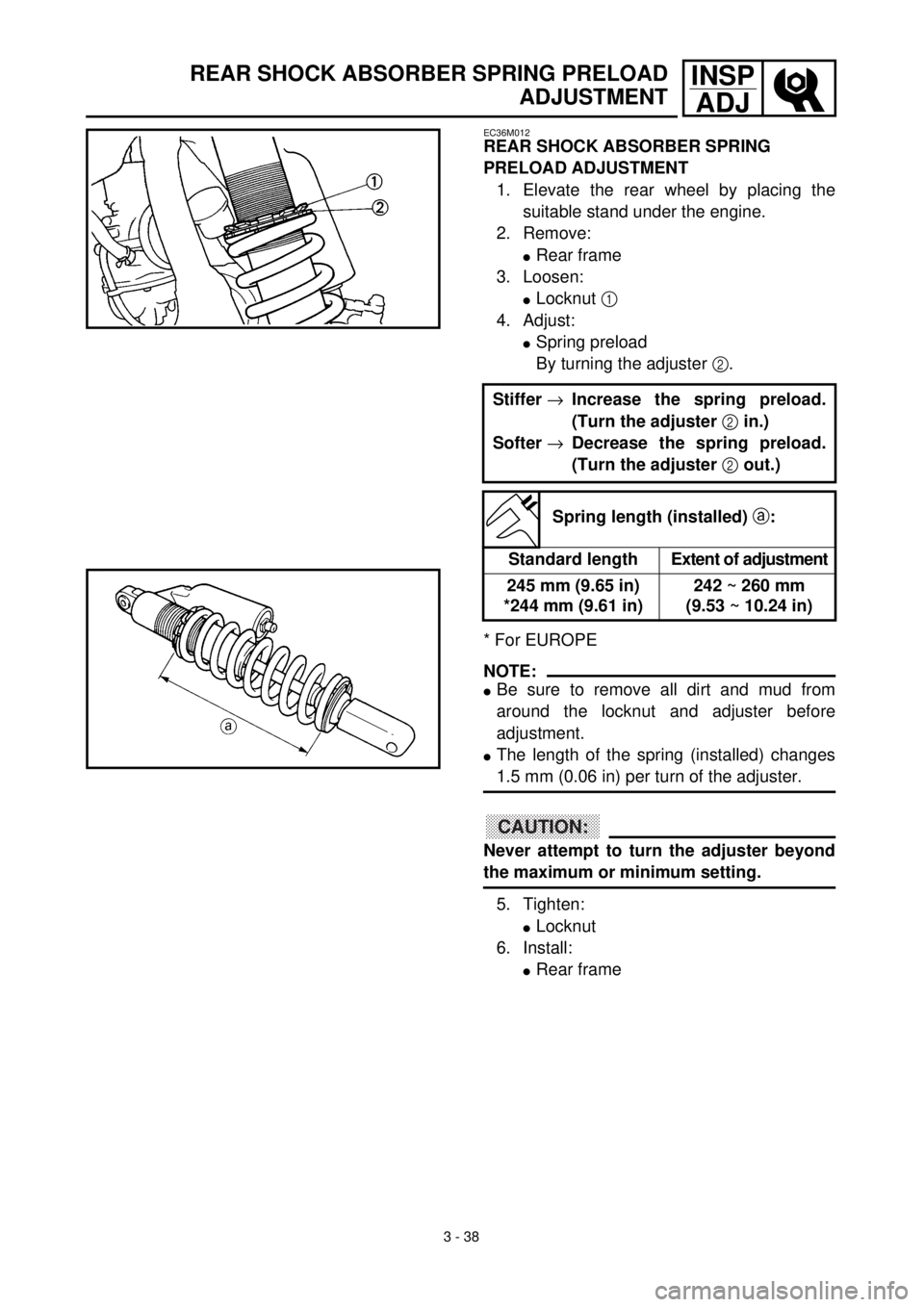

EC36M012

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Remove:

lRear frame

3. Loosen:

lLocknut 1

4. Adjust:

lSpring preload

By turning the adjuster 2.

* For EUROPE

NOTE:

lBe sure to remove all dirt and mud from

around the locknut and adjuster before

adjustment.

lThe length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjuster.

CAUTION:

Never attempt to turn the adjuster beyond

the maximum or minimum setting.

5. Tighten:

lLocknut

6. Install:

lRear frame Stiffer ®Increase the spring preload.

(Turn the adjuster 2 in.)

Softer ®Decrease the spring preload.

(Turn the adjuster 2 out.)

Spring length (installed) a:

Standard lengthExtent of adjustment

245 mm (9.65 in)

*244 mm (9.61 in)242 ~ 260 mm

(9.53 ~ 10.24 in)

Page 250 of 654

3 - 43

INSP

ADJ

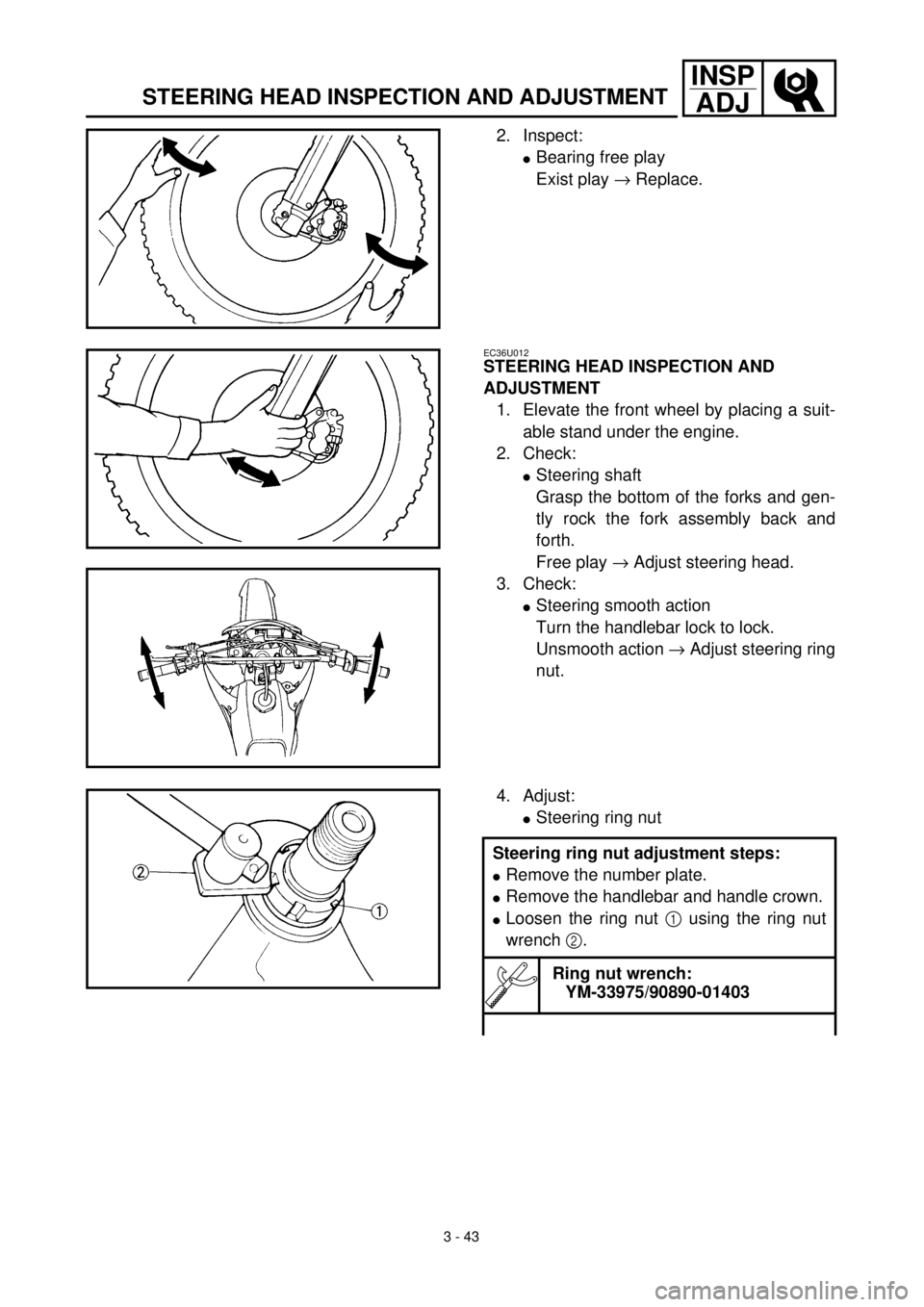

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

lBearing free play

Exist play ® Replace.

EC36U012

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

3. Check:

lSteering smooth action

Turn the handlebar lock to lock.

Unsmooth action ® Adjust steering ring

nut.

4. Adjust:

lSteering ring nut

Steering ring nut adjustment steps:

lRemove the number plate.

lRemove the handlebar and handle crown.

lLoosen the ring nut 1 using the ring nut

wrench 2.

Ring nut wrench:

YM-33975/90890-01403

Page 256 of 654

3 - 46

INSP

ADJ

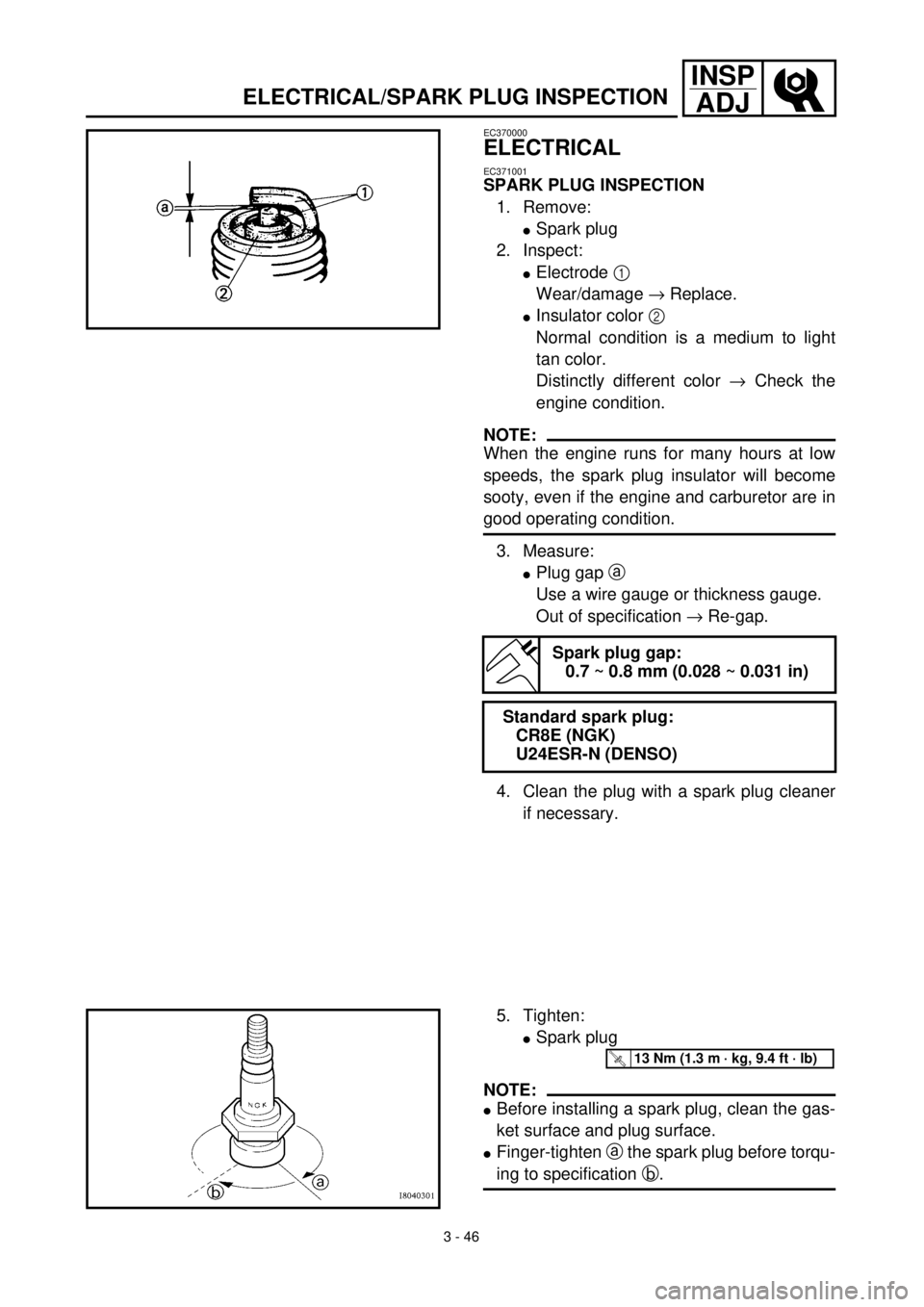

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

SPARK PLUG INSPECTION

1. Remove:

lSpark plug

2. Inspect:

lElectrode 1

Wear/damage ® Replace.

lInsulator color 2

Normal condition is a medium to light

tan color.

Distinctly different color ® Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

lPlug gap a

Use a wire gauge or thickness gauge.

Out of specification ® Re-gap.

4. Clean the plug with a spark plug cleaner

if necessary.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Standard spark plug:

CR8E (NGK)

U24ESR-N (DENSO)

5. Tighten:

lSpark plug

NOTE:

lBefore installing a spark plug, clean the gas-

ket surface and plug surface.

lFinger-tighten a the spark plug before torqu-

ing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 258 of 654

3 - 47

INSP

ADJ

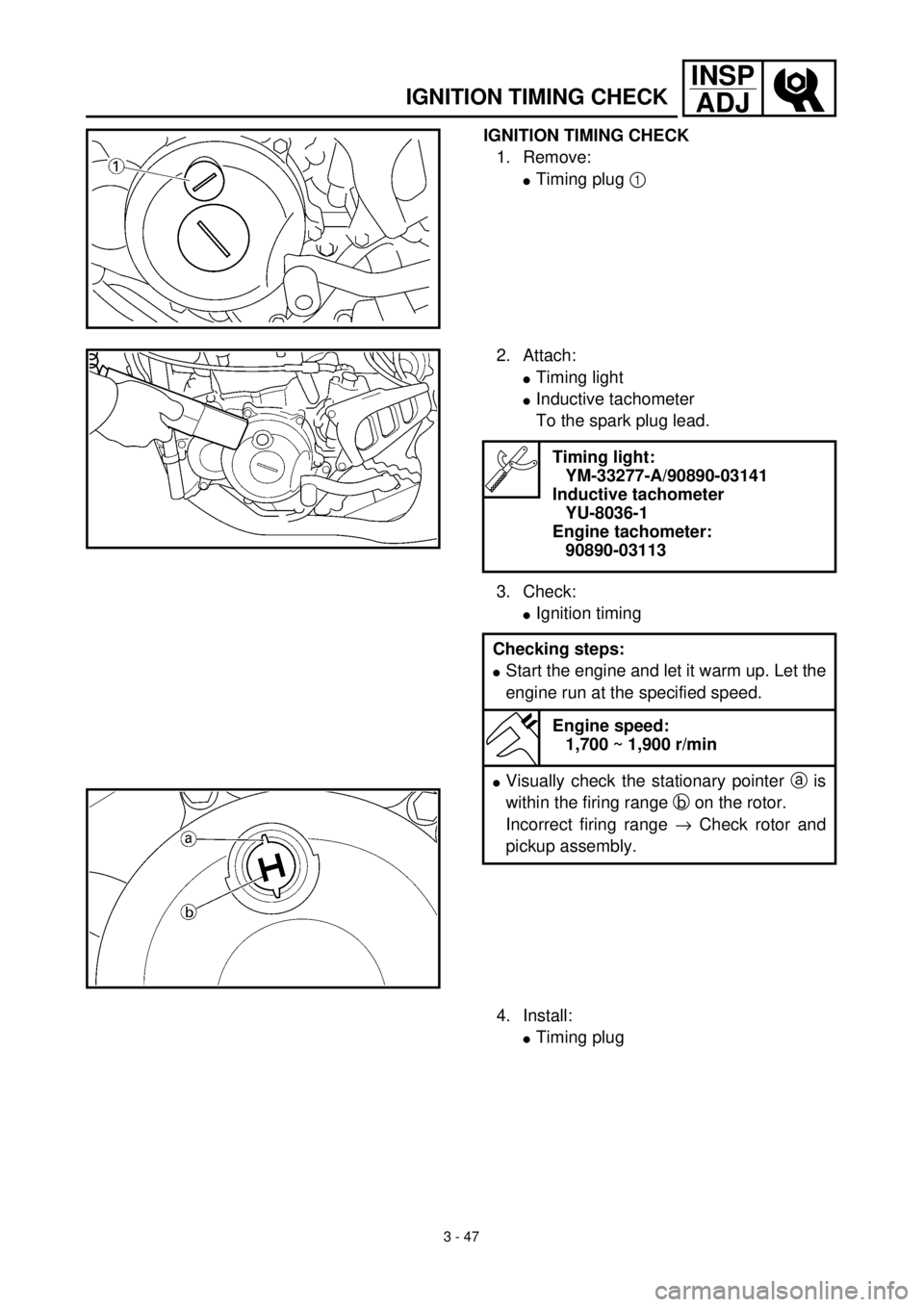

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lTiming plug 1

2. Attach:

lTiming light

lInductive tachometer

To the spark plug lead.

3. Check:

lIgnition timing

Timing light:

YM-33277-A/90890-03141

Inductive tachometer

YU-8036-1

Engine tachometer:

90890-03113

Checking steps:

lStart the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,700 ~ 1,900 r/min

lVisually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range ® Check rotor and

pickup assembly.

4. Install:

lTiming plug

Page 264 of 654

ENG

4 - 1

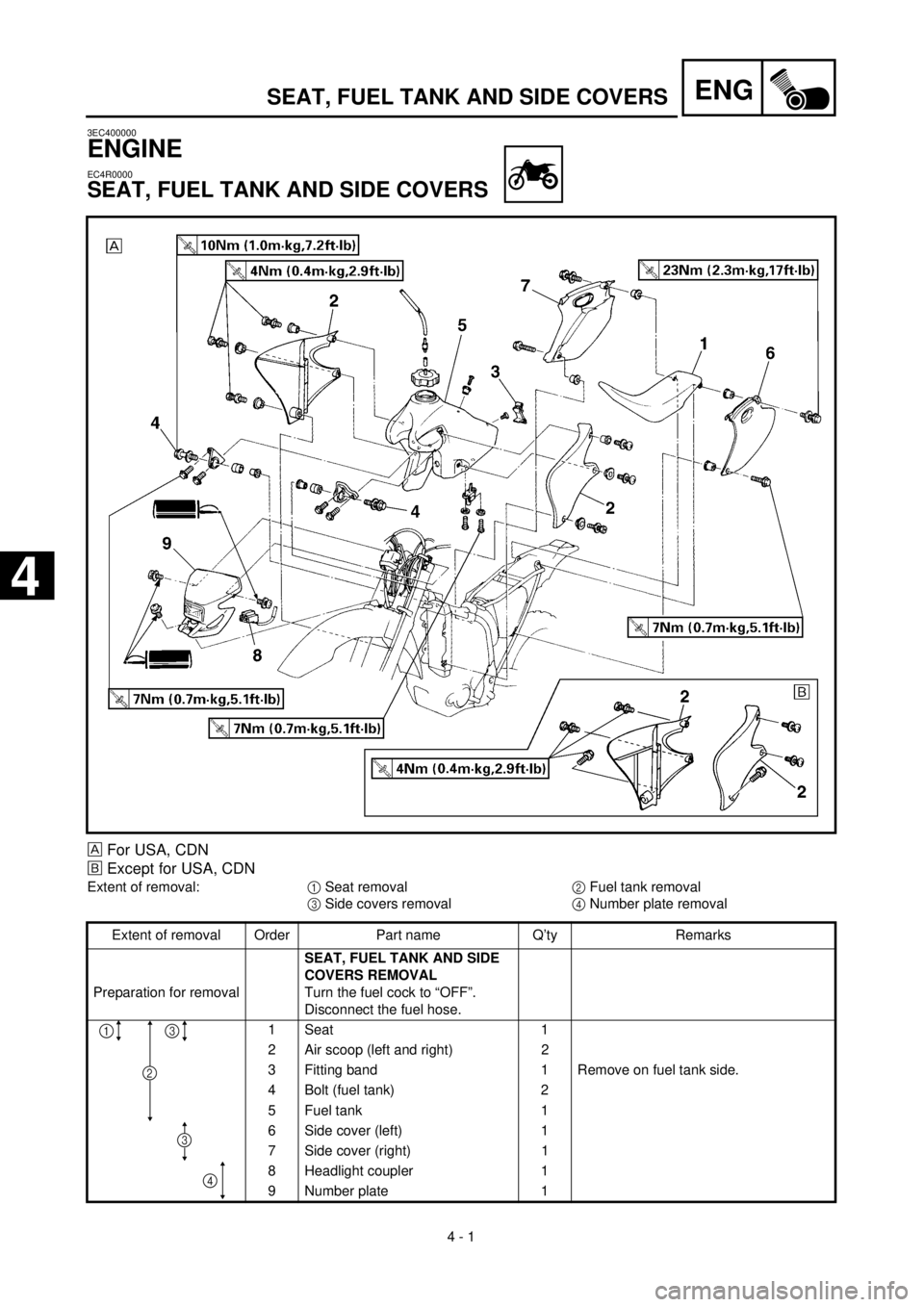

3EC400000

ENGINE

EC4R0000

SEAT, FUEL TANK AND SIDE COVERS

SEAT, FUEL TANK AND SIDE COVERS

For USA, CDN

õ

Except for USA, CDN

Extent of removal:

1

Seat removal

2

Fuel tank removal

3

Side covers removal

4

Number plate removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

SEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1 Seat 1

2 Air scoop (left and right) 2

3 Fitting band 1 Remove on fuel tank side.

4 Bolt (fuel tank) 2

5 Fuel tank 1

6 Side cover (left) 1

7 Side cover (right) 1

8 Headlight coupler 1

9 Number plate 1

13

4

2

3

4

Page 268 of 654

ENG

4 - 3

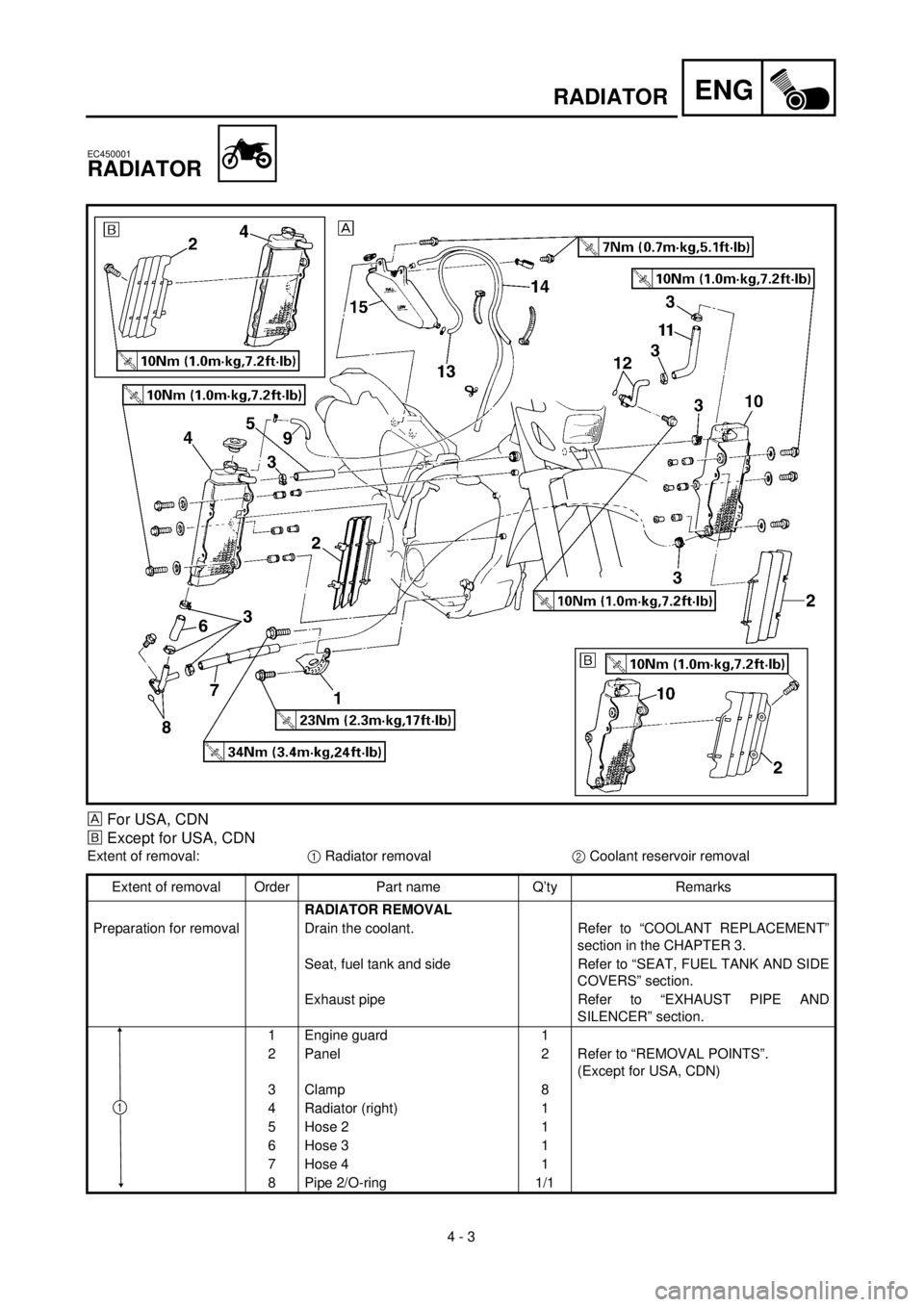

RADIATOR

EC450001

RADIATOR

For USA, CDN

õ

Except for USA, CDN

Extent of removal:

1

Radiator removal

2

Coolant reservoir removal

Extent of removal Order Part name Q’ty Remarks

RADIATOR REMOVAL

Preparation for removal Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Seat, fuel tank and side Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Exhaust pipe Refer to “EXHAUST PIPE AND

SILENCER” section.

1 Engine guard 1

2 Panel 2 Refer to “REMOVAL POINTS”.

(Except for USA, CDN)

3 Clamp 8

4 Radiator (right) 1

5 Hose 2 1

6 Hose 3 1

7 Hose 4 1

8 Pipe 2/O-ring 1/1

1

Page 272 of 654

4 - 5

ENG

RADIATOR

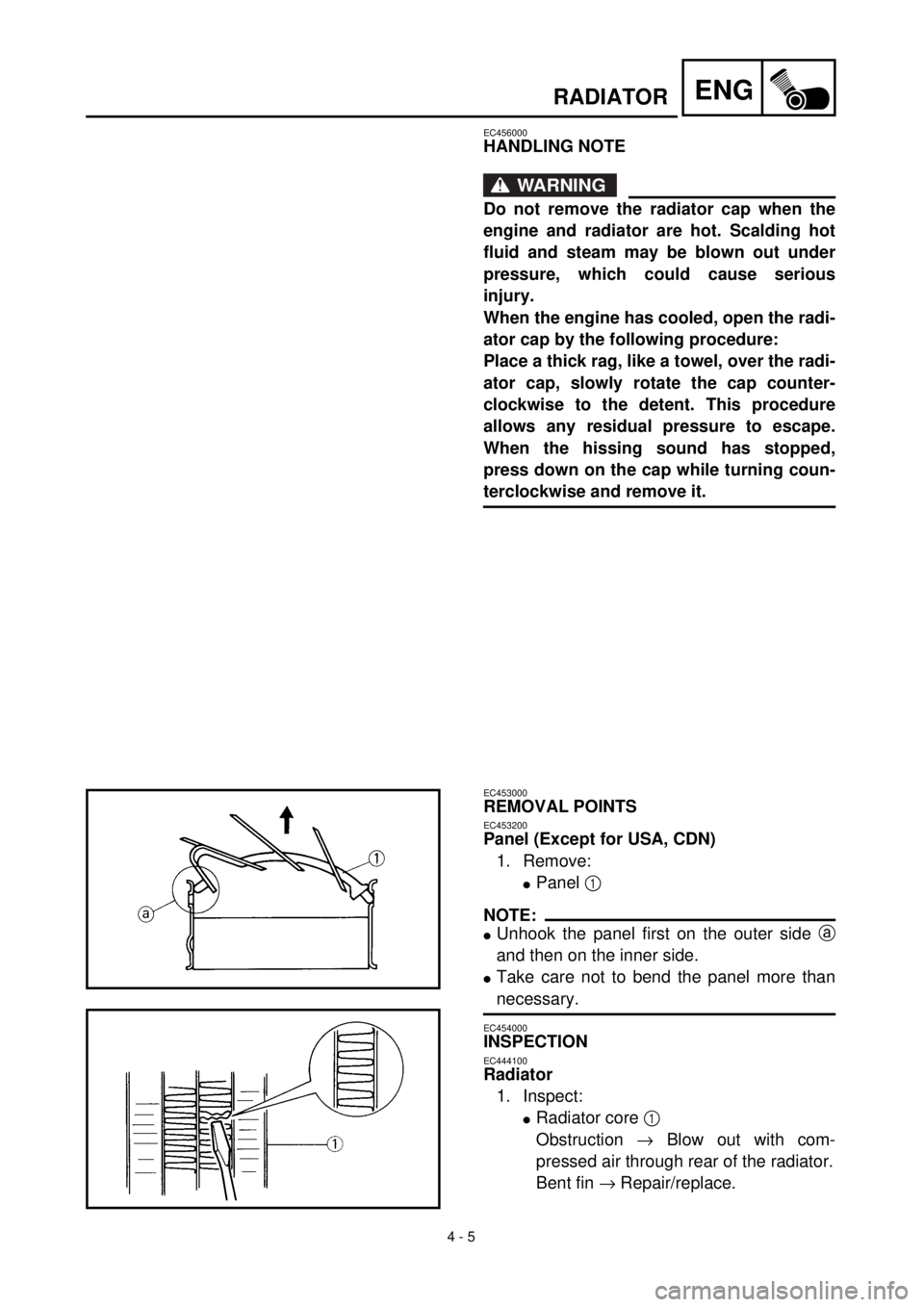

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

EC453000

REMOVAL POINTS

EC453200

Panel (Except for USA, CDN)

1. Remove:

l

Panel

1

NOTE:

l

Unhook the panel first on the outer side

a

and then on the inner side.

l

Take care not to bend the panel more than

necessary.

EC454000

INSPECTION

EC444100

Radiator

1. Inspect:

l

Radiator core

1

Obstruction

®

Blow out with com-

pressed air through rear of the radiator.

Bent fin

®

Repair/replace.